Article Contents

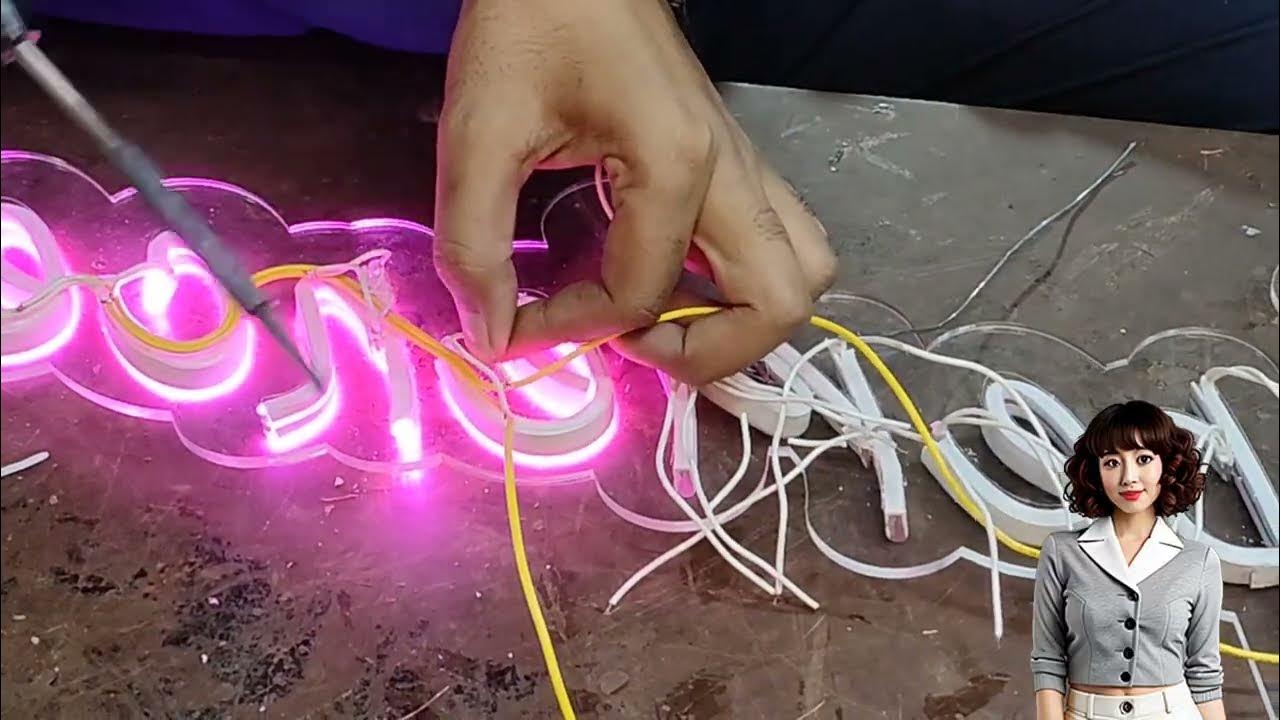

Industry Insight: Diy Led Neon Sign

The commercial and industrial lighting sector is experiencing a significant shift as DIY LED neon signs transition from niche decorative novelties to legitimate tools for branding, wayfinding, and ambient enhancement within professional environments. While initially popular in residential settings, businesses increasingly recognize the value of customizable, energy-efficient signage for retail storefronts, hospitality venues, corporate lobbies, and even industrial facility identification. However, this adoption brings critical considerations beyond aesthetics. Commercial applications demand robust performance, longevity under continuous operation, and crucially, adherence to stringent safety and electromagnetic compatibility standards like ETL and CE. These certifications are non-negotiable for professional installations, ensuring products meet rigorous electrical safety requirements and can operate reliably without interfering with other sensitive equipment – a vital factor often overlooked in uncertified consumer-grade DIY kits that pose significant fire and operational risks in business settings. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution. Leveraging over two decades of specialized expertise in LED lighting engineering and manufacturing, we understand the unique demands of commercial and industrial clients. We focus on delivering DIY LED neon sign solutions engineered not just for visual appeal, but for the durability, safety compliance, and consistent performance required to meet the exacting standards of professional environments, providing businesses with a reliable and certified path to integrate this dynamic lighting technology.

