Article Contents

Industry Insight: Glue Led Strip

The commercial and industrial lighting sector demands LED solutions engineered for relentless performance, stringent safety, and seamless integration into demanding environments. Glue LED strips, specifically designed with robust adhesive backing for secure, vibration-resistant mounting on diverse substrates like metal beams, concrete, and machinery, have become indispensable for task lighting, under-shelf illumination, cove lighting in retail, and safety marking in warehouses and factories. However, the critical nature of these applications necessitates far more than basic illumination; adherence to rigorous safety and performance standards is non-negotiable. Certifications such as ETL (verifying compliance with North American safety standards) and CE (indicating conformity with European health, safety, and environmental requirements) are essential markers, ensuring electrical safety, reliable operation, and regulatory acceptance for installers, facility managers, and end-users. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over two decades of specialized expertise to this demanding market. We have consistently engineered high-reliability glue LED strips and associated power solutions specifically built to meet and exceed the exacting demands of commercial and industrial projects, where durability, certified safety, and consistent light output are paramount to operational success and longevity.

Technical Specs & Certifications

The glue LED strip offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability in both residential and commercial lighting applications. These strips feature a high lumen efficacy, typically delivering between 110 to 130 lumens per watt, depending on the specific configuration and color temperature. This efficiency ensures optimal energy consumption while maintaining bright, consistent illumination across extended run lengths.

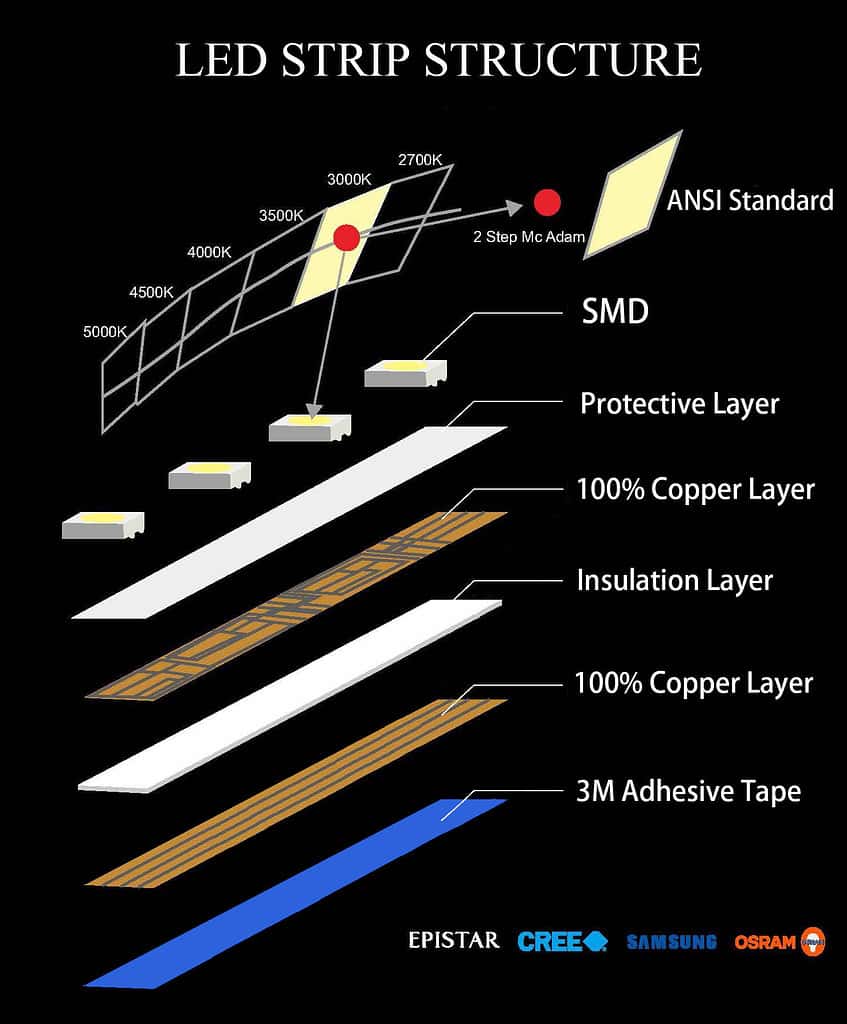

A key highlight of Beauty STC’s glue LED strips is their exceptional color rendering capability. The strips are designed with high-quality SMD LEDs—commonly 2835 or 5050 types—that achieve a Color Rendering Index (CRI) greater than 90. This high CRI ensures accurate and vibrant color representation, making the strips ideal for environments where true color perception is critical, such as retail displays, art galleries, and high-end architectural lighting.

