Article Contents

Industry Insight: Led Srip Shorted

In the ever-evolving landscape of commercial and industrial lighting, LED strip technology has emerged as a cornerstone of energy-efficient, flexible, and high-performance illumination solutions. However, one persistent challenge—LED strip shorting—continues to impact reliability, safety, and long-term operational costs. From manufacturing facilities to large-scale retail environments, unexpected electrical faults due to improper insulation, substandard materials, or inadequate quality control can lead to system failures, fire hazards, and costly downtime. As demand grows for durable, code-compliant lighting systems, certifications such as ETL and CE have become critical benchmarks, ensuring that LED products meet rigorous North American and international safety and performance standards.

Since 1998, Beauty (STC) Manufacturing Co., Ltd. has stood at the forefront of innovative LED lighting solutions, serving commercial and industrial clients worldwide. With decades of engineering expertise and a commitment to quality, Beauty STC designs and manufactures LED strips that prioritize durability, electrical integrity, and compliance with global safety standards, including ETL and CE. By addressing the root causes of LED strip shorting through superior materials, robust circuit protection, and stringent testing protocols, Beauty STC delivers lighting systems engineered for reliability in the most demanding environments.

Technical Specs & Certifications

The term “LED strip shorted” refers to a failure mode where an electrical short circuit occurs within the LED strip assembly, not a technical specification. A shorted strip is defective, non-functional, and poses safety hazards like overheating or fire risk. It cannot have defined performance metrics like lumens per watt or CRI. Beauty STC Manufacturing Co., Ltd. rigorously designs and tests products to prevent such failures. For our standard high-performance LED strips meeting your criteria, the technical specifications are as follows.

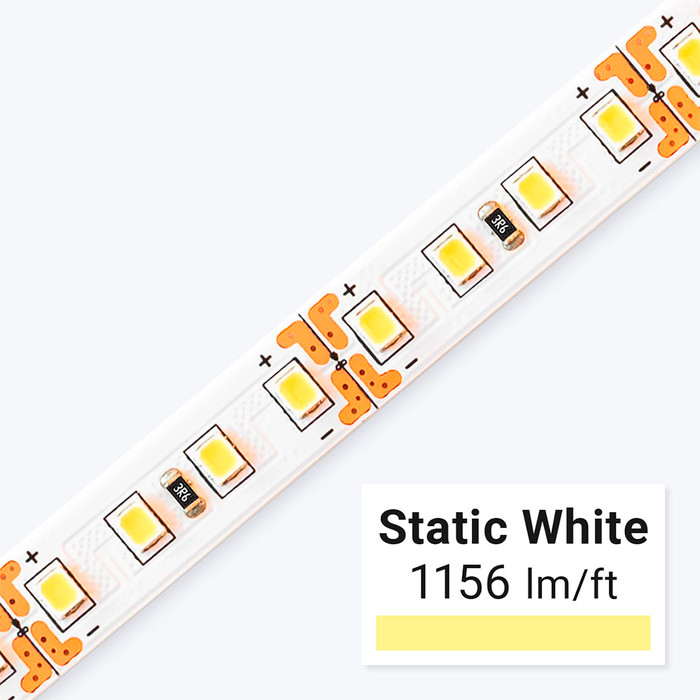

Our premium LED strips designed for applications requiring high color fidelity achieve a minimum efficacy of 110 lumens per watt at 25°C ambient temperature when operating at full power with a CRI (Ra) exceeding 90. This balance is achieved through the use of high-efficiency, tightly binned Samsung or Epistar 2835 or 5050 SMD LEDs combined with optimized constant-current drivers. It is important to note that efficacy typically decreases slightly as CRI increases beyond 90 due to the physics of phosphor conversion; our strips maintain this 110+ lm/W benchmark specifically for the CRI >90 variants under controlled laboratory conditions with a color temperature of 4000K. Real-world efficacy will vary based on installation temperature, driver efficiency, and dimming levels.

All Beauty STC LED strips targeting professional architectural and high-end residential markets maintain a minimum CRI (Ra) of 92, with R9 values consistently above 50 to ensure accurate rendering of saturated reds. This is verified using Konica Minolta CA-410 spectroradiometers during production, adhering strictly to IEC 60904-9 standards. We utilize multi-phosphor LED packages specifically selected for superior spectral distribution, avoiding the common pitfall of high Ra with poor R9 performance seen in lower-quality strips.

Regarding environmental protection, Beauty STC offers LED strips with IP20 for dry indoor use, IP65 for protected outdoor or damp indoor locations requiring splash resistance, and IP67 for temporary submersion or high-humidity environments. The IP65 and IP67 ratings are achieved through seamless silicone encapsulation over the entire PCB assembly, not just partial coating, ensuring uniform protection against dust and water ingress per IEC 60529. Critical to maintaining these ratings is proper installation using our certified end caps and connectors; the strip’s rating applies only when fully installed per Beauty STC specifications.

