Introduction: Navigating the Global Market for 12v dimmer switch

Navigating the global market for 12V dimmer switches is essential for B2B buyers seeking reliable, efficient, and cost-effective lighting control solutions. As demand for smart, energy-efficient, and adaptable lighting continues to rise across industries—from commercial installations to smart home integrations—understanding the nuances of 12V dimmer switches has become critical. These devices not only enhance user experience but also significantly contribute to energy savings and ambiance customization, making them a strategic component in diverse projects worldwide.

This comprehensive guide covers every vital aspect necessary for informed sourcing decisions. It explores various types of 12V dimmer switches, the materials and technologies that underpin their performance, and the quality assurance processes employed by leading manufacturers. Additionally, it provides insights into reputable suppliers, cost considerations, and market trends, particularly relevant for buyers from Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and the UAE.

By equipping international B2B buyers with expert knowledge, this guide aims to streamline procurement processes, mitigate risks, and optimize supply chain strategies. Whether sourcing for large-scale industrial projects or tailored smart lighting solutions, understanding the intricacies of the global 12V dimmer switch market empowers buyers to make confident, strategic decisions that align with their operational needs and growth ambitions.

Understanding 12v dimmer switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leading Edge Dimmer Switch | Uses a slide or rotary mechanism with a simple, manual interface; often basic electronic control. | Commercial lighting, retail displays, hospitality venues. | Pros: Cost-effective, easy installation, suitable for standard LED and incandescent bulbs. Cons: Limited features, less precise control, compatibility issues with some LED types. |

| Trailing Edge Dimmer Switch | Utilizes high-quality electronic components (MOSFETs) for smoother dimming; often more advanced. | High-end retail, hospitality, architectural projects. | Pros: Better flicker-free dimming, energy efficiency, compatible with dimmable LEDs. Cons: Higher initial cost, more complex installation. |

| Wireless/Digital Dimmer | Operates via RF, Wi-Fi, or Bluetooth; integrates with smart home ecosystems; programmable. | Smart building automation, remote-controlled lighting. | Pros: Remote operation, scheduling, integration with automation systems. Cons: Higher upfront investment, potential cybersecurity concerns, requires compatible infrastructure. |

| Magnetic Low-Voltage Dimmer | Designed specifically for magnetic transformers used in low-voltage lighting. | Landscape lighting, retail displays, architectural accents. | Pros: Reliable control of magnetic transformers, stable operation. Cons: Not suitable for electronic transformers, limited to specific low-voltage applications. |

| Phase-Control Dimmer (Triac-based) | Uses phase-cutting technology for universal compatibility; suitable for a wide range of bulbs. | General commercial and industrial lighting. | Pros: Wide compatibility, simple installation, cost-effective. Cons: May cause flickering with some LED bulbs, less smooth dimming compared to electronic types. |

Characteristics and Suitability

Leading Edge Dimmer Switches are the most traditional, often favored for their straightforward design and affordability. They are suitable for basic commercial environments where cost and simplicity are priorities. However, their limited compatibility with newer LED technologies can pose challenges, requiring careful product selection to avoid flickering or incompatibility issues. B2B buyers should evaluate the types of bulbs used in their installations and choose models that support those specifications.

Trailing Edge Dimmer Switches are more sophisticated, offering smoother, flicker-free dimming, especially with dimmable LEDs. These are ideal for premium commercial projects or hospitality venues where ambiance quality matters. Although they come at a higher initial cost, they reduce maintenance and replacement costs due to better performance and compatibility. B2B buyers should consider long-term energy savings and the compatibility of their lighting systems when opting for trailing edge dimmers.

Wireless/Digital Dimmer Switches are increasingly popular in smart building applications. They enable remote control, scheduling, and integration with building management systems, making them suitable for large-scale commercial or institutional projects. The main considerations include higher upfront costs and cybersecurity risks. B2B buyers should ensure their infrastructure supports these systems and assess the total cost of ownership, including maintenance and updates.

Magnetic Low-Voltage Dimmer Switches are specialized for low-voltage lighting systems using magnetic transformers. They are essential for landscape lighting, retail displays, or architectural lighting requiring precise control of low-voltage fixtures. Compatibility with electronic transformers is limited, so buyers must verify transformer types before purchase. These dimmers offer reliable performance in specific applications but are less versatile across different lighting systems.

Phase-Control (Triac-based) Dimmer Switches are versatile, widely used in various commercial settings due to their broad compatibility with different bulb types, including incandescent and dimmable LEDs. They are cost-effective and easy to install. However, flickering issues with some LED bulbs and less smooth dimming can be drawbacks. B2B buyers should weigh these factors, especially when specifying lighting for environments demanding high-quality dimming performance.

Related Video: How to Wire 12V Dimmer Switches | Interior Van Lighting Made Easy!

