Introduction: Navigating the Global Market for bendable circuit board

The surge in advanced electronics design has propelled bendable circuit boards to the forefront of innovation, enabling products that seamlessly integrate into complex, curved, or compact spaces. For international B2B buyers—especially in emerging and established markets across Africa, South America, the Middle East, and Europe—understanding the nuances of bendable circuit board technology is vital to sourcing components that meet stringent performance, durability, and cost criteria.

Bendable circuit boards combine flexibility with structural stability, allowing manufacturers to create devices that traditional rigid PCBs cannot accommodate. This capability is crucial for industries ranging from wearable health devices and foldable smartphones to automotive dashboards and IoT applications, all sectors witnessing rapid growth globally.

This comprehensive guide equips procurement professionals and engineers with actionable insights into the types of bendable circuit boards, their material compositions, and manufacturing and quality control standards that ensure reliability. It also demystifies supplier selection strategies, pricing dynamics, and emerging market trends—empowering buyers to make informed decisions aligned with their technical requirements and budget constraints.

Additionally, the guide addresses region-specific considerations such as supply chain logistics, certification compliance, and cost optimization tactics tailored for buyers in diverse economic environments like Spain, Brazil, Nigeria, and the UAE. A dedicated FAQ section further clarifies common challenges and technical queries.

Illustrative Image (Source: Google Search)

By leveraging this knowledge, international B2B buyers can confidently navigate the evolving global marketplace for bendable circuit boards, securing high-quality, cost-effective solutions that drive innovation and competitive advantage in their industries.

Understanding bendable circuit board Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Bend Bendable PCB | Designed for a one-time, fixed-angle bend; uses polyimide substrates with reinforced bend areas | Foldable smartphones, wearable devices, medical implants | Pros: Cost-effective, precise fit for curved spaces; Cons: Limited to single bending, less adaptable post-assembly |

| Multi-Bend Bendable PCB | Engineered to be bent multiple times during assembly but fixed afterward; enhanced mechanical durability | Automotive dashboards, curved display modules, IoT devices | Pros: Greater design flexibility, supports complex shapes; Cons: Higher manufacturing complexity and cost |

| Flexible Rigid-Flex PCB | Combines rigid PCB sections with flexible bendable circuits; integrates both rigid and bendable zones | Aerospace electronics, industrial controls, advanced medical equipment | Pros: Robustness of rigid PCBs with bendability; Cons: Complex design and higher unit cost |

| Ultra-Thin Bendable PCB | Extremely thin substrates allowing tight bending radii; often uses advanced polyimide or LCP materials | Compact wearable tech, foldable consumer electronics, space-constrained devices | Pros: Enables ultra-compact designs; Cons: Fragility risk, requires careful handling and assembly |

| Cost-Optimized Bendable PCB | Uses modified FR-4 or PET substrates for moderate bendability at lower cost | Consumer electronics with budget constraints, educational prototypes | Pros: Affordable, suitable for low-volume or less critical applications; Cons: Limited thermal and mechanical performance |

Single-Bend Bendable PCB

Single-bend bendable PCBs are tailored for applications requiring a one-time, permanent bend, typically at a fixed angle. They rely on polyimide substrates reinforced at bend points to maintain structural and electrical integrity after bending. This type is highly suitable for B2B buyers in consumer electronics, such as foldable smartphones and wearable health monitors, where precise fitting into curved housings is critical. Buyers should consider the manufacturing lead time and ensure design specifications are finalized since the bend is permanent and irreversible.

Multi-Bend Bendable PCB

Multi-bend bendable PCBs support multiple bends during assembly, offering enhanced flexibility for complex device shapes like automotive dashboards and IoT modules with irregular geometries. These boards use advanced materials and reinforced bend zones to sustain mechanical stress. For B2B purchasers, the trade-off includes higher costs and more intricate design requirements, but the payoff is in enabling innovative product form factors. Suppliers should be evaluated for their expertise in multi-bend fabrication and quality assurance.

Flexible Rigid-Flex PCB

Rigid-flex PCBs integrate rigid circuit board sections with bendable flexible areas, combining the best of both worlds. This hybrid type suits demanding industrial, aerospace, and medical applications where durability and flexibility coexist. For B2B buyers, rigid-flex PCBs offer reliability and design versatility but come with increased complexity and cost. Strategic sourcing involves partnering with manufacturers experienced in multilayer fabrication and stringent quality certifications to meet sector-specific standards.

Ultra-Thin Bendable PCB

Ultra-thin bendable PCBs utilize advanced thin polyimide or liquid crystal polymer substrates, enabling extremely tight bending radii and minimal device thickness. This type is ideal for high-end wearables and foldable devices where space constraints are paramount. B2B buyers must weigh the benefits of compactness against fragility risks, requiring careful handling and precise assembly processes. Selecting suppliers with proven expertise in ultra-thin PCB manufacturing and robust testing protocols is essential.

