Article Contents

Industry Insight: Led Strip For Home

The LED strip lighting market has experienced substantial growth in recent years, driven by increasing demand for energy-efficient, versatile, and durable lighting solutions across commercial and industrial sectors. Once considered primarily for decorative residential use, LED strips have evolved into critical components in professional environments—from retail displays and office architecture to warehouses and manufacturing facilities. Their adaptability in design, low power consumption, and long operational life make them ideal for applications requiring consistent, high-quality illumination with minimal maintenance. As regulatory standards tighten globally, compliance with safety and performance certifications such as ETL and CE has become essential, ensuring products meet rigorous electrical and environmental requirements for use in commercial installations.

At the forefront of this technological shift is Beauty (STC) Manufacturing Co., Ltd., a trusted name in the LED lighting industry since its establishment in 1998. With over two decades of engineering expertise, Beauty STC has built a strong reputation for delivering high-performance LED strip solutions tailored to the demands of commercial and industrial clients worldwide. By combining innovative design with strict adherence to international standards, including ETL and CE certifications, Beauty STC continues to set benchmarks in reliability, efficiency, and scalability—empowering businesses to achieve smarter, safer, and more sustainable lighting infrastructures.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces LED strips specifically engineered for residential applications where performance, visual comfort, and longevity are paramount. Our home-use LED strips prioritize balanced technical specifications to meet the demanding aesthetic and functional requirements of modern interiors. Key technical specifications are rigorously controlled during manufacturing.

Lumens per Watt efficiency is a core focus, reflecting our commitment to energy savings without compromising light quality. Our standard high-CRI home LED strips achieve a consistent luminous efficacy range of 100 to 120 lumens per watt under standard operating conditions at 25°C ambient temperature. This efficiency level is maintained while delivering superior color rendering, recognizing that higher CRI values typically involve a slight trade-off against peak theoretical efficacy. We utilize tightly binned mid-power LEDs on high-conductivity copper PCBs and pair them with optimized constant-current drivers to ensure this efficiency is sustained throughout the product’s operational life, minimizing thermal roll-off.

Critical to our home lighting philosophy is exceptional color fidelity, mandated by our specification requiring a minimum CRI Ra value of 90, with a strong emphasis on Ra9 (saturated red) exceeding 50. This ensures accurate and vibrant rendering of skin tones, fabrics, artwork, and natural materials within living spaces. We achieve this through the exclusive use of premium phosphor-converted LEDs from tier-1 suppliers, subjected to stringent binning processes. Every production batch undergoes spectrophotometric validation to guarantee Ra > 90 and Ra9 > 50, avoiding the inconsistent performance found in lower-cost alternatives that may only advertise a nominal CRI without verifying critical red rendering.

IP rating selection is application-specific for residential environments. For standard dry indoor locations like living rooms, bedrooms, and drywall coves, our IP20 rated strips provide optimal value and thermal management. For kitchens, bathrooms, under-cabinet installations, or any area potentially exposed to moisture or dust ingress, we supply IP65 rated strips as standard. These feature a continuous, optically clear silicone encapsulation over the entire LED and PCB assembly, not merely a conformal coating, providing true protection against water jets and dust. We do not recommend unnecessarily high IP ratings like IP67 for typical home use, as they can impede heat dissipation and increase cost without tangible benefit in dry or standard damp locations. Beauty STC’s IP65 strips undergo rigorous third-party testing to IEC 60529 standards, validating their suitability for residential damp zones.

Beauty STC’s quality assurance is integral to every LED strip. Our manufacturing adheres to ISO 9001 standards with in-line automated optical inspection and 100% end-of-line electrical and photometric testing. We utilize 2oz copper PCBs for superior thermal management and current handling compared to thinner industry standards, significantly reducing lumen depreciation. All strips undergo a mandatory 8-hour full-power aging test at elevated temperatures to identify early failures, a practice beyond basic industry norms. Components, including capacitors and drivers, are sourced from vetted global suppliers meeting AEC-Q200 automotive grade reliability where applicable. This commitment to robust engineering and validation is reflected in our industry-leading 5-year warranty, providing homeowners and professionals with confidence in long-term performance and color stability. The result is a residential LED strip that delivers consistent, high-quality light output, accurate color, and exceptional reliability day after day.

