Introduction: Navigating the Global Market for battery powered led strip

Battery powered LED strips are transforming lighting solutions across industries by offering unmatched flexibility, portability, and ease of installation—qualities highly sought after in diverse markets worldwide. For international B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of these innovative lighting products is essential to making informed sourcing decisions that align with specific operational needs and market demands.

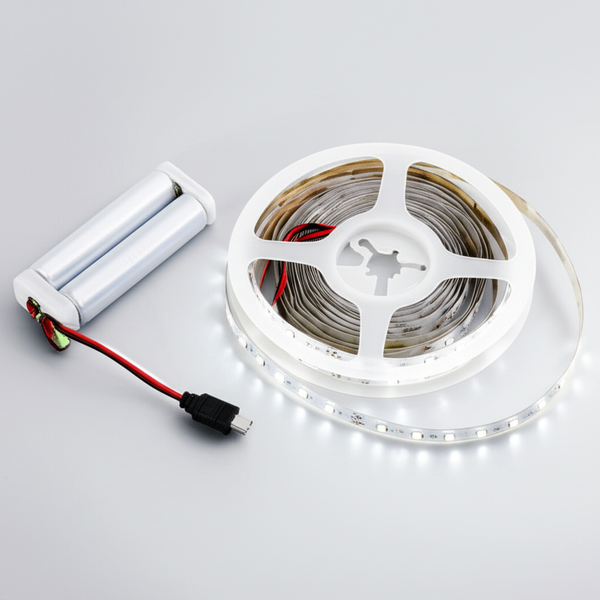

This comprehensive guide dives deep into the critical aspects of battery powered LED strips, beginning with the variety of battery types—from AA and lithium-ion to specialized 12V packs—that influence performance and runtime. It also explores the importance of quality materials, including high-grade LED chips and PCBs, which directly affect durability and efficiency. Detailed insights into manufacturing processes and rigorous quality control protocols ensure buyers can evaluate supplier reliability and product consistency with confidence.

Furthermore, the guide covers market trends and pricing dynamics across key regions, helping buyers anticipate cost variables and optimize procurement strategies. An extensive FAQ section addresses common technical and commercial questions, empowering buyers to mitigate risks and avoid costly mistakes.

By consolidating technical know-how, supplier evaluation criteria, and market intelligence, this guide serves as an indispensable resource for B2B buyers aiming to leverage battery powered LED strips effectively. Whether for retail, industrial, or event applications, the insights provided will enable buyers from emerging and established markets alike to secure high-quality, cost-efficient lighting solutions tailored to their unique environments and customer expectations.

Understanding battery powered led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 12V Lithium-Ion Battery LED Strips | Rechargeable lithium-ion batteries; typically 12V output; high energy density | Portable lighting for events, emergency backup, outdoor installations | Pros: Long runtime, lightweight, rechargeable; Cons: Higher upfront cost, requires charger and protection circuitry |

| AA/AAA Battery-Powered LED Strips | Uses standard AA or AAA batteries in series for voltage; widely available batteries | Small-scale projects, retail displays, temporary setups | Pros: Low cost, easy replacement; Cons: Shorter runtime, bulkier setup for higher voltages |

| 9V Battery LED Strips | Powered by single 9V batteries; simple connection | Quick temporary lighting, prototyping, short-term use | Pros: Easy to use, compact; Cons: Limited power capacity, not suitable for long strips |

| 12V Sealed Lead Acid (SLA) Battery LED Strips | Heavy-duty 12V SLA batteries; high capacity and durability | Industrial applications, large-scale installations, emergency lighting | Pros: High capacity, robust; Cons: Heavy, bulky, requires maintenance and proper disposal |

| 24V Battery Pack LED Strips | Higher voltage packs (24V), often series of 12V batteries | Commercial lighting, architectural lighting, longer LED strips | Pros: Supports longer strips, stable voltage; Cons: Larger size, increased complexity in wiring |

12V Lithium-Ion Battery LED Strips

These LED strips powered by 12V lithium-ion batteries are preferred for their excellent energy density and rechargeable nature. They are ideal for B2B buyers seeking portable, long-lasting lighting solutions, such as event organizers or emergency service providers. The rechargeable feature reduces operational costs over time, but initial investment and the need for compatible chargers must be factored into purchasing decisions. Ensuring battery protection circuitry is crucial to prevent over-discharge and extend battery life, especially for buyers in regions with varying power infrastructure.

AA/AAA Battery-Powered LED Strips

Utilizing standard AA or AAA batteries, these LED strips offer flexibility for small-scale or temporary lighting applications. B2B buyers such as retail outlets or exhibition organizers benefit from the easy availability and low upfront costs of these batteries. However, the shorter runtime and the bulkiness of using multiple batteries in series for higher voltage strips can limit scalability. Buyers should consider inventory management and replacement frequency when deploying these strips in large quantities.