In terms of environmental protection, Beauty STC provides multiple Ingress Protection (IP) rating options to suit various installation conditions. The standard non-coated strip is rated IP20, suitable for dry indoor environments. For damp or outdoor applications, the strips are available with silicone coating or full encapsulation, achieving IP65, IP67, or even IP68 ratings. These higher IP ratings ensure resistance to dust, moisture, and temporary or prolonged submersion, depending on the version, allowing for versatile use in kitchens, bathrooms, outdoor signage, and landscape lighting.

Beauty (STC) Manufacturing Co., Ltd. maintains stringent quality control throughout the production process. Each glue LED strip undergoes rigorous testing for solder joint integrity, adhesive bond strength, thermal performance, and photometric consistency. The use of premium phosphor coatings, consistent binning of LEDs, and high-purity flexible PCB materials contribute to uniform light output and extended lifespan—often exceeding 50,000 hours at L70. This commitment to quality ensures long-term reliability, minimal lumen depreciation, and superior performance in real-world conditions.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is strategically located in Jiangmen, Guangdong Province, China. This modern factory benefits from excellent infrastructure and proximity to key supply chain hubs like Shenzhen and Hong Kong, facilitating efficient logistics for both raw material sourcing and global shipment of finished goods. The facility operates under strict ISO 9001 quality management systems and features dedicated cleanroom environments for critical processes like Surface Mount Technology (SMT) assembly, ensuring a controlled atmosphere free from contaminants that could compromise component placement and soldering integrity. The Jiangmen plant is designed for high-volume production while maintaining the flexibility required for diverse customer specifications, particularly in the competitive LED strip lighting market.

Our SMT production lines are equipped with state-of-the-art high-speed placement machines, primarily from Yamaha and Fuji NXT series. Key assets include Yamaha YSM20 and Fuji NXT III platforms, capable of placing components at speeds exceeding 100,000 components per hour with exceptional accuracy down to ±25µm. These machines handle a wide range of component sizes, from ultra-small 0201 metric passives to larger integrated circuits and LED packages essential for strip production. The lines incorporate advanced vision systems for precise component alignment and automated optical inspection (AOI) stations immediately post-reflow soldering to verify solder joint quality, component presence, polarity, and alignment against IPC-A-610 standards. This robust SMT capability forms the foundation for producing reliable, high-density LED strips with consistent performance.

Rigorous aging and reliability testing are non-negotiable steps within our quality control protocol at the Jiangmen facility. Completed LED strips undergo mandatory aging tests in dedicated environmental chambers. Standard aging involves continuous operation at elevated temperatures typically between 60°C and 70°C for a minimum of 24 hours, often extended to 48 hours for critical orders or new product introductions. During this period, strips operate at full rated power. We monitor for early failure modes such as LED dropouts, color shift, or driver instability. Beyond basic thermal aging, we conduct extensive environmental stress testing including thermal cycling between -20°C and +60°C, humidity exposure tests at 85% RH, and salt spray testing for waterproof variants. Statistical process control data from these aging tests is meticulously analyzed to drive continuous improvement in our manufacturing processes and component selection.

Beauty STC possesses comprehensive OEM capabilities specifically tailored for adhesive-backed LED strips, commonly referred to as “glue led strips” in the industry. We offer extensive customization options starting from the reel level. Customers can specify exact cut lengths, reel packaging configurations including reel diameter and core type, and custom labeling with brand logos, specifications, or barcodes. Our engineering team works closely with clients to select the optimal LED package type, density, color temperature binning, and CRI requirements. We provide multiple waterproofing levels from basic silicone coating (IP65) to fully encapsulated strips in flexible PVC or silicone tubes (IP67/IP68), utilizing specialized extrusion and potting lines within the Jiangmen factory. Crucially, we offer flexibility in the adhesive system, including standard pressure-sensitive acrylic tapes and high-performance variants for demanding substrates or elevated temperature environments. Our SMT and assembly lines are configured to handle both low-volume prototype runs and high-volume production seamlessly, ensuring consistent quality and rapid time-to-market for our OEM partners’ branded products.

Application Scenarios

Glue LED strip lighting is widely used across various commercial environments including hotels, malls, and offices due to its versatility, sleek appearance, and ease of installation. The adhesive backing on these strips allows for quick and secure mounting on a variety of surfaces, making them ideal for both functional and decorative lighting applications.