Key Industrial Applications of 12v dimmer switch

| Industry/Sector | Specific Application of 12v dimmer switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality & Leisure | Adjustable mood lighting in hotel rooms, restaurants, and entertainment venues | Enhances ambiance, improves guest experience, and allows customization of lighting scenes | Compatibility with various lighting types, reliability, ease of installation, and compliance with local electrical standards |

| Retail & Commercial | Display lighting for showcases, signage, and product illumination | Improves product presentation, attracts customers, and reduces energy costs | Precise dimming control, durability, and availability of suitable voltage ratings (12V) |

| Architectural & Landscape | Exterior landscape lighting, architectural accent lighting, and garden features | Creates aesthetic appeal, extends outdoor usability, and conserves energy | Weather resistance, high-quality components, and compliance with regional outdoor electrical codes |

| Automotive & Marine | Interior lighting, dashboard illumination, and custom vehicle lighting | Offers customizable lighting environments, reduces glare, and improves safety | Compact size, vibration resistance, and compatibility with vehicle electrical systems |

| Industrial & Commercial | Warehouse, factory, and exhibition lighting systems | Provides flexible lighting control, energy efficiency, and enhanced worker safety | High load capacity, stable performance under continuous operation, and ease of integration |

Hospitality & Leisure

In the hospitality sector, 12V dimmer switches are crucial for creating inviting atmospheres in hotel rooms, restaurants, and entertainment venues. They enable operators to adjust lighting levels to suit different times of day or events, enhancing guest satisfaction and ambiance. For international B2B buyers, especially from regions like the Middle East or Africa, sourcing dimmers that are compatible with diverse lighting fixtures and meet local safety standards is vital. Reliability and ease of installation are also key, ensuring minimal downtime and seamless integration into existing electrical systems.

Retail & Commercial

Retail environments leverage 12V dimmer switches to optimize display lighting, making products more appealing and drawing customer attention. Adjustable lighting can highlight specific merchandise or signage, improving sales conversions. For B2B buyers in Europe or South America, sourcing dimmers with precise control, high-quality components, and compliance with regional electrical standards ensures consistent performance. Durability and compatibility with LED or halogen lighting are essential for long-term operational efficiency and energy savings.

Architectural & Landscape

Outdoor and architectural lighting applications benefit significantly from 12V dimmer switches, which enable dynamic lighting effects for buildings, gardens, and public spaces. These switches help create aesthetic appeal while conserving energy by adjusting brightness according to ambient conditions or time of day. For buyers in regions like the UAE or South America, weather-resistant and rugged designs are critical to withstand environmental factors such as humidity, heat, or rain. Ensuring compliance with regional outdoor electrical codes is essential for safe and reliable operation.

Automotive & Marine

In automotive and marine industries, 12V dimmer switches facilitate customizable interior lighting, dashboard illumination, and mood lighting for vehicles and boats. They offer enhanced control over lighting environments, improving safety and comfort. For international B2B buyers, especially in markets like Saudi Arabia or Europe, selecting compact, vibration-resistant, and corrosion-proof dimmers is vital. Compatibility with vehicle electrical systems and adherence to automotive safety standards are key sourcing considerations to ensure longevity and reliable performance.

Industrial & Commercial

Industrial facilities utilize 12V dimmer switches for warehouse, factory, and exhibition lighting, where flexibility and energy efficiency are paramount. These switches allow operators to adapt lighting levels based on operational needs, reducing energy consumption and improving worker safety. For B2B buyers from Africa or Europe, sourcing high-capacity, stable, and easy-to-integrate dimmers that can withstand continuous operation and harsh conditions is crucial. Compatibility with existing control systems and adherence to industrial safety standards are also critical factors for successful deployment.

Related Video: How to: Dimmer Switch Single-Pole wiring | Save Money TV

Strategic Material Selection Guide for 12v dimmer switch

Analysis of Common Materials for 12V Dimmer Switches

When selecting materials for manufacturing 12V dimmer switches, especially for international markets, it is essential to consider properties that influence product performance, durability, cost, and compliance with regional standards. Below are three commonly used materials, each with their respective characteristics, advantages, and limitations, tailored to meet the needs of diverse markets such as Africa, South America, the Middle East, and Europe.

1. Polycarbonate (PC)

Key Properties:

Polycarbonate is a high-performance thermoplastic known for its excellent impact resistance, high temperature tolerance (up to approximately 135°C), and good electrical insulation properties. It also offers good dimensional stability and can withstand environmental stressors.

Pros & Cons:

– Pros:

– Superior impact and mechanical strength, reducing breakage risks during installation or transport.

– Good flame retardancy when treated, aligning with many safety standards (UL94 V-0).

– Cost-effective for mass production due to ease of molding.

– Cons:

– Susceptible to UV degradation unless UV-stabilized, which can increase costs.

– Can be prone to scratching, impacting aesthetic longevity.

– Moderate resistance to certain chemicals, such as solvents, which may limit use in specific environments.

