Article Contents

Industry Insight: Sheet Led

In the evolving landscape of commercial and industrial lighting, sheet LED technology has emerged as a transformative solution, offering uniform illumination, energy efficiency, and sleek integration into modern architectural designs. Widely adopted in offices, retail spaces, warehouses, and manufacturing facilities, sheet LEDs provide high lumen output with minimal glare, ensuring optimal visibility and enhanced ambiance. Their low-profile design allows for seamless ceiling integration, while advanced thermal management systems contribute to extended service life and reduced maintenance costs—critical factors in large-scale operations.

Compliance with international safety and performance standards is paramount in these demanding environments. Sheet LED fixtures from reputable manufacturers are typically ETL and CE certified, ensuring they meet rigorous North American and European electrical, safety, and electromagnetic compatibility requirements. These certifications not only reflect product reliability but also support code compliance in regulated commercial installations.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-performance commercial and industrial lighting solutions, Beauty STC combines cutting-edge optical engineering with robust manufacturing practices to deliver sheet LED products that meet the exacting demands of global markets. With a strong commitment to quality, energy efficiency, and regulatory compliance, Beauty STC continues to be a trusted partner for specifiers, contractors, and facility managers seeking durable, code-compliant lighting systems.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. produces high-performance flexible LED strips and rigid LED panels commonly referred to as “sheet LED” solutions within the lighting industry. These products are engineered for demanding architectural, retail, and hospitality applications where uniform illumination and quality are paramount. Regarding the specific technical specifications requested:

Lumens per Watt efficiency for our high-CRI sheet LED products typically ranges from 120 to 150 lm/W under standard operating conditions at 25°C ambient temperature. This performance level is achieved while maintaining the stringent color quality requirements. It is important to note that achieving CRI >90 inherently involves a slight efficiency trade-off compared to standard LEDs, as the phosphor blends required for superior color rendering absorb more energy. Our engineering team optimizes thermal management and driver efficiency to maximize lm/W within this high-fidelity color constraint, ensuring our products remain competitive in energy savings without compromising light quality.

Color Rendering Index (CRI) performance is a core strength of Beauty STC’s premium sheet LED lines. We consistently deliver CRI values exceeding 90, with Ra typically between 92 and 95 across multiple production batches. Crucially, we prioritize high R9 (saturated red) values above 50 and maintain balanced R12 (blue) values to ensure accurate rendering of critical colors, particularly in skin tones and merchandise. Our manufacturing process includes strict binning protocols using high-grade Samsung LM301B or Epistar LEDs coupled with proprietary phosphor formulations. We further validate performance using TM-30-15 metrics, achieving Rf values above 85 and Rg values near 100, providing designers with the confidence that colors appear natural and vibrant under our illumination.

IP ratings for Beauty STC sheet LED products are rigorously tested and certified to meet specific environmental demands. Our standard flexible strip offerings feature IP20 for dry indoor environments, while IP65-rated versions utilize silicone encapsulation for protection against dust and low-pressure water jets, suitable for kitchens, bathrooms, or covered outdoor areas. For fully outdoor or submerged applications, we provide IP67-rated rigid panel solutions with hermetic sealing, capable of withstanding temporary immersion up to 1 meter depth. All IP-rated products undergo extended 1000-hour salt spray testing and thermal cycling per IEC 60529 standards, far exceeding basic certification requirements to ensure long-term reliability in harsh conditions.

Beauty STC’s commitment to quality is embedded throughout our manufacturing process. We implement six-sigma tolerances on critical parameters including lumen output consistency (±5%), correlated color temperature (±100K binning), and forward voltage matching. Every production batch undergoes 24-hour burn-in testing and photometric validation using calibrated Integrating Sphere systems traceable to NIST standards. Our thermal management solutions feature aerospace-grade aluminum substrates and optimized thermal interface materials, ensuring junction temperatures remain below 65°C at full load to maximize L70 lifetime beyond 50,000 hours. This rigorous approach, combined with ISO 9001-certified production and UL/cUL/CE safety certifications, delivers sheet LED products that consistently meet or exceed the demanding specifications required by professional lighting designers and specifiers worldwide. We prioritize real-world performance over inflated datasheet claims, providing reliable data sheets backed by independent third-party test reports.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located to support efficient production and logistics for both domestic and international markets. The Jiangmen factory is designed to meet high standards of quality control and manufacturing efficiency, particularly in the production of LED lighting products.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines, which are essential for the precise and reliable assembly of LED components onto printed circuit boards. These SMT machines are fully automated, ensuring high-speed placement of components with excellent accuracy and consistency. This automation supports high-volume production while maintaining tight tolerances and minimizing defects, which is critical for the performance and longevity of LED lighting products.

To ensure product reliability and durability, the Jiangmen factory conducts comprehensive aging tests on finished LED products. These tests simulate extended operation under controlled conditions, typically involving continuous power cycling at elevated temperatures. This process helps identify early failures, verify thermal management performance, and confirm the long-term stability of light output and electrical characteristics. The aging test procedures are integrated into the quality assurance workflow, ensuring that only products meeting strict reliability standards are released for shipment.

Beauty STC also offers strong OEM (Original Equipment Manufacturer) capabilities, particularly for customized LED sheet lights—also referred to as panel lights, flat panel LEDs, or sheet LED luminaires. The company can support clients in designing, prototyping, and mass-producing sheet LED products tailored to specific requirements, including dimensions, lumen output, color temperature, dimming functionality, and aesthetic design. Their engineering team works closely with clients to adapt optics, drivers, housings, and mounting solutions, providing end-to-end OEM services from concept to delivery.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to advanced manufacturing, quality assurance, and flexible customer solutions in the competitive LED lighting market.

