Article Contents

Industry Insight: Profile For Led

The commercial and industrial lighting landscape has undergone a profound transformation, driven by the relentless advancement and adoption of LED technology. Moving far beyond simple energy savings, modern LED solutions are now fundamental infrastructure for operational efficiency, occupant well-being, and sustainable facility management. Today’s discerning specifiers and facility managers demand more than just illumination; they require intelligent, durable, and compliant systems that deliver measurable returns through reduced energy consumption, lower maintenance costs, enhanced light quality, and seamless integration with building automation. Crucially, adherence to rigorous safety and performance standards like ETL for North American markets and CE marking for Europe is not merely a regulatory formality but a non-negotiable baseline for trust, liability protection, and market access in professional environments. These certifications validate that products meet essential health, safety, and environmental requirements, providing critical assurance to end-users investing in long-term lighting infrastructure.

Beauty STC Manufacturing Co., Ltd. stands as a dedicated partner within this evolving sector. Established in 1998, we have cultivated over 25 years of deep engineering expertise focused specifically on the demanding requirements of commercial and industrial LED lighting. Our foundation was built on understanding the unique challenges faced by warehouses, factories, offices, retail spaces, and public infrastructure – challenges where reliability, performance consistency, and total cost of ownership are paramount. We leverage this extensive experience to design and manufacture high-performance LED luminaires and systems engineered for the rigors of professional use, consistently meeting and exceeding global safety certifications including ETL and CE. At Beauty STC, our commitment is to deliver not just products, but proven, compliant lighting solutions that empower businesses to optimize their environments and achieve their operational and sustainability goals.

Technical Specs & Certifications

The profile for LED lighting solutions offered by Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver high performance, energy efficiency, and superior light quality for both commercial and industrial applications. Central to our design philosophy is the optimization of lumens per watt (lm/W), ensuring maximum light output with minimal energy consumption. Our LED profiles typically achieve an efficacy range of 120 to 150 lumens per watt, depending on the specific configuration and thermal management design. This high efficiency is realized through the integration of advanced SMD LED chips, precision optical engineering, and thermally efficient aluminum extrusions that promote effective heat dissipation, thereby maintaining consistent performance over extended operating periods.

Color Rendering Index (CRI) is a critical parameter in our product development, especially for applications where accurate color representation is essential—such as retail, healthcare, and architectural lighting. All our high-end LED profiles are designed to deliver a CRI greater than 90, with select models offering CRI values up to 97. This ensures vibrant, natural color rendition, closely mimicking daylight conditions and enhancing visual comfort and clarity.

Ingress Protection (IP) ratings are rigorously addressed to ensure durability and suitability across diverse environments. Our LED profiles are available in various IP ratings to meet specific application demands. For indoor use, standard profiles are typically rated IP20, providing basic protection against touch and dust. For damp or outdoor environments, we offer IP65-rated profiles that are fully protected against dust and low-pressure water jets. For more demanding applications such as outdoor pathways, wet locations, or industrial settings, we provide IP67-rated profiles that offer complete dust protection and temporary immersion resistance up to 1 meter for 30 minutes. These ratings are achieved through precision-sealed silicone gaskets, robust end caps, and high-purity diffusers that maintain optical clarity while ensuring environmental resilience.

Beauty (STC) Manufacturing Co., Ltd. upholds stringent quality control standards throughout the production process. Our LED profiles are manufactured using high-grade aluminum alloys, ensuring excellent thermal conductivity and mechanical strength. All components undergo rigorous testing for thermal cycling, UV resistance, and long-term lumen maintenance. We adhere to international certifications including CE, RoHS, and ISO 9001, reflecting our commitment to reliability, safety, and sustainability. With a focus on precision engineering and consistent performance, Beauty STC delivers LED profiles that combine aesthetic elegance with industrial-grade durability, making them a trusted choice for lighting professionals worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within the Pearl River Delta’s robust electronics supply chain ecosystem. This factory serves as a key production hub for our LED lighting solutions, integrating advanced surface mount technology, rigorous quality assurance protocols, and flexible OEM services tailored to client specifications.

The SMT production line at the Jiangmen facility utilizes state-of-the-art high-speed placement machines from leading manufacturers such as Fuji and Yamaha. These machines feature multi-head gantry systems capable of handling components ranging from ultra-fine 0201 passives to larger power LEDs and integrated circuits with exceptional placement accuracy, typically within ±25μm. The line includes automated solder paste printers with vision alignment, nitrogen-reflow soldering ovens for optimal thermal profiles, and automated optical inspection stations for real-time defect detection immediately after reflow. This comprehensive SMT setup ensures high first-pass yields and consistent solder joint integrity critical for LED thermal management and long-term reliability.

