Guide to Bulb Base Types

- Introduction: Navigating the Global Market for bulb base types

- Understanding bulb base types Types and Variations

- Key Industrial Applications of bulb base types

- Strategic Material Selection Guide for bulb base types

- In-depth Look: Manufacturing Processes and Quality Assurance for bulb base types

- Manufacturing and Quality Assurance of Bulb Base Types: Essential Insights for International B2B Buyers

- Comprehensive Cost and Pricing Analysis for bulb base types Sourcing

- Spotlight on Potential bulb base types Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for bulb base types

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bulb base types Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of bulb base types

- Strategic Sourcing Conclusion and Outlook for bulb base types

Introduction: Navigating the Global Market for bulb base types

In the global lighting industry, the bulb base is a deceptively small component that plays a pivotal role in ensuring seamless electrical connectivity and optimal performance. For international B2B buyers—especially those operating across Africa, South America, the Middle East, and Europe—the challenge lies not only in identifying the right bulb base type but also in navigating a complex landscape of regional standards, supplier variations, and application-specific requirements. Selecting the correct bulb base is crucial: it affects compatibility with fixtures, energy efficiency, maintenance costs, and ultimately, the reliability of your lighting solutions.

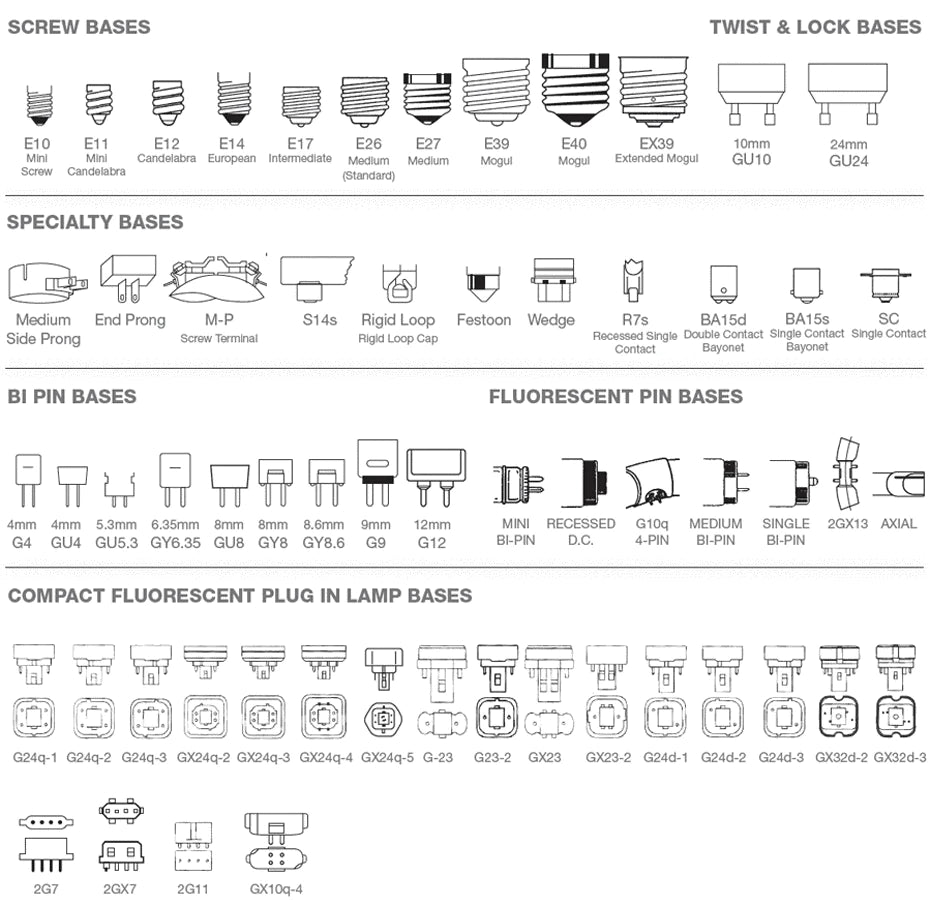

This comprehensive guide delivers actionable insights into the diverse world of bulb base types, covering everything from standard screw and bayonet bases to specialized pin and plug-in configurations. Beyond types, it delves into the materials used, manufacturing and quality control standards, and how these influence durability and performance in different industrial and commercial settings. You will also find critical analysis of leading global suppliers, cost considerations, and market trends tailored to the needs of buyers sourcing for warehouses, retail outlets, hospitality venues, and specialized facilities.

Designed to empower procurement professionals and technical buyers, this guide equips you with the knowledge to make informed sourcing decisions that align with your operational demands and regional compliance. Whether upgrading to LED technology or maintaining legacy systems, understanding bulb base nuances ensures your lighting investments deliver maximum value and sustainability across diverse international markets.

