Guide to Lighted Stairs

- Introduction: Navigating the Global Market for lighted stairs

- Understanding lighted stairs Types and Variations

- Key Industrial Applications of lighted stairs

- Strategic Material Selection Guide for lighted stairs

- In-depth Look: Manufacturing Processes and Quality Assurance for lighted stairs

- Comprehensive Cost and Pricing Analysis for lighted stairs Sourcing

- Spotlight on Potential lighted stairs Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for lighted stairs

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the lighted stairs Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of lighted stairs

- Strategic Sourcing Conclusion and Outlook for lighted stairs

Introduction: Navigating the Global Market for lighted stairs

Lighted stairs have emerged as a pivotal element in modern architectural and commercial projects, marrying safety with sophisticated design. For international B2B buyers, particularly those operating in dynamic markets across Africa, South America, the Middle East, and Europe, sourcing the right lighted stair solutions can significantly enhance building functionality, user experience, and aesthetic appeal. These markets demand products that are not only reliable and compliant with diverse safety standards but also adaptable to regional design preferences and environmental conditions.

This comprehensive guide delves into every critical aspect of lighted stairs, empowering buyers with actionable insights to make informed procurement decisions. It covers the full spectrum of product types—from LED strips and recessed lighting to sensor-integrated systems—and explores the variety of materials and finishes that affect durability and style. Understanding manufacturing processes and quality control measures is emphasized to ensure buyers partner with suppliers who deliver consistent, high-performance solutions.

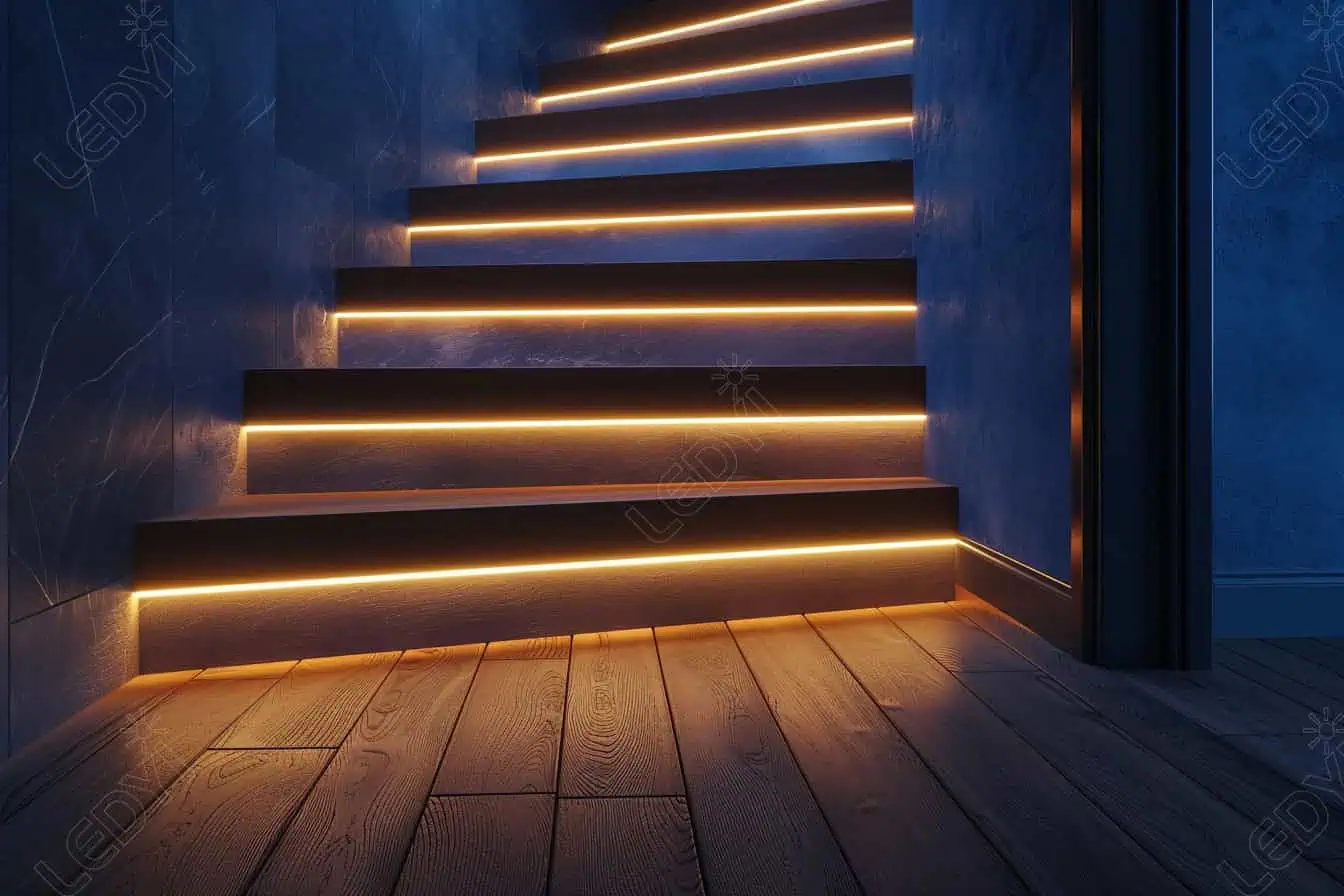

Illustrative Image (Source: Google Search)

Additionally, the guide provides a detailed analysis of global supplier landscapes, cost structures, and emerging market trends, helping buyers navigate complexities such as import regulations, energy efficiency requirements, and smart lighting integrations. A curated FAQ section addresses common challenges faced by international buyers, including installation considerations and after-sales support.