Impact on Application:

Polycarbonate’s durability makes it suitable for consumer-facing switch housings and control interfaces exposed to frequent handling. Its high temperature resistance ensures reliable operation in hot climates typical of Middle Eastern and African regions.

International Considerations:

Polycarbonate complies with global standards like UL and IEC, facilitating export to Europe and other regions. For markets with strict safety requirements (e.g., EU RoHS, REACH), suppliers must ensure the material is free of hazardous additives. UV-stabilized variants are preferred for outdoor applications in sunny climates.

2. Polyamide (Nylon)

Key Properties:

Polyamide offers excellent mechanical strength, high wear resistance, and good thermal stability (up to 150°C). It also exhibits good chemical resistance, especially to oils and greases, and has inherent self-lubricating properties.

Pros & Cons:

– Pros:

– Exceptional durability under mechanical stress, ideal for high-use environments.

– Good chemical and moisture resistance, suitable for humid or chemically aggressive regions.

– Relatively low cost for high-performance plastics.

– Cons:

– Sensitive to prolonged exposure to UV light unless stabilized, which can lead to degradation.

– Higher processing complexity due to moisture absorption during manufacturing, requiring pre-drying.

– Slightly higher material cost compared to standard plastics.

Impact on Application:

Polyamide’s robustness makes it ideal for switches subjected to frequent operation or outdoor use where environmental exposure is significant. Its resistance to chemicals is advantageous in industrial or humid regions like South America and parts of the Middle East.

International Considerations:

Polyamide materials must meet regional standards such as JIS in Japan or DIN in Europe. For export, suppliers should verify compliance with environmental regulations like REACH and ensure UV stabilization for outdoor applications.

3. Aluminum (Anodized)

Key Properties:

Aluminum is a lightweight, corrosion-resistant metal when anodized, with high thermal conductivity and excellent mechanical strength. It is commonly used for decorative or heat-dissipating parts of dimmer switches.

Pros & Cons:

– Pros:

– Superior corrosion resistance, especially in coastal or humid environments common in Middle East and South America.

– Excellent thermal management, aiding in heat dissipation for electronic components.

– Aesthetic appeal with a premium look, suitable for high-end markets in Europe.

– Cons:

– Higher manufacturing costs due to machining and anodizing processes.

– Less impact-resistant compared to plastics, requiring design considerations for shock absorption.

– Conductivity necessitates proper insulation to prevent electrical hazards.

Impact on Application:

Aluminum components enhance the durability and aesthetic appeal of premium dimmer switches, especially in outdoor or high-temperature environments. They are suitable for applications demanding both form and function, such as in smart home systems in Europe or upscale markets in the Middle East.

International Considerations:

Aluminum parts must comply with environmental standards like RoHS and REACH, especially regarding anodizing chemicals. Proper certification ensures acceptance across diverse markets, including strict European regulations.

Summary Table of Material Selection for 12V Dimmer Switches

| Material | Typical Use Case for 12V dimmer switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | External housings, user interfaces exposed to handling and impact | High impact resistance, good thermal stability | UV degradation without stabilization, scratching issues | Low |

| Polyamide | Mechanical components, high-wear parts, outdoor or humid environments | Excellent mechanical strength, chemical resistance | UV sensitivity, moisture absorption during processing | Med |

| Aluminum | Heat sinks, decorative faceplates, outdoor enclosures | Corrosion resistance, excellent thermal conductivity | Higher cost, requires careful insulation for electrical safety | High |

This comprehensive material analysis provides international B2B buyers with critical insights into selecting the optimal materials for 12V dimmer switches, considering regional environmental conditions, compliance standards, and cost implications. Proper material choice enhances product reliability, safety, and aesthetic appeal across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 12v dimmer switch

Manufacturing of 12V dimmer switches involves a comprehensive series of processes designed to ensure high-quality, reliable products that meet international standards. For B2B buyers, understanding these stages and associated quality control (QC) measures is essential to select reputable suppliers capable of delivering consistent performance across diverse markets such as Africa, South America, the Middle East, and Europe.

Material Preparation and Component Sourcing

The manufacturing process begins with sourcing high-grade electronic components and raw materials, including semiconductors (e.g., TRIACs, thyristors), resistors, capacitors, PCB substrates, and enclosures. Reputable manufacturers prioritize suppliers with ISO 9001 certification or equivalent to ensure material consistency and traceability. Given the critical role of components in safety and longevity, B2B buyers should verify supplier certifications and request material certificates (e.g., ROHS compliance) before procurement.

Forming and Circuit Board Assembly

The core electronic assembly involves designing and fabricating printed circuit boards (PCBs) tailored for 12V dimmer functionality. Surface-mount technology (SMT) is commonly employed for precision and compactness, facilitating automated placement and soldering of components. During this stage, manufacturers perform in-line inspection (IPQC) to detect issues such as soldering defects, misalignments, or component shortages. Advanced manufacturers utilize AOI (Automated Optical Inspection) systems to enhance accuracy and reduce defect rates.