9V Battery LED Strips

9V battery-powered LED strips cater to quick, temporary lighting needs with simple wiring and compact form factors. This type suits prototype development, quick demonstrations, or emergency lighting where portability is paramount. The limited power capacity and shorter lifespan restrict their use to smaller or short-term projects. B2B buyers should evaluate the trade-off between convenience and operational duration, particularly in markets where battery replacement logistics may impact maintenance costs.

12V Sealed Lead Acid (SLA) Battery LED Strips

SLA batteries provide a robust and high-capacity power source for LED strips in industrial or large-scale applications. Their durability makes them suitable for warehouses, factories, or emergency backup lighting systems. However, their heavy weight and maintenance requirements pose challenges for portability and lifecycle management. B2B buyers must ensure compliance with local environmental regulations for disposal and consider the infrastructure needed for charging and maintaining these batteries.

24V Battery Pack LED Strips

Designed for higher voltage LED strips, 24V battery packs often consist of two 12V batteries connected in series. These are well-suited for commercial and architectural lighting projects requiring longer runs without voltage drop issues. Buyers benefit from stable voltage output and extended strip length compatibility but must manage increased wiring complexity and larger battery sizes. Strategic planning in installation and power management is essential for buyers targeting large-scale deployments across diverse geographic regions.

Related Video: How to use 3.7V Battery to Power 5 Meter 12V LED Strip in 2025

Key Industrial Applications of battery powered led strip

| Industry/Sector | Specific Application of Battery Powered LED Strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Event Management | Portable ambient and decorative lighting for outdoor and indoor events | Enables flexible, wireless lighting setups; enhances event aesthetics without reliance on fixed power infrastructure | Battery capacity and runtime, weather-resistant design, ease of installation and transport |

| Retail & Visual Merchandising | Illuminated display cases and promotional stands in locations without direct power access | Attracts customer attention with dynamic lighting; supports temporary or seasonal displays | Battery life, compatibility with dimming controls, safety certifications (CE, RoHS) |

| Emergency & Safety Services | Portable emergency lighting in evacuation routes and temporary shelters | Provides reliable, independent lighting during power outages or in remote locations | Long battery life, ruggedness, compliance with safety standards, ease of replacement |

| Agriculture & Horticulture | Supplemental lighting in greenhouses or remote farming sites | Supports plant growth cycles where power outlets are unavailable; enables mobile lighting solutions | Waterproofing, battery efficiency in variable climates, compatibility with solar charging |

| Transportation & Logistics | Interior and cargo area lighting in vehicles, trailers, or containers | Improves visibility and safety during loading/unloading; reduces wiring complexity | Compact battery packs, shock resistance, voltage compatibility with LED strips |

Event Management

Battery powered LED strips are increasingly used in event management for creating flexible lighting that can be deployed anywhere without dependency on electrical outlets. This is especially valuable for outdoor festivals, weddings, and corporate events in regions with inconsistent power infrastructure, such as parts of Africa and South America. These strips allow event planners to design dynamic lighting effects that enhance ambiance and attendee experience. Buyers should prioritize battery packs with sufficient capacity to last the entire event duration and weatherproofing to withstand outdoor conditions.

Retail & Visual Merchandising

In retail environments, battery powered LED strips serve as an effective tool for illuminating display cases and promotional stands, particularly in temporary or pop-up stores common in Europe and the Middle East. The wireless nature allows retailers to reposition displays without electrical constraints, increasing visual appeal and customer engagement. International buyers must ensure the LED strips support dimming controls for mood lighting, have certifications like CE for European markets, and offer a balance between battery life and brightness.

Emergency & Safety Services

Emergency responders and safety managers rely on battery powered LED strips for portable illumination in evacuation routes, temporary shelters, and disaster zones. The independence from fixed power sources ensures lighting is available even during outages or in remote locations, critical in regions prone to power instability such as some African and Middle Eastern countries. Key considerations for procurement include long-lasting batteries, rugged designs to endure harsh environments, and compliance with safety certifications to guarantee reliability.

Agriculture & Horticulture

In agriculture, particularly in remote or off-grid greenhouses in South America and Europe, battery powered LED strips provide supplemental lighting to optimize plant growth cycles. Their portability allows farmers to adjust lighting setups as needed without rewiring. Buyers should focus on products with high waterproof ratings and efficient battery performance under varying temperature conditions. Additionally, compatibility with solar charging systems can be a significant advantage for sustainable operations.

Transportation & Logistics

Battery powered LED strips are valuable in transportation for lighting cargo areas, vehicle interiors, and trailers where installing wired lighting can be challenging or costly. This application is relevant across Europe and the Middle East, where logistics companies seek flexible and energy-efficient solutions to improve loading safety and operational efficiency. Buyers should seek compact, shock-resistant battery packs with voltage compatibility tailored to the LED strips used, ensuring durability during transit and ease of maintenance.

