Article Contents

Industry Insight: Led Strip And Power Supply

The commercial and industrial lighting sector continues its decisive shift toward LED strip solutions, driven by the relentless demand for energy efficiency, design flexibility, and long-term operational cost reduction. While the visible linear light output captures attention, the critical role of the power supply often determines the system’s ultimate reliability, lifespan, and safety in demanding environments like warehouses, retail spaces, factories, and healthcare facilities. Selecting compatible, high-quality LED strips paired with robust, appropriately rated power supplies is not merely an installation detail; it is a fundamental requirement for achieving consistent performance, minimizing maintenance disruptions, and ensuring compliance with stringent building and safety codes. Certifications such as ETL (indicating compliance with North American safety standards) and CE (demonstrating adherence to European health, safety, and environmental regulations) are non-negotiable prerequisites in these professional settings. They provide essential assurance that components have undergone rigorous third-party testing, mitigating fire hazards, electrical risks, and liability exposure – factors that directly impact project acceptance and end-user safety.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of specialized engineering and manufacturing expertise to this critical segment. As a trusted partner for commercial and industrial lighting professionals globally, we focus on developing integrated LED strip and power supply solutions engineered for real-world performance. Our commitment lies in delivering not just components, but dependable, certified systems designed to meet the rigorous demands of professional installations, ensuring projects are completed on time, within spec, and built to last.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd. offers high-performance LED strip and power supply solutions engineered for superior efficiency, color accuracy, and durability. Our LED strips are designed to meet the demanding requirements of both commercial and residential lighting applications, ensuring reliable performance and exceptional light quality.

Each LED strip is built using high-density SMD chips—commonly SMD2835, SMD3528, or SMD5050—selected for optimal lumen output and thermal management. Our standard LED strips achieve a luminous efficacy of 120 to 140 lumens per watt, with select high-efficiency models reaching up to 150 lumens per watt. This high lumens/watt ratio ensures energy savings without compromising brightness, making our products ideal for long-term installations where operational cost and performance are critical.

Color Rendering Index (CRI) is a key focus in our product development. All premium-grade LED strips from Beauty STC deliver a CRI greater than 90, with options available up to CRI 95+. This ensures accurate and natural color reproduction, essential for retail lighting, art galleries, healthcare facilities, and high-end residential environments where true-to-life color is vital.

We offer a comprehensive range of IP (Ingress Protection) rated LED strips to suit various environmental conditions. Our standard non-waterproof strips are IP20 rated, suitable for indoor dry locations. For damp or outdoor applications, we provide IP65-rated strips, featuring a silicone coating that protects against dust and low-pressure water jets. For fully submersible or high-moisture environments, our IP67 and IP68-rated LED strips are available, capable of withstanding temporary or continuous immersion in water, respectively. These robust sealing standards ensure long-term reliability in challenging conditions.