Mechanical Assembly and Enclosure Integration

Following electronic assembly, the PCBs are integrated into the device enclosures—typically plastic or metal casings designed for durability and thermal management. Mechanical assembly involves inserting PCBs into enclosures, attaching knobs or touch interfaces, and wiring connections. Precision in assembly is critical to ensure proper fit, ease of installation, and compliance with safety standards. Manufacturers often conduct functional tests at this stage to verify operational integrity before proceeding.

Finishing and Final Testing

The final phase involves comprehensive testing and quality assurance to confirm product compliance. This includes:

- Electrical Testing: Verifying dimming range, load compatibility, and circuit protection features.

- Environmental Testing: Assessing resistance to temperature fluctuations, humidity, and vibration, especially for markets with harsh conditions.

- Safety Testing: Ensuring insulation integrity, leakage current, and electrical safety per IEC, CE, UL, or other applicable standards.

- Labeling and Packaging: Confirming correct labeling, including certification marks, voltage ratings, and installation instructions, aligned with regional requirements.

Manufacturers often employ Statistical Process Control (SPC) techniques during production to monitor variation and maintain consistency.

Quality Assurance and Certification Standards

For international B2B transactions, adherence to recognized standards is non-negotiable. Key standards include:

- ISO 9001: The foundation for quality management systems, emphasizing process control, continuous improvement, and customer satisfaction.

- CE Marking (Europe): Demonstrates compliance with EU safety, health, and environmental directives, including Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC).

- UL Certification (North America): Ensures safety and performance, often required for export to North American markets.

- IEC Standards: International standards for electrical safety and performance, applicable across many regions.

Manufacturers should provide traceability documentation, test reports, and certificates of conformity (CoC) upon request, facilitating compliance verification for B2B buyers.

Inspection and Testing Methods

Rigorous testing is integral to quality assurance, including:

- In-Circuit Testing (ICT): Detects component defects, shorts, or opens during assembly.

- Functional Testing: Checks dimmer operation, load compatibility, and dimming smoothness.

- High-Voltage Testing: Ensures insulation and safety compliance.

- Environmental Stress Testing: Simulates real-world conditions—temperature cycling, humidity, vibration.

- Burn-In Testing: Operates products under load for extended periods to identify early failures.

Advanced manufacturers often employ automated test stations to increase throughput and accuracy.

Verification of Supplier Quality for International Buyers

B2B buyers from regions with diverse regulatory environments should adopt robust verification protocols:

- Audits: Conduct on-site audits or rely on third-party inspection agencies to assess manufacturing facilities, quality systems, and compliance processes.

- Quality Documentation: Review test reports, calibration certificates, and process control records to verify adherence to standards.

- Third-Party Inspection: Engage independent inspection firms (e.g., SGS, Bureau Veritas) to perform pre-shipment audits, product sampling, and certification verification.

- Supplier Certifications: Prioritize suppliers with internationally recognized certifications such as ISO 9001, ISO 14001, or industry-specific standards like UL or CE.

This approach reduces risks related to substandard components, non-compliance, or product failures in demanding markets.

Considerations for Market-Specific Nuances

For buyers in Africa, South America, the Middle East, and Europe, understanding regional standards and certification requirements is critical. For instance:

- European Markets: Emphasize CE marking, RoHS, and EMC compliance. Ensure products meet the Low Voltage Directive (LVD) and have appropriate electrical safety certifications.

- Middle East and Africa: Verify compliance with local standards (e.g., SASO in Saudi Arabia, EAEU standards). Given diverse regulatory landscapes, sourcing from manufacturers with experience exporting to these regions can streamline certification processes.

- South America: Ensure conformity with regional standards (e.g., INMETRO in Brazil). Consider local certification agencies’ requirements for customs clearance and market acceptance.

Summary

A comprehensive understanding of manufacturing processes and quality assurance mechanisms is vital for B2B buyers sourcing 12V dimmer switches internationally. Reputable manufacturers employ meticulous material selection, advanced assembly techniques, and rigorous testing aligned with global standards. Buyers should actively verify supplier certifications, audit manufacturing facilities, and review detailed QC documentation to ensure product reliability and compliance. Tailoring verification strategies to regional regulatory environments enhances risk mitigation, ensuring that imported dimmer switches meet safety, performance, and environmental standards demanded by end markets.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for 12v dimmer switch Sourcing

Cost Structure Breakdown for 12V Dimmer Switches

Understanding the comprehensive cost components involved in sourcing 12V dimmer switches is crucial for effective pricing negotiations and profitability planning. The primary cost elements include:

-

Materials: High-quality electronic components such as TRIACs, circuit boards, switches, housings, and wiring. The choice between standard and premium materials significantly impacts costs. For example, switches with enhanced durability or certifications (e.g., CE, UL) often command higher material costs.