Aging tests represent a non-negotiable phase in our quality control process at the Jiangmen plant. All finished LED lighting products undergo mandatory burn-in procedures within our dedicated environmental chambers. Standard aging protocols involve operating units at elevated temperatures, typically 50-60°C, for durations of 24 to 72 hours depending on the product category and client requirements. During this period, we continuously monitor critical parameters including lumen output, color temperature stability, forward voltage, and thermal performance using integrated photometric sensors and data loggers. Units exhibiting any deviation beyond our stringent acceptance criteria are automatically flagged for rework or analysis, ensuring only units demonstrating stable initial performance reach customers.

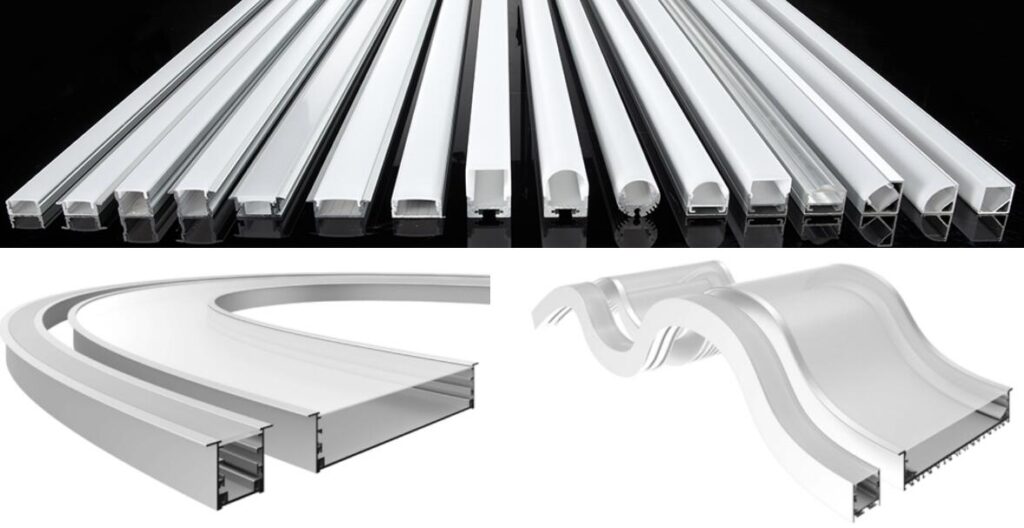

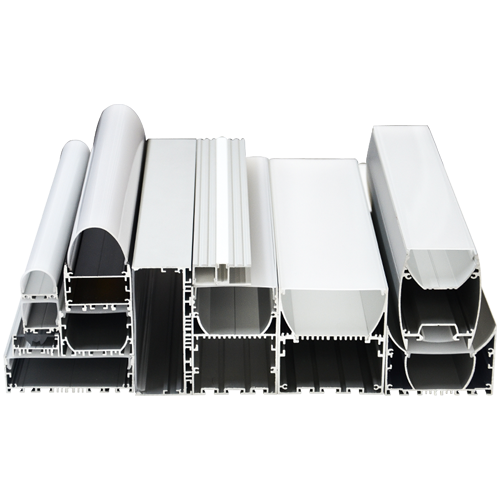

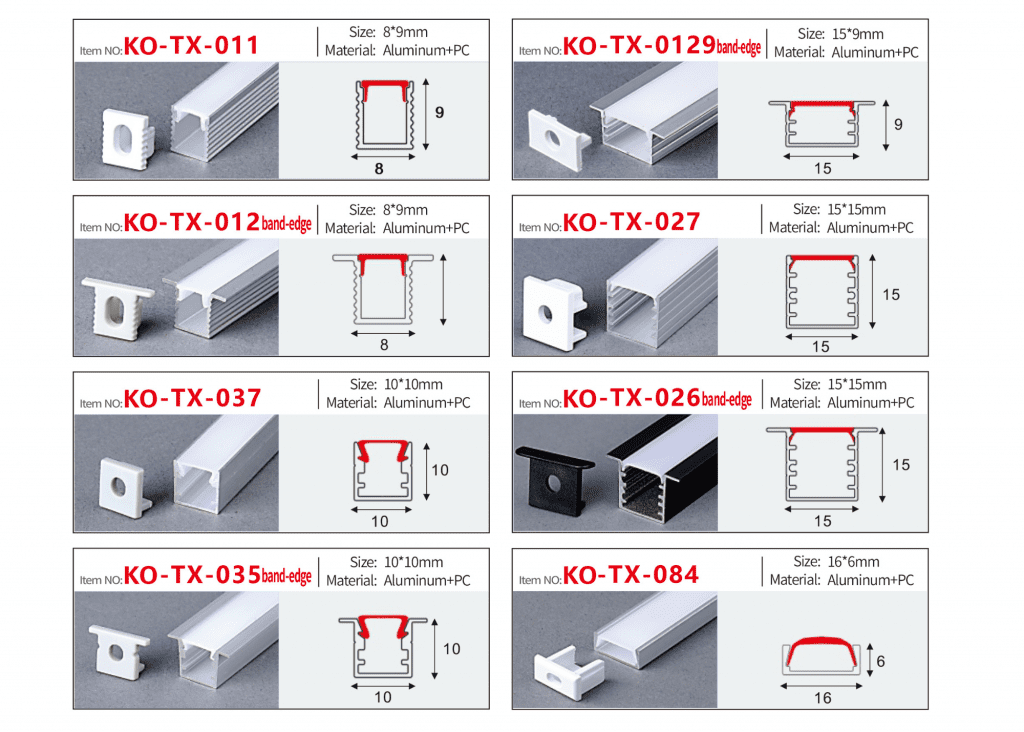

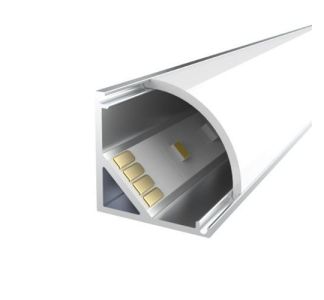

Our OEM capability specifically for LED profiles is a significant strength of the Jiangmen operation. We provide end-to-end customization for aluminum extrusion profiles used in linear LED systems, from initial design consultation through to finished integrated lighting modules. Clients can supply dimensional specifications, thermal requirements, and aesthetic preferences including surface finishes such as anodizing, powder coating, or wood grain texturing. Our engineering team collaborates closely with customers to optimize profile geometry for thermal dissipation, optical performance, and mechanical integration. The facility houses extrusion tooling capabilities alongside secondary processing equipment for cutting, drilling, and surface treatment, enabling us to produce custom profiles in various lengths and finishes. Crucially, we integrate these profiles directly with our SMT lines to mount client-specified LED components, drivers, and diffusers, delivering fully assembled, tested, and branded LED lighting solutions meeting exact OEM requirements. This vertical integration ensures seamless transition from profile extrusion to final product assembly under one roof.

Application Scenarios

The term “profile for LED” typically refers to aluminum or plastic channels designed to house and protect LED strips, providing a clean and professional finish while also helping with heat dissipation and light diffusion. These profiles are widely used across various commercial and hospitality environments including hotels, malls, and offices due to their functional and aesthetic benefits.

In hotels, LED profiles are commonly used in guest rooms to create ambient lighting along coves, headboards, under cabinets, or in walk-in closets. They enhance the guest experience by adding a modern, luxurious feel. In lobbies and corridors, recessed LED profiles in ceilings or walls provide indirect lighting that contributes to a welcoming atmosphere. Bathrooms often feature profiles under mirrors or along vanity edges for both functionality and style.