Related Video: LED Light Strip Powered By Dewalt Battery

Strategic Material Selection Guide for battery powered led strip

When selecting materials for battery powered LED strips, international B2B buyers must consider factors such as durability, electrical performance, environmental resistance, and compliance with regional standards. The choice of materials directly impacts the longevity, safety, and efficiency of the LED strip, especially in diverse climates and regulatory environments found across Africa, South America, the Middle East, and Europe. Below is an analysis of four common materials used in the construction of battery powered LED strips, focusing on their properties, pros and cons, application impact, and considerations for global buyers.

1. Flexible Polyimide (PI) PCB Substrate

Key Properties:

Polyimide is a high-performance polymer known for excellent thermal stability (up to 260°C), chemical resistance, and mechanical flexibility. It offers good dielectric strength and can withstand repeated bending without cracking.

Pros & Cons:

– Pros: Enables flexible LED strips that can conform to curved surfaces, ideal for innovative lighting designs. High temperature tolerance supports longer LED lifespan by efficient heat dissipation.

– Cons: Higher material and manufacturing costs compared to traditional rigid PCBs. Requires precise manufacturing processes, increasing lead times and complexity.

Impact on Application:

Flexible PI substrates are perfect for wearable, portable, or curved installations common in event lighting or architectural accents. Their flexibility allows integration into compact battery-powered setups without compromising durability.

International Buyer Considerations:

Buyers in Europe (Germany, Poland) often require compliance with RoHS and REACH standards, both of which PI substrates can meet. In regions like Africa and the Middle East, where ambient temperatures can be high, PI’s thermal stability is advantageous. However, buyers should verify supplier certifications and manufacturing quality to ensure consistent performance.

2. Rigid FR-4 PCB Material

Key Properties:

FR-4 is a fiberglass-reinforced epoxy laminate with good mechanical strength, moderate thermal resistance (up to 130°C), and electrical insulation properties. It is the most common PCB substrate in electronics.

Pros & Cons:

– Pros: Cost-effective and widely available, making it suitable for high-volume production. Provides stable mounting for LED chips and is easy to handle during assembly.

– Cons: Lack of flexibility limits use in curved or portable designs. Lower thermal tolerance compared to PI can reduce LED lifespan under high load or ambient heat.

Impact on Application:

Ideal for stationary battery powered LED strips where flexibility is not required, such as cabinet lighting or signage. Its affordability benefits buyers targeting cost-sensitive markets in South America and Africa.

International Buyer Considerations:

FR-4 is globally recognized and typically meets ASTM and IEC standards. European buyers should ensure compliance with EU directives on hazardous substances. In hot climates, additional heat management strategies may be needed to maintain performance.

3. Silicone or Polyurethane Coating (Encapsulation)

Key Properties:

These materials provide a protective, waterproof, and UV-resistant coating over LED strips. Silicone offers excellent flexibility and temperature tolerance (-60°C to 200°C), while polyurethane is known for abrasion resistance.

Pros & Cons:

– Pros: Enhances durability by protecting against moisture, dust, and mechanical damage. Silicone’s flexibility complements flexible PCBs, enabling outdoor or harsh environment use.

– Cons: Adds to manufacturing complexity and cost. Polyurethane coatings can yellow over time under UV exposure, potentially reducing light quality.

Impact on Application:

Critical for battery powered LED strips used outdoors or in humid environments, such as garden lighting or automotive applications. Coatings extend product life and reduce maintenance needs.

International Buyer Considerations:

Buyers from Middle Eastern and African markets should prioritize silicone-coated strips for superior heat and UV resistance. European buyers must verify compliance with EN standards for outdoor electrical equipment. Packaging and shipping should also protect coated strips from physical damage.

4. Adhesive Backing Materials (3M VHB or Acrylic Adhesives)

Key Properties:

High-quality adhesive backings ensure strong, long-lasting attachment to various surfaces. 3M VHB tapes offer excellent shear strength, temperature resistance (-40°C to 90°C), and chemical resistance.

Pros & Cons:

– Pros: Simplifies installation, especially for portable or temporary setups. Durable adhesives prevent peeling, critical for maintaining electrical connections and aesthetic integrity.

– Cons: Some adhesives may lose tackiness in extreme heat or humidity. Removal can leave residue, complicating reusability.

Impact on Application:

Adhesive choice affects ease of installation and reliability in diverse environments. Strong adhesives are essential for battery powered LED strips used in mobile or outdoor applications.

International Buyer Considerations:

European buyers often require adhesives compliant with DIN standards for material safety. In South America and Africa, where surface conditions vary widely, buyers should test adhesive performance on local substrates. Middle Eastern buyers should consider UV-resistant adhesives to withstand desert conditions.

