Article Contents

Industry Insight: Diffused Led Tape

The commercial and industrial lighting sector continues to demand solutions that balance exceptional performance, rigorous safety compliance, and seamless integration into demanding architectural and operational environments. Traditional linear lighting often struggles with harsh glare, visible hotspots, and inconsistent light distribution, creating visual discomfort in offices, retail spaces, warehouses, and manufacturing facilities where precise, uniform illumination is critical for productivity, safety, and aesthetics. Diffused LED tape has emerged as a transformative technology addressing these core challenges, offering a continuous, shadow-free luminous plane that enhances visual comfort and design flexibility while meeting the stringent durability requirements of professional settings. Crucially, widespread adoption in these regulated markets hinges on adherence to globally recognized safety certifications; therefore, specifying diffused LED tape solutions bearing ETL listing for North America and CE marking for Europe is non-negotiable, ensuring electrical safety, reliability, and code compliance from installation through operational life. At Beauty STC, we bring over 25 years of specialized LED engineering expertise to this critical space, having pioneered advanced diffused tape technologies since our founding in 1998. Our commitment to manufacturing excellence and deep understanding of commercial-industrial application demands position us to deliver not just products, but certified, high-performance lighting solutions that architects, engineers, and facility managers trust for their most demanding projects.

Technical Specs & Certifications

Diffused LED tape from Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and consistent quality, designed to meet the demands of both residential and commercial lighting applications. These LED tapes feature a uniformly diffused output, minimizing hotspots and delivering smooth, continuous illumination ideal for cove lighting, under-cabinet installations, display lighting, and architectural accents.

In terms of efficiency, Beauty STC’s diffused LED tapes typically achieve a luminous efficacy range of 100 to 130 lumens per watt, depending on the specific configuration, color temperature, and drive current. This high efficiency ensures optimal energy consumption while maintaining excellent light output, contributing to lower operational costs and reduced environmental impact.

Color Rendering Index (CRI) is a critical performance metric, and Beauty STC’s premium diffused LED tapes are designed with CRI values exceeding 90—many reaching CRI 95 or higher. This superior color fidelity ensures that illuminated objects appear natural and vibrant, making these tapes especially suitable for retail environments, art galleries, hospitality spaces, and any application where accurate color representation is essential.

Regarding environmental protection, Beauty STC offers diffused LED tapes in multiple IP (Ingress Protection) ratings to suit various installation conditions. Standard non-protected versions are available as IP20 for dry indoor environments. For damp or outdoor applications, the tapes are available in IP65 and IP67 ratings. IP65-rated tapes are protected against low-pressure water jets and dust ingress, making them ideal for kitchens, bathrooms, and outdoor signage. IP67-rated versions provide full dust protection and can withstand temporary immersion in water up to 1 meter, suitable for more demanding exterior or landscape uses.

Beauty STC maintains rigorous quality control throughout the manufacturing process, utilizing high-grade SMD LEDs, precision optical diffusers, and robust FPC (Flexible Printed Circuit) materials. Their diffused LED tapes undergo extensive testing for thermal management, lumen maintenance (L70/L90), and electrical stability, ensuring long service life—typically rated at 50,000 hours under proper operating conditions. With consistent binning, tight tolerances in color temperature (±200K), and reliable solder joints, Beauty STC’s LED tapes reflect a commitment to durability, performance, and optical excellence trusted by lighting professionals worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility for LED lighting products, including diffused LED tape, is strategically located in Jiangmen, Guangdong Province, within the Pearl River Delta manufacturing hub. This factory is a modern, vertically integrated operation designed for high-volume, precision LED production with stringent quality control. The facility spans over 20,000 square meters and operates under ISO 9001 and ISO 14001 management systems, featuring dedicated cleanrooms for critical processes to minimize contamination.

The Surface Mount Technology (SMT) production lines form the core of our component assembly capability. We utilize multiple high-speed, high-precision Yamaha YS series SMT machines, specifically configured for the demanding requirements of LED strip manufacturing. These machines handle ultra-fine pitch components down to 0201 package sizes with exceptional placement accuracy, critical for mounting the dense arrays of LED chips and associated passive components onto flexible printed circuit boards (FPCBs). Each line incorporates automated solder paste printing with laser alignment, nitrogen-reflow soldering profiles optimized for LED thermal sensitivity, and comprehensive Automated Optical Inspection (AOI) systems both pre and post-reflow. This AOI performs 100% real-time checks for component presence, polarity, alignment, and solder joint quality, ensuring minimal defects before the strips proceed to the next stage.

Rigorous aging and reliability testing is a non-negotiable step in our production flow, directly contributing to product longevity and performance consistency. All diffused LED tape reels undergo mandatory burn-in testing within our dedicated environmental test chambers. Strips are powered at their rated voltage and current, typically for a minimum of 24 hours but often extended to 48 hours for critical orders or new product introductions, while maintained at elevated temperatures (usually 50-60°C). This process accelerates the identification of early-life failures, such as weak LED chips, poor solder joints, or driver component issues. During aging, the strips are continuously monitored for consistent light output, color point stability, and absence of flicker or dead sections. Automated photometric systems may log lumen maintenance data, and visual inspections are performed at intervals. Only strips passing this stringent aging protocol are cleared for final packaging and shipment.