Understanding bulb base types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Edison Screw (E26/E27, E39/E40, E12/E14) | Threaded screw base, standardized diameters (26mm, 27mm, 39mm, 40mm, 12mm, 14mm) | General commercial lighting, industrial high bays, decorative fixtures | Pros: Widely available, simple installation; Cons: Not ideal for vibration-prone environments |

| Bayonet Base (BA15s, BA15d) | Push-and-twist locking mechanism, stable connection under vibration | Automotive, marine, outdoor, industrial signaling | Pros: Secure fit in harsh environments; Cons: Less common globally, may require specific fixtures |

| Pin Base (G4, G5.3, G9, G13, GU10) | Two or more pins inserted into socket; some with twist-lock (GU10) | LED tubes, spotlights, retail display, specialty lighting | Pros: Compact, precise fit, ideal for directional lighting; Cons: Requires matching fixture type exactly |

| Specialty Bases (2G11, G24, GX16d) | Unique configurations for specialized bulbs, often plug-in or double-ended | Stage lighting, HID bulbs, CFL plug-ins, agriculture grow lights | Pros: Tailored for specific applications; Cons: Limited interchangeability, may need ballast compatibility |

Edison Screw Bases

Edison screw bases are the most common globally, with E26/E27 being the standard for general lighting in commercial and residential markets. Larger sizes like E39/E40 serve high-output industrial needs such as warehouses and factories. Smaller E12/E14 bases cater to decorative and specialty fixtures. For B2B buyers, sourcing these bases is straightforward due to their ubiquity, but verifying regional standards (e.g., E27 in Europe, E26 in the U.S.) is critical to ensure compatibility and avoid costly returns.

Bayonet Bases

Bayonet bases use a push-and-twist locking mechanism that offers superior stability in environments with vibration or movement, such as marine, automotive, and outdoor industrial settings. While less common than screw bases, they are essential for applications requiring secure connections. Buyers should consider the availability of compatible fixtures and regional preferences, especially in markets like the Middle East and parts of Europe where bayonet bases are more prevalent.

Pin Bases

Pin bases are characterized by two or more pins inserted into the socket, with variants like GU10 offering twist-lock features for directional lighting. They are widely used in LED tube lighting, retail track lights, and specialty applications like under-cabinet or grow lights. For B2B procurement, ensuring exact pin spacing and fixture compatibility is crucial to prevent installation issues and maintain lighting performance, especially in sophisticated commercial environments.

Specialty Bases

Specialty bases such as 2G11, G24, and GX16d cater to niche markets including stage lighting, high-intensity discharge (HID) applications, and compact fluorescent lamps (CFL). These bases often require ballast compatibility and careful specification matching. For international buyers, particularly in industrial or agricultural sectors, understanding these specialized bases is vital for securing reliable lighting solutions tailored to unique operational demands.

Related Video: Choosing the Right Light Bulb – Step 1 The Right Fit | GE Lighting

Key Industrial Applications of bulb base types

| Industry/Sector | Specific Application of Bulb Base Types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing & Warehousing | High bay LED lighting with E39/E40 mogul bases | High-intensity, energy-efficient illumination for large spaces | Compatibility with existing fixtures, durability, voltage standards |

| Retail & Commercial Spaces | Directional track lighting using GU10 and E26/E27 bases | Enhanced product visibility, flexible lighting control | Quality of beam focus, dimmability, regional socket standards |

| Transportation & Heavy Machinery | Signal and indicator lighting with BA15s bayonet bases | Secure, vibration-resistant connections for safety-critical applications | Robust locking mechanism, resistance to environmental stress |

| Hospitality & Decorative Lighting | Accent and decorative lighting with E12/E14 candelabra bases | Aesthetic enhancement with energy-saving options | Matching fixture specifications, availability of dimmable options |

| Agriculture & Horticulture | Grow lights with G4, G5.3 pin bases | Optimized plant growth with specialized spectral output | Heat management, ballast compatibility, and IP ratings |

Manufacturing & Warehousing

In manufacturing plants and large warehouses, high bay lighting is essential for safety and productivity. Bulbs with E39 or E40 mogul bases are commonly used in these settings due to their ability to support high-wattage HID or LED bulbs that provide intense, uniform illumination over wide areas. For B2B buyers in Africa, South America, the Middle East, and Europe, it is critical to ensure that the mogul base bulbs comply with local voltage and fixture standards. Durability and ease of replacement also matter, as downtime can be costly. Opting for LED upgrades with compatible mogul bases can drastically reduce energy consumption and maintenance costs.

Retail & Commercial Spaces

Retail environments rely heavily on focused lighting to highlight products and create an inviting atmosphere. GU10 and E26/E27 screw bases are popular choices for track lighting and general ambient illumination. These bulb base types enable easy installation and replacement, and many offer dimmable features to adjust light intensity throughout the day. International buyers should verify that the bulb bases match the fixture sockets prevalent in their markets and consider beam angle and color temperature to optimize visual merchandising. Energy-efficient LED bulbs with these bases also support sustainability goals.