Cost-Optimized Bendable PCB

For buyers prioritizing cost-efficiency, bendable PCBs made from modified FR-4 or PET substrates offer moderate bendability at a lower price point. These are suitable for less demanding consumer electronics or prototype development. While they lack the thermal and mechanical robustness of premium materials, they allow budget-conscious firms to experiment with bendable designs. B2B buyers should clearly define performance expectations and opt for suppliers who provide transparent material specifications and flexible order quantities.

Key Industrial Applications of bendable circuit board

| Industry/Sector | Specific Application of bendable circuit board | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Foldable smartphones and curved-edge tablets | Enables compact, innovative designs that enhance user experience and product differentiation | Material durability, precise bending tolerance, high thermal stability, and reliable supply chain for rapid prototyping and mass production |

| Medical Devices | Wearable health monitors and hearing aids | Provides lightweight, ergonomic designs that conform to body contours, improving patient comfort and device reliability | Compliance with medical-grade materials, biocompatibility, and certifications; scalability for volume orders; customization capabilities |

| Automotive Industry | Curved dashboard systems and embedded sensors | Facilitates integration of electronics into non-flat surfaces, reducing assembly complexity and enhancing design flexibility | High-temperature resistance, vibration tolerance, long lifecycle, and supplier quality certifications (e.g., ISO/TS standards) |

| Internet of Things (IoT) | Compact sensors and smart devices with irregular form factors | Supports miniaturization and installation in constrained or uniquely shaped environments, enhancing device functionality | Consistent electrical performance, environmental resistance, and flexible logistics solutions for global distribution |

| Aerospace & Defense | Lightweight avionics and flexible control panels | Reduces weight and space, improving fuel efficiency and system reliability under harsh conditions | Strict quality control, traceability, compliance with industry standards, and robust supplier partnerships for long-term contracts |

Consumer Electronics

In the consumer electronics sector, bendable circuit boards are pivotal for foldable smartphones and tablets featuring curved edges. These boards allow manufacturers to create sleek, compact devices that conform to innovative form factors impossible with rigid PCBs. For B2B buyers in Europe and South America, sourcing bendable PCBs requires attention to material resilience against repeated bending and thermal stresses, as well as the ability to meet tight production timelines to keep pace with fast-moving consumer markets.

Medical Devices

Wearable health monitors and hearing aids rely heavily on bendable circuit boards to achieve ergonomic designs that comfortably conform to the human body. This application demands materials that are not only flexible but also biocompatible and compliant with medical safety standards. Buyers from the Middle East and Africa should prioritize suppliers offering certification support and scalable manufacturing to meet both small-batch clinical trials and larger commercial runs.

Automotive Industry

In automotive manufacturing, bendable PCBs enable the integration of electronics into curved dashboard panels and embedded sensors, simplifying assembly and enhancing aesthetic appeal. These boards must withstand high temperatures, vibrations, and long operational lifespans. European and South American automotive suppliers must verify supplier adherence to automotive quality standards (e.g., IATF 16949) and ensure local or regional support for just-in-time delivery.

Internet of Things (IoT)

The IoT sector benefits from bendable circuit boards in compact sensors and smart devices designed for irregular or constrained spaces. These boards facilitate greater device miniaturization and installation versatility. For buyers in Africa and the Middle East, sourcing considerations include ensuring consistent electrical performance under diverse environmental conditions and securing flexible logistics options to accommodate varying import regulations and infrastructure.

Aerospace & Defense

Bendable circuit boards are increasingly used in aerospace for lightweight avionics and flexible control panels, contributing to weight reduction and enhanced system reliability. These applications require strict quality control, traceability, and compliance with aerospace standards. B2B buyers from Europe and South America should focus on suppliers with proven aerospace certifications and the capacity to support long-term contracts with rigorous quality assurance processes.

Related Video: Industrial Control Panel Basics

Strategic Material Selection Guide for bendable circuit board

Polyimide (PI)

Key Properties:

Polyimide is renowned for its exceptional thermal stability, often withstanding continuous operating temperatures up to 260°C. It exhibits excellent chemical resistance, low moisture absorption, and outstanding mechanical strength, making it highly suitable for bendable circuit boards that require durability under stress and environmental exposure.

Pros & Cons:

Polyimide offers superior flexibility combined with high heat resistance, ideal for complex bending without cracking. It is compatible with high-frequency applications and maintains dimensional stability. However, polyimide materials tend to be more expensive than alternatives and require precise manufacturing controls, which can increase lead times and costs.

Impact on Application:

Its robustness makes polyimide-based bendable PCBs perfect for aerospace, automotive, and high-end consumer electronics, where reliability under thermal and mechanical stress is critical. Its chemical inertness also suits applications exposed to harsh environments or corrosive media.

Considerations for International B2B Buyers:

Buyers in regions like Africa, South America, the Middle East, and Europe should verify compliance with international standards such as ASTM D-3389 or IPC-4204 for polyimide films. European buyers, especially in Spain, may prioritize RoHS compliance and REACH regulations, while Middle Eastern and South American buyers should assess supplier certifications to ensure material authenticity and performance consistency.