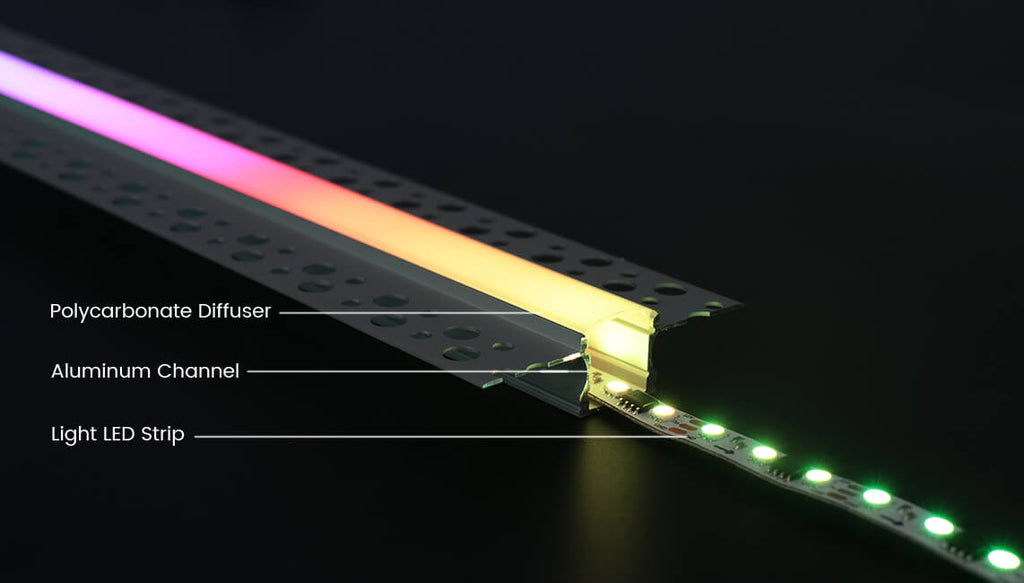

Our OEM capability for diffused LED tape is a significant strength, built upon the foundation of our Jiangmen factory’s flexible manufacturing and engineering expertise. We offer extensive customization options tailored to specific client requirements. This includes designing and producing diffused LED tapes with varying PCB widths, LED densities (e.g., 30, 60, 120 LEDs per meter), and lengths per reel. Crucially for diffused tape, we provide multiple diffuser material and profile options, such as flexible silicone extrusions in various opacities (soft, medium, high diffusion) or rigid polycarbonate lenses, each impacting the beam angle and homogeneity. Color temperature options span the full range from 1800K to 6500K with tight binning (SDCM ≤ 3), and we support both standard and high CRI versions (Ra >90, Ra>95). Electrical specifications like input voltage (12V, 24V DC), power per meter, and IP ratings (from IP20 to IP67/IP68) are fully customizable. Our engineering team collaborates closely with clients from the initial design phase through prototyping and validation, ensuring the final product meets exact optical, mechanical, and electrical specifications. The factory’s scale allows us to efficiently handle both low-volume, high-mix custom orders and very high-volume production runs while maintaining consistent quality through our integrated SMT and testing processes.

Application Scenarios

Diffused LED tape is widely used across various commercial and hospitality environments due to its ability to provide smooth, uniform illumination without visible hotspots or individual LED dots. Its soft, glare-free light makes it ideal for creating ambient and architectural lighting effects in high-end interior spaces.

In hotels, diffused LED tape is commonly used in guest rooms, lobbies, and corridors to enhance ambiance and wayfinding. It is often installed under cabinets in bathrooms, along cove ceilings, behind headboards, and within wardrobe interiors to create a luxurious, welcoming atmosphere. In hotel lobbies and reception areas, it highlights architectural features such as columns, curved walls, and feature ceilings, contributing to a modern and elegant aesthetic.

In malls and retail environments, diffused LED tape is used to accentuate product displays, signage, and shelving. It provides even illumination for cove lighting in walkways and atriums, improving visibility while maintaining a visually pleasing environment. The uniform light distribution helps reduce harsh contrasts, making spaces feel more open and inviting. It is also used in suspended ceiling perimeters and stair treads for both decorative and functional lighting.

In offices, diffused LED tape supports both task and ambient lighting strategies. It is frequently installed in cove lighting systems, under cabinets, within partition systems, and above suspended ceilings to provide indirect, comfortable illumination that reduces eye strain. In executive offices and meeting rooms, it adds a touch of sophistication while maintaining a professional atmosphere. It’s also used in drop ceilings and service areas for discreet yet effective lighting.