Application Scenarios

The term “sheet LED” is not standard industry terminology within professional LED lighting. It is likely a colloquial or misapplied reference to flat LED panel lights or LED flat panels, which are thin, rectangular luminaires designed to replace traditional fluorescent troffers or provide seamless, uniform illumination in suspended ceiling grids. These are the products relevant to your query regarding hotels, malls, and offices. Below is a precise application guide and critical installation advice based on Beauty (STC) Manufacturing Co., Ltd.’s engineering expertise.

In hotels, flat LED panels excel in lobbies, conference rooms, and back-of-house areas where clean, shadow-free light is essential. Guest corridors benefit from their low glare and consistent output, enhancing wayfinding and perceived safety. In guest room ceilings, particularly above vanities or in closets, these panels provide flattering, even illumination without the hotspots common in older fixtures. Ballrooms and banquet halls utilize them for flexible ambient lighting during events, while staff break rooms and laundry facilities leverage their durability and high efficiency for cost-sensitive operational areas. Avoid direct installation in high-moisture zones like shower enclosures unless specifically rated for wet locations.

Malls deploy flat LED panels extensively in main concourse ceilings to create bright, inviting retail environments that highlight merchandise without excessive heat output. They are ideal for food court ceilings due to their low maintenance needs and resistance to ambient temperature fluctuations. Specialty retail stores use them in fitting rooms to ensure accurate color rendering for clothing, while suspended ceiling grids in administrative offices and security command centers rely on their uniform light for visual comfort during extended tasks. Entryway canopies and information kiosks also benefit from their slim profile and modern aesthetic, though direct exposure to weather requires outdoor-rated variants.

Offices represent the highest-volume application for flat LED panels. Open-plan workspaces use them in standard 2×2 ft or 2×4 ft grid configurations to minimize glare on computer screens and reduce eye strain, directly supporting productivity and WELL Building Standard compliance. Private offices and executive suites employ them for a professional appearance with flicker-free operation critical for video conferencing. Meeting rooms and training facilities utilize dimmable panels for ambiance control during presentations. Server rooms and data closets leverage their cool operation to avoid adding thermal load to sensitive equipment. Reception areas and executive lobbies often specify ultra-thin or frameless designs for a premium architectural look.

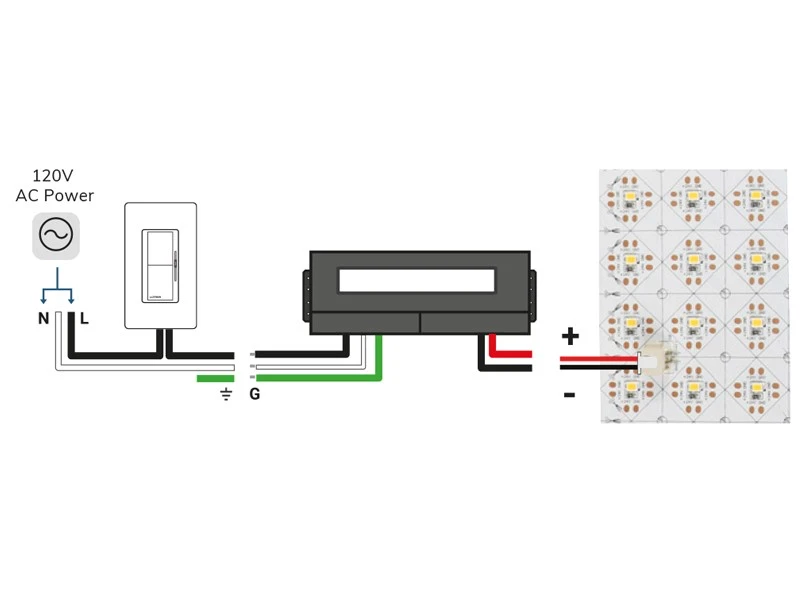

Installation requires strict adherence to structural and thermal protocols. Always verify ceiling grid load capacity exceeds the panel weight by 25% minimum; lightweight aluminum grids may require supplemental cross-bracing at each panel corner to prevent sagging. Electrical connections must use certified quick-connectors or wire nuts within the plenum space, never relying solely on spring clips, to prevent arcing from vibration. Thermal management is non-negotiable: maintain at least 1 inch of clearance above the panel housing for convection cooling, and never insulate over installed panels. In suspended ceilings, align panels precisely with grid lines using laser levels to avoid visible gaps that cause light leakage and aesthetic defects. For dimming compatibility, confirm the driver matches the control system protocol (0-10V, DALI, etc.) during specification—field retrofitting often causes flicker. Finally, handle panels by the frame only; pressure on the diffuser can crack the internal light guide plate, causing permanent dark spots. Always power-test units for 15 minutes pre-installation to catch early driver failures. Adhering to these practices ensures optimal lumen maintenance and avoids costly callbacks.

Why Choose Beauty STC Lighting

Discover the future of lighting with Beauty STC’s premium sheet LED solutions. Engineered for performance, durability, and seamless integration, our sheet LEDs are ideal for a wide range of commercial, industrial, and architectural applications. As a trusted manufacturing partner, Beauty STC combines advanced technology with rigorous quality control to deliver products that exceed expectations.

Partner with us to access custom lighting solutions, scalable production, and expert technical support. Whether you’re developing a new project or upgrading existing systems, our team is ready to help you succeed.

For more information or to discuss your specific requirements, contact our sales manager at [email protected]. Let’s illuminate your next project together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.