Modified FR-4 with Enhanced Bendability

Key Properties:

Modified FR-4 substrates incorporate additives or thinner laminates to improve flexibility while retaining the traditional epoxy glass-reinforced structure. Typical temperature ratings are around 130–140°C, with moderate moisture resistance and mechanical strength.

Pros & Cons:

This material is cost-effective and widely available, making it attractive for budget-conscious projects. It supports moderate bending but is less tolerant of repeated flexing or tight bend radii compared to polyimide. Manufacturing processes are relatively straightforward, leveraging existing rigid PCB infrastructure.

Impact on Application:

Modified FR-4 bendable PCBs are suitable for consumer electronics with limited bending requirements, such as curved display backplanes or simple foldable devices. They are less ideal for high-reliability or high-temperature applications.

Considerations for International B2B Buyers:

In emerging markets across Africa and South America, modified FR-4 offers a balance between cost and performance, but buyers should ensure suppliers meet IPC-4101 and UL94-V0 flammability standards. European and Middle Eastern buyers may require additional certifications for fire safety and environmental compliance, considering local regulations.

Polyethylene Terephthalate (PET)

Key Properties:

PET is a thermoplastic polymer with moderate thermal resistance (typically up to 120°C) and good chemical resistance. It is lightweight and exhibits good dimensional stability but has lower mechanical strength compared to polyimide.

Pros & Cons:

PET is a low-cost alternative with ease of processing and good dielectric properties. However, its lower temperature tolerance limits its use in high-heat environments, and it is less durable under mechanical stress or repeated bending cycles.

Impact on Application:

PET-based bendable PCBs are best suited for cost-sensitive applications such as disposable electronics, simple wearable devices, or low-end consumer gadgets where high thermal or mechanical performance is not critical.

Considerations for International B2B Buyers:

Buyers from cost-sensitive regions like parts of Africa and South America may find PET advantageous. However, they should verify compliance with ASTM D150 or ISO 527 standards and confirm that suppliers provide traceability and quality assurance. European buyers should be cautious about PET’s environmental impact and check for recyclability certifications.

Liquid Crystal Polymer (LCP)

Key Properties:

LCP offers excellent electrical properties, very low moisture absorption, and high thermal resistance (up to 260°C). It has superior chemical resistance and dimensional stability, with inherent flexibility suitable for bendable PCBs requiring high-frequency performance.

Pros & Cons:

LCP is ideal for advanced applications needing minimal signal loss and high reliability, such as RF modules and aerospace electronics. Its manufacturing complexity and high material cost can be limiting factors for large-scale or cost-sensitive projects.

Impact on Application:

LCP bendable PCBs excel in telecommunications, military-grade electronics, and high-frequency circuits where performance and durability are paramount.

Considerations for International B2B Buyers:

European and Middle Eastern buyers often demand strict adherence to IEC and IPC standards when sourcing LCP materials. In South America and Africa, buyers should assess supplier capabilities carefully due to the specialized manufacturing requirements and ensure that logistics support timely delivery to avoid production delays.

| Material | Typical Use Case for bendable circuit board | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide (PI) | High-reliability electronics, aerospace, automotive | Exceptional thermal stability and durability | Higher cost and complex manufacturing | High |

| Modified FR-4 | Budget consumer electronics with moderate bending | Cost-effective and widely available | Limited thermal tolerance and flexibility | Low |

| Polyethylene Terephthalate (PET) | Disposable electronics, low-end wearables | Low cost and easy processing | Lower temperature resistance and durability | Low |

| Liquid Crystal Polymer (LCP) | High-frequency telecom and aerospace applications | Superior electrical performance and stability | High material cost and manufacturing complexity | High |

In-depth Look: Manufacturing Processes and Quality Assurance for bendable circuit board

Manufacturing Processes for Bendable Circuit Boards

The production of bendable circuit boards involves specialized manufacturing techniques designed to balance flexibility with durability. Understanding these processes is crucial for B2B buyers aiming to source high-quality components that meet stringent application requirements.

1. Material Preparation

The foundation of a bendable circuit board is its substrate, commonly polyimide (PI), modified FR-4, or polyethylene terephthalate (PET). Material preparation includes:

- Substrate selection and inspection: Ensuring substrates meet thickness, thermal, and mechanical specifications.

- Copper foil lamination: Applying ultra-thin copper layers (typically 0.5oz to 1oz) to maintain conductivity while allowing bending.

- Coverlay application: A protective polymer layer is laminated to protect copper traces and provide mechanical support at bend points.

For buyers from regions such as Africa, South America, the Middle East, and Europe, verifying substrate quality is essential, as material inconsistencies can lead to premature failure under bending stress.

2. Forming and Patterning

This stage involves defining the circuit pattern and forming the board into its intended bendable shape:

- Photolithography and etching: Using high-resolution masks to pattern copper traces precisely, critical for maintaining electrical integrity post-bend.

- Controlled bending/forming: Boards are bent or shaped to the exact angle required during assembly. This one-time forming process must be executed with precision to avoid micro-cracking.