In malls, LED profiles are essential for accentuating architectural features, guiding foot traffic, and highlighting retail displays. They are frequently installed in coves, stair treads, handrails, and ceiling soffits to create visual interest and improve spatial perception. Back-of-house areas such as service corridors and loading zones also benefit from durable LED profiles that offer efficient, long-lasting illumination.

Offices use LED profiles to support a professional and productive environment. They are installed in drop ceilings, suspended grids, under cabinets, and along workstations to provide even, glare-free lighting. Task lighting in meeting rooms and reception desks often incorporates LED profiles for a sleek appearance. Indirect lighting via cove profiles helps reduce eye strain and creates a more open, airy workspace.

When installing LED profiles, it is important to plan the layout carefully to ensure even light distribution and avoid dark spots. Always measure the installation area precisely and cut the profile to size using appropriate tools—typically a fine-tooth saw for aluminum. Secure the profile using clips, brackets, or adhesive, depending on the surface and load requirements. Ensure the surface is clean and dry before applying adhesive-mounted profiles.

Always insert the LED strip into the profile before connecting it to the power supply, and make sure the strip is properly seated to avoid hotspots or uneven light output. Use diffuser lenses—milky or clear—depending on the desired effect; frosted diffusers provide a smoother, more uniform glow. For optimal thermal management, especially with high-density LED strips, aluminum profiles are preferred as they dissipate heat effectively, extending the lifespan of the LEDs.

Finally, consider accessibility for maintenance. In high-traffic or hard-to-reach areas, use profiles with removable diffusers or snap-on covers to simplify future servicing. Proper installation not only enhances visual appeal but also ensures long-term reliability and performance of the LED lighting system.

Why Choose Beauty STC Lighting

Partner with Beauty STC to access precision-engineered LED lighting solutions designed for superior performance and reliability. As a leading manufacturer, we specialize in innovative LED profiles and custom lighting systems tailored to meet the exacting demands of commercial and architectural projects. Our engineering expertise ensures optimal thermal management, exceptional light quality, and seamless integration for your applications. Elevate your lighting solutions with a trusted partner committed to quality and technical excellence. Contact our dedicated team today at [email protected] to discuss your project requirements and discover how Beauty STC can deliver the right LED profile for your needs.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.