By synthesizing technical knowledge with market intelligence, this guide serves as an indispensable resource for procurement professionals seeking to elevate their projects with expertly sourced lighted stairs that meet stringent quality and design standards across diverse international markets.

Understanding lighted stairs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| LED Strip Lighting | Flexible, linear LED strips installed under stair nosing | Commercial offices, hotels, retail malls | Energy-efficient, customizable, but requires professional installation and wiring |

| Recessed Stair Lights | Small, flush-mounted LED fixtures embedded in stair risers or walls | Hospitality, corporate, luxury residential | Sleek, minimal design; enhances safety; higher upfront cost and installation complexity |

| Handrail Integrated Lighting | LED lights integrated within or beneath handrails | Public buildings, airports, educational institutions | Enhances visibility and aesthetics; durable; may require custom fabrication and maintenance |

| Step Edge Lighting | LED or fiber optic lights highlighting stair edges | Theaters, event venues, commercial complexes | Improves safety by defining edges; visually striking; may be prone to damage in high-traffic areas |

| Smart Sensor Lighting | Motion-activated or ambient light-responsive stair lighting | Modern office buildings, smart homes, airports | Energy-saving and convenient; higher technology cost and need for system integration |

LED Strip Lighting

LED strip lighting is widely used for its flexibility and ease of customization, making it ideal for a variety of commercial and hospitality environments. These strips are typically installed beneath the stair nosing, providing continuous illumination that enhances both safety and ambiance. For B2B buyers, key considerations include ensuring compatibility with existing electrical infrastructure and selecting strips with high IP ratings for durability in high-traffic or outdoor settings. The energy efficiency and long lifespan of LED strips make them cost-effective over time despite the initial installation investment.

Recessed Stair Lights

Recessed stair lights offer a clean, minimalistic look by embedding fixtures directly into stair risers or adjacent walls. This type is preferred in luxury hotels, corporate offices, and upscale residential buildings where aesthetics and safety are paramount. B2B buyers should evaluate installation complexity and costs, as these fixtures require precise cutting and wiring. Additionally, selecting fixtures with adjustable brightness and color temperature can help tailor the lighting to specific design themes and functional needs.

Illustrative Image (Source: Google Search)

Handrail Integrated Lighting

Integrating lighting into handrails is an innovative solution that combines form and function. This type is particularly suitable for public buildings and transportation hubs where enhanced visibility and safety are critical. For international buyers, especially in markets like the Middle East and Europe, custom fabrication options may be necessary to comply with local building codes and design preferences. Maintenance accessibility and durability under frequent use are important factors to consider during procurement.

Step Edge Lighting

Step edge lighting focuses on illuminating the edges of each stair tread, often using LEDs or fiber optics. This method significantly improves safety by clearly defining stair boundaries in dim environments, making it popular in theaters and event venues. B2B buyers should assess the robustness of materials and the ease of replacement, as exposed edge lighting can be vulnerable to wear. Aesthetically, this type offers a dynamic visual effect that can complement modern architectural styles.

Smart Sensor Lighting

Smart sensor lighting systems utilize motion detectors or ambient light sensors to activate stair lighting only when needed, optimizing energy use and convenience. This technology is increasingly favored in smart buildings and airports, where automation enhances user experience. Buyers should consider integration capabilities with existing building management systems and ensure reliable sensor performance in diverse environmental conditions. While initial costs are higher, the long-term savings and advanced control features provide strong value for forward-thinking enterprises.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of lighted stairs

| Industry/Sector | Specific Application of lighted stairs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Tourism | Illuminated stairs in hotels and resorts | Enhances guest safety and aesthetic appeal, elevating brand image | Compliance with local safety codes, durability in high-traffic areas, customizable design options |

| Commercial Real Estate | Office buildings and shopping centers | Improves safety during low-light conditions and creates modern ambiance | Energy-efficient LED technology, integration with building automation, ease of maintenance |

| Healthcare Facilities | Hospitals and clinics staircases | Reduces accident risk, supports accessibility standards, improves patient and staff navigation | Hygiene-compliant materials, anti-glare lighting, emergency power backup compatibility |

| Transportation Hubs | Airports, train stations, and metro stations | Ensures passenger safety, guides traffic flow, and enhances wayfinding | Robustness for heavy foot traffic, weather resistance for outdoor stairs, compliance with accessibility laws |

| Industrial & Manufacturing | Factory and warehouse stairways | Increases worker safety, reduces downtime due to accidents, supports compliance with occupational safety regulations | Explosion-proof fixtures for hazardous zones, high-impact resistant materials, easy retrofit options |

Hospitality & Tourism

In the hospitality sector, lighted stairs are frequently used in hotels, resorts, and entertainment venues to combine safety with a luxurious atmosphere. Illuminated staircases help guests navigate safely in dimly lit environments such as lobbies, nightclubs, and outdoor terraces. For international B2B buyers in regions like the Middle East and Europe, sourcing options that comply with local fire and safety regulations while offering customizable designs to fit diverse architectural styles is crucial. Durable, energy-efficient LED solutions that withstand high foot traffic ensure long-term value.