- Reinforcement at bend zones: Application of adhesives or flexible coverlay reinforcements to prevent delamination or cracking.

B2B buyers should inquire about suppliers’ capabilities in controlled bending processes, especially for complex or tight-radius applications common in wearable devices or automotive interiors.

3. Assembly

Assembly integrates components onto the bendable board:

- Surface mount technology (SMT): Components are mounted using low-temperature soldering processes to prevent thermal damage to flexible substrates.

- Flexible interconnects: Use of flexible connectors and conductive adhesives to maintain electrical paths through bends.

- Encapsulation and protection: Selective coating or potting to protect sensitive areas from environmental stress while preserving flexibility.

For international buyers, compatibility with regional component standards and temperature profiles is critical, ensuring reliable operation in varied climates such as tropical Africa or temperate Europe.

4. Finishing and Packaging

Final steps ensure durability and safe transport:

- Final inspection and cleaning: Removal of residues and contaminants that could affect performance.

- Protective coatings: Application of conformal coatings or laminates that resist moisture, dust, and chemical exposure.

- Customized packaging: Anti-static, moisture barrier bags, and cushioning tailored for long-distance shipping to protect the bendable PCBs during transit.

Buyers should confirm packaging standards align with import/export regulations and environmental conditions of their target markets.

Quality Assurance and Control (QA/QC) for Bendable Circuit Boards

Robust QA/QC frameworks are vital to guarantee product reliability, especially for international B2B buyers sourcing bendable circuit boards for critical applications.

International and Industry Standards

- ISO 9001: The global benchmark for quality management systems, ensuring consistent manufacturing quality and continuous improvement.

- IPC Standards (e.g., IPC-6013 for flexible and rigid-flex PCBs): Industry-specific criteria governing material, design, and workmanship quality.

- CE Marking: Mandatory for products entering the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- Other regional certifications: Depending on end-use, certifications like API for automotive or medical device standards (e.g., ISO 13485) may apply.

Buyers in Europe (Spain), the Middle East, Africa, and South America (Brazil) should verify supplier compliance with both international and local standards to facilitate smooth regulatory approvals.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials and components, including substrate thickness, copper adhesion, and chemical purity.

- In-Process Quality Control (IPQC): Monitoring critical manufacturing steps such as lamination, etching, bending/forming, and soldering. This includes visual inspections, dimensional checks, and real-time defect tracking.

- Final Quality Control (FQC): Comprehensive testing of finished boards before shipment, ensuring mechanical integrity and electrical functionality.

Common Testing Methods

- Visual and microscopic inspection: Detects surface defects, cracks, or delamination at bend zones.

- Electrical testing: Continuity, insulation resistance, and impedance tests verify circuit integrity.

- Bend and flex testing: Simulates mechanical stress to confirm durability of the formed shape without electrical failure.

- Thermal cycling: Assesses performance under temperature fluctuations relevant to target environments.

- Adhesion and peel tests: Ensure coverlay and copper adhesion withstand bending stresses.

Verifying Supplier Quality Control

International B2B buyers should implement multi-layered verification strategies:

- Factory audits: On-site or virtual inspections focusing on process controls, equipment calibration, and staff expertise.

- Quality documentation: Request detailed QC reports, process flow charts, and test data for traceability.

- Third-party inspections: Engage independent laboratories or certification bodies to perform pre-shipment inspections and testing.

- Sample testing: Order prototype or pilot batches for in-house validation before committing to large orders.

This approach mitigates risks of receiving substandard products, particularly important for buyers in regions where local recourse options may be limited.

QC and Certification Nuances for International Buyers

- Regional regulatory differences: For instance, European buyers must consider RoHS and REACH compliance, while Middle Eastern and African markets may require additional certifications aligned with local import regulations.

- Climate considerations: Quality testing should reflect environmental conditions such as high humidity in parts of South America or temperature extremes in the Middle East, ensuring boards perform reliably post-shipment.

- Language and documentation: Ensure QC documents, certifications, and communication are available in languages relevant to the buyer’s team (e.g., Spanish for South America and Spain) to avoid misunderstandings.

- Supply chain transparency: Demand clear visibility into supplier sourcing and production to comply with international trade policies and corporate social responsibility requirements.

Actionable Insights for B2B Buyers from Africa, South America, the Middle East, and Europe

- Prioritize suppliers with demonstrated expertise in bendable PCB manufacturing, including controlled bending and reinforcement techniques.

- Require adherence to ISO 9001 and IPC standards, and confirm CE marking or equivalent regional certifications for regulatory compliance.

- Establish robust QC verification protocols, incorporating factory audits, third-party inspections, and detailed reporting to ensure consistent quality.

- Consider environmental and logistical factors unique to your region when evaluating quality and packaging to minimize damage during transit.

- Engage in early-stage collaboration with suppliers to align design and manufacturing capabilities with your application’s bend radius, durability, and reliability requirements.

By integrating these insights into their procurement strategy, international B2B buyers can secure reliable, high-performance bendable circuit boards tailored to their market and application needs.