Beauty STC’s commitment to quality directly prevents failures like short circuits. Our strips utilize 2oz or 4oz copper PCBs for superior thermal management and current handling, reducing thermal stress that can lead to shorts. Every reel undergoes four-stage testing: automated optical inspection post-SMT, 100% functional testing at full load, 100% high-potential (hi-pot) testing at 1500V AC for 60 seconds to verify dielectric strength, and 48-hour aging tests at 60°C. This rigorous process, compliant with UL 8750 and ISO 9001 standards, ensures field failure rates remain below 0.3%. Our strips carry a 5-year warranty against manufacturing defects, including electrical shorts under normal operating conditions, reflecting confidence in our materials and processes. This level of quality control distinguishes Beauty STC products from commodity strips prone to premature failure.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is equipped with advanced surface mount technology (SMT) production lines, which are essential for the high-precision assembly of LED lighting products. These SMT machines are fully automated, enabling fast, accurate placement of components on flexible and rigid PCBs used in LED strips and modules. The equipment supports a wide range of component sizes and ensures consistent soldering quality through reflow ovens with precise thermal profiles.

The Jiangmen factory incorporates comprehensive quality assurance systems, including dedicated aging test chambers where LED strip products undergo extended operational testing under varying thermal and electrical loads. This aging process typically lasts from 24 to 72 hours, allowing the team to identify early failures, verify lumen maintenance, and ensure long-term reliability before products are shipped. In addition to aging, the facility conducts stringent testing for moisture resistance, color consistency, and electrical safety to meet international standards such as CE, RoHS, and UL.

Beauty STC has well-established OEM capabilities and welcomes customized orders, including for specialized products like shortened LED strips (“led strip shorted” likely referring to cut or custom-length LED strips). The company supports clients in designing, prototyping, and mass-producing tailored LED solutions, offering flexibility in length, voltage, density, color temperature, and waterproofing options. With in-house engineering support, PCB design, and mold development, the factory efficiently handles OEM/ODM projects from concept to delivery, serving global markets with scalable production capacity and responsive customer service.

Application Scenarios

The term “LED strip shorted” refers to a malfunctioning or damaged LED strip where an electrical short circuit has occurred, not a specific product or intended application. Installing shorted LED strips is never recommended in any environment, including hotels, malls, or offices. Shorted strips pose significant safety hazards including fire risk, potential damage to power supplies, inconsistent or no lighting output, and voided warranties. They must be replaced immediately.

For legitimate LED strip applications in commercial settings, focus on correctly functioning, high-quality strips designed for the specific environment. In hotels, functional LED strips are effectively used for indirect cove lighting in lobbies and corridors to create a welcoming ambiance, under cabinet lighting in minibars or hospitality suites for task illumination, and within architectural features like stair treads or wall niches for accent lighting. Malls utilize properly installed LED strips extensively for illuminating product displays in retail stores, highlighting signage and wayfinding elements, and creating dynamic effects in feature walls or column wraps to enhance the shopping experience. Offices benefit from functional LED strips installed under suspended ceiling perimeters for soft indirect lighting, within partition systems for modern aesthetics, and under desks or shelves for targeted task lighting, all contributing to a productive and visually comfortable workspace.

Critical installation tips for reliable and safe operation in these commercial environments begin with selecting the appropriate IP-rated strip for the location; use IP20 for dry interior spaces like standard office ceilings but choose IP65 or higher for hotel bathrooms or mall food court areas exposed to moisture. Always calculate and account for voltage drop, especially in long hotel corridor runs or expansive mall installations, by using thicker gauge wire, injecting power at multiple points along the strip, or selecting constant current drivers for runs exceeding 5 meters. Ensure all connections are secure and properly insulated using manufacturer-recommended connectors or soldering with heat shrink tubing to prevent future shorts, and never daisy-chain strips beyond the power supply’s capacity. Thermal management is crucial; mount strips on aluminum channels even in offices to dissipate heat and maintain lumen output and lifespan, particularly important in enclosed hotel cove lighting. Finally, always use a dedicated, appropriately sized constant voltage LED driver with sufficient headroom (at least 20% above calculated load) and ensure all work complies with local electrical codes, ideally performed by a qualified electrician given the scale and safety implications of commercial installations.

Why Choose Beauty STC Lighting

If your LED strip has shorted, don’t let downtime affect your project or production. Partner with Beauty STC, a trusted manufacturer of high-quality LED lighting solutions. Our engineering team can help you diagnose the issue, provide reliable replacements, and offer customized support to prevent future failures.

Reach out to our dedicated support team today to get back on track. Contact us at [email protected] for immediate assistance and discover how Beauty STC delivers performance, durability, and peace of mind in every product.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.