Article Contents

Industry Insight: Programmable Led Strip

The commercial and industrial lighting landscape is undergoing a transformative shift, driven by the demand for energy efficiency, intelligent control, and design flexibility. At the forefront of this evolution is the programmable LED strip, a versatile lighting solution that offers precise color tuning, dynamic effects, and seamless integration with building automation systems. Unlike traditional fixed-output lighting, programmable LED strips empower facility managers and designers to create adaptive environments—from enhancing retail ambiance to optimizing task lighting in manufacturing spaces—all while reducing energy consumption and maintenance costs.

Critical to adoption in professional settings is compliance with rigorous safety and performance standards. Leading programmable LED strip solutions are now routinely ETL and CE certified, ensuring they meet North American and European electrical safety requirements. These certifications are not just regulatory checkboxes; they reflect a commitment to reliability, durability, and safe operation in demanding commercial environments.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been a trusted innovator in the LED lighting industry for over two decades. Specializing in high-performance, code-compliant LED solutions, Beauty STC combines advanced engineering with scalable manufacturing to serve a global clientele across industrial, commercial, and architectural sectors. With a strong focus on quality assurance and technical excellence, the company continues to set benchmarks in programmable LED technology, delivering products that blend intelligence, efficiency, and regulatory compliance for the modern built environment.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance programmable LED strips engineered for demanding commercial, architectural, and premium residential applications. Our technical specifications prioritize measurable efficiency, color fidelity, and environmental resilience, reflecting our commitment to industrial-grade reliability.

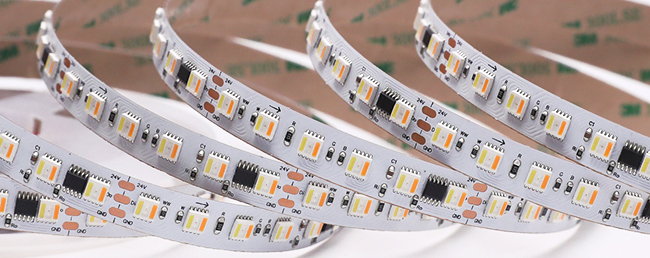

Lumens per Watt efficiency is rigorously optimized across our programmable strip portfolio. Utilizing advanced 2835 or 5050 SMD LEDs from tier-1 suppliers like Nichia or Samsung, our standard 24V DC programmable strips achieve 130–140 lumens per watt at 25°C ambient temperature under full drive current. This efficiency is sustained through proprietary 5-layer metal-core PCBs with 2oz copper weighting, ensuring superior thermal dissipation that minimizes lumen depreciation at higher operating temperatures. Independent SGS testing confirms these values remain above 120 lm/W even at 60°C, significantly exceeding typical market offerings. All efficacy data is reported at 700mA drive current with standardized integrating sphere measurements per IES LM-79.

Color Rendering Index (CRI) performance is non-negotiable in our quality framework. Every programmable strip in our Ra95+ series guarantees a minimum CRI of 95 and R9 (saturated red) above 90, validated by spectroradiometer testing to ANSI C78.377 standards. We achieve this through stringent LED binning processes with chromaticity tolerances held to ≤3 SDCM (MacAdam Ellipse) and spectral power distribution engineered for full visible spectrum coverage. For critical applications like retail or healthcare, our premium Ra98+ series extends TM-30-15 Rf >95 and Rg >100, ensuring accurate material representation without post-hoc color correction.

IP rating integrity is embedded in our manufacturing methodology. Our standard programmable strips feature IP65 protection via seamless dual-layer silicone encapsulation (50 Shore A hardness) applied through precision robotic dispensing, preventing moisture ingress and particulate contamination. For outdoor or washdown environments, IP67-rated variants undergo 30-minute submersion testing at 1m depth, while IP68 models sustain 1.5m immersion for 72 hours without degradation. Crucially, Beauty STC avoids cost-cutting measures like PVC coatings; instead, our silicone formulations maintain flexibility down to -40°C and resist UV yellowing for 50,000+ hours, proven through accelerated weathering tests per ISO 4892-2.