Summary Table of Materials for Battery Powered LED Strips

| Material | Typical Use Case for battery powered led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Polyimide (PI) PCB | Flexible, curved, or wearable LED strips | High thermal stability and flexibility | Higher cost and manufacturing complexity | High |

| Rigid FR-4 PCB | Stationary, flat surface LED strips for indoor use | Cost-effective and widely available | Limited flexibility and lower heat tolerance | Low |

| Silicone/Polyurethane Coating | Outdoor, waterproof, and harsh environment LED strips | Excellent protection against moisture and UV | Increased cost; potential yellowing with polyurethane | Medium |

| Adhesive Backing (3M VHB/Acrylic) | Installation on diverse surfaces, portable battery powered strips | Strong adhesion and easy installation | May degrade under extreme conditions; residue issues | Medium |

This guide equips international B2B buyers with actionable insights to select materials that balance performance, cost, and regulatory compliance tailored to their regional market needs. Prioritizing the right combination of PCB substrate, protective coatings, and adhesives ensures battery powered LED strips deliver reliable, efficient lighting solutions across varied applications and environments.

In-depth Look: Manufacturing Processes and Quality Assurance for battery powered led strip

Battery powered LED strips represent a convergence of advanced lighting technology and portable power solutions, requiring a meticulous manufacturing process and stringent quality assurance measures. For international B2B buyers—especially from regions like Africa, South America, the Middle East, and Europe—understanding these processes is crucial for selecting reliable suppliers and ensuring product longevity and compliance.

Manufacturing Process of Battery Powered LED Strips

The production of battery powered LED strips involves several key stages, each critical to the final product’s performance and reliability:

1. Material Preparation and Sourcing

High-quality raw materials form the foundation of superior LED strips. This includes:

- LED Chips: Sourced from reputable manufacturers offering high luminous efficacy and long lifespan. Premium chips reduce energy consumption and heat generation.

- Printed Circuit Boards (PCBs): Typically flexible PCBs are preferred for LED strips to enable versatile installation. The PCB material must offer excellent heat dissipation to prevent premature LED degradation.

- Battery Components: Battery packs (commonly lithium-ion or 12V sealed lead-acid) must meet voltage and capacity specifications aligned with the LED strip’s power requirements.

- Adhesive Backing: Industrial-grade adhesives ensure the strips securely attach to surfaces without peeling, even in diverse environmental conditions.

Material sourcing is often the first quality gate, as substandard components can compromise safety, durability, and performance.

2. PCB Fabrication and LED Chip Mounting

- PCB Fabrication: Precision manufacturing of the PCB traces ensures consistent electrical conductivity and heat management. For battery powered strips, PCB design also integrates connectors for battery packs and control circuitry.

- LED Mounting: Surface-mount technology (SMT) places LED chips accurately on the PCB. Automated machines solder LEDs with high precision, ensuring uniform light output and reducing defects.

- Battery Integration: Battery packs are assembled or attached to the strips with secure wiring and protective casings to prevent shorts and damage during use.

3. Assembly and Wiring

- Connector Assembly: Battery terminals, switches, and sometimes dimmer controls are installed.

- Wiring: Correct polarity and secure connections between battery packs and LED strips are vital. Insulated wiring and solder joints reduce risk of failure.

- Encapsulation: Protective coatings or silicone layers may be applied to safeguard LEDs and circuitry from moisture and dust, especially for outdoor or portable applications.

4. Finishing and Packaging

- Final Inspection: Visual and mechanical inspections check for physical defects or assembly errors.

- Packaging: Custom packaging protects the strips and batteries during transit. For international shipping, packaging often complies with regional regulations on hazardous materials (e.g., lithium-ion batteries).

Quality Assurance and Control (QA/QC) in Battery Powered LED Strip Manufacturing

Robust QA/QC frameworks ensure products meet stringent safety, performance, and regulatory standards. International B2B buyers should assess these controls carefully.

Relevant International and Industry Standards

- ISO 9001: A global benchmark for quality management systems, ensuring consistent manufacturing processes and continual improvement.

- CE Marking (Europe): Indicates compliance with EU safety, health, and environmental requirements, essential for buyers in Germany, Poland, and other European markets.

- RoHS Compliance: Restricts hazardous substances, crucial for environmental safety and regulatory acceptance worldwide.

- UL Certification (USA): While primarily for North America, UL standards for electrical safety are respected globally.

- IEC Standards: International standards for LED performance and battery safety.

- UN38.3: Safety test standard for lithium batteries during air transport, critical for international shipping.

Buyers should verify that suppliers hold these certifications to ensure product legality and safety in their respective markets.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection and testing of raw materials such as LED chips, PCBs, and batteries before production to weed out defective components.

- In-Process Quality Control (IPQC): Continuous monitoring during PCB assembly, LED soldering, and wiring to detect defects early, minimizing scrap and rework.

- Final Quality Control (FQC): Comprehensive testing of finished products, including visual checks, electrical testing, and functional verification of battery operation and LED brightness.

Common Testing Methods

- Electrical Testing: Verifies voltage, current, and power consumption align with specifications to prevent overheating or premature battery drain.

- Thermal Imaging: Detects hotspots on the PCB or LED chips, ensuring heat dissipation is effective.