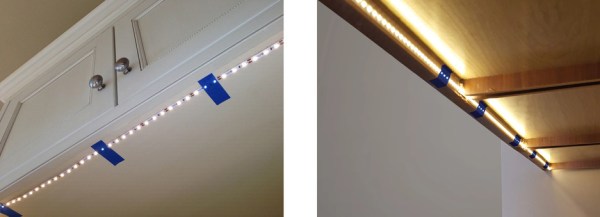

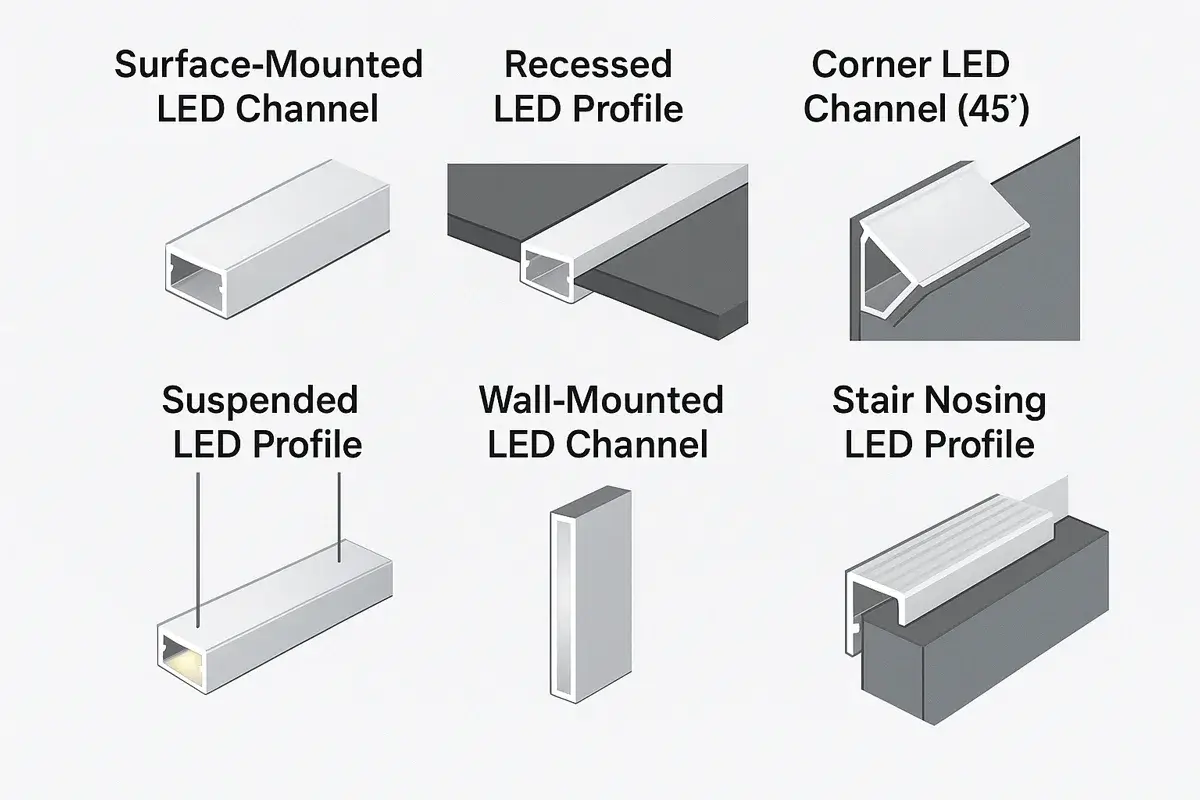

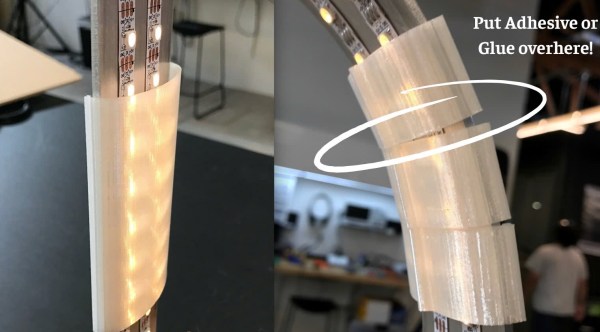

When installing diffused LED tape, proper preparation and technique are essential for optimal performance. First, ensure the mounting surface is clean, dry, and free of dust or grease to promote strong adhesion of the tape’s backing. Use aluminum channels designed for LED tape to help dissipate heat and improve longevity—this also enhances the diffusion effect when paired with a frosted or milky cover. Always cut the tape only at the designated cut points to avoid damaging the circuitry. For longer runs, consider using a constant voltage power supply with appropriate gauge wiring to prevent voltage drop, which can cause dimming at the end of the strip. Connect the tape securely using proper connectors or soldered joints, and insulate all connections to prevent short circuits. Finally, test the installation before finalizing the diffuser or cover placement to ensure even light output and correct operation.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium diffused LED tape, engineered for seamless illumination and unmatched visual comfort. Our advanced diffusion technology eliminates hotspots and glare, delivering a perfectly uniform glow ideal for architectural cove lighting, retail displays, automotive accents, and high-end residential applications. Partner with Beauty STC to access reliable, high-performance solutions backed by rigorous quality control and tailored engineering support.

Contact our dedicated team today at [email protected] to discuss your specific requirements and discover how our diffused LED tape can enhance your next project. Let Beauty STC be your trusted manufacturing partner for innovative, consistent, and professional-grade lighting results. Reach out now to start the conversation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.