Transportation & Heavy Machinery

Bayonet base bulbs, such as BA15s, are favored in transportation and heavy machinery applications because their twist-and-lock design prevents accidental disconnection due to vibration. These bases are used in signal lights, indicators, and control panels where reliability is paramount. For buyers in regions with harsh climates like the Middle East or Africa, sourcing bulbs with robust locking mechanisms and resistance to dust and moisture is essential. Ensuring compliance with international safety standards and compatibility with vehicle or machinery electrical systems will minimize operational risks.

Hospitality & Decorative Lighting

In hospitality venues, decorative lighting plays a vital role in ambiance creation. Smaller screw bases like E12 and E14 are common for chandeliers, sconces, and accent fixtures. These bases support a variety of bulb shapes and technologies, including energy-efficient LEDs and dimmable options. B2B buyers from Europe and Australia should prioritize sourcing bulbs that fit imported fixtures and meet local electrical codes. The availability of bulbs with consistent color rendering and long lifespans can enhance guest experience while reducing replacement frequency and energy costs.

Agriculture & Horticulture

Specialized grow lights using pin bases such as G4 and G5.3 are critical in controlled agricultural environments and research facilities. These bases accommodate halogen or LED bulbs tailored for plant growth, delivering specific light spectra. Buyers from South America and Africa involved in agribusiness should focus on bulbs that offer ballast compatibility, efficient heat dissipation, and IP-rated protection against moisture. Selecting the right bulb base ensures seamless integration with existing lighting systems, promoting healthier crops and higher yields while optimizing energy use.

Related Video: LBO Model Tutorial: Sources & Uses and Financial Forecast

Strategic Material Selection Guide for bulb base types

When selecting materials for bulb bases, international B2B buyers must balance performance, cost, and compliance with regional standards. The choice of material directly affects the durability, electrical safety, and environmental resistance of the bulb base. Below is an analysis of four common materials used for bulb bases, focusing on their key properties, pros and cons, application impact, and considerations for buyers from Africa, South America, the Middle East, and Europe (including Australia and the UAE).

Brass

Key Properties:

Brass is an alloy primarily composed of copper and zinc, known for excellent electrical conductivity, moderate corrosion resistance, and good mechanical strength. It can withstand moderate temperatures typically encountered in lighting applications.

Pros & Cons:

Brass offers excellent machinability and a naturally attractive finish, which is beneficial for decorative and exposed fixtures. It resists corrosion better than pure copper but can tarnish over time, requiring surface treatment for aesthetic longevity. Manufacturing complexity is moderate, and brass components tend to be mid-range in cost.

Impact on Application:

Brass bases are ideal for indoor commercial lighting where electrical conductivity and moderate corrosion resistance are critical. They perform well in environments with low to moderate humidity but may require plating or coating in highly corrosive atmospheres.

International Buyer Considerations:

Brass complies with many international standards such as ASTM B16 and EN 12164, which facilitates cross-border procurement. Buyers in humid or coastal regions like parts of Africa and the Middle East should specify plated brass bases (e.g., nickel or tin plating) to enhance corrosion resistance. European and Australian markets often prefer brass bases with RoHS compliance and REACH certifications due to environmental regulations.

Aluminum

Key Properties:

Aluminum is lightweight, has good thermal conductivity, and offers excellent corrosion resistance due to the formation of a protective oxide layer. It has a lower electrical conductivity than copper or brass but is valued for its weight-to-strength ratio.

Pros & Cons:

Aluminum bases are cost-effective and easy to manufacture with modern extrusion and machining techniques. However, aluminum’s lower electrical conductivity means it is less common for direct electrical contacts without special coatings. It is highly corrosion-resistant, especially in marine or industrial environments, but can suffer from galvanic corrosion if paired with incompatible metals.

Impact on Application:

Aluminum is often used in bulb bases for outdoor or industrial lighting where weight reduction and corrosion resistance are priorities. It is suitable for fixtures exposed to harsh environments, such as warehouses or outdoor commercial spaces.

International Buyer Considerations:

Buyers in South America and the Middle East, where high ambient temperatures and corrosive environments prevail, benefit from aluminum’s durability. Compliance with ISO 209 and ASTM B209 standards ensures quality. However, buyers must ensure compatibility with fixture materials to avoid galvanic corrosion, especially in mixed-metal assemblies common in European and Australian markets.

Thermoplastic (High-Temperature Resistant Polymers)

Key Properties:

Thermoplastics used in bulb bases, such as polycarbonate or PBT (polybutylene terephthalate), offer excellent electrical insulation, high heat resistance (up to 150°C or more), and good impact resistance. They are non-conductive and lightweight.

Pros & Cons:

Thermoplastics are cost-effective and allow complex shapes through injection molding, reducing manufacturing costs for high-volume production. They provide excellent dielectric strength but may degrade under prolonged UV exposure or extreme temperatures beyond their rating. Mechanical strength is lower compared to metals.

Impact on Application:

Thermoplastic bases are ideal for LED bulbs and low-heat applications, especially where electrical insulation and safety are paramount. They are common in residential and commercial lighting fixtures that require lightweight and cost-efficient solutions.

