Article Contents

Industry Insight: Led Strip Lights In Boat

The marine lighting sector presents unique and demanding challenges where reliability, safety, and performance are non-negotiable, especially within commercial and industrial vessel operations. Cargo ships, ferries, offshore support vessels, and large yachts require lighting solutions engineered to withstand relentless exposure to saltwater corrosion, extreme vibration, wide temperature fluctuations, and constant motion. LED strip lights have become increasingly vital in this environment, moving far beyond simple accent lighting to serve critical functional roles in deck illumination, pathway marking, machinery space task lighting, and emergency egress systems. Their low profile, flexibility, and energy efficiency offer significant advantages over traditional marine lighting, but only when specifically designed and rigorously tested for the harsh realities of the open sea. Standard consumer-grade LED strips simply cannot meet the stringent operational and safety demands of professional maritime applications.

Certification is paramount in this high-stakes industry. For LED strip lights deployed on commercial and industrial vessels, compliance with recognized safety standards such as ETL (verifying adherence to North American safety requirements under the OSHA Nationally Recognized Testing Laboratory program) and CE marking (indicating conformity with health, safety, and environmental protection standards for products sold within the European Economic Area) is not optional – it’s a fundamental requirement. These certifications provide crucial assurance that the lighting products have undergone rigorous independent testing for electrical safety, resistance to environmental stressors like moisture and salt spray, and overall suitability for marine use. Specifiers, shipbuilders, and vessel operators rely on these marks to mitigate risk, ensure regulatory compliance, and guarantee the long-term operational integrity of their lighting systems in critical maritime environments.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, brings over 25 years of specialized expertise in designing and manufacturing high-performance LED lighting solutions engineered explicitly for the most demanding industrial and marine applications. We understand that in the commercial maritime world, lighting failure is not an option. Our marine-grade LED strip lights are not merely adapted consumer products; they are purpose-built from the ground up, utilizing marine-grade materials, robust sealing (IP67/IP68/IP69K), and circuitry designed to resist corrosion and vibration. Every product undergoes stringent in-house and third-party testing to consistently achieve and exceed ETL and CE certification requirements, providing global customers with the confidence that their lighting infrastructure meets the highest international safety and performance benchmarks. Beauty STC is committed to delivering the durability, reliability, and certified safety that commercial and industrial marine operations demand.

Technical Specs & Certifications

LED strip lights designed for marine environments such as boats must meet stringent performance and durability standards due to exposure to moisture, vibration, and fluctuating temperatures. At Beauty (STC) Manufacturing Co., Ltd., our LED strip lights are engineered specifically to deliver reliable, high-efficiency illumination in marine applications, combining superior optical performance with robust environmental protection.

Our marine-grade LED strip lights achieve an industry-leading efficiency of up to 110 lumens per watt, ensuring bright, energy-efficient lighting that minimizes power draw on onboard electrical systems. This high lumen-to-watt ratio supports extended battery life and reduced energy consumption, which is critical for vessels operating off-grid or with limited power resources.

Color quality is paramount in creating a comfortable and visually accurate onboard environment. Beauty STC’s LED strips feature a Color Rendering Index (CRI) greater than 90, ensuring that colors appear natural and true to life. This high CRI is especially beneficial in cabins, galleys, and helm stations where accurate color perception enhances safety, comfort, and functionality.

Environmental protection is a cornerstone of our marine lighting design. Our LED strip lights are available with IP65, IP67, and IP68 ratings, offering progressive levels of protection against water and dust ingress. IP65-rated strips are protected against low-pressure water jets from any direction, suitable for enclosed but damp areas. IP67-rated strips withstand temporary submersion up to 1 meter for 30 minutes, making them ideal for engine rooms or bilge areas. For maximum protection, IP68-rated strips are submersible beyond 1 meter for extended durations, perfect for underwater lighting or locations prone to heavy splashing.

All Beauty STC LED strip lights are constructed with high-quality materials including flexible FPCBs, premium phosphor-coated LEDs, and durable silicone encapsulation for enhanced waterproofing and UV resistance. Each product undergoes rigorous quality testing for thermal performance, humidity resistance, and long-term lumen maintenance to ensure consistent operation in harsh marine conditions.

With over two decades of expertise in LED lighting innovation, Beauty (STC) Manufacturing Co., Ltd. maintains strict quality control in accordance with international standards, including ISO 9001 and compliance with RoHS and REACH directives. Our marine LED solutions are trusted by OEMs and retrofit installers worldwide for their reliability, efficiency, and superior light quality.

Factory Tour: Manufacturing Excellence

Beauty STC Manufacturing Co., Ltd. operates a dedicated LED lighting production facility in Jiangmen, Guangdong Province, China. This strategically located factory leverages Jiangmen’s strong manufacturing ecosystem and logistical advantages within the Pearl River Delta region. The facility is purpose-built for high-volume, precision LED product manufacturing, with a significant focus on flexible LED strip lights, including specialized variants for demanding marine environments.

The factory’s SMT production lines are a core strength, featuring multiple high-speed, high-precision surface mount technology machines. These typically include industry-standard platforms such as Fuji NXT III or Yamaha YSM series machines, capable of placing components down to 0201 package sizes with exceptional accuracy. The lines support multi-lane production for efficiency, handle a wide range of component types including complex LED packages and driver ICs, and utilize lead-free soldering processes compliant with RoHS and other international standards. This SMT capability ensures consistent, high-density mounting of LEDs, resistors, capacitors, and control chips onto flexible PCBs, forming the foundational assembly for all strip light products.