Related Video: JMK Smart source Factory builds stable production with strength

Comprehensive Cost and Pricing Analysis for bendable circuit board Sourcing

Understanding Cost Components in Bendable Circuit Board Sourcing

When sourcing bendable circuit boards, a clear grasp of the underlying cost components is essential for international B2B buyers aiming to optimize procurement budgets and negotiate effectively. The primary cost drivers include:

-

Materials: High-performance substrates such as polyimide or specialized modified FR-4 form the bulk of raw material costs. Copper thickness, coverlay materials, and adhesives tailored for bending durability also influence pricing. Premium materials for enhanced thermal or electrical performance typically command higher prices.

-

Labor: Skilled labor is required for precise bending and assembly processes. Labor costs vary significantly by manufacturing location, impacting overall unit cost, especially for complex bendable PCB designs.

-

Manufacturing Overhead: This includes expenses related to factory utilities, equipment depreciation, and process controls. Advanced bending technologies or custom tooling add to overhead, especially for low-to-mid volume runs.

-

Tooling and Setup: Initial setup costs, including custom bending jigs and prototype tooling, can be substantial. These costs are amortized over production volume but can inflate unit costs for small batch orders.

-

Quality Control (QC): Rigorous inspection processes, including electrical testing and mechanical bend testing, are critical for bendable PCBs due to their specialized nature. Enhanced QC ensures reliability but adds to cost.

-

Logistics and Import Duties: Freight charges, customs tariffs, and import regulations must be factored in, especially for buyers in Africa, South America, the Middle East, and Europe. These can materially affect landed cost.

-

Supplier Margin: Manufacturers and distributors include profit margins that reflect market demand, competition, and service level.

Key Pricing Influencers for Bendable Circuit Boards

Pricing in bendable PCB sourcing is not static and depends on several dynamic factors:

-

Order Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce per-unit cost due to economies of scale and amortization of tooling/setup expenses. Buyers with smaller requirements should negotiate MOQ or seek suppliers specializing in low-volume production.

-

Technical Specifications and Customization: Complex bend angles, multi-layer constructions, and tight tolerances increase production difficulty and cost. Custom features such as embedded components or rigid-flex hybrids also elevate pricing.

-

Material Selection: High-grade substrates like polyimide or LCP used for high-frequency or high-temperature applications are costlier than standard FR-4 variants.

-

Quality Certifications: Suppliers with certifications such as ISO 9001, UL, or IPC standards often command premium prices but reduce risk for buyers seeking high reliability.

-

Supplier Location and Reputation: Established manufacturers in Asia may offer competitive pricing but require careful vetting on quality and delivery. European or Middle Eastern suppliers might charge more but provide faster lead times and localized support.

-

Incoterms and Payment Terms: Shipping terms (FOB, CIF, DDP) impact the total cost and risk exposure. Favorable payment terms can improve cash flow for buyers but may influence pricing.

Strategic Buyer Tips for Cost-Efficient Bendable PCB Procurement

To navigate pricing complexities and achieve cost-effective sourcing, international B2B buyers should consider the following:

-

Leverage Volume Aggregation: Consolidate orders across product lines or partners to increase volume and negotiate better unit pricing and tooling amortization.

-

Specify Clear and Realistic Technical Requirements: Avoid over-specification. Engaging with suppliers early to optimize design for manufacturability can reduce unnecessary cost premiums.

-

Evaluate Total Cost of Ownership (TCO): Assess beyond unit price—consider quality, reliability, rework rates, warranty, and after-sales support, which can substantially affect lifecycle costs.

-

Negotiate Incoterms Wisely: For buyers in regions with complex import logistics (e.g., Brazil, South Africa, UAE), negotiating Delivered Duty Paid (DDP) terms can simplify customs clearance, albeit at a higher upfront price. Conversely, buyers with strong local logistics may prefer FOB or EXW to reduce costs.

-

Choose Suppliers with Proven Quality and Certifications: While initial price may be higher, certified suppliers reduce risks of failure and costly recalls, especially critical in automotive, medical, or aerospace sectors.

-

Plan for Lead Times and Buffer Stock: Longer lead times can sometimes secure better pricing. Maintain buffer stock to mitigate supply chain disruptions common in international trade.

-

Engage in Transparent Pricing Discussions: Request detailed quotations breaking down costs to identify negotiation levers and cost-saving opportunities, such as alternative materials or simplified designs.

Indicative Pricing Disclaimer

Prices for bendable circuit boards vary widely based on technical complexity, volume, and supplier geography. Typical unit costs may range from a few dollars for simple, low-layer boards at high volume to several tens of dollars for complex, multi-layer customized designs in low quantities. Buyers should treat any quoted prices as indicative and seek formal quotations tailored to their specific requirements and sourcing conditions.

By understanding these cost and pricing dynamics, international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—can make informed decisions, negotiate effectively, and optimize the total cost and value of bendable circuit board sourcing.