International Buyer Considerations:

Buyers from regions with strict fire safety and electrical standards, such as the EU (EN 60695) and Australia (AS/NZS 60335), should specify thermoplastics with UL or IEC certifications. In hot climates like parts of Africa and the Middle East, selecting UV-stabilized and flame-retardant grades is critical to ensure longevity and compliance.

Nickel-Plated Steel

Key Properties:

Steel provides high mechanical strength and durability, while nickel plating offers enhanced corrosion resistance and improved electrical contact surfaces. The plating also provides a smooth finish that resists wear and oxidation.

Pros & Cons:

Nickel-plated steel bases are robust and suitable for heavy-duty industrial applications. They are more cost-effective than solid brass but heavier. The plating process adds manufacturing complexity and cost but significantly extends service life in harsh environments.

Impact on Application:

This material is preferred for high-impact, vibration-prone environments such as automotive lighting, industrial machinery, and outdoor fixtures. Its durability makes it suitable for regions with fluctuating temperatures and exposure to dust or moisture.

International Buyer Considerations:

For buyers in South America and Africa, where industrial environments can be harsh and maintenance costly, nickel-plated steel offers a balance of durability and cost. Compliance with ASTM B689 and ISO 4520 for plating quality is essential. European buyers may require RoHS-compliant plating processes, while Middle Eastern markets value corrosion resistance against saline atmospheres.

| Material | Typical Use Case for bulb base types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Indoor commercial and decorative lighting | Excellent electrical conductivity and moderate corrosion resistance | Tarnishes without plating; moderate cost | Medium |

| Aluminum | Outdoor, industrial, and weight-sensitive applications | Lightweight with excellent corrosion resistance | Lower electrical conductivity; galvanic corrosion risk | Medium |

| Thermoplastic (High-Temp Polymers) | LED and low-heat residential/commercial lighting | High electrical insulation and cost-effective manufacturing | Lower mechanical strength; UV degradation risk | Low |

| Nickel-Plated Steel | Heavy-duty industrial, automotive, and outdoor lighting | High mechanical strength and corrosion resistance | Heavier; plating adds cost and complexity | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for bulb base types

Manufacturing and Quality Assurance of Bulb Base Types: Essential Insights for International B2B Buyers

Understanding the manufacturing processes and quality assurance (QA) protocols behind bulb base types is crucial for B2B buyers seeking reliable, high-performance lighting components. This knowledge enables buyers from Africa, South America, the Middle East, and Europe to make informed procurement decisions, ensuring compatibility, safety, and durability in their applications.

Typical Manufacturing Processes for Bulb Bases

The production of bulb bases involves several precise and controlled stages designed to meet exacting performance and safety standards. These main stages include:

1. Material Preparation

- Raw Material Selection: Bulb bases commonly use metals such as brass, aluminum, or copper alloys for their excellent conductivity and corrosion resistance. Plastic components, often heat-resistant thermoplastics or thermosetting polymers, are selected for insulation parts.

- Material Conditioning: Metals are cleaned, annealed, or surface-treated to enhance ductility and bonding properties. Plastic resins may undergo drying and compounding for uniformity.

Illustrative Image (Source: Google Search)

2. Forming

- Metal Stamping and Turning: Metal parts like screw threads (Edison bases) or bayonet pins are shaped through stamping, turning, or cold forming. High precision is vital to ensure the bases fit sockets securely.

- Injection Molding: Plastic components are formed via injection molding, enabling complex shapes such as insulating sleeves or locking features with tight tolerances.

- Machining: Secondary machining may refine threads, pins, or contact surfaces to meet design specifications.

3. Assembly

- Component Integration: Metal and plastic parts are assembled using automated or semi-automated processes. For example, metal pins are inserted and fixed into plastic insulators.

- Soldering and Welding: Electrical contacts are soldered or welded to ensure reliable conductivity and mechanical strength.

- Press Fitting and Locking: For bayonet and other locking bases, precise press fitting or locking mechanisms are engaged to maintain secure connections.

4. Finishing

- Surface Treatment: Metal parts may undergo plating (e.g., nickel or tin) to enhance corrosion resistance and electrical conductivity.

- Cleaning and Inspection: Final cleaning removes residues or contaminants.

- Marking: Bases are often laser-marked with specifications or certification symbols for traceability.

Key Quality Assurance (QA) and Quality Control (QC) Practices

To guarantee product integrity, manufacturers implement robust QA and QC frameworks aligned with international and industry-specific standards.

Relevant International and Industry Standards

- ISO 9001: The foundational global standard for quality management systems, ensuring consistent manufacturing processes and continual improvement.

- IEC 60061 & IEC 60064: International Electrotechnical Commission standards specifying dimensions and safety requirements for lamp caps and holders.

- CE Marking: Mandatory for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- UL and CSA Certifications: North American safety standards relevant for manufacturers targeting those markets.

- API (American Petroleum Institute): Applicable when bulb bases are used in hazardous or industrial environments requiring explosion-proof designs.