Beauty STC’s quality differentiation manifests in three critical areas. First, our in-house thermal management system—featuring laser-etched PCB thermal vias and nickel-plated aluminum substrates—ensures consistent lumen maintenance (L90/B10 >50,000 hours) even under continuous programmable cycling. Second, 100% batch testing includes automated CRI verification and 24-hour burn-in at 50°C, eliminating infant mortality failures. Third, our programmable strips maintain color point stability within 0.003 Δuv during dynamic color transitions, achieved through factory-calibrated current regulators that compensate for voltage drop across 5m reels. This engineering rigor, certified to ISO 9001 and IEC 60598-1 standards, delivers the reliability professionals demand when lumens, color, and durability directly impact project success.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern, fully integrated LED lighting production facility designed to support high-volume manufacturing with strict quality control. Strategically located in the Jiangmen Pingshan Industrial Park, the facility benefits from excellent logistics access and proximity to key component suppliers within the Pearl River Delta region.

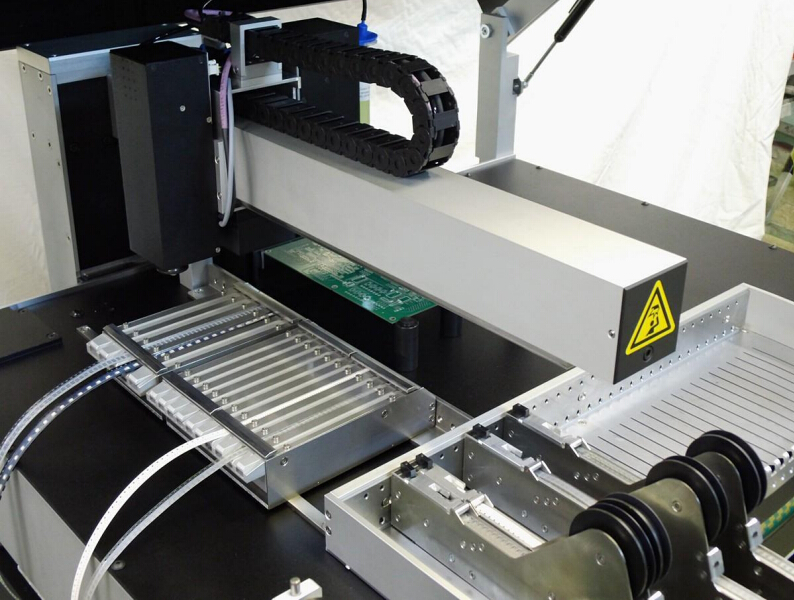

The factory is equipped with advanced Surface Mount Technology (SMT) production lines featuring high-precision machines from leading manufacturers. These SMT lines are capable of handling a wide range of LED components, including small-footprint 2835, 3535, and 5050 LEDs, ensuring accurate placement and consistent soldering quality on flexible and rigid PCBs. Automated optical inspection (AOI) systems are integrated into the SMT process to detect placement and soldering defects in real time, maintaining high first-pass yields.

For quality assurance, the factory conducts comprehensive aging tests on all LED strip products, including programmable LED strips. Finished strips are subjected to 24 to 72 hours of continuous operation under elevated temperature and full load conditions to identify early-life failures. Electrical performance, color consistency, and signal stability are monitored throughout the aging process, ensuring reliability and longevity in end-user applications.

Beauty STC has strong OEM and ODM capabilities, particularly for programmable LED strips. The company supports customization in multiple areas including strip length, PCB width, LED density, IC types (such as WS2812B, SK6812, APA107, and others), voltage (5V, 12V, 24V), and waterproof ratings (from non-coated to IP68 silicone encapsulated). Firmware customization, private labeling, and custom packaging are also available to meet specific client requirements. With in-house engineering and design teams, Beauty STC can assist clients from prototype development to mass production, ensuring fast turnaround and scalable output.