Commercial Real Estate

Office buildings and shopping centers benefit from lighted stairs by enhancing both safety and the visual experience for employees and customers. These installations reduce slip and trip hazards during low-light periods and contribute to a contemporary aesthetic that can increase property value. B2B buyers from Africa and South America should prioritize lighting systems that integrate easily with existing building management systems and offer energy savings, considering the variable power infrastructure in some regions. Maintenance-friendly designs also reduce operational costs.

Healthcare Facilities

Hospitals and clinics require stair lighting solutions that meet strict safety and hygiene standards. Properly illuminated stairs reduce the risk of falls among patients, visitors, and healthcare workers, especially in emergency situations or night shifts. Buyers in international healthcare markets must look for non-glare, easy-to-clean fixtures that comply with medical safety codes and can be integrated with emergency lighting systems. Reliability and quick installation are key factors for healthcare administrators investing in stair lighting.

Transportation Hubs

Airports, train stations, and metro stations are high-traffic environments where lighted stairs play a critical role in passenger safety and efficient crowd movement. These lighting systems improve visibility, assist in wayfinding, and help meet stringent accessibility requirements. For buyers in fast-developing regions such as the Middle East and South America, sourcing durable, weather-resistant fixtures that can withstand heavy use and harsh outdoor conditions is essential. Integration with smart lighting controls can also enhance energy management.

Industrial & Manufacturing

In industrial settings, lighted stairs are vital for worker safety in factories and warehouses, especially in low-light or hazardous areas. They help prevent accidents and support compliance with occupational health and safety regulations. Buyers from Europe and Africa should consider explosion-proof and high-impact resistant lighting fixtures for environments with flammable substances or heavy machinery. Additionally, solutions that are easy to retrofit into existing infrastructure can minimize downtime during installation, increasing operational efficiency.

Related Video: USES OF ELECTROMAGNETIC WAVES

Strategic Material Selection Guide for lighted stairs

When selecting materials for lighted stairs, international B2B buyers must consider factors such as durability, environmental compatibility, manufacturing complexity, and compliance with regional standards. The choice of material impacts not only the aesthetic and functional performance of the stair lighting but also installation, maintenance, and long-term cost-effectiveness. Below is an analysis of four common materials used in lighted stairs, tailored to the needs of buyers from Africa, South America, the Middle East, and Europe.

1. Tempered Glass

Key Properties:

Tempered glass offers high strength and thermal resistance, typically withstanding temperatures up to 250°C. It has excellent corrosion resistance and is non-porous, making it easy to clean and maintain. Its transparency allows for optimal light diffusion and aesthetic appeal.

Pros & Cons:

Pros include its modern, sleek appearance and ability to evenly distribute LED lighting. It is also fire-resistant and highly durable against impact compared to regular glass. However, tempered glass can be costly and requires precision manufacturing to avoid defects. It is brittle under extreme impact and may shatter into small granules, which could be a safety consideration.

Impact on Application:

Ideal for environments where visual appeal and light diffusion are priorities, such as commercial lobbies or upscale retail spaces. It is less suitable for heavy industrial settings or outdoor installations with high mechanical stress.

International Considerations:

Buyers in regions like Europe and the Middle East should ensure compliance with standards such as EN 12150 (European standard for tempered glass) or ASTM C1048 (US standard often accepted internationally). In Africa and South America, sourcing tempered glass that meets these or equivalent ISO standards is critical to ensure safety and durability. The material’s weight and fragility may increase shipping and handling costs, which should be factored into procurement decisions.

2. Aluminum Alloy

Key Properties:

Aluminum alloys used in stair lighting fixtures typically have good corrosion resistance, especially when anodized, and can withstand temperatures up to 200°C. They offer a high strength-to-weight ratio and excellent thermal conductivity, which aids in heat dissipation from LED components.

Pros & Cons:

Aluminum is lightweight, cost-effective, and easy to machine or extrude into custom shapes, making it popular for intricate lighting designs. However, it can corrode in highly saline or acidic environments if not properly treated, and its surface may scratch easily without protective coatings.

Impact on Application:

Best suited for indoor and semi-outdoor applications where moderate environmental exposure exists. Its thermal conductivity helps prolong LED lifespan by preventing overheating.

International Considerations:

Standards such as ASTM B221 (aluminum extrusions) and EN 573 (aluminum alloy chemical composition) are relevant. Buyers in coastal regions of Africa and the Middle East should specify anodized or powder-coated finishes to enhance corrosion resistance. In South America, availability of high-grade aluminum alloys may vary, so verifying supplier certifications is important.

3. Stainless Steel (Grades 304/316)

Key Properties:

Stainless steel offers excellent corrosion resistance, with grade 316 providing superior resistance in chloride-rich environments. It withstands high temperatures (up to 870°C intermittently) and has strong mechanical properties, making it highly durable.

Pros & Cons:

The material is highly durable, low maintenance, and provides a premium, polished look. It is heavier and more expensive than aluminum or glass, and manufacturing complexity is higher due to its hardness. Welding and finishing require skilled labor.