- Regional Standards: Buyers in the Middle East, Africa, South America, and Australia should verify compliance with local standards such as SABS (South Africa), INMETRO (Brazil), and AS/NZS (Australia/New Zealand).

QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Inspection and testing of raw materials and components to verify specifications before manufacturing begins. For example, metal alloy composition and plastic resin quality are assessed.

- In-Process Quality Control (IPQC): Continuous monitoring during forming and assembly stages, including dimensional checks, torque testing on screw threads, and visual inspections for defects.

- Final Quality Control (FQC): Comprehensive testing of finished bulb bases, including electrical continuity, mechanical fit tests, and surface finish inspections.

Common Testing Methods

- Dimensional Verification: Use of precision gauges, micrometers, and coordinate measuring machines (CMM) to confirm adherence to design tolerances.

- Electrical Tests: Resistance and conductivity tests ensure optimal electrical performance.

- Mechanical Strength Testing: Torque and pull tests validate the durability of screw threads and locking mechanisms.

- Environmental Tests: Corrosion resistance (salt spray), thermal cycling, and vibration tests simulate operating conditions, especially important for industrial and outdoor applications.

- Safety Compliance: Dielectric strength and insulation resistance tests verify electrical safety.

How B2B Buyers Can Verify Supplier Quality Assurance

For international buyers, especially in regions with diverse regulatory environments, due diligence on supplier QA practices is vital. Recommended verification steps include:

- Factory Audits: On-site or virtual audits by buyer representatives or third-party inspectors to review manufacturing processes, equipment, and worker training.

- Review of Quality Documentation: Request ISO 9001 certificates, test reports, material certificates, and compliance declarations (e.g., CE, UL).

- Third-Party Inspection Services: Independent testing labs or inspection agencies can provide unbiased verification of product conformity and performance.

- Sample Testing: Procuring product samples for in-house or local lab testing helps confirm suitability before large-scale orders.

- Supplier Track Record: Evaluate the supplier’s experience with international markets, responsiveness to quality issues, and history of recalls or defects.

QC and Certification Nuances for International B2B Buyers

- Regional Certification Variations: For buyers in Africa, South America, and the Middle East, be aware that local certification bodies may have additional or differing requirements from global standards. For example, INMETRO certification is mandatory in Brazil and may involve unique testing protocols.

- Customs and Import Regulations: Some countries require proof of compliance with recognized standards before import clearance. Early engagement with suppliers to ensure documentation is complete can prevent delays.

- Climate and Environmental Factors: Buyers in hot, humid, or corrosive environments should prioritize bulb bases tested for enhanced durability and corrosion resistance.

- Compatibility with Local Electrical Systems: Voltage and socket standards vary; ensure bulb bases meet local dimensional and electrical specifications to avoid retrofit challenges.

- Sustainability and RoHS Compliance: Increasingly, buyers in Europe and Australia demand compliance with environmental regulations restricting hazardous substances.

In summary, a thorough grasp of the manufacturing stages and quality assurance protocols for bulb bases empowers B2B buyers to select suppliers who deliver consistent, safe, and compatible products. International buyers should emphasize verification of manufacturing certifications, conduct supplier audits, and consider region-specific standards and environmental conditions to optimize their procurement strategies. This approach mitigates risks, reduces costly returns, and supports long-term partnerships in the global lighting supply chain.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for bulb base types Sourcing

Understanding Cost Components in Bulb Base Types

When sourcing bulb base types for industrial or commercial lighting, understanding the underlying cost structure is vital for effective procurement and budgeting. The primary cost components include:

- Materials: The base material—often brass, aluminum, or thermoplastics—significantly impacts costs. Higher-grade metals and specialized coatings for corrosion resistance or conductivity raise material expenses.

- Labor: Skilled labor for assembly, especially for complex bayonet or pin bases, adds to costs. Automation can reduce labor charges but may not be feasible for customized or low-volume orders.

- Manufacturing Overhead: Factory utilities, equipment depreciation, and indirect labor contribute to overhead, influencing unit costs.

- Tooling and Molds: Initial tooling for screw or bayonet bases requires capital investment. Custom tooling for specialty or proprietary bases increases upfront costs but lowers per-unit cost at scale.

- Quality Control: Rigorous inspection, testing for electrical compatibility, and certification processes (e.g., CE, RoHS) add to production costs but ensure reliability.

- Logistics: Shipping, import duties, and warehousing, especially for international buyers, affect landed costs. Bulky or fragile packaging can increase freight expenses.

- Margin: Suppliers factor in profit margins, which vary based on market competition, exclusivity, and order volume.

Key Pricing Influencers for International B2B Buyers

Several factors influence the final pricing of bulb base types, crucial for buyers from Africa, South America, the Middle East, and Europe to consider:

- Order Volume and Minimum Order Quantities (MOQs): Larger orders typically secure better unit pricing. MOQ requirements differ by supplier and base type complexity.

- Specifications and Customization: Customized bases or those with enhanced features (e.g., heat resistance, locking mechanisms) command premium pricing.