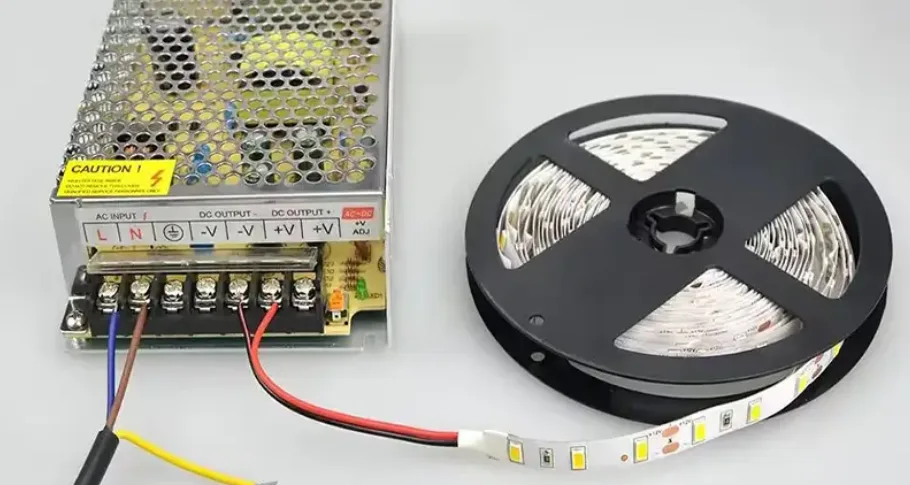

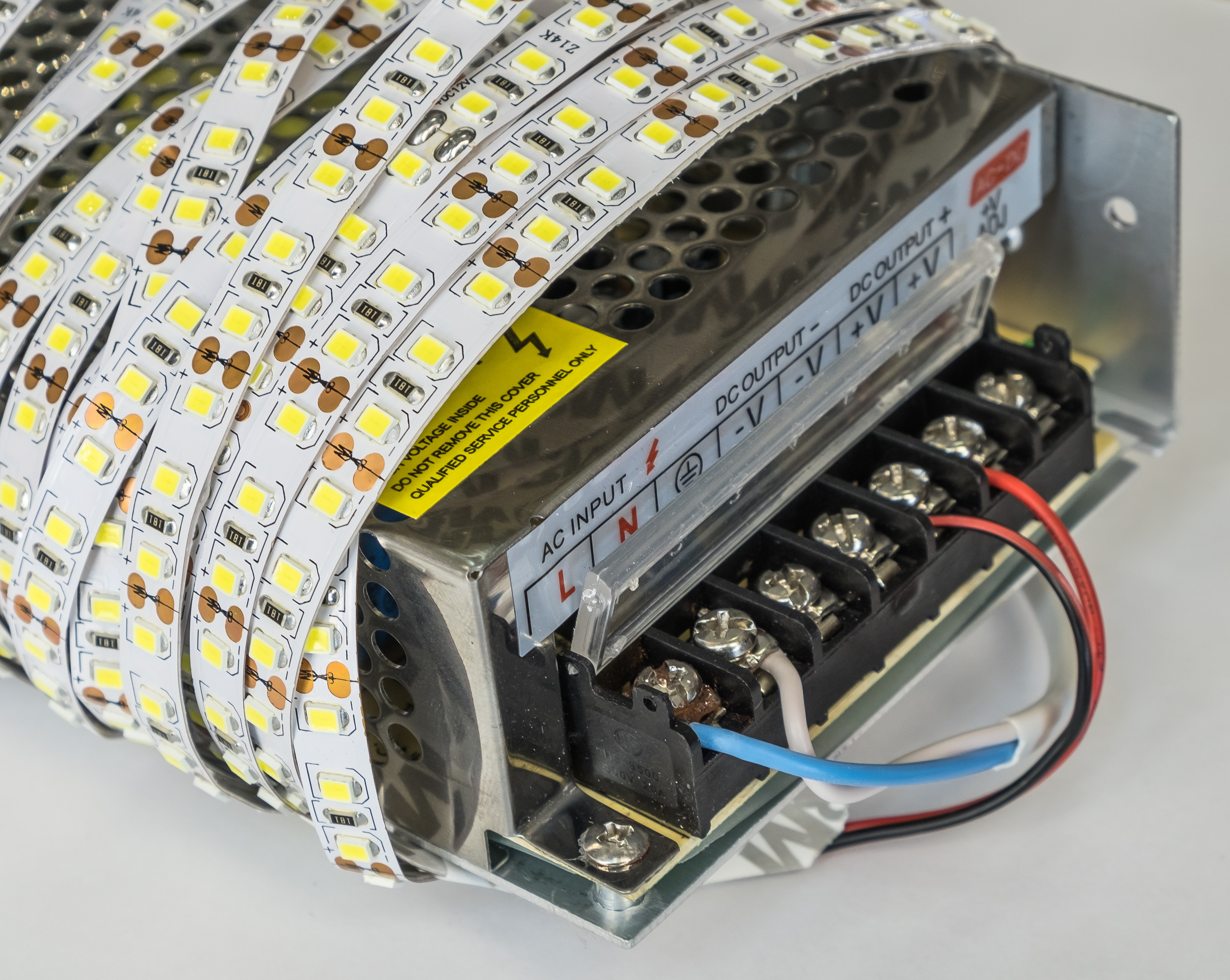

Each LED strip is paired with a compatible, UL/CB/CE-certified power supply designed for stable voltage output and efficient power conversion. Our drivers feature wide input voltage ranges (typically 100–240V AC), over-voltage, over-current, and thermal protection, ensuring safety and longevity. Power supply efficiency exceeds 88%, aligning with global energy standards.

Beauty STC maintains rigorous quality control throughout manufacturing, adhering to ISO9001 standards and conducting 100% aging and photometric testing on production lines. Our components are RoHS compliant and undergo extensive thermal cycling, humidity, and lifespan testing—ensuring a rated operational life of 50,000 hours or more under normal conditions. With consistent color bins, tight tolerance in performance metrics, and durable materials, Beauty STC LED strips and power supplies deliver professional-grade lighting performance trusted by clients worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility is a dedicated LED lighting production hub strategically located within the Pearl River Delta region, leveraging strong supply chain logistics and skilled technical labor. The factory spans over 15,000 square meters and operates under strict ISO 9001 quality management protocols, with a primary focus on high-volume, precision manufacturing of flexible LED strips and matching constant voltage/current power supplies for global markets.