-

Labor: Manufacturing labor costs vary widely by region. Countries with lower labor rates, such as certain Asian or African manufacturing hubs, offer competitive pricing, whereas European or Middle Eastern facilities may have higher labor costs but often provide higher precision and quality.

-

Manufacturing Overhead: Includes factory utilities, machinery depreciation, and indirect labor. Efficient factories with high automation tend to reduce overhead costs, making their products more price-competitive.

-

Tooling & Setup: One-time costs for molds, fixtures, and tooling are significant for initial production runs. Larger volume orders dilute these costs, resulting in lower unit prices. Customization or unique design features increase tooling expenses.

-

Quality Control & Certifications: Additional costs arise from rigorous testing, certifications, and compliance with international standards. Buyers in regions like Europe and the Middle East often require CE, RoHS, or UL certifications, which can add to costs but enhance product credibility.

-

Logistics & Incoterms: Shipping costs depend on volume, destination, and chosen Incoterms (e.g., FOB, CIF). Sourcing from regions with well-established logistics networks reduces transit times and costs, especially for African or South American buyers dealing with complex customs procedures.

-

Margins: Manufacturers typically aim for a profit margin ranging from 10% to 30%, influenced by order volume, customization, and buyer-supplier relationships.

Price Influencers and Their Impact

Several factors shape the final pricing landscape for 12V dimmer switches:

-

Order Volume & MOQ: Higher volumes significantly lower per-unit costs due to economies of scale. For example, a MOQ of 1,000 units might attract a unit price of $3–$5, whereas smaller orders could range from $6–$10.

-

Specifications & Customization: Standard models are more cost-effective. Custom features—such as specific dimming protocols, waterproofing, or integration with smart home systems—drive up costs due to additional engineering, tooling, and certification needs.

-

Materials & Quality Standards: Opting for high-grade components or certified products increases material costs but reduces warranty and failure risks. For regions with stringent quality expectations, investing in certified products is advisable.

-

Supplier Factors: Established suppliers with proven quality records may charge premium prices but offer reliability. Conversely, emerging manufacturers may provide lower prices but pose risks related to quality consistency.

-

Incoterms & Logistics: FOB terms are preferred for control over shipping, but CIF or DDP options include logistics costs, which should be factored into the total landed cost.

Strategic Tips for International B2B Buyers

-

Negotiate Pricing Based on Volume: Leverage larger purchase commitments to negotiate better unit prices, especially for bulk orders exceeding 5,000 units.

-

Focus on Total Cost of Ownership (TCO): Consider not just the unit price but also shipping, customs duties, warranty, and after-sales support costs. A slightly higher upfront cost might translate into lower TCO if it ensures better durability and compliance.

-

Assess Certification & Quality Standards: Confirm that suppliers provide necessary certifications for your target markets (e.g., CE for Europe, SASO for Saudi Arabia). This reduces risk of customs delays or product rejection.

-

Explore Local Sourcing Options: For regions like the Middle East and Africa, sourcing from nearby manufacturers can reduce logistics costs and lead times. However, verify quality standards and supplier reliability.

-

Build Long-term Relationships: Consistent communication and reliable payment terms foster better pricing and priority production slots, especially critical when dealing with fluctuating demand.

Price Range and Disclaimer

Indicative prices for 12V dimmer switches vary widely depending on specifications, volume, and region. As a rough guide:

- Small Orders (less than 1,000 units): $6–$10 per unit

- Mid-Volume Orders (1,000–5,000 units): $4–$6 per unit

- Large Orders (above 5,000 units): $3–$5 per unit

These figures are approximate and subject to fluctuations based on market conditions, raw material prices, and supplier negotiations. Buyers should conduct detailed supplier assessments and request quotations tailored to their specific requirements.

In summary, effective sourcing of 12V dimmer switches hinges on understanding the intricate cost components, leveraging economies of scale, and navigating regional factors. Strategic negotiations, focus on quality certifications, and comprehensive cost analysis are essential for optimizing procurement outcomes across diverse international markets.

Spotlight on Potential 12v dimmer switch Manufacturers and Suppliers

This section looks at several manufacturers active in the ’12v dimmer switch’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 12v dimmer switch

Key Technical Properties of 12V Dimmer Switches

1. Voltage Compatibility:

A fundamental property is the rated voltage, typically 12 volts DC for these switches. Ensuring compatibility with the power supply is critical to prevent electrical failures or safety hazards. For B2B transactions, sourcing switches with precise voltage ratings ensures reliable operation across various lighting systems, especially in regions with differing power standards.

2. Load Capacity (Wattage):

This specifies the maximum wattage the dimmer can handle, often expressed in watts (W). For example, a 12V dimmer rated for 96W can control up to 8A of current (since Power = Voltage x Current). Selecting a switch with appropriate load capacity prevents overheating, component failure, and ensures long-term durability—key considerations for commercial and industrial applications.