Spotlight on Potential bendable circuit board Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘bendable circuit board’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for bendable circuit board

Critical Technical Properties of Bendable Circuit Boards

Understanding the essential technical properties of bendable circuit boards is crucial for international B2B buyers to ensure product reliability, manufacturability, and cost-effectiveness.

-

Material Grade (Substrate Type)

The substrate is the base material of the bendable PCB, most commonly polyimide (PI) due to its excellent thermal resistance and mechanical strength. Some applications may use modified FR-4 or polyethylene terephthalate (PET) for cost efficiency or specific flexibility needs. Selecting the right material grade impacts durability, operating temperature range, and bending tolerance—key for applications in harsh environments like automotive or wearable devices. -

Bend Radius and Flexibility

Bend radius defines the minimum curvature the board can achieve without damage. It is usually expressed as a ratio relative to the board thickness (e.g., 10× thickness). A smaller bend radius allows tighter folds but requires higher-quality materials and precision manufacturing. For B2B buyers, specifying the bend radius upfront helps avoid production delays and ensures the PCB fits the product’s physical design constraints. -

Copper Thickness

Copper foil thickness typically ranges from 0.5oz to 1oz per square foot for bendable PCBs. Thinner copper layers reduce the risk of cracking during bending but may affect current-carrying capacity. Buyers should balance electrical performance requirements against mechanical flexibility, particularly for power-sensitive or high-frequency applications. -

Tolerance and Dimensional Accuracy

Tolerances refer to allowable variations in board dimensions, hole sizes, and trace widths, often in microns (µm). Tight tolerances are vital for complex, miniaturized devices to ensure seamless assembly and performance. International buyers should confirm that suppliers meet industry-standard tolerances, as poor accuracy can lead to costly rework or product failure. -

Coverlay and Protective Coating

The coverlay is a flexible insulating layer protecting copper traces at bend points. High-quality coverlays prevent cracking and environmental damage, significantly extending the PCB’s lifespan. Buyers in regions with high humidity or dust should prioritize coverlay materials with proven resistance to moisture and contaminants. -

Thermal Stability

Bendable PCBs must withstand operating temperature ranges without deformation or loss of function. Polyimide substrates, for example, typically tolerate temperatures up to 260°C, suitable for soldering processes and harsh operational environments. Buyers should ensure the thermal rating aligns with their product’s use case to avoid failures during manufacturing or in-field use.

Key Industry and Trade Terminology for Bendable Circuit Boards

For effective communication and negotiation with suppliers, B2B buyers should familiarize themselves with common trade terms and industry jargon related to bendable PCBs.

-

OEM (Original Equipment Manufacturer)

Refers to companies that design and manufacture products or components that are purchased by another company and retailed under that purchasing company’s brand. Understanding if your supplier is an OEM or a contract manufacturer helps clarify responsibilities for quality, intellectual property, and after-sales support. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to produce in a single order. MOQ impacts pricing and inventory management. Buyers from emerging markets or smaller businesses should negotiate MOQs to balance cost efficiency without overstocking. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting detailed pricing, lead times, and specifications for a particular PCB order. A well-prepared RFQ accelerates supplier evaluation and ensures you receive competitive and comparable bids. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and customs clearance between buyers and sellers. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Clear understanding of Incoterms prevents misunderstandings and hidden costs in international transactions. -

Lead Time

The time required from placing an order to receiving the finished product. Bendable PCB manufacturing can vary in lead time depending on complexity and materials. Buyers should factor lead time into project timelines and negotiate expedited options if needed. -

Panelization

The process of arranging multiple PCB units on a single manufacturing panel to optimize production efficiency and reduce costs. Understanding panelization options helps buyers discuss volume, yield, and assembly considerations with suppliers.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement strategies, and establish productive partnerships with bendable circuit board manufacturers. This knowledge is especially valuable for markets in Africa, South America, the Middle East, and Europe, where supply chain efficiency and product customization are key competitive factors.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bendable circuit board Sector

Market Overview & Key Trends

The global bendable circuit board market is experiencing robust growth driven by the surge in demand for compact, lightweight, and innovative electronic devices. Key sectors fueling this growth include consumer electronics, automotive, healthcare, and Internet of Things (IoT) applications. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe (notably Spain and Brazil), understanding regional market dynamics is crucial for effective sourcing.

Emerging trends reveal a strong preference for bendable PCBs in foldable smartphones, wearable health monitors, and curved automotive dashboards, where space constraints and ergonomic design are paramount. Buyers should note the increasing adoption of polyimide and other advanced substrates that enhance thermal stability and mechanical durability. In these regions, local demand is rapidly growing alongside infrastructure modernization and digital transformation initiatives, creating new opportunities for suppliers who can provide customized bendable PCB solutions.

From a sourcing perspective, agility and supply chain resilience are critical. Geopolitical factors and logistics challenges, especially in Africa and parts of South America, necessitate partnering with manufacturers who have global footprints or regional hubs. European buyers benefit from proximity to advanced manufacturing centers but must navigate stringent quality and environmental standards. Additionally, the rise of Industry 4.0 technologies, such as automated PCB assembly and real-time quality inspection, is reshaping supplier capabilities and expectations globally.