- Durability Testing: Simulates mechanical stress and environmental conditions such as vibration, humidity, and temperature cycling.

- Battery Performance Testing: Measures charge/discharge cycles, capacity retention, and safety under load.

- Safety Testing: Checks for short circuits, insulation resistance, and protection against overcurrent or overvoltage.

How B2B Buyers Can Verify Supplier Quality Assurance

For buyers, especially those importing to diverse regions, validating supplier QC practices is essential to mitigate risks:

- Factory Audits: On-site inspections to review manufacturing processes, equipment, workforce training, and quality management systems.

- Review of Quality Documentation: Request detailed QC reports, test certificates, and compliance documentation (e.g., ISO 9001 certificates, CE declarations).

- Third-Party Inspections: Independent agencies can perform random batch testing and factory audits, providing unbiased quality assessments.

- Sample Testing: Procuring product samples for in-house or third-party lab testing to verify performance claims.

- Supplier Track Record: Evaluate supplier history for consistency, responsiveness, and after-sales support.

QC and Certification Nuances for International Markets

- Africa & South America: Regulatory frameworks may vary widely. Buyers should prioritize suppliers with international certifications (CE, RoHS, ISO) to ease customs clearance and market acceptance.

- Middle East: Compliance with Gulf Cooperation Council (GCC) standards and certification bodies is often required. Battery safety and hazardous material handling are highly regulated.

- Europe (Germany, Poland): Extremely stringent on environmental and safety standards. CE marking and RoHS compliance are mandatory, and buyers should ensure the supplier’s certification is up to date and traceable.

- Documentation: Accurate and transparent certification documents, including test reports and material declarations, are critical for customs and regulatory approval.

- Battery Regulations: Lithium-ion battery shipments are subject to strict international transport regulations (IATA, UN38.3), which must be adhered to for global logistics.

Summary for B2B Buyers:

When sourcing battery powered LED strips, prioritize suppliers with comprehensive manufacturing processes that emphasize high-quality material sourcing, precision assembly, and robust battery integration. Verify adherence to international quality management and product safety standards, supported by rigorous IQC, IPQC, and FQC procedures. Utilize audits, third-party inspections, and thorough documentation review to ensure supplier reliability. Tailor your quality expectations to your regional regulatory landscape, ensuring smooth market entry and customer satisfaction across Africa, South America, the Middle East, and Europe.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for battery powered led strip Sourcing

Understanding the cost structure and pricing dynamics of battery powered LED strips is crucial for international B2B buyers aiming to optimize procurement strategies and total cost of ownership. This analysis breaks down the key cost components, factors influencing pricing, and practical tips tailored for buyers from Africa, South America, the Middle East, and Europe.

Key Cost Components in Battery Powered LED Strip Production

- Materials

The largest portion of cost typically stems from raw materials, including LED chips, printed circuit boards (PCBs), battery packs, and adhesive backings. Premium LED chips and high-quality lithium-ion or 12V battery packs increase upfront costs but enhance durability and performance. Material sourcing locations and quality certifications (e.g., RoHS, CE) also impact pricing.

Illustrative Image (Source: Google Search)

-

Labor

Labor costs vary significantly by manufacturing location. Asian factories often offer lower labor expenses, but European suppliers may charge more due to higher wages and stricter labor regulations. Labor quality affects assembly precision, impacting product reliability. -

Manufacturing Overhead

This includes factory utilities, machinery depreciation, and indirect labor. Advanced production lines with automated soldering and quality control systems may have higher overhead but ensure consistency and reduce defect rates. -

Tooling and Setup

Initial tooling for PCB fabrication, battery integration, and custom connectors can be substantial, especially for bespoke designs or small production runs. Amortizing tooling costs over larger volumes reduces per-unit costs. -

Quality Control (QC)

Rigorous testing for voltage compatibility, battery safety, and LED longevity is critical. QC processes add cost but minimize returns and warranty claims, safeguarding brand reputation. -

Logistics and Shipping

Battery powered LED strips require careful handling, especially when shipping batteries due to hazardous material regulations. Air freight costs are higher for lithium-ion batteries, and customs clearance can introduce delays. Sea freight is more economical but slower, influencing inventory planning. -

Supplier Margin

Manufacturers and distributors add a margin reflecting their operational costs and profit expectations. Margins vary by market competitiveness and order volume.

Price Influencers for International B2B Buyers

-

Order Volume and Minimum Order Quantity (MOQ)

Larger volumes usually unlock significant price breaks. MOQ requirements vary; some suppliers set high MOQs to justify tooling and production runs, while others offer flexible quantities at a premium. -

Product Specifications and Customization

Custom lengths, color temperatures, battery capacities, or connector types increase complexity and cost. Standardized products are generally cheaper and faster to procure. -

Material Quality and Certifications

Compliance with international standards (e.g., CE for Europe, UL for North America) can raise costs but is often mandatory for market access. Higher-grade LEDs and batteries command premium pricing but reduce long-term maintenance. -

Supplier Reputation and Location

Established suppliers with proven track records may charge higher prices but reduce risk. Proximity to buyers can lower logistics costs and lead times. -

Incoterms and Payment Terms

The choice of Incoterms (e.g., FOB, CIF, DDP) affects who bears shipping, insurance, and customs risks and costs. Negotiating favorable terms can improve cash flow and reduce hidden expenses.