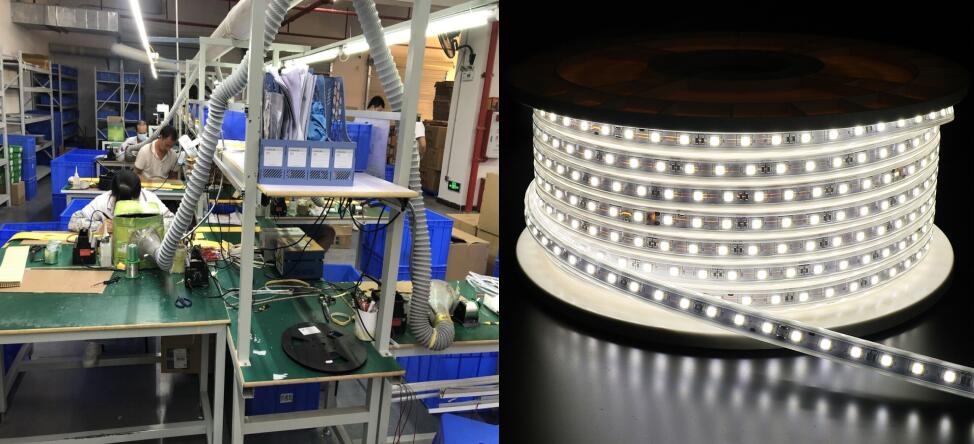

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is purpose-built for high-efficiency LED lighting manufacturing, with a strong emphasis on quality control, automation, and scalability to support both domestic and international markets.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines that ensure precision and consistency in assembling LED components. These SMT machines are fully automated and capable of handling high-volume production with minimal defect rates. They support a wide range of LED packages and are optimized for producing flexible and rigid LED strips, including those used in home lighting applications. The SMT process is closely monitored through automated optical inspection (AOI) systems to verify component placement, alignment, and soldering quality before the boards move to the next stage.

To ensure long-term reliability and performance, all LED strips undergo rigorous aging tests at the Jiangmen factory. Completed strips are subjected to continuous operation under elevated temperatures and voltage stress for durations ranging from 24 to 72 hours. This aging process helps identify early failure modes and ensures that only stable, high-quality products are delivered to customers. Environmental testing chambers are also used to simulate real-world operating conditions, including humidity and thermal cycling, further validating product durability.

Beauty STC has robust OEM capabilities tailored specifically for the ‘LED strip for home’ market. The company supports full customization, including color temperature options (such as warm white, cool white, and tunable white), RGB and RGBIC color control, various waterproof ratings (from non-coated to IP65 and IP67 silicone encapsulated), and different voltages (12V and 24V DC). Clients can specify cut lengths, packaging formats, labeling, and even private branding. The engineering team works closely with customers to develop custom PCB layouts, select optimal LED densities (e.g., 60, 120, or 240 LEDs per meter), and integrate compatible controllers or smart systems such as Wi-Fi or Bluetooth for home automation compatibility.

Overall, the Jiangmen factory combines advanced automation, stringent quality assurance, and flexible manufacturing processes to deliver reliable, high-performance LED lighting solutions, making Beauty STC a trusted partner for OEM brands in the residential lighting sector.

Application Scenarios

LED strips designed for residential use serve distinct purposes in homes compared to commercial environments like hotels, malls, or offices. While you may observe similar LED strip lighting in those commercial settings for architectural accents, signage, or task lighting, the applications within a private residence focus on ambiance, functionality, and personalization. In a home, LED strips excel in areas where adjustable, low-profile illumination enhances daily living. Common residential applications include under-cabinet lighting in kitchens to illuminate countertops without harsh overhead glare, cove lighting in living rooms or bedrooms to create a soft, indirect glow that defines the space, and within entertainment units or shelving to highlight decor or media equipment. They are also effectively used for stairway step lighting to improve safety at night, inside wardrobes or pantries for convenient task lighting, and along pathways in home corridors or hallways for subtle guidance during evening hours. Unlike commercial installations which prioritize high-output, uniform illumination for large crowds, home installations emphasize mood setting, energy efficiency for personal comfort, and integration with smart home systems for individual control.

Proper installation is critical for both performance and safety in residential settings. Always begin by ensuring the power is completely disconnected at the circuit breaker before handling any electrical components. Select a strip voltage appropriate for the application; 12V strips are generally safer for DIY home use in dry areas like cabinets or shelves, while 24V strips offer longer run lengths for larger cove installations but require compatible drivers. Thoroughly clean and dry the mounting surface—dust, grease, or moisture will prevent the adhesive backing from bonding securely over time. Avoid installing strips on heat-generating surfaces like ovens or enclosed fixtures without adequate ventilation, as excessive heat drastically shortens LED lifespan. Use aluminum mounting channels wherever possible; they provide structural support, improve heat dissipation, and create a clean finished look. Match the power supply wattage to the strip’s requirements plus a 20% safety margin to prevent overheating—undersized drivers cause premature failure. For dimming functionality, verify compatibility between the LED strip, dimmer switch, and power supply to avoid flickering. Finally, never cover installed strips with insulation, fabric, or other materials that trap heat, and ensure all connections are secure and insulated to eliminate fire hazards. Following these steps ensures your home LED strip installation operates safely, efficiently, and delivers the intended aesthetic for years.

Why Choose Beauty STC Lighting

Transform your living spaces with high-quality LED strip lighting designed for modern homes. At Beauty STC, we specialize in energy-efficient, durable, and versatile LED solutions that bring elegance and functionality to any residential environment. Whether you’re illuminating kitchens, bedrooms, or outdoor areas, our LED strips offer seamless integration and superior performance.

Partner with Beauty (STC) Manufacturing Co., Ltd. to access OEM and ODM services, competitive pricing, and reliable production capacity. As a trusted name in LED lighting manufacturing, we are committed to delivering products that meet international standards and exceed customer expectations.

For collaboration opportunities or product inquiries, contact our sales manager at [email protected] and let Beauty STC light up your home lighting projects.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.