Article Contents

Industry Insight: Cob Led Vs Led

In the rapidly evolving landscape of commercial and industrial lighting, the choice between COB (Chip-on-Board) LED technology and traditional LED solutions has become a pivotal consideration for facility managers, engineers, and lighting designers. As energy efficiency, maintenance costs, and illumination quality continue to drive decision-making, understanding the performance distinctions between COB LED and standard LED fixtures is essential. COB LEDs, known for their high lumen density, uniform light output, and reduced glare, are increasingly favored in high-bay lighting, warehouses, and manufacturing facilities where consistent, bright illumination is critical. Meanwhile, conventional LED arrays remain relevant for applications requiring modular design and targeted beam control.

Regulatory compliance further shapes these decisions, with certifications such as ETL and CE becoming non-negotiable benchmarks for safety, performance, and market access in North America and the European Union. These certifications ensure that lighting systems meet rigorous electrical and environmental standards—especially important in industrial settings where reliability under demanding conditions is paramount.

At the forefront of this technological shift is Beauty (STC) Manufacturing Co., Ltd., a trusted name in professional lighting solutions since 1998. With over two decades of engineering expertise, Beauty STC has consistently delivered high-performance, code-compliant LED lighting systems designed specifically for commercial and industrial environments. By integrating advanced COB LED modules with robust thermal management and certified electrical components, the company continues to set industry standards for durability, efficiency, and optical precision.