Our SMT production line is centered around four high-speed Yamaha YS24 series placement machines operating in dual-lane configuration. These machines handle components from 0201 metric packages up to large power ICs, achieving placement accuracy of ±25μm and throughput exceeding 60,000 components per hour per line. The process includes automated solder paste inspection (SPI) with 3D laser profiling, nitrogen-reflow soldering profiles optimized for LED thermal sensitivity, and AOI systems performing real-time defect detection on every board. This setup ensures consistent assembly of densely populated LED strip PCBs with tight pitch LEDs like 2835 and 5050, as well as complex driver circuitry requiring precise component alignment.

Aging and reliability testing constitute a critical 1,200 square meter dedicated zone. LED strips undergo mandatory 24-hour burn-in at 1.2x rated voltage in temperature-controlled chambers maintained at 50°C±2°C, with automated current monitoring to detect early lumen depreciation or color shift. Power supplies complete 48-hour full-load aging tests at 40°C ambient, including line/load regulation checks and harmonic distortion analysis. For premium OEM projects, we implement extended 72-hour accelerated life testing with periodic lumen maintenance and chromaticity measurements per IES LM-80 standards. All aging racks feature redundant thermal cutoffs and remote monitoring, processing over 5,000 strip meters and 2,000 drivers daily.

Our OEM capabilities for LED strips and power supplies encompass full vertical integration from component sourcing to finished goods. We support customizations including specialized PCB widths (8mm to 24mm), IP-rated silicone encapsulation up to IP68, multi-zone addressable strips with custom IC programming, and tailored CCT tuning within ±50K tolerance. Power supply OEM services include bespoke form factors, universal input ranges (90-305VAC), dimming compatibility (TRIAC, 0-10V, DALI), and custom labeling/cabling. The factory maintains UL-certified component libraries and can manage both consigned material builds and turnkey solutions with lead times starting at 30 days for 50,000-meter orders. Every OEM project undergoes rigorous first-article validation against client specifications before mass production, with full traceability from reel to finished product.

This integrated approach—combining advanced SMT precision, statistically validated aging protocols, and flexible OEM engineering—enables Beauty STC to deliver LED strip and driver solutions meeting UL, CE, and TÜV safety standards while maintaining a field failure rate below 0.15%. All production adheres to our 5-year product warranty commitment.

Application Scenarios

LED strips and power supplies are versatile lighting solutions widely used across various commercial and hospitality environments due to their energy efficiency, design flexibility, and long service life. Their applications in hotels, malls, and offices can significantly enhance ambiance, functionality, and visual appeal.