Actionable Buyer Tips for Cost-Efficient Sourcing

-

Negotiate Based on Total Cost of Ownership (TCO)

Focus beyond unit price; consider battery lifespan, energy efficiency, warranty terms, and after-sales support. A slightly higher upfront cost for premium components can yield savings in replacements and energy consumption. -

Leverage Volume Consolidation

Buyers from regions like Africa and South America can collaborate or consolidate orders to meet MOQs and access better pricing tiers. -

Request Samples and Conduct Quality Audits

Testing samples and performing factory audits helps verify claims and avoid costly defects, especially critical for buyers in Europe where compliance is strict. -

Understand Regional Logistics Challenges

Factor in customs duties, import restrictions on batteries, and local infrastructure constraints. Working with freight forwarders experienced in hazardous materials shipping can streamline delivery. -

Choose the Right Incoterms

For buyers new to international trade, Delivered Duty Paid (DDP) reduces complexity but may cost more upfront. Experienced buyers might prefer FOB or EXW to control freight and customs clearance directly. -

Monitor Currency Fluctuations and Payment Methods

Currency volatility can affect landed costs. Negotiating payment in stable currencies or using letters of credit can mitigate financial risks.

Indicative Pricing Disclaimer

Prices for battery powered LED strips vary widely depending on specifications, order size, and supplier location. As a rough benchmark, basic 12V LED strips with battery packs can range from $5 to $15 per meter at medium volumes. Custom or certified products may command higher prices. Buyers should request detailed quotations and breakdowns from multiple suppliers to make informed decisions.

By comprehensively understanding the cost drivers and pricing influencers, international B2B buyers can strategically source battery powered LED strips that balance quality, compliance, and cost-efficiency tailored to their regional market demands.

Spotlight on Potential battery powered led strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘battery powered led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for battery powered led strip

Critical Technical Properties of Battery Powered LED Strips

Understanding key technical specifications is essential for international B2B buyers to ensure product compatibility, quality, and longevity when sourcing battery powered LED strips.

-

Voltage Rating (12V or 24V)

This specifies the operating voltage the LED strip requires. Battery packs must match this voltage exactly to prevent damage or inefficient performance. For buyers, confirming voltage compatibility ensures seamless integration with existing battery systems or power sources. -

Power Consumption (Watts per Meter)

Indicates how much energy the strip consumes per meter, commonly ranging from 4.8W to 14.4W. This directly impacts battery life and operational costs. Buyers should calculate total power needs based on strip length to select appropriate battery capacity and optimize runtime. -

LED Chip Quality and Type

The LED chips determine brightness, color rendering, and lifespan. Premium chips offer higher luminous efficacy and durability. For B2B buyers, sourcing strips with reliable chip manufacturers reduces maintenance costs and enhances end-customer satisfaction. -

PCB Material and Flexibility

The printed circuit board (PCB) supports and connects LEDs. Options include flexible PCBs for curved or irregular installations and rigid PCBs for stable, flat surfaces. High-grade PCBs ensure efficient heat dissipation, preventing premature failure. Buyers should specify PCB type based on application needs. -

Battery Compatibility and Connector Type

Battery powered LED strips require compatible connectors and wiring configurations to match battery packs, especially when using series or parallel battery arrangements. Clear specifications on connectors and polarity help avoid installation errors and ensure safety. -

Adhesive Backing Strength

The quality of the adhesive layer affects installation ease and durability, particularly in varying climates or surface conditions. Strong adhesive backing prevents peeling and reduces warranty claims. Buyers targeting outdoor or mobile applications should prioritize durable adhesives.

Common Industry and Trade Terms for B2B Buyers

Grasping prevalent trade terminology helps buyers communicate effectively with manufacturers and streamline procurement processes.

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce products or components to be branded and sold by another company. Buyers seeking custom-branded battery powered LED strips often engage OEMs for tailored specifications and exclusive designs. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. MOQs can vary significantly by manufacturer and impact pricing and inventory decisions. Buyers should negotiate MOQs aligning with budget and market demand, especially when testing new products. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting pricing, lead times, and terms for a specified product. RFQs enable buyers to compare offers objectively and select the best supplier for battery powered LED strips based on cost, quality, and delivery capabilities. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities and risks between buyers and sellers during shipping. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms helps buyers manage logistics costs and import compliance efficiently. -

Luminous Efficacy

Measures the amount of light produced per unit of power (lumens per watt). Higher luminous efficacy means brighter light with less energy consumption. Buyers focused on energy-efficient lighting solutions should prioritize this metric. -

Color Temperature (Kelvin, K)

Describes the color appearance of the light emitted, ranging from warm (2700K) to cool daylight (6500K). Selecting the right color temperature affects ambiance and customer preferences, making it a key factor in product specification.