Impact on Application:

Ideal for high-traffic, outdoor, or harsh environments where durability and corrosion resistance are critical, such as public infrastructure or commercial buildings in humid or coastal areas.

International Considerations:

Compliance with ASTM A240 or EN 10088 standards is essential. Buyers in the Middle East and coastal Africa should prioritize grade 316 for saltwater resistance. European buyers often require certification for food-grade or architectural stainless steel, depending on the application. The heavier weight impacts shipping and installation logistics.

4. Polycarbonate

Key Properties:

Polycarbonate is a lightweight, impact-resistant thermoplastic with good thermal stability up to approximately 135°C. It offers excellent transparency and UV resistance when treated, making it suitable for outdoor use.

Pros & Cons:

It is highly durable against impact and shattering, more flexible than glass, and easier to fabricate. However, it can scratch easily and may yellow over time if UV protection is inadequate. It is generally less premium in appearance compared to glass or metal.

Impact on Application:

Well-suited for environments requiring high impact resistance and safety, such as public stairways in schools or transportation hubs. Its lightweight nature simplifies installation.

International Considerations:

Buyers should ensure compliance with ISO 4589 (flammability) and ASTM D3935 (UV resistance). In regions with intense sunlight like the Middle East and parts of Africa, UV-stabilized polycarbonate is critical. South American buyers should verify local availability of treated polycarbonate to avoid premature degradation.

| Material | Typical Use Case for lighted stairs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tempered Glass | High-end commercial and residential staircases | Superior light diffusion and aesthetics | Fragile under impact; higher shipping costs | High |

| Aluminum Alloy | Indoor and semi-outdoor stair lighting fixtures | Lightweight with good thermal conductivity | Corrosion risk if untreated; surface scratches | Medium |

| Stainless Steel | Outdoor, high-traffic, and corrosive environments | Exceptional durability and corrosion resistance | Heavy, costly, complex manufacturing | High |

| Polycarbonate | Public and safety-critical staircases needing impact resistance | High impact resistance and lightweight | Prone to scratching and UV yellowing | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for lighted stairs

Manufacturing lighted stairs involves a combination of advanced materials engineering, precision assembly, and rigorous quality assurance to meet the safety and aesthetic demands of commercial and residential projects. For international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe—understanding these processes and quality checkpoints is critical to ensure reliable, compliant, and durable products.

Key Manufacturing Stages for Lighted Stairs

1. Material Preparation

The foundation of quality lighted stairs begins with the careful selection and preparation of materials. Common materials include tempered glass, aluminum or stainless steel for framing, and LED modules for lighting. Material prep involves cutting, shaping, and treating components to enhance durability and corrosion resistance. For example, aluminum components often undergo anodizing or powder coating to improve wear resistance and aesthetic appeal.

2. Forming and Shaping

Forming is a precision-driven stage where materials are bent, molded, or machined to exact specifications. Laser cutting and CNC machining are frequently employed for metal parts to ensure tight tolerances and clean edges. Glass panels are tempered and cut to size, sometimes incorporating etched or frosted designs to diffuse light evenly. This phase requires advanced machinery and skilled operators to avoid defects that could compromise structural integrity or lighting performance.

3. Assembly

Assembly integrates the structural and lighting components into a cohesive unit. This involves mounting LED strips or modules into stair treads or risers, wiring the electrical components, and securing glass or metal elements. Manufacturers often use modular assembly lines with standardized fixtures to maintain consistency and reduce human error. Proper electrical insulation and waterproofing are applied during this stage to ensure safety and longevity, especially for outdoor or high-traffic applications.

4. Finishing

Finishing includes surface treatments such as polishing, painting, or coating to enhance appearance and protect against environmental factors. For lighted stairs, diffusers and lenses are installed to control light distribution and minimize glare. The finishing stage also involves final hardware installation and packaging preparation tailored for international shipping, which might include anti-corrosion wraps and vibration-proof crates.

Quality Assurance and Control (QA/QC) Framework

Robust QA/QC protocols are essential to ensure lighted stairs meet both performance and regulatory standards. International buyers should expect manufacturers to comply with globally recognized certifications and maintain rigorous inspection routines.

Relevant International and Industry Standards:

– ISO 9001: The cornerstone for quality management systems, ensuring consistent product quality and continuous improvement.

– CE Marking: Mandatory for products sold in the European Economic Area, indicating compliance with EU safety, health, and environmental requirements.

– IEC Standards: Particularly IEC 60598 for lighting fixtures, ensuring electrical safety and performance.

– RoHS Compliance: Restricts hazardous substances in electrical components, critical for environmentally conscious buyers.

– Local Standards: Buyers in regions such as Saudi Arabia and South America should verify compliance with regional standards like SASO (Saudi Standards, Metrology and Quality Organization) or INMETRO (Brazilian Institute of Metrology, Standardization and Industrial Quality).

QC Checkpoints in the Manufacturing Cycle:

– Incoming Quality Control (IQC): Inspection of raw materials and components to verify specifications, material certificates, and absence of defects before production.

– In-Process Quality Control (IPQC): Continuous monitoring during forming, assembly, and finishing stages to detect deviations early. This includes dimensional checks, solder joint inspections, and functional testing of LED modules.