3. Dimming Range and Resolution:

The dimming range indicates the span of brightness adjustment, commonly from 0% (off) to 100% (full brightness). Higher resolution allows finer control over lighting levels, which is essential for creating specific ambiance or energy-saving scenarios. B2B buyers should verify that the dimmer offers a smooth, flicker-free transition, especially in environments requiring consistent lighting quality.

4. Compatibility with Light Types:

Not all light bulbs are compatible with dimmer switches. The switch’s specifications should specify whether it is compatible with LED, CFL, incandescent, or halogen bulbs. For international markets, selecting switches that support the prevalent bulb types ensures customer satisfaction and reduces product returns or complaints.

5. Material Quality and Durability:

Materials such as high-grade fire-resistant plastics and corrosion-resistant metals extend the lifespan of the switch. For B2B buyers, sourcing switches with certified material grades reduces warranty costs and enhances brand reputation, especially in regions with harsher environmental conditions.

6. Compliance and Certifications:

Industry standards such as CE, UL, RoHS, or IEC certification indicate compliance with safety and environmental regulations. These certifications are often mandatory for international trade, ensuring the product meets regional electrical safety standards and can be legally marketed in different countries.

Common Industry and Trade Terms

1. OEM (Original Equipment Manufacturer):

Refers to companies that produce dimmer switches that other brands can rebrand and sell. Understanding OEM options allows B2B buyers to customize products to specific markets or customer requirements, often at lower costs with guaranteed quality.

2. MOQ (Minimum Order Quantity):

The smallest quantity of units a supplier is willing to produce or sell in a single order. Negotiating MOQ is vital for balancing inventory costs and market entry strategies, especially when targeting niche markets or testing new regions.

3. RFQ (Request for Quotation):

A formal request sent to suppliers for pricing and terms for specific products. An RFQ helps buyers compare offers, negotiate better prices, and clarify technical specifications before committing to large orders.

4. Incoterms (International Commercial Terms):

Standardized trade definitions published by the ICC that clarify shipping responsibilities, costs, and risk transfer points between buyer and seller. Familiarity with Incoterms (e.g., FOB, CIF) ensures clear contractual agreements, minimizing misunderstandings in international transactions.

5. Lead Time:

The period between placing an order and receiving the goods. For B2B procurement, understanding lead times helps in planning inventory and avoiding production delays, especially in regions with logistical challenges.

6. Certification and Compliance Standards:

Terms like UL, CE, RoHS denote adherence to safety, environmental, and quality standards. Ensuring products meet these standards is crucial for market access and regulatory compliance across different regions.

Summary for B2B Buyers

Focusing on these technical properties and industry terms enables informed decision-making when sourcing 12V dimmer switches for international markets. Prioritizing compatibility, safety certifications, and supplier terms ensures smooth procurement processes, minimizes risks, and aligns product offerings with regional standards. Understanding these key specifications and trade terminology supports strategic planning, enhances product quality, and ultimately delivers better value to end customers worldwide.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 12v dimmer switch Sector

Market Overview & Key Trends

The global market for 12V dimmer switches is experiencing significant growth driven by rising demand for energy-efficient and customizable lighting solutions across various sectors. Key drivers include increasing urbanization, smart home integration, and regulatory pressures for sustainability, especially in regions like Europe, the Middle East, Africa, and South America. In Europe, stringent energy efficiency standards and a focus on smart building automation foster demand for advanced dimmer technologies compatible with LED and CFL lighting. Middle Eastern markets, particularly the UAE and Saudi Arabia, are expanding their infrastructure projects, emphasizing modern, energy-conscious lighting controls. Africa and South America are witnessing rapid urban development and increased adoption of smart lighting, though market penetration remains uneven due to supply chain and cost considerations.

Emerging B2B sourcing trends include a shift toward modular, IoT-enabled dimmer solutions that facilitate remote management and integration with broader smart building systems. Manufacturers are increasingly offering customizable, scalable options that meet diverse regional standards and voltage requirements. International buyers are prioritizing suppliers with robust supply chains capable of delivering high-quality, certified products swiftly. Additionally, there is a notable rise in sourcing from regions with mature manufacturing ecosystems, such as Southeast Asia and Eastern Europe, which offer competitive pricing and technological innovation.

Market dynamics are also shaped by the transition from traditional incandescent-compatible dimmers to those optimized for LED and low-voltage applications. Buyers are seeking products with longer lifespan, improved flicker-free performance, and compliance with local safety and energy regulations. As the industry evolves, companies that can offer innovative, reliable, and cost-effective solutions will secure a competitive edge, especially in emerging markets where modernization efforts are accelerating.