- Material Quality: Certified, high-grade materials aligned with international standards increase costs but reduce failure rates and maintenance.

- Certifications and Compliance: Products with regional certifications (e.g., CE for Europe, SASO for the Middle East) may cost more but ease regulatory approval and market acceptance.

- Supplier Reliability and Location: Established manufacturers with proven track records might price higher but reduce risk. Proximity affects shipping time and costs.

- Incoterms and Payment Terms: Understanding terms like FOB, CIF, or DDP helps anticipate responsibility for freight, insurance, and taxes, impacting total expenditure.

Practical Tips for Cost-Efficient Sourcing and Negotiation

To optimize procurement costs while ensuring quality and compliance, international B2B buyers should:

- Leverage Volume for Discounts: Consolidate orders across regions or projects to meet MOQs and negotiate better pricing tiers.

- Assess Total Cost of Ownership (TCO): Evaluate beyond unit price, considering energy efficiency, lifespan, maintenance, and replacement costs linked to bulb base compatibility.

- Clarify Specifications Early: Provide detailed requirements upfront to avoid costly redesigns or sourcing delays.

- Request Samples and Certifications: Validate quality and compatibility before bulk purchasing, especially for specialty or imported bases.

- Negotiate Incoterms: Where possible, negotiate favorable shipping terms to control logistics costs and reduce customs clearance complexities.

- Consider Local Regulations: Factor in import duties, taxes, and compliance costs specific to your region, such as VAT in Europe or import levies in Africa.

- Build Long-Term Supplier Relationships: Trusted partnerships can unlock better pricing, priority production slots, and flexible payment options.

Pricing Nuances Across Regions

- Africa: Import duties and limited local manufacturing can elevate landed costs. Prioritize suppliers offering DDP terms or local warehousing to reduce delays and fees.

- South America: Currency volatility necessitates contract terms in stable currencies or price adjustment clauses. Regional certifications (e.g., INMETRO in Brazil) may affect sourcing decisions.

- Middle East (including UAE): Strong demand for quality and certification compliance can increase prices. Logistics hubs like Dubai offer strategic advantages for distribution.

- Europe: High standards and certifications often mean higher upfront costs but lower risk. Bulk procurement and EU-compliant products facilitate smoother market entry.

Disclaimer: Pricing for bulb base types varies widely depending on specifications, volume, supplier, and region. The insights provided are indicative and should be supplemented with direct supplier quotations and market research tailored to your sourcing needs.

Spotlight on Potential bulb base types Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘bulb base types’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for bulb base types

Critical Technical Properties of Bulb Bases

Understanding the technical properties of bulb bases is essential for ensuring compatibility, durability, and safety in your lighting solutions. Here are key specifications that international B2B buyers should prioritize:

-

Material Grade

Bulb bases are typically made from metals such as brass, aluminum, or nickel-plated steel. The material grade affects corrosion resistance, electrical conductivity, and mechanical strength. For buyers in humid or coastal regions (e.g., Middle East, Africa), opting for corrosion-resistant materials ensures longer lifespan and reduces maintenance costs. -

Dimensional Tolerance

Precision in diameter and pin spacing is critical. Tolerances define acceptable deviations from nominal dimensions, ensuring a secure fit between bulb and socket. Suppliers adhering to tight tolerances minimize installation issues and improve fixture reliability, which is crucial for large-scale commercial or industrial projects. -

Electrical Rating (Voltage & Current Capacity)

Each base type supports specific voltage and current levels. Ensuring the base matches your system’s electrical requirements prevents failures and safety hazards. For example, E39 mogul bases support high-wattage industrial lamps, while smaller bases like E12 suit decorative low-wattage bulbs. -

Locking Mechanism and Contact Design

Bases differ in how they secure bulbs (e.g., screw, bayonet twist-lock, or pin insert). The type affects vibration resistance and ease of replacement. For environments with heavy machinery or transport (common in industrial facilities), bayonet or locking pin bases reduce accidental disconnections. -

Thermal Resistance

Bulb bases must withstand operating temperatures, especially in high-intensity or halogen lighting. Materials and design that dissipate heat effectively prevent deformation and electrical faults, extending fixture life. -

Compliance with International Standards

Look for bases that meet standards such as IEC, ANSI, or local certifications. Compliance assures quality and facilitates customs clearance, a significant advantage in cross-border transactions.

Common Industry and Trade Terminology for Bulb Bases

Navigating the global lighting supply chain requires familiarity with key trade and procurement terms. Here are terms that every international B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to the manufacturer that produces components or bulbs to be branded and sold by another company. Understanding OEM relationships helps buyers negotiate pricing, ensure product quality, and secure after-sales support. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell. MOQ impacts inventory planning and cash flow. Buyers from emerging markets or smaller enterprises should discuss flexible MOQs or consolidated shipments to optimize costs. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting pricing, lead times, and terms for specific products. Crafting detailed RFQs specifying bulb base types, technical specs, and certifications accelerates supplier response and reduces misunderstandings. -

Incoterms (International Commercial Terms)

Standardized trade terms (e.g., FOB, CIF, DDP) defining responsibilities for shipping, insurance, and customs clearance. Clear agreement on Incoterms avoids disputes and unexpected costs during international logistics. -

Lead Time

The period between order placement and delivery. Understanding supplier lead times is vital for project scheduling, especially for large orders or custom base types requiring manufacturing. -

Compatibility

Denotes the suitability of a bulb base with specific fixtures or ballast types. Buyers must verify compatibility to avoid costly returns or performance issues, particularly when upgrading to LED or retrofit lighting solutions.