– Final Quality Control (FQC): Comprehensive testing of the finished product, including electrical safety tests, load-bearing capacity, waterproofing integrity, and visual inspections for surface defects.

Common Testing Methods for Lighted Stairs

- Electrical Safety Testing: Verifies insulation resistance, grounding continuity, and absence of electrical leakage using instruments like megohmmeters.

- Load and Stress Testing: Ensures the stairs can withstand expected weight loads without structural failure, typically using static and dynamic load simulations.

- Environmental Testing: Includes humidity, temperature cycling, and UV exposure to assess durability under various climate conditions, crucial for buyers in harsh environments such as the Middle East or tropical South America.

- Photometric Testing: Measures light output, color temperature, and uniformity to ensure consistent and safe illumination.

- Ingress Protection (IP) Testing: Confirms resistance to dust and water ingress, especially important for outdoor or wet-area installations.

Verifying Supplier Quality: Best Practices for B2B Buyers

For buyers sourcing lighted stairs internationally, due diligence on supplier quality practices is essential to mitigate risks and ensure compliance.

- Factory Audits: Conduct on-site inspections or engage third-party auditors to evaluate manufacturing capabilities, quality management systems, and workforce expertise. Audits should cover production processes, equipment maintenance, storage, and testing facilities.

- Review of Quality Documentation: Request and scrutinize quality manuals, process flow charts, inspection reports, and certification documents such as ISO 9001 certificates or CE declarations of conformity.

- Third-Party Inspections: Employ independent inspection agencies to perform pre-shipment inspections, including random sampling, functional testing, and packaging verification. This adds an unbiased layer of assurance.

- Sample Testing: Obtain product samples for in-house or third-party lab testing, particularly to verify electrical safety and material compliance with regional standards.

- Supplier References and Track Record: Check the supplier’s history with other international clients, focusing on delivery performance, product reliability, and after-sales support.

QC and Certification Nuances for International Markets

Africa & South America:

Importers should prioritize suppliers with certifications recognized by local regulatory bodies (e.g., SABS in South Africa, INMETRO in Brazil). Given variable infrastructure, emphasis on robust packaging and product durability under diverse environmental conditions is crucial.

Middle East (e.g., Saudi Arabia):

Compliance with SASO standards and IEC electrical safety norms is mandatory. Given the harsh climate, products must pass rigorous environmental testing, including high-temperature and dust ingress resistance.

Europe:

CE marking and RoHS compliance are non-negotiable. European buyers should also consider energy efficiency ratings and sustainability certifications, reflecting regional priorities for green building practices.

Thailand and Southeast Asia:

While regional standards may be less stringent, buyers benefit from insisting on IEC and ISO certifications, as well as supplier experience exporting to developed markets, which often ensures higher quality benchmarks.

Summary

Understanding the manufacturing process and quality assurance framework behind lighted stairs empowers international B2B buyers to make informed sourcing decisions. Key manufacturing stages—material prep, forming, assembly, and finishing—must be supported by rigorous quality controls including IQC, IPQC, and FQC. Compliance with international standards like ISO 9001, CE, and IEC ensures safety and performance, while region-specific certifications address local regulatory demands. Buyers are advised to verify supplier quality through audits, documentation reviews, third-party inspections, and sample testing. This comprehensive approach mitigates risk and secures high-quality, durable lighted stairs tailored to diverse market needs.

Related Video: China’s Top 5 Manufacturing and Mass Production Videos | by @miracleprocess

Comprehensive Cost and Pricing Analysis for lighted stairs Sourcing

When sourcing lighted stairs for commercial or residential projects, understanding the intricate cost and pricing structure is essential for international B2B buyers aiming to optimize investment and ensure quality. This analysis breaks down the key cost components, pricing influencers, and strategic buyer tips tailored for markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in Lighted Stairs Manufacturing

-

Materials

The cost of raw materials significantly impacts the final pricing. Common materials include aluminum or stainless steel for stair frames, tempered glass or acrylic for treads, and LED lighting modules. Premium-grade materials, such as high-quality LEDs with superior color rendering or durable coatings, elevate costs but improve lifespan and safety. -

Labor

Skilled labor for assembling lighted stairs—especially when integrating electrical components and ensuring compliance with safety standards—adds to the cost. Labor intensity varies by complexity, such as custom designs or embedded sensors. -

Manufacturing Overhead

Overhead includes factory utilities, equipment depreciation, and indirect labor. Precision manufacturing facilities with advanced LED integration and quality control systems may have higher overhead but deliver better product consistency. -

Tooling and Customization

Custom molds, dies, or CNC programming for unique stair shapes or lighting patterns require upfront investment. Tooling costs can be amortized over large orders but increase unit cost for smaller volumes or bespoke designs. -

Quality Control (QC)

Rigorous testing for electrical safety, durability, and lighting performance is critical. Costs here include inspection labor, testing equipment, and certification processes (e.g., CE, UL, RoHS). -

Logistics and Import Duties

Shipping, customs clearance, and import taxes vary widely by region. Buyers from Africa, South America, the Middle East, and Europe must account for these fluctuating costs, which can add 10-30% to the product cost depending on trade agreements and transport mode. -

Supplier Margin

Suppliers factor in profit margins, which can vary based on their market position, exclusivity of design, and after-sales service offerings. Negotiation on margin is possible, especially for bulk orders or long-term partnerships.