Technical Specs & Certifications

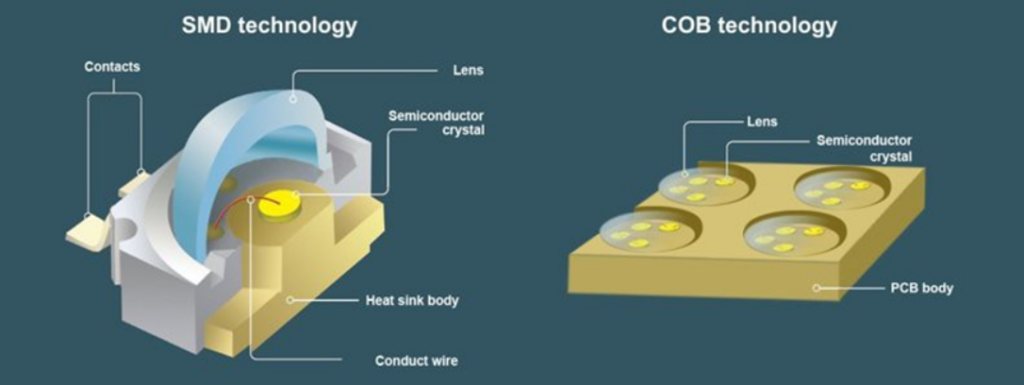

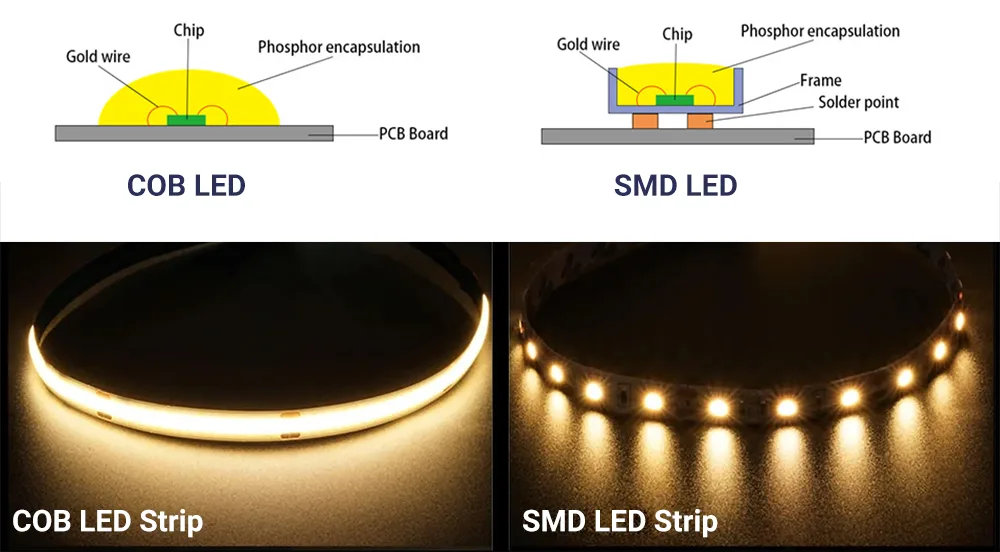

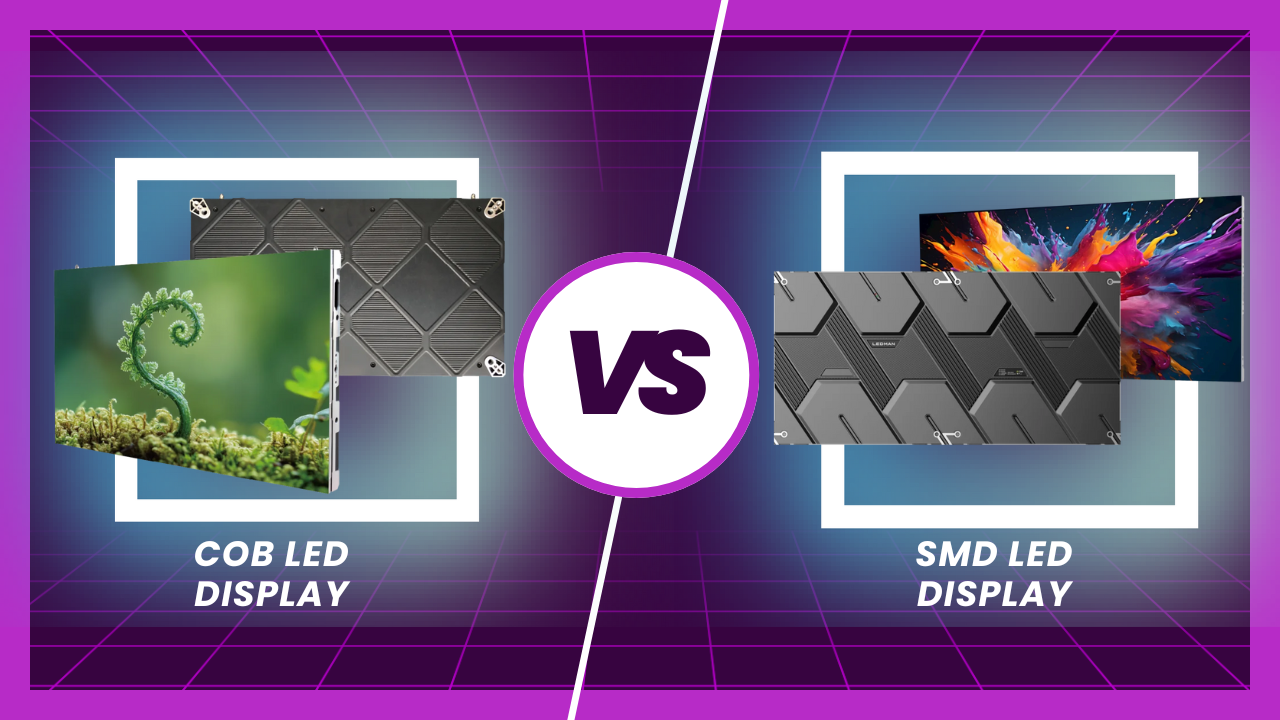

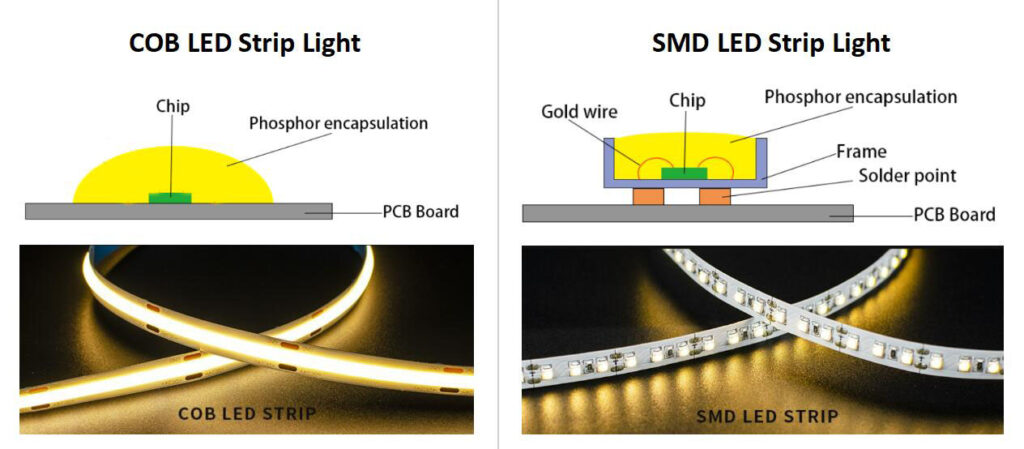

COB LED and multi-die SMD LED represent distinct packaging technologies within solid-state lighting, each with performance characteristics relevant to high-efficiency, high-CRI applications. Lumens per watt (lm/W) efficiency is comparable at the chip level for both technologies when using premium epitaxy, though system-level differences emerge. Modern COB arrays typically achieve 150-180 lm/W in commercial high-CRI fixtures due to reduced packaging complexity and superior thermal path design from the single large substrate directly to the heatsink. Multi-die SMD arrays (using individual 2835, 3030, or similar packages) can reach similar 145-175 lm/W ranges in well-engineered systems, but thermal resistance between multiple discrete packages and the heatsink sometimes incurs a slight efficiency penalty at very high drive currents compared to COB’s monolithic thermal structure. Both technologies can meet or exceed 150 lm/W while maintaining CRI >90 when utilizing high-quality phosphor blends and optimized drive currents.

Achieving CRI >90 (specifically Ra >90 with strong R9 values) is feasible with both COB and SMD LED solutions, but the implementation differs. COB designs inherently produce a more uniform point source of light, minimizing color variation across the beam since all emitters share a single phosphor layer. This simplifies optical control for consistent high-CRI output. Multi-die SMD arrays require precise binning of individual LEDs and sophisticated phosphor application to ensure color uniformity across the array, as minor variations between discrete packages can cause spatial color separation if not meticulously managed. At Beauty STC, we utilize rigorously binned Nichia or Seoul Semiconductor chips for both platforms, applying our proprietary multi-phosphor formulations and stringent in-line spectrophotometric testing. Every production batch undergoes CRI verification with calibrated spectroradiometers, guaranteeing Ra >92 and R9 >50 consistently, regardless of whether the fixture employs COB or high-density SMD arrays. Our process ensures no perceptible color shift over lifetime, exceeding standard industry tolerances.

IP ratings are determined primarily by the fixture’s mechanical design and sealing methodology, not the LED type itself. However, the inherent structure influences the sealing approach. COB modules, being single units with fewer solder joints penetrating the substrate, often simplify achieving high IP ratings like IP66 or IP67. The reduced number of potential ingress points allows for more robust potting or gasket sealing directly around the COB assembly. Multi-die SMD arrays present more solder joints and component edges, requiring more complex multi-stage gasketing or conformal coating