Technical Specs & Certifications

When designing or selecting components for a DIY LED neon sign, understanding the technical specifications is crucial to achieving both visual appeal and long-term performance. Key parameters such as lumens per watt (lm/W), Color Rendering Index (CRI), and Ingress Protection (IP) ratings directly impact the sign’s efficiency, color accuracy, and durability.

Lumens per watt (lm/W) measures the luminous efficacy of the LED neon system, indicating how much visible light is produced per unit of electrical power. High-quality LED neon solutions, such as those engineered by Beauty (STC) Manufacturing Co., Ltd., typically deliver between 90 to 110 lumens per watt. This range ensures energy-efficient operation without sacrificing brightness, making it ideal for both indoor displays and extended outdoor use. Higher efficacy not only reduces power consumption but also minimizes heat generation, contributing to longer lifespan and reliability.

Color Rendering Index (CRI) is a measure of how accurately a light source reveals the true colors of objects compared to natural light. For professional-grade LED neon signs—especially those used in retail, hospitality, or artistic installations—a CRI greater than 90 is essential. Beauty STC’s premium LED neon products consistently achieve CRI values of 90 to 95, ensuring vibrant, true-to-life color representation. This high color fidelity enhances visual impact and is particularly important when the sign is used to represent brand colors or detailed artwork.

Ingress Protection (IP) ratings define the level of protection an LED neon sign has against dust and moisture. For DIY applications, the appropriate IP rating depends on the installation environment. Indoor signs typically require at least IP65, which provides protection against dust and low-pressure water jets. For outdoor or high-moisture environments such as bathrooms or covered patios, IP67 or higher is recommended, offering full dust tightness and temporary immersion resistance. Beauty STC manufactures LED neon solutions with robust silicone encapsulation and seamless construction, enabling IP65 to IP68 ratings across their product lines. This ensures long-term resilience against environmental stressors including UV exposure, temperature fluctuations, and humidity.

Beauty (STC) Manufacturing Co., Ltd. is recognized for its commitment to quality and innovation in LED lighting. Their LED neon signs are produced using precision extrusion techniques, high-grade flexible PCBs, and consistent SMD LED placement, resulting in uniform illumination with no visible hotspots. Each product undergoes rigorous testing for electrical safety, color consistency, and environmental durability, meeting international standards such as CE, RoHS, and UL. With a focus on performance and reliability, Beauty STC’s LED neon solutions provide an optimal foundation for DIY sign builders seeking professional-grade results.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial regions to leverage supply chain efficiencies and skilled labor. The factory is purpose-built for the production of advanced LED lighting solutions, with a significant focus on flexible LED neon signage, including specialized capabilities for the rapidly growing DIY market segment.

The surface-mount technology (SMT) production line forms the backbone of precision assembly at the Jiangmen facility. We utilize multiple high-speed, multi-head SMT machines from leading manufacturers, capable of placing components with micron-level accuracy. These lines are optimized for handling the fine-pitch LEDs, resistors, and integrated circuits critical to neon flex production, supporting both standard and custom PCB designs. Automated optical inspection (AOI) systems are integrated directly into the SMT process to verify component placement and solder joint integrity in real-time, ensuring minimal defects before boards proceed to subsequent stages. This capability is essential for maintaining the consistent light output and reliability expected in both commercial and consumer-grade neon signs.

Rigorous aging and burn-in testing is a non-negotiable phase for all LED neon products, including DIY kits, before shipment. At Jiangmen, dedicated aging chambers subject finished neon flex strips and assembled sign modules to controlled thermal and electrical stress for a minimum of 48 hours under continuous operation. Testing parameters simulate real-world conditions, including elevated temperatures up to 65°C and cyclic power loading, to identify early-life failures and validate long-term performance. For DIY neon signs, this process specifically verifies the resilience of pre-cut segments, connector integrity, and driver compatibility under sustained use, ensuring end-users receive components that perform reliably upon installation. Statistical process control data from these tests is continuously monitored to drive yield improvements and proactive quality management.