Influencing Factors on Final Pricing

-

Order Volume and Minimum Order Quantity (MOQ)

Larger orders typically reduce per-unit costs due to economies of scale. Small buyers should anticipate higher unit prices or seek suppliers offering flexible MOQs. -

Specification and Customization Level

Tailored lighting solutions with smart controls, motion sensors, or color-changing LEDs command premium pricing. Standard models with basic illumination are more cost-effective but less versatile. -

Material Quality and Certifications

Certified products adhering to international safety and environmental standards cost more but reduce risk and enhance market acceptance. -

Supplier Location and Reliability

Proximity to manufacturing hubs (e.g., China, Europe) affects logistics costs and lead times. Established suppliers with proven track records may price higher but reduce risks related to delays or quality issues. -

Incoterms and Payment Terms

Terms such as FOB, CIF, or DDP influence the buyer’s responsibility and cost exposure. Buyers should clarify these terms upfront to avoid unexpected expenses.

Practical Tips for International B2B Buyers

-

Negotiate Based on Total Cost of Ownership (TCO)

Beyond purchase price, consider installation, maintenance, energy consumption, and warranty support. LED-based lighted stairs with energy-efficient drivers may have higher upfront costs but lower operational expenses. -

Leverage Volume and Long-Term Contracts

Buyers in emerging markets like South America or the Middle East can negotiate better pricing and payment terms by committing to multi-phase projects or repeat orders. -

Assess Supplier Certifications and Compliance

Prioritize suppliers with international quality certifications to ensure safety and durability, critical for regulated markets in Europe and Saudi Arabia. -

Factor in Local Import Regulations and Duties

Collaborate with logistics experts to optimize shipping routes and classify products correctly to minimize tariffs, especially in regions with complex customs procedures. -

Request Detailed Quotes with Cost Breakdowns

Transparent pricing helps identify unnecessary markups and enables targeted negotiations on specific cost components like tooling or logistics. -

Consider Currency Fluctuations and Payment Methods

International transactions can be affected by exchange rates and bank fees. Using stable currencies or payment platforms that minimize fees can reduce overall costs.

Indicative Pricing Disclaimer

Prices for lighted stairs vary widely depending on design complexity, materials, order size, and supplier location. Typical unit costs can range from USD 150 to USD 800 per stair unit for standard LED-illuminated models, with fully customized systems priced higher. Buyers should obtain multiple quotations and conduct thorough cost-benefit analyses before finalizing contracts.

By understanding these cost dynamics and pricing influencers, international B2B buyers can make informed sourcing decisions, negotiate effectively, and secure lighted stair solutions that balance quality, aesthetics, and budget considerations across diverse global markets.

Spotlight on Potential lighted stairs Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘lighted stairs’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for lighted stairs

Critical Technical Properties for Lighted Stairs

When sourcing lighted stairs, understanding the key technical specifications is essential to ensure product durability, safety, and compatibility with your project requirements. Here are the most critical properties to consider:

-

Material Grade and Finish

Lighted stairs commonly use materials such as anodized aluminum, stainless steel, or tempered glass. The material grade determines the product’s resistance to corrosion, wear, and environmental factors, which is crucial for longevity—especially in humid or outdoor environments prevalent in regions like the Middle East or coastal Africa. A high-grade finish also impacts aesthetics and maintenance needs. -

Ingress Protection (IP) Rating

The IP rating specifies the level of protection against dust and water ingress. For stair lighting, a minimum of IP65 is often recommended to withstand exposure to moisture and dust, ensuring reliable performance in commercial and outdoor settings. This is vital for buyers in diverse climates to avoid frequent replacements or failures. -

Tolerance and Dimensional Accuracy

Precision in dimensions and tolerances ensures that lighting fixtures fit seamlessly into stair designs without gaps or misalignment. Tighter tolerances reduce installation complexity and avoid costly modifications on-site, which is particularly important for large-scale commercial projects in Europe or South America where regulatory compliance is strict. -

Light Output and Color Temperature

Measured in lumens and Kelvin (K), these parameters define brightness and light tone. For safety and visual comfort, stair lighting should provide uniform illumination around 300-500 lumens with color temperatures between 2700K (warm white) to 4000K (neutral white). Buyers should specify these to balance ambiance and functionality. -

Power Consumption and Efficiency

LED-based lighted stairs offer energy-efficient solutions with lower power consumption and longer lifespan compared to traditional lighting. Knowing wattage and luminous efficacy (lumens per watt) helps buyers evaluate operational costs and sustainability credentials, a growing priority in European and Middle Eastern markets. -

Control and Sensor Compatibility

Integration with motion sensors, dimmers, or smart building systems enhances safety and energy savings. Compatibility with standard control protocols (e.g., DALI, Zigbee) allows for seamless integration into modern smart infrastructure, a key consideration for technologically advanced buyers.