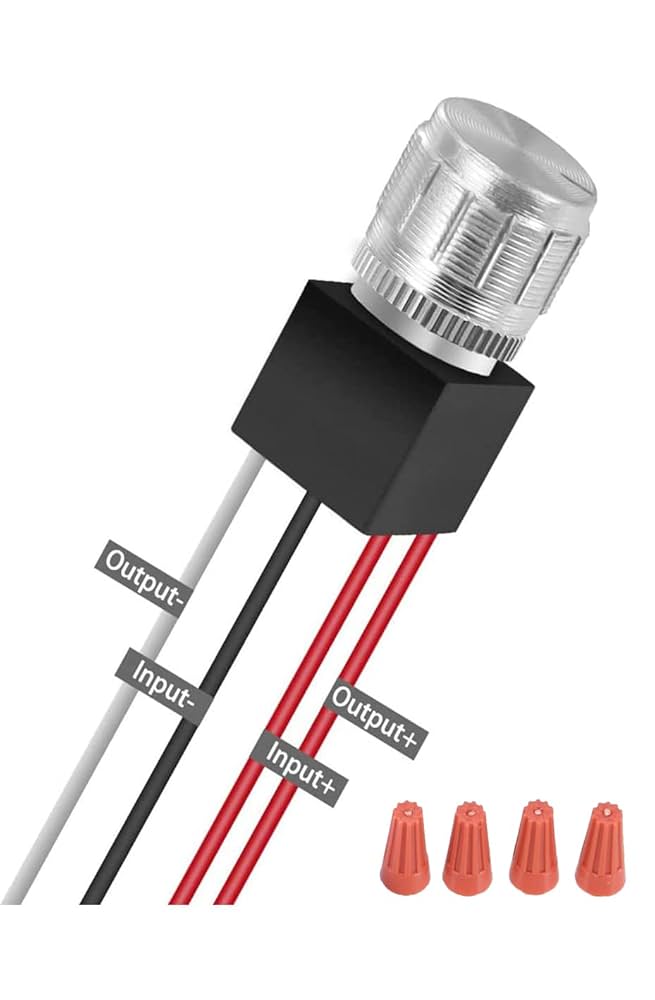

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central concern in the sourcing of 12V dimmer switches, driven by both regulatory requirements and corporate social responsibility commitments. The environmental impact of electronic components, including the extraction of raw materials like rare earth elements and conflict minerals, necessitates a focus on ethical sourcing practices. International buyers from Africa, South America, the Middle East, and Europe are increasingly scrutinizing supply chains to ensure compliance with environmental standards and human rights laws.

Certifications such as RoHS (Restriction of Hazardous Substances), WEEE (Waste Electrical and Electronic Equipment), and ISO 14001 are now standard benchmarks for ethically sourced electronic components. Green certifications also encompass the use of eco-friendly materials—such as recyclable plastics, low-impact circuit board substrates, and sustainably sourced metals—reducing the carbon footprint of manufacturing processes. Suppliers that demonstrate transparency through supply chain traceability and third-party audits are gaining favor among conscientious buyers.

Moreover, adopting sustainable practices can enhance product appeal in environmentally conscious markets. For instance, offering dimmers with energy-saving features, long-lasting components, and recyclable packaging aligns with global efforts to reduce electronic waste. Investing in eco-friendly manufacturing not only mitigates environmental risks but also provides a competitive advantage by meeting evolving regulatory standards and consumer expectations for greener products.

Brief Evolution/History (Optional)

The development of 12V dimmer switches has evolved considerably since their inception, paralleling advances in electronic control systems. Initially designed for incandescent lighting, early dimmers relied on simple rheostats and basic phase-cutting technology. With the advent of solid-state electronics, modern dimmers transitioned to TRIAC-based circuits, enabling more precise control and compatibility with low-voltage LED and CFL lighting.

Over the past two decades, integration with smart home ecosystems and IoT connectivity has transformed dimmer switches into multifunctional devices capable of remote operation, scheduling, and energy monitoring. This evolution reflects a broader shift toward automation and energy efficiency in commercial and residential sectors worldwide. For international B2B buyers, understanding this technological progression is vital for sourcing solutions that are future-proof, scalable, and compliant with regional standards, ensuring long-term value and adaptability in diverse markets.

Related Video: Trade and tariffs | APⓇ Microeconomics | Khan Academy

Frequently Asked Questions (FAQs) for B2B Buyers of 12v dimmer switch

-

How can I verify the credibility and reliability of a 12V dimmer switch supplier?

To ensure supplier credibility, thoroughly review their business credentials, such as ISO or CE certifications, and request references from previous international clients. Evaluate their experience in exporting electrical components, especially dimmer switches, and check for a proven track record of timely deliveries. Conduct virtual or in-person audits if possible, and verify their manufacturing capabilities through factory visits or third-party inspection reports. Additionally, assess their communication responsiveness and willingness to share detailed product documentation, including test reports and quality assurance processes, to mitigate risks in international trade. -

Can suppliers customize 12V dimmer switches to meet specific regional standards or client requirements?