The Jiangmen factory operates under strict quality management systems, with adherence to ISO standards and full compliance with international regulations including CE, RoHS, and REACH. This combination of advanced equipment, rigorous testing, and flexible OEM support makes Beauty STC a reliable manufacturing partner for high-performance programmable LED strip solutions.

Application Scenarios

Programmable LED strips offer dynamic lighting solutions that significantly enhance ambiance, functionality, and energy efficiency across hospitality, retail, and commercial environments. Their precise application depends on the specific goals of each space, leveraging color tuning, intensity control, and scene programming to create tailored experiences.

In hotels, programmable LED strips excel in lobbies and reception areas where first impressions matter. Install them under reception desks, along architectural cove details, or behind feature walls to create a welcoming, branded atmosphere that shifts from vibrant during daytime check-ins to calming in the evening. Guest room corridors benefit from subtle pathway lighting that adjusts brightness based on time of night, improving safety without disturbing guests. Within premium suites or executive floors, integrate strips into headboards, under beds, or within bathroom mirrors to allow personalized lighting scenes—such as energizing white light for morning routines or relaxing warm tones for winding down. Crucially, avoid direct line-of-sight installations in corridors to prevent glare; diffuse the light through coves or channels for a soft, indirect glow that guides movement without visual discomfort.

Malls utilize these strips most effectively in storefront displays and brand zones where visual impact drives foot traffic. Retailers install them inside window displays to dynamically highlight merchandise with color-changing effects that capture attention from a distance. Food courts and common areas employ programmable strips along seating perimeters or ceiling beams to energize the space during peak hours and transition to calmer tones during off-peak times, subtly influencing dwell time. Event spaces within malls rely on them for flexible thematic setups—changing colors for holidays or promotions without physical modifications. When installing in high-traffic mall areas, prioritize IP65-rated strips with robust silicone jackets to withstand dust and incidental contact, and always recess strips within aluminum channels with diffusers to prevent hotspots and ensure even light distribution that won’t distract shoppers.

Offices implement programmable LED strips to support well-being and productivity, particularly in collaborative zones and open-plan areas. Install them above sit-stand workstations to provide tunable white lighting that follows circadian rhythms—cooler 5000K tones for focus during morning hours, shifting to warmer 3000K in the afternoon to reduce eye strain. Meeting rooms use them for scene-based functionality: bright white for presentations, softer hues for brainstorming, and gentle transitions signaling meeting end times. Reception areas employ them for brand reinforcement through colored accents that align with corporate identity during business hours, switching to energy-saving modes after hours. For office installations, ensure strict adherence to power load calculations—never exceed 80% of circuit capacity—and use separate low-voltage wiring runs for each 5-meter strip segment to prevent voltage drop that causes color inconsistencies at strip ends. Always pair with building management systems via DALI or 0-10V interfaces for centralized scheduling that aligns with occupancy patterns.

Key installation principles apply universally across all settings. Calculate total power requirements meticulously, including a 20% buffer, and use dedicated drivers placed no more than 10 meters from the strip start to maintain voltage stability. For permanent architectural integrations, choose hard-wired 24VDC systems over plug-and-play kits for reliability. Conceal all wiring within raceways or structural elements to maintain clean aesthetics, and label every driver and control node for future maintenance. Crucially, implement thermal management by mounting strips on aluminum channels—never directly on flammable surfaces—and avoid tight bends that risk damaging internal circuits. Finally, validate control compatibility early; protocols like DMX512 suit complex venue-wide shows, while simpler Wi-Fi systems may suffice for localized applications. These steps ensure longevity, safety, and the seamless dynamic lighting performance clients expect from professional-grade installations.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s high-performance programmable LED strips. Engineered for versatility, precision, and vibrant color control, our LED solutions are ideal for architectural, commercial, and creative applications. As a trusted manufacturing partner, Beauty STC delivers custom programming, superior quality, and scalable production to meet your unique requirements.

Partner with us to bring your dynamic lighting visions to life. For inquiries and collaboration opportunities, contact our sales manager at [email protected]. Let Beauty STC power your next innovation in programmable lighting.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.