Common Trade Terminology in Lighted Stair Procurement

Navigating international B2B transactions requires familiarity with industry jargon that governs purchasing, manufacturing, and shipping processes. Here are essential terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce components or complete products that are branded and sold by another company. Buyers looking for customized branding or design modifications often work with OEMs to tailor lighted stairs to specific market needs. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to produce in one order. Understanding MOQ helps buyers plan budgets and inventory, especially important for emerging markets in Africa or South America where demand volumes may vary. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting detailed pricing, lead times, and specifications for a particular product. RFQs enable buyers to compare offers and negotiate terms effectively before committing. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs clearance between buyers and sellers. Common terms like FOB (Free On Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid) clarify who bears risk and cost at each stage, critical for managing cross-border shipments to regions such as the Middle East or Europe. -

Lead Time

The total time from order confirmation to product delivery. Accurate lead time estimates are vital for project planning and avoiding costly delays, particularly for large-scale commercial installations. -

IP Rating (Ingress Protection)

Although a technical term, it also appears frequently in trade discussions. Buyers should insist on clear IP ratings in quotes to ensure product suitability for intended environments.

By focusing on these technical properties and mastering trade terminology, international B2B buyers can make informed decisions that optimize safety, quality, and cost-efficiency when procuring lighted stairs. This approach minimizes risk and aligns product performance with market expectations across Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the lighted stairs Sector

Market Overview & Key Trends

The global market for lighted stairs is experiencing robust growth driven by increasing urbanization, architectural innovation, and heightened safety regulations across commercial and residential sectors. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are witnessing a surge in demand for integrated lighting solutions that combine functionality with aesthetic appeal. Regions such as the Middle East (e.g., Saudi Arabia) and Europe are investing heavily in luxury real estate and commercial infrastructure, where lighted stairs serve as both safety features and design elements.

Key market drivers include advancements in LED technology, smart lighting integration, and customization capabilities. LED fixtures dominate due to their energy efficiency, long lifespan, and versatility in design. Smart controls, including motion sensors and app-based management systems, are emerging trends that enhance user convenience and optimize energy consumption. Buyers increasingly seek modular and scalable systems that can be tailored to diverse architectural styles and project requirements.

From a sourcing perspective, there is a growing preference for manufacturers who offer end-to-end solutions—from design consultation to installation and after-sales support. International buyers value suppliers who can navigate complex logistics, provide compliance with regional safety standards, and offer competitive pricing without compromising quality. For markets in Africa and South America, where infrastructure development is accelerating, demand for durable, cost-effective lighting solutions is particularly strong.

Furthermore, digital platforms and virtual product demonstrations have become essential tools in the procurement process, enabling buyers to evaluate custom lighting options remotely. This trend facilitates more informed decision-making and fosters stronger supplier relationships across borders.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical criterion for B2B buyers in the lighted stairs sector, driven by regulatory pressures and increasing corporate responsibility mandates worldwide. The environmental impact of lighting systems is significant, particularly concerning energy consumption and material sourcing. LED-based stair lighting reduces power usage substantially compared to traditional incandescent or halogen fixtures, aligning with global energy efficiency goals.

Ethical sourcing is equally important; buyers are scrutinizing supply chains to ensure materials are responsibly obtained and manufacturing practices minimize environmental harm. Certifications such as RoHS (Restriction of Hazardous Substances), UL Environment, and ENERGY STAR are increasingly sought after, as they provide verifiable assurances of product safety, energy efficiency, and reduced ecological footprint.

Materials used in lighted stairs—such as recycled aluminum, sustainable plastics, and low-VOC (volatile organic compounds) coatings—are gaining traction. These choices not only lower environmental impact but also appeal to end clients who prioritize green building standards, such as LEED and BREEAM certifications.

For buyers in emerging markets like Africa and South America, aligning with suppliers who demonstrate transparent ethical practices can mitigate risks associated with compliance and reputational damage. Moreover, sustainable lighting solutions often offer long-term cost savings through reduced maintenance and energy bills, providing compelling business value.

Ultimately, integrating sustainability and ethical sourcing into procurement strategies enhances brand reputation, meets evolving market expectations, and supports global efforts to reduce carbon footprints within the built environment.

Evolution of Lighted Stairs in B2B Context

The concept of illuminated stairs has evolved significantly from simple safety lighting to sophisticated architectural features. Initially, stair lighting focused primarily on enhancing visibility to prevent accidents in commercial and public buildings. The advent of LED technology in the early 2000s revolutionized the sector by enabling energy-efficient, low-profile fixtures that could be seamlessly integrated into stair designs.

Over the past decade, customization and smart technology have transformed lighted stairs into dynamic design statements. Today, manufacturers offer solutions that incorporate color tuning, programmable effects, and sensor-triggered illumination, catering to diverse market needs—from luxury hotels in Europe to modern office complexes in the Middle East.

This evolution reflects broader trends in smart building technologies and sustainable design, positioning lighted stairs as both functional necessities and integral components of modern architectural aesthetics. For B2B buyers, understanding this progression is key to selecting cutting-edge solutions that align with contemporary safety standards, energy regulations, and design ambitions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of lighted stairs

-

How can I effectively vet suppliers of lighted stairs for international B2B transactions?

To vet suppliers, start by verifying their business licenses and certifications relevant to lighting and electrical safety standards applicable in your region (e.g., CE, UL, or IEC). Request detailed product specifications, test reports, and client references. Conduct virtual or on-site factory audits if possible. Check their experience with international shipping and compliance with export regulations. Engaging a third-party inspection company for quality and compliance checks before shipment can also mitigate risks. Prioritize suppliers with transparent communication and proven track records in delivering customized lighting solutions. -

What customization options are typically available for lighted stairs, and how can I ensure they meet my project requirements?