By focusing on these technical properties and trade terms, B2B buyers from Africa, South America, the Middle East, and Europe can make informed purchasing decisions, negotiate effectively, and ensure the battery powered LED strips they source meet both functional and commercial expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the battery powered led strip Sector

Market Overview & Key Trends

The global market for battery powered LED strips is experiencing robust growth, driven by increasing demand for portable, energy-efficient lighting solutions across diverse sectors such as events, retail, automotive, and outdoor installations. For international B2B buyers in regions like Africa, South America, the Middle East, and Europe (notably Germany and Poland), this sector presents unique opportunities fueled by urbanization, rising infrastructure investments, and a shift towards flexible lighting applications.

Key market dynamics include the growing preference for wireless, battery-operated LED strips that enable mobility and ease of installation without reliance on fixed power sources. This is particularly relevant in emerging markets where electrical infrastructure may be limited or unreliable. Additionally, the rise of smart lighting integrations, including Bluetooth and IoT-enabled LED strips, is reshaping sourcing priorities, with buyers seeking products compatible with advanced controls and energy management systems.

From a sourcing perspective, buyers should be attentive to battery technology trends. Lithium-ion battery packs dominate due to their rechargeability, energy density, and lightweight properties, although cost considerations prompt some markets to still utilize alkaline or AA battery configurations for smaller or short-term applications. Voltage compatibility (typically 12V or 24V) remains critical, and suppliers offering customizable battery solutions tailored to specific LED strip configurations gain competitive advantage.

Moreover, supply chain resilience is a growing concern amid global disruptions. Buyers are increasingly favoring manufacturers with transparent sourcing practices and diversified supply bases to mitigate risks. The European market, in particular, places emphasis on compliance with stringent safety and efficiency standards, influencing procurement decisions towards certified and high-quality LED strips and battery packs.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a decisive factor in the procurement of battery powered LED strips. The environmental impact of both LED components and battery systems necessitates a focus on eco-friendly materials, energy efficiency, and end-of-life recyclability. For B2B buyers, especially in Europe and the Middle East where regulatory frameworks are rigorous, sourcing products compliant with certifications such as RoHS, CE, and REACH ensures adherence to environmental and safety standards.

Illustrative Image (Source: Google Search)

Ethical sourcing is equally vital. Responsible manufacturers prioritize conflict-free raw materials—particularly for lithium and rare earth elements used in battery production—and maintain transparent supply chains to prevent labor abuses. Buyers targeting African and South American markets should seek suppliers with verifiable ethical practices to align with global corporate social responsibility (CSR) commitments.

Green credentials extend beyond raw materials to include the energy efficiency of LED chips and the sustainability of battery technologies. Lithium-ion batteries with protective circuitry prolong lifespan and reduce waste, while advanced PCB materials and adhesives contribute to product durability, minimizing replacement frequency. Packaging innovations that reduce plastic use and enhance recyclability further support sustainable procurement.

For B2B buyers, partnering with suppliers offering sustainability reports, eco-labels, and lifecycle assessments can help demonstrate compliance to end customers and stakeholders, fostering trust and enabling entry into markets with strict environmental regulations.

Brief Evolution & Historical Context

The evolution of battery powered LED strips reflects broader trends in lighting technology and portable power solutions. Initially, LED strips were primarily powered through fixed AC adapters, limiting their deployment to locations with accessible mains electricity. The integration of battery packs, especially rechargeable lithium-ion types, emerged in the late 2000s, enabling unprecedented flexibility for lighting designers and end-users.

This shift coincided with advancements in LED chip efficiency and miniaturization of battery technology, allowing longer runtimes and more compact form factors. Over the past decade, innovations such as smart controls and modular battery designs have further expanded the applications of battery powered LED strips, making them indispensable in sectors ranging from temporary event lighting in South America to emergency lighting solutions in remote African regions.

Today, the battery powered LED strip market is characterized by a balance between cost-efficiency and high performance, with growing emphasis on sustainability and supply chain ethics as buyers across continents demand products that align with evolving regulatory and environmental expectations.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of battery powered led strip

-

How can I effectively vet suppliers of battery powered LED strips for international B2B purchases?

When sourcing battery powered LED strips internationally, prioritize suppliers with verifiable certifications such as CE, RoHS, and UL that comply with your region’s safety and environmental standards. Request factory audits or virtual tours to assess production capabilities and quality controls. Check references and sample quality before bulk orders. Additionally, review supplier responsiveness and after-sales support policies to ensure reliable communication. For buyers in regions like Africa, South America, the Middle East, and Europe, partnering with suppliers familiar with export regulations and international logistics can mitigate risks and streamline procurement. -

What customization options are typically available for battery powered LED strips in B2B orders?