Yes, many reputable manufacturers offer customization options tailored to regional standards, voltage specifications, or specific client needs. For international buyers, ensure the supplier is familiar with regional certifications such as CE, RoHS, or UL, and can provide compliant products. Customization may include adjusting the dimmer’s load capacity, input voltage range, casing design, or integration with smart home systems. Clarify upfront whether customization incurs additional costs or lead times, and request prototypes or sample approvals before bulk production to guarantee product conformity. -

What are typical minimum order quantities (MOQs) and lead times for bulk procurement of 12V dimmer switches?

MOQs for 12V dimmer switches vary depending on the supplier, often ranging from 500 to 5,000 units for standard models. Custom or OEM products generally require higher MOQs. Lead times typically span 4 to 8 weeks from order confirmation, depending on the supplier’s manufacturing capacity, stock availability, and customization complexity. To optimize supply chain planning, negotiate flexible MOQs and confirm stock levels or production schedules early. Establish clear timelines, including prototypes, mass production, and shipping, to align with your project deadlines. -

What payment terms and conditions are common in international transactions for dimmer switch purchases?

Common international payment methods include Telegraphic Transfer (T/T), Letters of Credit (L/C), and sometimes PayPal for smaller orders. T/T is preferred for straightforward transactions, often with 30% upfront deposit and 70% balance upon shipment or delivery. Letters of Credit provide security for both parties but may involve higher bank fees and longer processing times. Negotiate payment terms that balance risk and cash flow, and consider using escrow services or trade financing options. Always clarify currency options, bank charges, and applicable taxes to avoid unexpected costs. -

What quality assurance (QA) measures and certifications should I expect from a reputable dimmer switch manufacturer?

Leading suppliers should provide comprehensive QA documentation, including CE, RoHS, UL, or ETL certificates, confirming compliance with regional safety and environmental standards. They should implement strict incoming material inspection, in-process testing, and final product testing, including load capacity, electrical safety, and durability. Request detailed test reports and quality control procedures. Additionally, consider suppliers with ISO 9001 certification, indicating a robust quality management system. Regular third-party audits or factory inspections can further assure consistent product quality for long-term supply reliability. -

How do I manage logistics, shipping costs, and customs clearance for international delivery of dimmer switches?

Coordinate with suppliers experienced in international shipping, preferably with established freight forwarding partners. Clarify Incoterms (e.g., FOB, CIF) to define responsibility for shipping costs and risks. Choose reliable carriers such as DHL, FedEx, or sea freight options for cost efficiency, depending on order volume and urgency. Prepare all necessary customs documentation, including commercial invoices, packing lists, and certificates of origin. Engage local customs brokers if needed to expedite clearance, and stay updated on import tariffs and regulations in your country to avoid delays or unexpected charges. -

What steps should I take if I face disputes or quality issues with the supplier’s dimmer switches?

First, document all communications, inspection reports, and photographs evidencing the issue. Review the purchase agreement and warranty terms to understand your rights. Contact the supplier promptly, providing detailed evidence, and request a resolution such as replacement, repair, or refund. Negotiate in good faith, leveraging any quality certifications or test reports as proof of defect. If unresolved, escalate through arbitration clauses in the contract or seek assistance from trade associations or legal counsel specializing in international trade disputes. Establishing clear quality standards and inspection procedures upfront can prevent such issues. -

What are key considerations for ongoing supplier evaluation and building long-term partnerships?

Develop a comprehensive supplier evaluation framework that includes quality consistency, on-time delivery, communication responsiveness, and compliance with regional standards. Regularly review their production capacity, financial stability, and ability to scale with your demand. Foster transparent communication, including sharing forecasts and feedback, to build trust. Consider visiting their manufacturing facilities periodically or commissioning third-party audits. Building strategic relationships with reliable suppliers can lead to better pricing, priority service, and access to innovations, ensuring your supply chain remains resilient amid regional or global disruptions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 12v dimmer switch

Strategic Sourcing Outlook for 12V Dimmer Switch

Effective strategic sourcing remains critical for international B2B buyers seeking reliable, high-quality 12V dimmer switches. Prioritizing reputable manufacturers with proven compliance to safety standards, innovative technology, and scalable supply chains ensures long-term competitiveness. Diversifying sourcing channels—such as exploring manufacturers from Asia, Europe, and emerging markets—can mitigate risks and unlock cost efficiencies.

Illustrative Image (Source: Google Search)

As demand for smart and energy-efficient lighting solutions grows across Africa, South America, the Middle East, and Europe, buyers should focus on establishing partnerships that support customization, rapid delivery, and after-sales support. Embracing digital procurement tools and supplier evaluations will enhance transparency and foster resilient supply networks.

Looking ahead, the evolving landscape of smart lighting and IoT integration presents significant opportunities. Proactive engagement with innovative suppliers and continuous market analysis will position buyers to capitalize on technological advancements and regulatory shifts. Now is the time for international B2B buyers to refine their sourcing strategies—building robust, adaptable supply chains that meet future demands and drive sustainable growth in the global lighting industry.

Illustrative Image (Source: Google Search)