Most manufacturers offer customization in terms of LED color temperature, brightness levels, fixture design, materials, and control systems (e.g., motion sensors, smart integration). To ensure your specifications are met, provide detailed architectural drawings and lighting requirements upfront. Collaborate closely with the supplier’s design team and request 3D renderings or prototypes before mass production. Confirm that the supplier can adapt to local electrical standards and environmental conditions, especially for regions with specific voltage or climate considerations. -

What are common minimum order quantities (MOQs) and lead times for lighted stairs, especially for buyers in Africa, South America, the Middle East, and Europe?

MOQs vary widely depending on customization and supplier scale but typically range from 50 to 200 units per order. Lead times generally span 6 to 12 weeks, factoring in design approval, manufacturing, quality control, and shipping. Buyers from Africa and South America should account for potentially longer shipping durations and customs clearance times. To optimize lead times, place orders well in advance and confirm production schedules. Some suppliers offer flexible MOQs for repeat clients or sample orders, facilitating initial testing before bulk purchases. -

Which payment terms are standard in international B2B transactions for lighted stairs, and how can buyers protect themselves?

Common payment terms include 30% upfront deposit with balance paid against shipping documents or after inspection. Letters of credit (LC) and escrow services offer additional security for larger transactions. Buyers should negotiate payment terms aligned with project milestones and verify the supplier’s banking credentials. Utilizing trade assurance platforms or involving a reputable freight forwarder can further protect payments. Always ensure contracts clearly specify payment schedules, penalties for delays, and dispute resolution mechanisms. -

What quality assurance (QA) measures and certifications should I expect from reputable lighted stairs manufacturers?

Reputable manufacturers provide QA documentation including ISO 9001 certification, electrical safety certificates (CE, UL, or equivalent), and product test reports for LED lifespan, waterproof ratings (IP ratings), and electromagnetic compatibility. Factory audits and in-process inspections are standard to ensure consistent quality. Request samples or pilot runs before full production and insist on pre-shipment inspections by independent third parties. This is especially critical for buyers in regions with strict import regulations, as non-compliance can lead to customs delays or product recalls.

-

How do logistics and shipping processes typically work for international orders of lighted stairs?

Lighted stairs are generally shipped via sea freight for cost efficiency, with air freight as an option for urgent orders. Packaging must ensure protection from moisture, vibration, and impact during transit. Buyers should confirm Incoterms (e.g., FOB, CIF) to clarify responsibility for shipping costs and risks. Coordination with experienced freight forwarders familiar with the destination country’s customs requirements (especially in Africa and the Middle East) is crucial to avoid delays. Tracking systems and clear communication from suppliers help monitor shipment progress and prepare for timely customs clearance. -

What are effective strategies to resolve disputes or quality issues with international suppliers of lighted stairs?

Start by documenting all communications and discrepancies with photos or videos. Refer to contract terms and warranty clauses to seek resolution through negotiation or mediation. Engage third-party inspection or certification bodies for impartial evaluation if quality disputes arise. For persistent issues, consider arbitration under internationally recognized rules (e.g., ICC arbitration). Maintaining professional and clear communication channels helps prevent misunderstandings. Building long-term supplier relationships with transparent problem-solving frameworks reduces future risks. -

Are there any regional considerations buyers from Africa, South America, the Middle East, and Europe should be aware of when sourcing lighted stairs?

Yes. Electrical standards vary: for example, Europe uses 230V/50Hz, while some African and Middle Eastern countries may have different voltages or require specific certifications. Climate conditions (high humidity, dust) influence the choice of IP-rated fixtures. Import duties, taxes, and certification requirements differ by country, necessitating local compliance knowledge. Language barriers and time zone differences can affect communication efficiency, so working with suppliers offering multilingual support is advantageous. Understanding these regional factors upfront ensures smoother procurement and installation processes.

Strategic Sourcing Conclusion and Outlook for lighted stairs

Strategic sourcing of lighted stairs offers international B2B buyers a unique opportunity to blend safety, design innovation, and energy efficiency in their projects. For markets in Africa, South America, the Middle East, and Europe, prioritizing customizable, high-quality LED lighting solutions ensures compliance with local standards while elevating architectural aesthetics. Key sourcing considerations include selecting suppliers with proven expertise in tailored lighting systems, robust quality assurance processes, and the ability to integrate smart controls and sustainable technologies.

Emphasizing strategic partnerships with manufacturers who provide end-to-end services—from design consultation to installation and after-sales support—can significantly reduce project risks and enhance value delivery. Additionally, leveraging regional insights and supplier networks will help navigate logistical challenges and optimize cost structures.

Looking ahead, the demand for energy-efficient, intelligent lighting solutions in staircases will continue to grow, driven by global sustainability trends and evolving safety regulations. Buyers are encouraged to adopt a forward-thinking approach by investing in adaptable lighting technologies that can integrate with smart building systems. Engaging with innovative suppliers now will position businesses to capitalize on emerging market opportunities and deliver exceptional environments that prioritize both functionality and style.