strategies to reach equivalent IP66/IP67 ratings. Beauty STC excels in thermal and environmental engineering for both platforms. Our patented sealing techniques, including dual-compound silicone gaskets and pressure-equalizing vents for IP67, combined with marine-grade aluminum housings and rigorous 100% IP testing per IEC 60529, ensure all high-CRI luminaires meet or exceed stated IP ratings. Fixtures undergo extended salt-spray testing and thermal cycling validation to guarantee long-term ingress protection integrity in harsh environments, a critical differentiator in our quality commitment. This systems-level approach ensures reliability where others might compromise optical performance for environmental sealing.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped factory located in Jiangmen, Guangdong Province, a region known for its strong manufacturing infrastructure and supply chain efficiency. The facility is designed to support high-volume production of LED lighting products with a strong emphasis on quality control, automation, and customization for global clients.

The factory is equipped with advanced SMT (Surface Mount Technology) production lines, which are critical for the precise and efficient assembly of LED components onto printed circuit boards. These SMT machines ensure high-speed placement of tiny LED chips and other electronic elements with excellent accuracy and consistency. The use of automated optical inspection (AOI) systems integrated into the SMT process allows for real-time defect detection, ensuring high yield rates and product reliability.

A key part of the quality assurance process at the Jiangmen facility is the comprehensive aging test procedure. Finished LED products undergo rigorous aging tests under controlled thermal and electrical conditions, typically running at full power for extended periods—often 12 to 24 hours or more. This process helps identify early-life failures, verifies thermal management performance, and ensures long-term stability before products are shipped to customers. Environmental testing chambers are also used to simulate different operating conditions, further validating product durability.

Beauty STC has strong OEM/ODM capabilities, particularly in the design and production of various LED lighting solutions, including both COB (Chip-on-Board) LED and traditional multi-chip LED products. The company can customize lighting modules and fixtures based on client specifications, whether it’s for residential, commercial, or industrial applications. For COB LED versus standard SMD LED products, Beauty STC offers tailored solutions that leverage the advantages of each technology—COB LEDs for high-intensity, uniform light output with better thermal performance, and SMD LEDs for flexibility in design and color mixing. The factory supports full turnkey services from PCB design and thermal management solutions to optical engineering, housing integration, and final assembly.