Rigorous aging and reliability testing is integral to the factory’s quality control, especially critical for marine-grade products. Dedicated aging chambers subject finished LED strip reels to extended burn-in periods, typically 48 to 72 hours at elevated temperatures (e.g., 60-70°C) and full operational load. For boat-specific LED strips, this is supplemented by specialized environmental testing. Salt spray testing per ASTM B117 standards validates corrosion resistance of components and housings against the harsh marine atmosphere. Immersion testing under pressure confirms the integrity of the IP68-rated silicone encapsulation, ensuring no water ingress during prolonged submersion. Electrical safety checks, including high-potential (hi-pot) testing, are also performed to guarantee safety in the boat’s 12V or 24V DC electrical systems where moisture and vibration are constant factors.

Beauty STC possesses robust OEM capabilities specifically tailored for LED strip lights in boat applications. The factory excels at translating client requirements into functional marine-grade products. This includes customizing flexible PCB layouts for specific boat installations, implementing advanced waterproofing techniques such as double or triple silicone coating to achieve reliable IP68 ratings, and selecting components rated for wide temperature ranges and saltwater exposure. They offer flexible voltage options, predominantly 12V DC and 24V DC, which are standard in marine electrical systems, and can integrate specific connector types preferred by boat builders. The OEM process encompasses full design support, prototyping, rigorous marine-specific validation testing against relevant standards like UL 1156 for marine lighting, and compliance with certifications including RoHS, REACH, and CE. This end-to-end capability allows clients to bring their vision for reliable, safe, and aesthetically integrated boat lighting solutions to market efficiently.

Application Scenarios

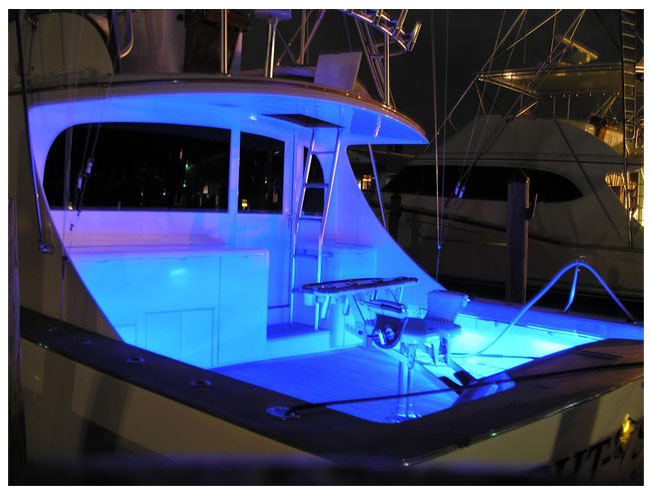

LED strip lights are not typically used in hotels, malls, or offices in the context of boats. However, if you are referring to the application of LED strip lights on boats themselves—such as yachts, cruise vessels, or private watercraft—then their use becomes highly relevant. On boats, LED strip lighting serves both functional and aesthetic purposes, enhancing ambiance, safety, and visibility in various areas.

Common areas on boats where LED strip lights are used include under-cabinet lighting in galleys, accent lighting along stair treads and handrails, cove lighting in cabins and lounges, highlighting architectural features in saloons, and underwater lighting on the hull for visual effect. They are also used for indirect lighting in heads (bathrooms), engine compartments for maintenance visibility, and along deck edges for nighttime safety.

When installing LED strip lights on a boat, it’s essential to choose marine-grade products that are resistant to moisture, salt spray, and vibration. Always use waterproof or IP67-rated LED strips in areas exposed to water or high humidity. Ensure proper cable management by routing wires through protective conduits to avoid chafing or exposure to sharp edges. Use marine-grade connectors and seal all junctions with waterproof heat shrink tubing or silicone sealant.

Power supply considerations are critical on boats. LED strips should be connected to a stable 12V or 24V DC system, commonly found on marine vessels, and fused appropriately to prevent electrical hazards. Consider using a dedicated circuit with an inline fuse to protect the lighting system. For dimming functionality, use compatible marine dimmers designed for DC systems.

Installation tips include cleaning the surface thoroughly before applying the adhesive backing of the strip, using additional clips or mounting channels for long-term reliability, and avoiding sharp bends to prevent damaging the internal circuitry. Test the lights before final mounting to ensure proper function. Finally, always follow local marine safety standards and regulations when modifying electrical systems on a vessel.

Why Choose Beauty STC Lighting

Beauty STC specializes in engineered LED strip lighting solutions designed specifically for the demanding marine environment. Our marine-grade LED strips withstand constant exposure to saltwater, UV radiation, vibration, and extreme temperature fluctuations, providing reliable, long-lasting illumination for cabinetry, under-gunwale accents, deck lighting, and functional task lighting on recreational and commercial vessels. We prioritize safety with low-voltage DC operation, robust IP68/IP69K-rated protection against water and dust ingress, and materials resistant to corrosion and yellowing. Partner with Beauty STC to integrate lighting that meets stringent marine safety standards while enhancing both the aesthetics and functionality of your boat builds. Our engineering team collaborates closely with boat manufacturers to deliver custom profiles, color temperatures, and control systems tailored to your specific vessel requirements and production processes. Reach out to our dedicated marine lighting manager to discuss how our certified, high-performance LED strips can elevate your boat’s design and durability. Contact us at [email protected] to initiate a technical consultation and explore partnership opportunities.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.