Article Contents

Industry Insight: Led Controllers

The evolution of commercial and industrial lighting has been profoundly shaped by advancements in LED technology, with LED controllers emerging as a critical component in modern lighting systems. These intelligent control solutions enable precise management of light intensity, color temperature, scheduling, and energy consumption—offering businesses greater operational efficiency, reduced maintenance costs, and enhanced environmental sustainability. As building operators and facility managers increasingly prioritize smart, scalable lighting infrastructures, the demand for reliable, code-compliant LED controllers has never been higher. Regulatory certifications such as ETL and CE have become essential benchmarks, ensuring that these devices meet rigorous safety, performance, and electromagnetic compatibility standards required in commercial and industrial environments across North America and Europe.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED control solutions since its founding in 1998. With over two decades of engineering expertise, Beauty STC has built a reputation for delivering high-performance, code-compliant LED controllers designed specifically for demanding commercial and industrial applications. From warehouses and manufacturing plants to office complexes and retail spaces, Beauty STC’s products combine robust construction, advanced functionality, and global certification support to meet the evolving needs of the modern built environment.

Technical Specs & Certifications

LED controllers themselves do not possess lumens per watt (lm/W) or Color Rendering Index (CRI) specifications. These metrics are inherent properties of the LED light source and the complete luminaire, not the control device. Lumens per watt measures the efficacy of the LED engine – how efficiently it converts electrical power into visible light. CRI, specifically requiring values greater than 90 (often denoted as CRI >90 or Ra>90), is a measure of the light source’s ability to accurately reveal the colors of objects compared to a natural reference source; this is determined by the phosphor blend and spectral output of the LEDs within the fixture. Beauty STC designs and manufactures high-performance LED modules and luminaires where achieving CRI >90 and high lm/W are core engineering objectives, utilizing premium phosphor-converted LEDs and optimized thermal management.

LED controllers, however, are critical for enabling and maintaining the performance of these high-quality light sources. Beauty STC controllers are engineered to provide stable, ripple-free constant current or constant voltage output essential for preserving the rated lm/W efficiency and preventing flicker that could negatively impact perceived light quality. Our controllers ensure precise dimming compatibility down to very low levels without color shift, which is vital for maintaining the high CRI performance expected in applications like retail, hospitality, and architectural lighting where accurate color representation is paramount. The controller’s role is to deliver clean, regulated power that allows the LED engine to perform at its specified lm/W and CRI levels.

Regarding IP Ratings, this specification applies to the physical protection level of the controller unit itself against dust and moisture ingress, defined by the IEC 60529 standard. Beauty STC offers a comprehensive range of controllers with varying IP ratings tailored to the installation environment. For indoor applications within luminaires or dry locations, our standard controllers typically carry an IP20 rating, providing basic protection against touch and larger particles. For outdoor use, wet locations, or direct burial applications such as landscape lighting, Beauty STC provides robustly sealed controllers rated IP65, IP67, or IP68. An IP67 rating signifies complete dust protection and the ability to withstand temporary immersion in water up to 1 meter depth, while IP68 denotes protection against continuous submersion under conditions specified by the manufacturer. All Beauty STC controllers undergo rigorous environmental testing per IEC standards to verify their stated IP ratings, ensuring long-term reliability in demanding conditions.

Beauty STC’s commitment to quality is embedded throughout our controller manufacturing process. We utilize automotive-grade electronic components and implement stringent quality control procedures, including 100% functional testing and automated optical inspection (AOI) on all production lines. Our controllers consistently exceed industry standards for surge immunity (IEC 61000-4-5), electrostatic discharge (ESD) protection, and operational lifetime, typically rated for 50,000 hours or more at 40°C ambient temperature. This focus on robust design, superior component selection, and meticulous manufacturing ensures that Beauty STC controllers provide the stable, reliable power delivery required to maximize the performance and longevity of high-efficiency, high-CRI LED lighting systems, solidifying our reputation for premium, dependable lighting solutions in the global market.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, designed to support high-volume production of LED lighting products and related electronic components. The factory is equipped with advanced Surface Mount Technology (SMT) production lines that ensure precision and efficiency in assembling printed circuit boards (PCBs) used in LED controllers and lighting systems. These SMT machines are fully automated and capable of handling fine-pitch components, ensuring high-density mounting with excellent repeatability and minimal defect rates. The integration of automated optical inspection (AOI) systems further enhances quality control during the SMT process.

To ensure product reliability and longevity, the Jiangmen factory implements comprehensive aging test procedures. Completed LED controllers and lighting units undergo extended operational testing under elevated temperature and voltage conditions, simulating real-world usage over prolonged periods. This aging process helps identify early-life failures and ensures that only robust, stable products reach customers. Environmental testing chambers and electrical load banks are used to replicate various operating conditions, validating performance across different climates and usage scenarios.