Most manufacturers offer customization on LED chip type, voltage (commonly 12V or 24V), battery pack capacity, strip length, color temperature, adhesive backing, and waterproof ratings. For international buyers, specifying battery type (e.g., lithium-ion vs. alkaline), connector types, and packaging tailored to local market preferences enhances product suitability. Custom firmware for dimming or remote control integration can also be requested. Clear communication of technical requirements and volume commitments is essential to negotiate feasible MOQ and lead times for customized products. -

What are common MOQ and lead time expectations when ordering battery powered LED strips internationally?

Minimum order quantities (MOQ) vary widely but typically range from 500 to 2,000 meters of LED strip, depending on customization complexity and supplier scale. Lead times usually span 3 to 8 weeks, accounting for production, quality checks, and international shipping. Buyers should clarify MOQ upfront and negotiate smaller pilot orders if possible. Early communication about order schedules helps suppliers allocate resources efficiently. For buyers in Africa and South America, factoring in longer shipping times and customs clearance is crucial for accurate delivery planning. -

Which payment terms are standard for international B2B transactions involving battery powered LED strips?

Common payment terms include a 30%-50% deposit upfront with the balance paid before shipment or upon delivery. Letters of credit (LC) are frequently used for larger orders to protect both parties. Trusted suppliers may offer net 30 or net 60 day terms after establishing a credit history. It’s advisable to use secure payment methods such as wire transfers through reputable banks or escrow services. Buyers should confirm payment milestones align with production and inspection schedules to mitigate financial risks. -

What quality assurance processes should I expect from reputable battery powered LED strip manufacturers?

Top-tier manufacturers conduct thorough quality control at each stage, including incoming material inspections, in-process testing of LED chips and PCBs, and final product validation for brightness, voltage, and battery performance. Compliance with international standards like CE, RoHS, and UL is essential. Request independent third-party testing reports and certifications as proof. For battery-powered solutions, verifying battery safety, protective circuitry, and runtime consistency is critical to avoid failures and warranty claims. -

How can I ensure compliance with international standards and certifications when importing battery powered LED strips?

Verify that suppliers provide documentation for relevant certifications accepted in your target markets, such as CE for Europe, FCC for the US, and local standards applicable in Africa, the Middle East, or South America. Ensure batteries meet UN38.3 for transport safety and that products comply with RoHS restrictions on hazardous substances. Engaging a local compliance consultant or testing lab can help validate certifications and identify regulatory updates, minimizing customs delays and legal risks. -

What logistics considerations should I keep in mind when importing battery powered LED strips?

Battery powered LED strips often contain lithium-ion batteries classified as dangerous goods, requiring special packaging, labeling, and shipping methods (e.g., air freight restrictions). Confirm that your supplier uses certified logistics partners familiar with hazardous material handling. Plan for customs clearance delays by preparing accurate import documentation and harmonized system (HS) codes. For buyers in remote regions of Africa or South America, selecting suppliers with consolidated shipping options or regional warehouses can reduce transit times and costs. -

How should I handle disputes or quality issues with international suppliers of battery powered LED strips?

Establish clear contract terms covering product specifications, inspection rights, and dispute resolution mechanisms such as arbitration or mediation. Upon receiving goods, conduct immediate quality inspections and document any discrepancies with photos and reports. Communicate issues promptly and professionally with the supplier to seek resolution through replacement, repair, or refunds. Maintaining open dialogue and leveraging third-party inspection services can strengthen your position. Building long-term relationships with reputable suppliers reduces the risk of recurring disputes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for battery powered led strip

Battery powered LED strips represent a versatile lighting solution that combines portability with energy efficiency, making them ideal for diverse applications across markets in Africa, South America, the Middle East, and Europe. For B2B buyers, strategic sourcing is paramount: selecting high-quality LED chips, reliable battery packs matched to voltage requirements, and durable materials ensures product longevity and customer satisfaction. Understanding the interplay between battery capacity, LED power consumption, and wiring integrity empowers buyers to optimize product performance and cost-effectiveness.

Key takeaways for international buyers include:

– Prioritize suppliers with proven quality control and compliance certifications (e.g., CE, RoHS) to meet regional regulatory standards.

– Opt for flexible sourcing strategies that balance cost, quality, and supply chain resilience, especially in emerging markets with fluctuating logistics.

– Leverage partnerships with manufacturers experienced in producing battery-compatible LED strips to customize solutions tailored to local consumer needs and environmental conditions.

Looking ahead, the demand for portable, energy-efficient lighting solutions will continue to grow, driven by expanding outdoor activities, emergency preparedness, and smart infrastructure development worldwide. Buyers in Africa, South America, the Middle East, and Europe should proactively engage with suppliers who innovate in battery technology and material sourcing to stay competitive. Investing in strategic sourcing today lays the foundation for sustainable growth and market leadership in tomorrow’s dynamic lighting landscape.