In hotels, glue LED strips are commonly installed under cabinets in guest room minibars, along cove ceilings in lobbies, beneath bed frames for ambient lighting, and within wardrobe interiors to enhance visibility. They contribute to a modern, luxurious atmosphere and are often used in corridors and restrooms for low-level accent lighting. The discreet nature of LED strips complements high-end interior designs without drawing attention to the light source itself.

In malls and retail environments, glue LED strips are frequently applied to highlight product displays, illuminate signage, and accent architectural features such as columns, stairs, and ceiling details. They are also used in ceiling coves and under shelves in kiosks to create inviting and well-lit shopping areas. The uniform light output helps emphasize merchandise and improves the overall visual appeal of the space.

In office settings, glue LED strips can be installed under desks, within partition cove areas, or behind monitors to reduce eye strain and create a comfortable working environment. They are also used in reception areas, meeting rooms, and hallways for both task and decorative lighting. Their energy efficiency and long lifespan make them a cost-effective lighting solution for commercial spaces with extended operating hours.

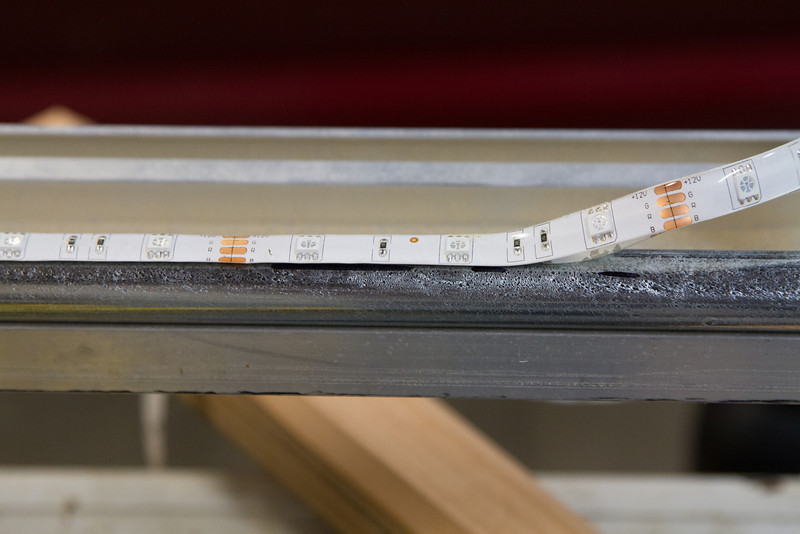

When installing glue LED strips, proper surface preparation is essential. The mounting surface should be clean, dry, and free of dust, grease, or debris to ensure strong adhesion. Wiping the area with isopropyl alcohol before application can improve bond strength. For best results, press the strip firmly along its entire length during installation, especially in corners or along curves.

Avoid installing LED strips on uneven or porous surfaces where adhesion may fail over time. In high-temperature environments or areas subject to vibration, consider using additional mechanical fasteners such as clips or brackets to reinforce the strip. Also, ensure that the LED strip is compatible with the power supply and dimming system being used to avoid performance issues.

For outdoor or high-moisture areas, even if using a glue-backed strip, verify that the product has an appropriate IP rating for the environment. In such cases, silicone adhesive or sealant may be used to supplement the backing and protect against moisture ingress.

Proper planning of run length and power distribution is crucial to avoid voltage drop, especially in long installations. For extended runs, it is recommended to feed power from both ends or use a higher voltage system where applicable. Always follow manufacturer guidelines for maximum run lengths and circuit loading.

By selecting the right color temperature—such as warm white for hospitality spaces and cool white for offices—and strategically placing the strips, glue LED lighting can significantly enhance the functionality and aesthetic quality of any commercial environment.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s premium adhesive LED strips engineered for seamless integration and lasting performance. As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I validate that our strips deliver superior adhesion, uniform illumination, and thermal stability even in demanding environments—critical for architectural, retail, and residential applications where reliability cannot be compromised. Partner with us to access custom solutions backed by rigorous quality control and responsive engineering support throughout your product lifecycle.

Elevate your offerings by collaborating with a trusted manufacturing partner committed to innovation and precision. Contact our dedicated team at [email protected] to discuss how Beauty STC’s adhesive LED strips can meet your specific requirements and accelerate your time to market. Let us engineer the brilliance your projects deserve.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.