Article Contents

Industry Insight: Led Sheet Panel

The commercial and industrial lighting sector continues its decisive shift toward LED sheet panels, driven by the relentless pursuit of energy efficiency, operational cost reduction, and superior light quality in demanding environments. From expansive warehouses and manufacturing facilities to modern office complexes and healthcare institutions, these slim, uniform luminaires have largely superseded traditional fluorescent troffers and bulky fixtures. Their appeal lies not only in significant energy savings and extended lifespans but also in providing glare-free, high-CRI illumination essential for productivity, safety, and occupant well-being. Crucially, market acceptance hinges on rigorous safety and performance validation; panels bearing ETL certification for the North American market and CE marking for Europe are non-negotiable requirements, assuring facility managers and specifiers of compliance with stringent electrical safety and electromagnetic compatibility standards. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution. With over two decades of dedicated engineering expertise in LED technology, we understand the exacting demands of commercial and industrial applications. Our commitment to innovation, quality manufacturing, and adherence to global certifications like ETL and CE positions Beauty STC as a trusted partner for professionals seeking reliable, high-performance LED sheet panel solutions that deliver tangible value and illuminate spaces effectively for years to come. The industry is evolving beyond basic illumination, and Beauty STC is engineered to meet that future.

Technical Specs & Certifications

The LED sheet panel offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability in commercial and residential lighting applications. These panels are designed to deliver uniform, glare-free illumination while maintaining exceptional energy efficiency and color accuracy.

In terms of efficiency, our LED sheet panels achieve a luminous efficacy ranging from 120 to 150 lumens per watt, depending on the model and size. This high lumen-to-watt ratio ensures significant energy savings over traditional lighting solutions without compromising brightness or coverage. The panels utilize high-efficiency SMD LEDs paired with optimized driver technology to maintain consistent output and longevity.

Color Rendering Index (CRI) is a critical factor in lighting quality, especially in environments where accurate color representation is essential, such as retail spaces, offices, and healthcare facilities. Beauty STC’s LED sheet panels are manufactured with CRI values exceeding 90, with select models reaching up to 95. This ensures natural and vibrant color reproduction, enhancing visual comfort and clarity.

Regarding environmental protection and durability, our LED sheet panels are available in various IP (Ingress Protection) ratings to suit different installation environments. Standard models typically feature an IP40 rating, protecting against solid objects larger than 1mm, making them ideal for indoor, dry locations. For applications requiring enhanced protection—such as in damp or dusty environments—we offer IP54-rated panels, which provide safeguards against limited dust ingress and water splashing from any direction. These ratings ensure reliable operation in a wide range of conditions.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process. Our LED sheet panels are constructed using high-grade materials, including precision diffusers and aluminum frames for effective heat dissipation. Each unit undergoes strict testing for photometric performance, thermal management, and electrical safety to meet international standards such as CE, RoHS, and ISO 9001. This commitment to quality ensures long service life, stable performance, and customer satisfaction across global markets.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province serves as our primary production hub for advanced LED lighting solutions, including LED sheet panels. The factory is a modern, vertically integrated operation spanning approximately 35,000 square meters, designed to stringent international quality and environmental standards.

Regarding SMT capabilities, the Jiangmen facility houses multiple high-speed Yamaha YS series SMT production lines. These lines feature precision placement machines capable of handling components down to 0201 metric package size, essential for the dense PCB layouts of modern LED panels. Each line integrates automated solder paste inspection (SPI) systems, 8-zone nitrogen-assisted reflow ovens with precise thermal profiling, and automated optical inspection (AOI) stations operating both pre- and post-reflow. This setup ensures exceptional placement accuracy (±25µm) and solder joint reliability critical for maintaining uniform light output and thermal management in slim-profile LED sheet panels.

Aging and reliability testing represent a cornerstone of our quality process. All LED sheet panels undergo mandatory 24-hour continuous aging tests at 60°C ambient temperature, simulating extended operational stress. This occurs in dedicated climate-controlled aging rooms equipped with real-time monitoring systems that track lumen maintenance, chromaticity shift, and driver performance. Panels exceeding 0.5% lumen depreciation or 0.005 Δuv shift during aging are automatically flagged for rework. Additionally, we conduct accelerated life testing per IES LM-80 and TM-21 standards, with samples subjected to 6,000+ hours of testing to validate L70/L90 lifetime projections for customer-specific thermal designs.

Our OEM capabilities for LED sheet panels are comprehensive and flexible. We support full customization from initial design through mass production, accommodating specifications including ultra-thin profiles (as low as 6mm), custom dimensions (up to 1200x600mm), multiple frame finishes (anodized aluminum, powder-coated, frameless), and diverse optical options (diffusers, prismatic lenses, batwing distributions). Electrical customization covers AC input voltages (100-277V), integrated drivers with DALI-2, 0-10V, or Bluetooth Mesh dimming, and CRI options from 80 to 98. We maintain UL/cUL, CE, and TÜV-certified production lines, enabling rapid prototyping within 15 days and scalable production up to 500,000 units monthly. All OEM projects benefit from our in-house optical simulation, thermal modeling, and photometric testing labs, ensuring performance validation against customer requirements before volume production.