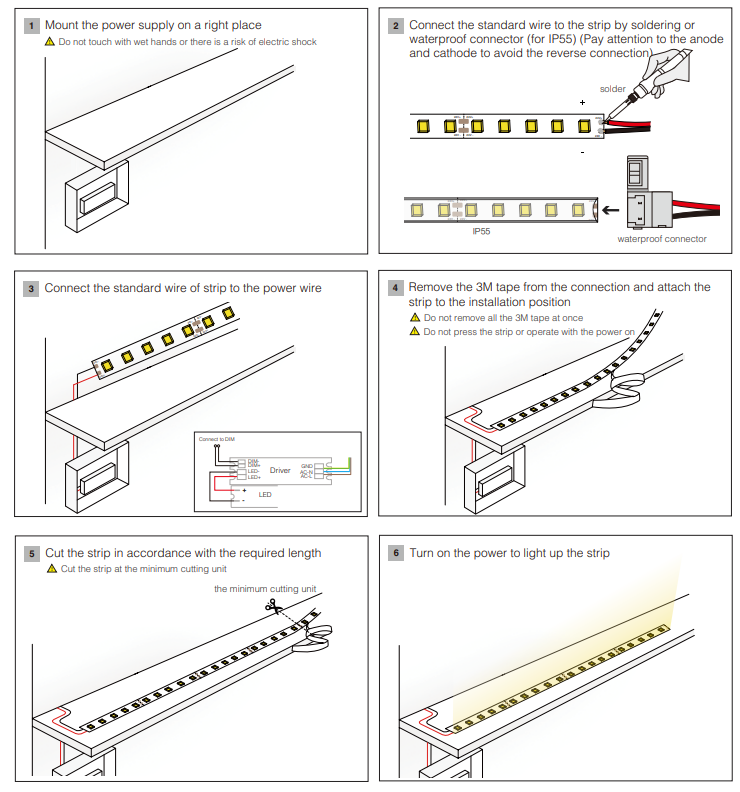

In hotels, LED strips are commonly used in guest rooms to highlight architectural features such as cove lighting, headboards, under-cabinet lighting in minibars, and within wardrobes. They are also used in lobbies, corridors, and restrooms to create a welcoming atmosphere. Power supplies should be concealed in accessible junction boxes or service areas to allow for maintenance. It is important to use dimmable drivers in guest rooms to offer adjustable lighting moods and ensure compatibility with the hotel’s lighting control system.

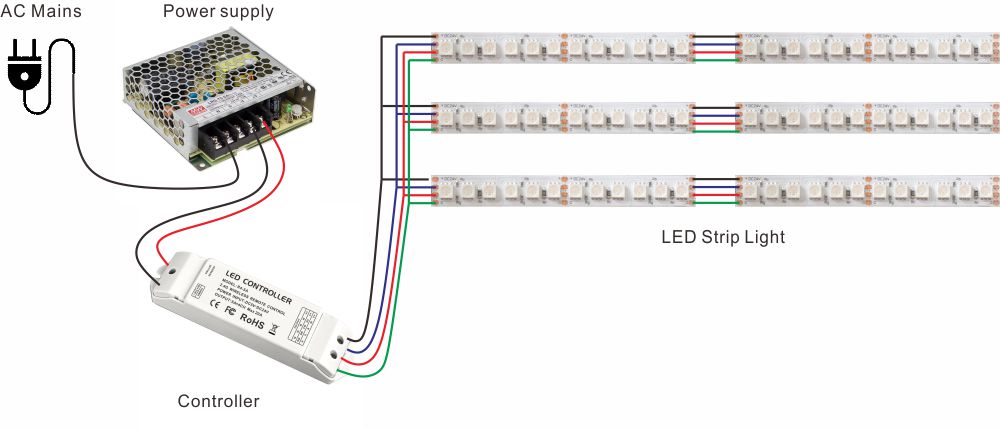

In malls and retail spaces, LED strips are ideal for accent lighting in display windows, signage backlighting, cove lighting in common areas, and under shelving to highlight products. They help draw attention to key areas and improve the overall shopping experience. For such high-traffic environments, it is advisable to use high-quality, stable power supplies with sufficient wattage headroom—typically 20% above the total strip load—to prevent overheating and ensure longevity. Waterproof strips and drivers are recommended in areas exposed to cleaning or moisture, such as food courts or restrooms.

In offices, LED strips are often installed under cabinets, in suspended ceilings, or as task lighting to reduce glare and improve visual comfort. They contribute to a modern, professional environment while supporting energy-saving goals. For open-plan offices, linear lighting with consistent color temperature (typically 4000K for a balanced white) ensures visual clarity and comfort. Power supplies should be mounted in ceiling voids or electrical closets with adequate ventilation. Using constant voltage drivers with surge protection helps maintain reliability, especially in buildings with fluctuating power supply.

Installation tips include measuring the required length accurately and cutting the strip only at designated cut marks. Ensure the surface is clean and dry before applying adhesive-backed strips. For long runs, avoid voltage drop by feeding power from both ends or using higher voltage strips such as 24V DC. Always match the power supply output (voltage and current) precisely to the LED strip specifications. Use proper wiring techniques and enclosures to meet local electrical codes, and conduct thorough testing after installation to verify performance and safety. Regular maintenance checks on drivers and connections will help prevent failures and ensure consistent lighting quality over time.

Why Choose Beauty STC Lighting

Partner with Beauty STC for seamless integration of high-performance LED strip lighting and precisely matched power supplies. Our engineering team designs both components as a unified system, eliminating compatibility issues and ensuring optimal thermal management, consistent brightness, and extended lifespan for your projects. This integrated approach guarantees reliability you can trust in demanding commercial and architectural applications.

We understand that mismatched components lead to premature failures and costly callbacks. Beauty STC’s rigorously tested LED strips and power supplies are engineered together for stability, efficiency, and effortless installation. Reduce your project risks and enhance end-user satisfaction with a solution built to perform reliably from day one.

Contact our dedicated engineering support team directly at [email protected] to discuss your specific requirements and discover how our integrated LED strip and power supply solutions can elevate your next project. Let us help you deliver flawless lighting performance.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.