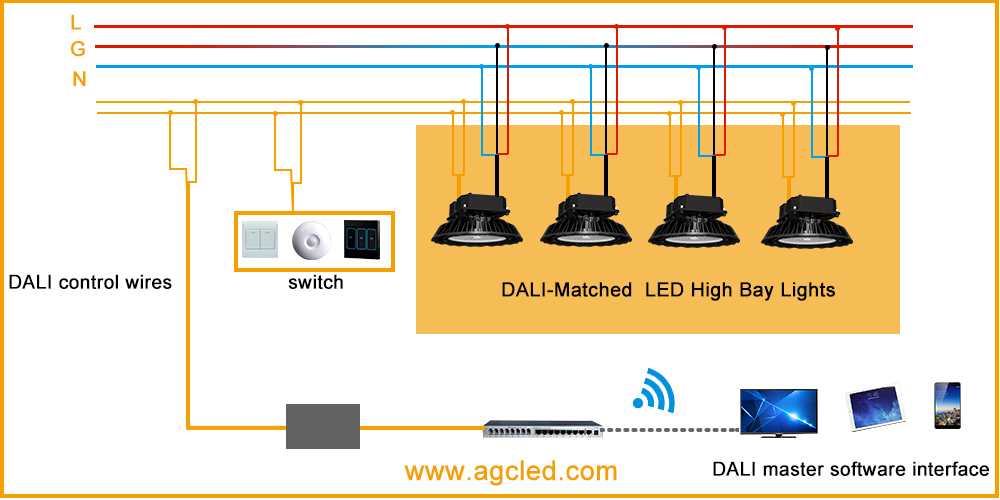

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities specifically for LED controllers. The company supports custom design, engineering, and manufacturing services tailored to client specifications, including but not limited to form factor, voltage requirements, control protocols (such as PWM, 0-10V, DALI, or wireless RF/Zigbee), and integration with smart lighting systems. With in-house R&D, PCB design, firmware development, and tooling support, the factory can deliver fully customized controller solutions from prototyping through to mass production. The OEM process is backed by strict quality management systems, ensuring compliance with international standards and certifications required for global markets.

Application Scenarios

LED controllers are essential for intelligent lighting management across commercial environments, enabling dynamic control, energy savings, and enhanced user experiences. In hotels, they are strategically deployed in lobbies for ambiance shifts from morning brightness to evening warmth, guest room systems allowing personalized scene selection (e.g., wake-up, relaxation, sleep modes), pool and spa areas for color-changing effects that enhance guest experience, and exterior facades for architectural lighting that highlights design features during nighttime. Corridors benefit from occupancy-sensing dimming to conserve energy while maintaining safety, and banquet halls utilize them for seamless transitions between event setups like weddings or conferences.

Malls implement LED controllers extensively in retail storefronts to spotlight merchandise with adjustable color temperatures, common areas for creating vibrant seasonal displays or holiday themes, food courts where lighting adapts to time of day for comfort, and parking structures for motion-activated dimming that reduces operational costs. Large-scale video walls or feature installations often integrate DMX512 or Art-Net controllers for synchronized visual effects during promotions, while directional signage lighting uses controllers for dynamic path guidance during peak hours.

Offices leverage controllers primarily in open-plan workspaces for circadian lighting systems that adjust intensity and color temperature to boost productivity and reduce eye strain, meeting rooms for preset scenes tailored to presentations or brainstorming sessions, executive suites for customizable executive preferences, and reception areas to convey brand identity through lighting moods. Breakout zones may use them for subtle energizing or calming effects, while perimeter zones integrate with daylight harvesting sensors to dim electric lights near windows when natural light suffices.

Installation requires meticulous planning to ensure reliability. Always verify the total connected load does not exceed the controller’s maximum capacity by 20% to prevent overheating, and use dedicated circuit breakers with surge protection given commercial power fluctuations. For large installations like malls or hotel lobbies, segment the system into zones controlled by separate drivers to isolate faults and simplify troubleshooting. Maintain strict separation between low-voltage control wiring and mains power cables, crossing them at 90-degree angles if unavoidable, to eliminate electromagnetic interference that causes flickering. In humid areas such as hotel pools, select controllers rated at least IP65 and house them in ventilated enclosures away from direct water exposure. Networked systems demand a dedicated VLAN with QoS settings to prioritize lighting traffic over general IT use, preventing delays in scene changes during critical events. Crucially, document all channel mappings and scene configurations during commissioning—this saves hours during maintenance when staff inevitably request adjustments months later. Finally, train facility personnel on the controller interface; complex systems fail when users resort to manual overrides due to poor usability. At Beauty (STC), our controllers include plug-and-play topology recognition specifically to address these real-world deployment challenges while ensuring seamless integration with building management systems.

Why Choose Beauty STC Lighting

Discover the future of lighting innovation with Beauty STC—your trusted partner in advanced LED controller solutions. Engineered for precision, reliability, and seamless integration, our LED controllers empower smart, dynamic lighting systems across residential, commercial, and industrial applications. Whether you’re developing architectural lighting, hospitality environments, or energy-efficient building systems, Beauty STC delivers cutting-edge control technology that enhances performance and elevates user experience.

Partner with Beauty STC to access OEM/ODM capabilities, scalable manufacturing, and expert technical support tailored to your project needs. Our team is ready to help you bring smarter lighting solutions to market faster.

For collaboration opportunities and product inquiries, contact our sales manager at [email protected]. Let’s shape the next generation of intelligent lighting—together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.