By mastering these technical properties and trade terms, B2B buyers across Africa, South America, the Middle East, and Europe can make informed purchasing decisions. This knowledge ensures the right bulb bases are selected for specific applications, optimizing operational efficiency and long-term value in international lighting projects.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bulb base types Sector

Market Overview & Key Trends

The global market for bulb base types is shaped by the accelerating transition to energy-efficient lighting solutions, primarily driven by widespread LED adoption. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, this shift represents both opportunity and complexity. The demand for standardized yet versatile bulb bases, such as E27/E26 for general lighting and GU10 for directional applications, is rising due to infrastructure modernization and urbanization. Moreover, industrial sectors in these regions increasingly prioritize high-output bases like E39 for warehouses and manufacturing plants, where durable and reliable lighting is critical.

Sourcing trends reveal a growing preference for suppliers who can offer comprehensive product ranges—including screw, bayonet, and pin bases—aligned with regional electrical standards and fixture compatibility. Buyers are seeking partners who provide technical support for base identification and integration, minimizing the risk of mismatches that disrupt operations. Additionally, the rise of smart and connected lighting systems is influencing base type demand, as certain bases facilitate easier integration with IoT-enabled fixtures.

Market dynamics also emphasize supply chain resilience, particularly in Africa and the Middle East, where logistical challenges and tariff fluctuations can impact lead times and costs. Buyers in Europe and Australia prioritize suppliers with robust quality certifications and proven compliance with regional electrical safety standards. Furthermore, emerging trends include customization of bulb bases for niche applications such as agricultural grow lights and hospitality-focused accent lighting, reflecting the need for adaptable lighting solutions across diverse commercial environments.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone for B2B procurement decisions in the bulb base sector. The environmental impact of lighting components—ranging from raw material extraction to end-of-life disposal—necessitates a focus on eco-friendly sourcing and manufacturing processes. Ethical supply chains that ensure responsible mining of metals (e.g., copper, brass) and reduced use of hazardous substances in bulb base production are critical to meeting corporate social responsibility (CSR) goals.

Buyers should prioritize suppliers offering green certifications such as RoHS (Restriction of Hazardous Substances), REACH compliance, and ISO 14001 environmental management standards. These certifications not only guarantee lower environmental footprints but also ensure safer working conditions and ethical labor practices throughout the supply chain. Additionally, the adoption of recyclable and durable materials in bulb bases enhances product longevity and reduces waste, aligning with circular economy principles.

In emerging markets like Africa and South America, sustainability initiatives are often coupled with local community engagement and capacity building, creating shared value beyond simple procurement. For Middle Eastern and European buyers, transparency in supplier environmental practices is increasingly non-negotiable, influencing contract awards and long-term partnerships. Leveraging suppliers who invest in energy-efficient manufacturing, reduce carbon emissions, and provide take-back or recycling programs for used lighting components offers a strategic advantage in an evolving regulatory landscape focused on sustainability.

Evolution of Bulb Base Types: A Brief Perspective

The evolution of bulb base types reflects the broader technological advancements in lighting technology and the growing complexity of global lighting needs. Initially dominated by simple screw bases like the Edison E26/E27, the sector has expanded to include a variety of specialized bases such as bayonet, pin, and plug-in types to support diverse applications—from industrial high bays to decorative and directional lighting.

This diversification corresponds with the rise of LED technology, which demands compatibility with legacy fixtures as well as new smart lighting systems. The development of secure locking mechanisms in bayonet and twist-lock bases responds to industrial and transportation environments requiring vibration-resistant connections. Simultaneously, the emergence of standardized pin bases for tube and specialty lamps has facilitated the widespread adoption of compact and energy-efficient lighting solutions.

For B2B buyers, understanding this historical context aids in making informed sourcing decisions that balance innovation with compatibility, ensuring investments in lighting infrastructure deliver operational efficiency and future-proofing.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of bulb base types

-

How can I effectively vet suppliers of bulb base types for international B2B purchases?

When sourcing bulb bases internationally, especially from diverse markets like Africa, South America, the Middle East, and Europe, thorough supplier vetting is critical. Start by verifying business licenses, certifications, and factory audits. Request samples to evaluate product quality and compatibility. Check references and past customer reviews for reliability and delivery performance. Utilize third-party inspection services to assess manufacturing standards and compliance with international regulations. Prioritize suppliers with transparent communication and documented experience exporting to your region to minimize risks and ensure smoother transactions. -

Is it possible to customize bulb base types for specific industrial or commercial applications?