Application Scenarios

LED sheet panels are widely used in commercial and institutional environments due to their slim profile, energy efficiency, uniform light distribution, and modern aesthetic. They are particularly well-suited for indoor applications where consistent, glare-free illumination is essential. Common applications include hotels, malls, and offices, each benefiting from the panels in different ways.

In hotels, LED sheet panels are ideal for lobbies, guest corridors, conference rooms, and back-of-house areas. Their clean, bright light enhances the ambiance of reception areas and creates a welcoming environment. In guest room corridors, the uniform lighting ensures safety and comfort. The low heat output and long lifespan reduce maintenance needs, which is crucial in 24/7 operations.

Malls utilize LED sheet panels extensively in ceiling grids within retail spaces, walkways, food courts, and restrooms. The panels provide even illumination that highlights merchandise and enhances the shopping experience. Their slim design integrates seamlessly into suspended ceiling systems, maintaining a sleek and modern look throughout large open areas. Energy savings over time make them a cost-effective choice for high-traffic venues with long operating hours.

Offices are among the most common applications for LED sheet panels. They are installed in open-plan workspaces, private offices, meeting rooms, and reception areas. The diffused, flicker-free light reduces eye strain and supports productivity and employee well-being. Their compatibility with daylight sensors and dimming systems allows for smart lighting control, contributing to energy efficiency and compliance with green building standards.

When installing LED sheet panels, several best practices should be followed. First, ensure the ceiling structure is compatible—most panels are designed for drop ceiling grid systems (e.g., T-bar ceilings) or surface mounting. Verify the panel dimensions match the ceiling grid size, commonly 2×2 ft or 2×4 ft. Always turn off power before installation to ensure safety. For recessed installations, confirm adequate ceiling plenum space for the panel and any required drivers or ballasts. If surface mounting, use appropriate brackets and ensure secure attachment to prevent sagging. Align panels carefully to maintain a uniform appearance, especially in large arrays. Finally, consider thermal management—avoid installing in enclosed fixtures unless the panel is rated for such use, and allow for some airflow around the unit to prolong lifespan.

Proper installation and placement will maximize the performance, longevity, and visual appeal of LED sheet panels across all these environments.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium LED sheet panels, engineered for superior performance, energy efficiency, and seamless integration into commercial and architectural applications. As a trusted leader in innovative LED solutions, we deliver precision-engineered panels that meet rigorous quality standards while offering exceptional brightness uniformity and thermal management. Partner with Beauty STC to access cutting-edge technology, customizable design support, and dedicated engineering expertise tailored to your specific project requirements. Our commitment to reliability and sustainability ensures long-term value for your clients and end-users. Reach out today to discuss how our LED sheet panels can enhance your portfolio and drive mutual growth. Contact our dedicated partnership manager directly at [email protected] to initiate a collaboration that illuminates success.

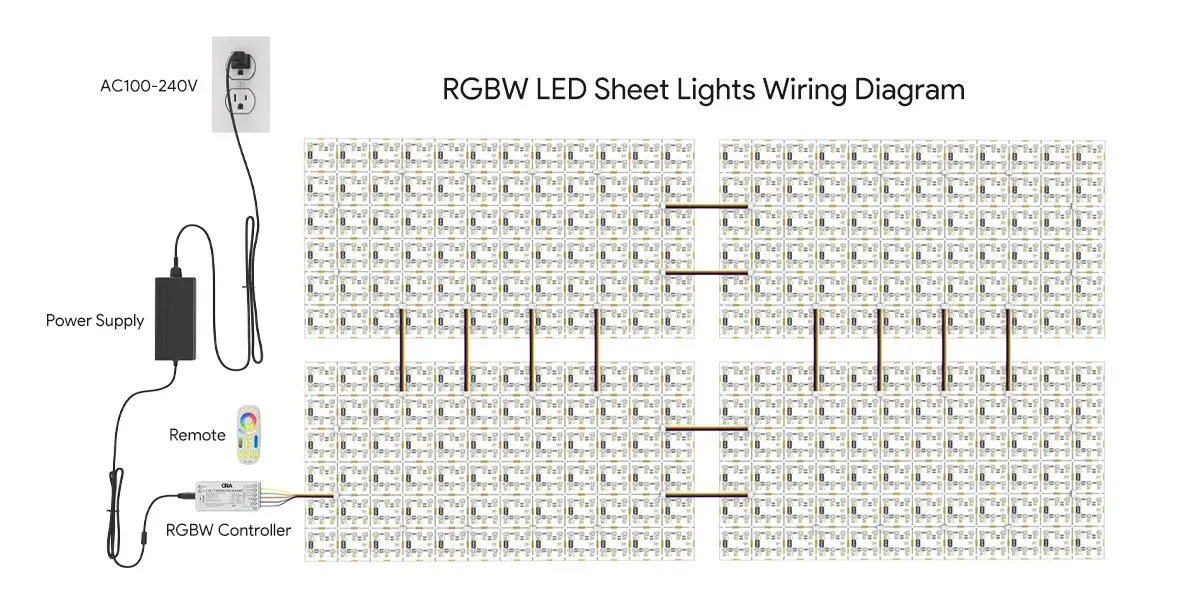

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.