This combination of advanced SMT machinery, stringent aging and reliability testing, and flexible OEM capabilities enables Beauty STC to deliver high-performance, customized LED lighting solutions that meet international standards and client-specific requirements.

Application Scenarios

COB LED and standard LED (typically referring to multi-chip SMD LEDs) serve distinct purposes in commercial lighting. Their optimal application depends on the specific visual and functional requirements of each space within hotels, malls, and offices. Understanding the core difference is key: COB LEDs integrate multiple diodes onto a single ceramic substrate, creating a single, intense, uniform light source ideal for directional beam control. Standard SMD LEDs consist of multiple discrete diodes mounted on a board, producing a broader, more diffuse light output better suited for general ambient illumination.

In hotel lobbies and reception areas, COB LED downlights excel for accentuating architectural features, artwork, or high-end finishes where a crisp, shadow-minimized spotlight effect is desired. The uniform beam without multiple shadows enhances perceived quality. Standard SMD LED panels or troffers are preferable for general ambient lighting in guest room corridors and back-of-house areas, providing even, glare-free illumination across wider surfaces without the need for precise beam control. Guest rooms themselves benefit from standard SMD LED tape or cove lighting for soft, diffuse ambient light, while COB LED spotlights might be used sparingly in bathrooms for focused task lighting around mirrors.

For retail environments within malls, COB LED track or recessed lights are essential for merchandise display lighting. Their high center-beam intensity and excellent optical control highlight product texture and color accurately, particularly for jewelry, cosmetics, or high-value items. Standard SMD LED linear fixtures or large-format panels are far more appropriate for general aisle and common area lighting, ensuring uniform horizontal illuminance across expansive floors without creating isolated hotspots that could distract shoppers or cause visual discomfort. Entrance canopies and food court seating areas also require the broad, comfortable light distribution of standard SMD solutions.

Office lighting demands careful segmentation. COB LED downlights or adjustable task lights are highly effective at individual workstations for focused desk illumination, reducing eye strain during detailed computer or document work due to their high intensity and precise beam spread. However, standard SMD LED panels or suspended linear systems dominate open-plan offices, private offices, and meeting rooms for ambient lighting. Their diffuse output minimizes screen glare, creates a visually comfortable environment for extended periods, and provides uniform illuminance across large ceiling areas critical for productivity. Conference room tables might use COB LED pendants for task focus, but the surrounding ceiling must rely on standard SMD for balanced ambient light.

Installation considerations significantly impact performance and longevity. For COB LED fixtures, thermal management is paramount due to the high power density concentrated on a small chip. Always ensure adequate thermal pathways within the fixture housing and verify sufficient airspace above recessed housings in insulated ceilings; inadequate heat dissipation drastically shortens LED life and causes lumen depreciation. Precisely match the beam angle to the application: a narrow 15-24° COB beam suits accent lighting but creates uncomfortable pools of light in general areas, while a 30-40° beam works better for task lighting. Use high-quality, compatible dimmers specifically listed for the COB LED driver to prevent flicker, especially critical in hotel guest rooms and conference spaces where smooth dimming is expected. For standard SMD LED installations, focus on achieving uniformity; maintain consistent fixture spacing and mounting heights across large areas like mall walkways or office floors to avoid visible variations in brightness. Ensure diffusers are clean and properly seated to prevent spotting or glare. Always verify the Color Rendering Index (CRI) and R9 value meet project specifications, particularly in retail and hospitality where accurate color representation is non-negotiable. Finally, meticulously follow manufacturer cutout dimensions and support requirements for recessed fixtures to prevent housing shift or ceiling damage over time.

Why Choose Beauty STC Lighting

Discover the key differences between COB LED and traditional LED lighting to make an informed choice for your next lighting project. Whether you’re looking for superior brightness, energy efficiency, or long-term performance, understanding COB LED vs LED technology is essential. At Beauty (STC) Manufacturing Co., Ltd., we specialize in high-quality LED solutions tailored to meet diverse industrial and commercial needs.

Partner with Beauty STC to access cutting-edge lighting technology, custom manufacturing capabilities, and expert technical support. Our team is ready to help you select the right LED solution for your application.

For more information or to discuss your requirements, contact us today at [email protected]. Let Beauty STC illuminate your success with reliable, innovative lighting solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.