Yes, many manufacturers offer customization services for bulb base types, including dimensions, materials, and electrical specifications to fit unique fixtures or regulatory requirements. When negotiating customization, clarify minimum order quantities (MOQs), lead times, and cost implications upfront. Providing detailed technical drawings and usage scenarios helps suppliers meet your exact needs. Customization is particularly valuable for specialized lighting sectors such as industrial high bays, agricultural grow lights, or hospitality lighting in international markets with diverse standards. -

What are typical MOQs and lead times when ordering bulb bases internationally, and how can I negotiate better terms?

MOQs vary widely depending on the supplier and customization level, ranging from hundreds to thousands of units. Lead times typically span 4 to 12 weeks, including production and shipping. To negotiate favorable terms, leverage volume commitments, establish long-term partnerships, or bundle orders with related products like bulbs or fixtures. Buyers from emerging markets can also explore consolidated shipments or regional warehouses to reduce costs and delivery times. Clear communication about demand forecasts and payment readiness often incentivizes suppliers to accommodate smaller MOQs or faster turnaround.

Illustrative Image (Source: Google Search)

-

Which quality assurance certifications should I require for bulb base types to ensure international compliance?

Key certifications include CE (Europe), RoHS (restriction on hazardous substances), UL or ETL (North America), and IEC standards for electrical safety. For Middle Eastern and African markets, compliance with local standards and approvals from bodies like SASO (Saudi Arabia) or SABS (South Africa) may be essential. Request factory quality management certifications such as ISO 9001 to verify consistent production quality. Insist on product testing reports and certification documents before purchase to avoid customs delays or market rejection. -

What logistics considerations are crucial when importing bulb bases from overseas suppliers?

Plan for packaging that protects delicate bases during transit, especially for pin and screw types. Choose reliable freight forwarders experienced in handling lighting components and customs clearance in your target markets. Understand Incoterms to clarify responsibilities and costs. Consolidate shipments when possible to optimize freight costs. Also, be aware of import duties, taxes, and compliance documentation required in your country to avoid delays. Establish a clear timeline for transit and customs to coordinate inventory replenishment effectively. -

How can I manage payment risks and secure transactions when dealing with international bulb base suppliers?

Use secure payment methods such as letters of credit (LC) or escrow services that protect both buyer and supplier interests. Negotiate payment terms that balance risk, like partial upfront deposits with balance after inspection or delivery. Verify supplier banking details and avoid direct wire transfers to unknown accounts. Engage trade finance specialists or export credit agencies if available in your region to mitigate currency fluctuation and non-payment risks. Building a trusted supplier relationship over time also reduces transactional uncertainties. -

What steps should I take if I encounter quality issues or disputes with my bulb base supplier?

Immediately document the issue with photos, batch numbers, and inspection reports. Communicate formally with the supplier, referencing contract terms and warranty clauses. Request corrective actions such as replacements, refunds, or discounts. If unresolved, engage third-party mediation or arbitration bodies specializing in international trade disputes. Maintain clear records of all correspondence and agreements. For future orders, consider adding stricter quality control checkpoints and third-party inspections to prevent recurrence. -

Are there regional differences in bulb base standards that I should be aware of when sourcing internationally?

Absolutely. For example, E26 bases are standard in the U.S. and some Middle Eastern countries, while E27 is prevalent across Europe and parts of Africa. Pin base types and bayonet bases may vary in dimension and locking mechanisms depending on the region. Voltage and socket compatibility also differ, impacting bulb base selection. Always confirm the local fixture requirements and electrical standards of your target market before ordering. Collaborate with suppliers who understand these regional nuances to ensure product compatibility and customer satisfaction.

Strategic Sourcing Conclusion and Outlook for bulb base types

In today’s global lighting market, understanding the nuances of bulb base types is essential for B2B buyers seeking reliability and efficiency. Whether sourcing for industrial warehouses in South America, retail environments in Europe, or specialized lighting in the Middle East and Africa, matching the correct base type to fixture requirements ensures optimal performance and reduces costly downtime. Familiarity with common bases—such as E26/E27 for general lighting, E39 for high-output industrial use, and pin bases for compact or specialty applications—enables precise specification and procurement.

Strategic sourcing goes beyond selecting the right base type. It involves evaluating supplier capabilities, verifying compatibility with existing electrical systems, and considering factors like wattage, dimmability, and ballast requirements. Buyers who prioritize these elements achieve better total cost of ownership and sustainability outcomes.

Looking ahead, the shift towards LED technology and smart lighting solutions will continue to influence bulb base designs and availability. International buyers are encouraged to establish partnerships with experienced suppliers who offer a broad portfolio and technical support tailored to regional standards and applications. By doing so, businesses in Africa, South America, the Middle East, and Europe can confidently navigate evolving lighting technologies and secure competitive advantages in their markets. Take proactive steps now to align your sourcing strategy with these trends and future-proof your lighting investments.