Our OEM capabilities for DIY LED neon signs are a core strength developed at the Jiangmen factory. We offer comprehensive customization from initial concept through to packaged kit delivery. Clients can specify unique shapes, colors (including RGBW and tunable white), lengths, and mounting hardware configurations. The factory supports low to high-volume production with flexible minimum order quantities tailored to market needs. Crucially for the DIY segment, we engineer user-friendly solutions such as pre-terminated cables, color-coded connectors, simplified mounting brackets, and clear assembly guides—all customizable with client branding. Packaging is designed for retail readiness or direct e-commerce fulfillment, incorporating protective materials and instructional inserts. Engineering collaboration extends to software integration for programmable signs and compliance testing against target market safety standards (UL, CE, RoHS), ensuring the final DIY product is both marketable and safe for consumer assembly.

This integrated approach—combining precision SMT assembly, exhaustive aging validation, and agile OEM customization—allows Beauty STC to deliver robust, brand-aligned DIY LED neon solutions that meet the exacting demands of global retailers and lighting brands from our Jiangmen base.

Application Scenarios

DIY LED neon signs are versatile decorative lighting solutions that can enhance the ambiance and visual appeal across various commercial and public spaces. In hotels, these signs are ideal for lobbies, reception areas, lounge bars, or themed guest rooms, where they can convey brand identity, display welcome messages, or create a cozy, modern atmosphere. Their customizable nature allows hotels to reflect unique design concepts, such as tropical motifs in beach resorts or minimalist typography in boutique establishments.

In malls and retail environments, DIY LED neon signs serve as eye-catching promotional tools. They can be used in storefronts, food courts, or event zones to highlight brand names, slogans, or seasonal campaigns. Their bright, even glow attracts attention and enhances the shopping experience, especially in dimly lit corridors or evening settings. Malls often use them for wayfinding or to accentuate entertainment areas like arcades or photo booths.

Offices, particularly creative agencies, coworking spaces, or tech startups, use DIY LED neon signs to foster a dynamic and inspiring work environment. Placing them in reception areas, breakout zones, or meeting rooms adds personality and can reinforce company culture—displaying mottos, core values, or playful graphics. The soft glow also helps reduce the sterility often associated with corporate interiors.

When installing DIY LED neon signs, it’s essential to begin by selecting a clean, dry, and flat surface that can support the sign’s weight. Most signs come with mounting hardware, including brackets or adhesive pads—ensure these are securely fastened according to the manufacturer’s instructions. For wall mounting, use a level to align the sign properly and avoid visual imbalance. Consider the power source location; plan the cable routing in advance, using cable clips or conduits to maintain a neat appearance. Avoid placing the sign in direct sunlight or high-moisture areas unless it is specifically rated for such conditions. Always turn off power when connecting to electrical outlets, and verify that the voltage matches local requirements. For larger installations or ceiling mounts, professional assistance may be advisable to ensure safety and optimal visual impact.

Why Choose Beauty STC Lighting

Ready to bring your creative vision to life with stunning, custom DIY LED neon signs? Partner with Beauty STC Manufacturing Co., Ltd., your trusted expert in advanced LED lighting solutions. We provide the engineering excellence and manufacturing precision needed to transform your unique designs into safe, vibrant, and energy-efficient neon signs that captivate any space. Our dedicated team supports you through every step, from concept refinement and material selection to final production, ensuring your DIY kits meet the highest standards of quality and reliability.

As your manufacturing partner, Beauty STC leverages years of specialized experience in flexible LED neon technology to deliver exceptional value. We understand the critical importance of consistent color rendering, durable construction, and user-friendly assembly for DIY applications. Our commitment to innovation means you benefit from the latest advancements in low-voltage LED systems, ensuring your products are not only visually striking but also safe and easy for end-users to install. We handle the complex engineering and rigorous quality control, so you can focus on your brand and your customers.

Take the next step toward creating exceptional DIY LED neon experiences. Contact our dedicated partnership manager today at [email protected] to discuss your project requirements, explore customization options, and receive a tailored solution that meets your specific needs. Let Beauty STC be the foundation of your success in the dynamic LED signage market.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.