In summary, successful B2B procurement in the bendable circuit board sector hinges on aligning with suppliers who can deliver high-performance materials, tailored designs, and consistent quality while adapting to evolving regional market needs and technological innovations.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a defining factor in the procurement of bendable circuit boards, as environmental impact and corporate responsibility gain prominence in global supply chains. The manufacturing of PCBs traditionally involves hazardous chemicals and energy-intensive processes. For B2B buyers, particularly in environmentally conscious markets like Europe and increasingly in emerging economies, prioritizing suppliers with green credentials is essential.

Ethical sourcing ensures that raw materials such as copper and polyimide are procured without contributing to conflict zones or labor exploitation. Buyers should seek certifications like ISO 14001 (Environmental Management), RoHS (Restriction of Hazardous Substances), and REACH compliance, which signal adherence to eco-friendly manufacturing and material safety standards. Some suppliers are also innovating with bio-based or recycled substrates and reducing the use of harmful solvents and heavy metals in their production lines.

Beyond certifications, transparency in the supply chain is vital. B2B buyers can leverage blockchain and digital traceability tools to verify the origin and sustainability claims of bendable PCBs. This approach not only mitigates reputational risks but also aligns with corporate ESG (Environmental, Social, and Governance) goals increasingly demanded by investors and regulators worldwide.

Adopting sustainable sourcing practices in the bendable circuit board sector not only reduces environmental footprint but can also enhance supply chain resilience and unlock new business opportunities with forward-thinking partners and customers.

Evolution of Bendable Circuit Boards

Bendable circuit boards have evolved significantly from traditional rigid PCBs, reflecting advances in materials science and manufacturing techniques. Initially, PCBs were rigid and bulky, limiting design flexibility. The advent of flexible PCBs introduced dynamic bending capabilities, but these were primarily designed for repeated flexing rather than permanent shaping.

Bendable PCBs emerged as a specialized solution allowing a one-time, precise bending or folding during assembly, enabling electronics to fit complex, curved geometries without compromising electrical performance. This innovation opened new frontiers in wearable technology, foldable devices, and compact medical electronics.

Materials like polyimide and liquid crystal polymer have played a pivotal role in this evolution, offering the thermal and mechanical properties necessary for reliable bending. Today’s bendable circuit boards represent a convergence of durability, precision engineering, and miniaturization, empowering B2B buyers to meet increasingly sophisticated product design demands across diverse global markets.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of bendable circuit board

-

How can I effectively vet and select reliable bendable circuit board suppliers internationally?

When sourcing bendable circuit boards globally, prioritize suppliers with proven experience in flexible and bendable PCB manufacturing, especially those with certifications like ISO 9001 and IPC standards compliance. Request detailed portfolios showcasing previous projects similar to your requirements. Verify their production capacity, quality assurance processes, and after-sales support. Engage in direct communication to assess responsiveness and technical expertise. For buyers in Africa, South America, the Middle East, and Europe, consider suppliers offering multilingual support and familiarity with regional trade regulations to ensure smooth collaboration. -

What customization options are typically available for bendable circuit boards, and how should I specify my requirements?

Bendable PCBs can be customized in terms of substrate materials (e.g., polyimide, modified FR-4), copper thickness, bend radius, layer count, and surface finish. Specify whether the board needs to be permanently bent or dynamically flexible, as this affects design and materials. Provide detailed mechanical drawings, bend angles, and environmental requirements (temperature, humidity). Early engagement with the supplier’s engineering team is crucial to optimize design for manufacturability and reliability, reducing risk of failure in your final application. -

What are common minimum order quantities (MOQs) and lead times for bendable circuit boards when ordering internationally?

MOQs for bendable PCBs vary widely depending on complexity and supplier scale but typically start from 50 to 500 pieces. Lead times generally range from 3 to 6 weeks, including prototyping and production, though expedited services may be available at a premium. For buyers in regions with longer shipping times like Africa or South America, factor in additional transit time and customs clearance. Always clarify MOQs upfront and negotiate batch sizes aligned with your production cycle to optimize inventory and cash flow. -

Which payment terms and methods are commonly accepted by bendable PCB manufacturers globally?

Manufacturers often request a deposit (30-50%) upfront with the balance paid before shipment or upon delivery. Common payment methods include wire transfers (T/T), Letters of Credit (L/C), and increasingly secure online platforms like PayPal or Alibaba Trade Assurance for smaller orders. For buyers from emerging markets, establishing trust through initial smaller orders and gradually increasing volumes can help negotiate more favorable terms. Always confirm payment security and currency exchange considerations to mitigate financial risk. -

What quality assurance certifications and testing standards should I expect from reputable bendable circuit board suppliers?

Look for suppliers certified with ISO 9001 for quality management and IPC-A-600/IPC-6013 standards specifically covering flexible and bendable PCB quality. Suppliers should provide electrical testing (ICT or flying probe), bend radius validation, thermal cycling, and adhesion tests to ensure durability. Request sample test reports and, if possible, third-party inspection certificates. These certifications and tests provide assurance that the boards will perform reliably in demanding applications, reducing costly failures post-deployment. -

How can I manage logistics and shipping challenges when importing bendable PCBs to regions like Africa, the Middle East, or South America?

Choose suppliers experienced in international shipping with knowledge of customs procedures in your region. Opt for DHL, FedEx, or UPS for reliable express shipping with tracking. Consider consolidated shipments if ordering multiple components to reduce costs. Prepare all import documentation accurately (commercial invoice, packing list, certificates of origin) to avoid customs delays. Engage a trusted local freight forwarder or customs broker to navigate tariffs and regulatory compliance efficiently, minimizing delivery disruptions. -

What are best practices for resolving disputes or quality issues with international bendable PCB suppliers?

Establish clear contractual terms including quality acceptance criteria, inspection processes, and return policies before order confirmation. Maintain thorough documentation of communications and inspection results. In case of disputes, initiate dialogue promptly to seek amicable solutions like rework, replacement, or partial refunds. Leverage third-party inspection services for unbiased quality verification. If unresolved, consider mediation or arbitration clauses in contracts. Building long-term partnerships with suppliers through transparent communication helps reduce conflicts. -

Are there specific considerations for sourcing bendable circuit boards from Europe, Spain, Brazil, or the Middle East?

Each region has unique market dynamics: Europe often emphasizes strict environmental and quality standards, so suppliers should comply with RoHS and REACH regulations. Spain’s electronics sector values local support and quick prototyping. Brazil and Middle Eastern buyers should consider import duties and certification requirements such as INMETRO (Brazil) or GSO (Gulf Cooperation Council). Understanding regional trade agreements, currency fluctuations, and local business practices is critical for smooth procurement and competitive pricing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bendable circuit board

Bendable circuit boards represent a transformative leap in PCB technology, offering unparalleled design flexibility and enabling innovative applications across industries such as consumer electronics, automotive, healthcare, and IoT. For international B2B buyers from Africa, South America, the Middle East, and Europe, strategic sourcing of bendable PCBs demands careful evaluation of supplier capabilities, material quality, and manufacturing expertise to ensure durability, performance, and cost-efficiency.

Key considerations include selecting suppliers proficient in advanced materials like polyimide and specialized adhesives, verifying compliance with international quality certifications, and leveraging technologies that support both one-time bending and long-term reliability. Establishing strong partnerships with manufacturers who provide design support and rapid prototyping can accelerate product development and market entry.

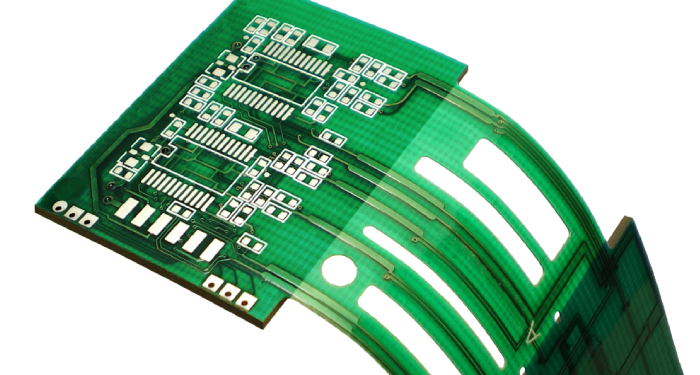

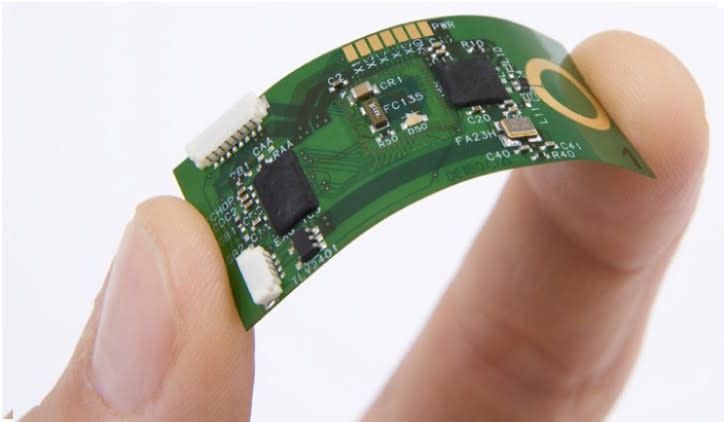

Illustrative Image (Source: Google Search)

Looking ahead, the demand for bendable circuit boards will continue to grow as industries pursue more compact, ergonomic, and high-performance electronic solutions. Buyers who proactively integrate strategic sourcing practices—emphasizing innovation, quality assurance, and supply chain resilience—will unlock competitive advantages in their respective markets. Now is the time to engage with trusted global suppliers and embrace bendable PCB technology to future-proof your product portfolio and meet evolving customer needs worldwide.