Article Contents

Industry Insight: Led Strip Lights Waterproof Outdoor

The commercial and industrial lighting sector increasingly demands robust, high-performance solutions capable of withstanding harsh outdoor environments while delivering significant energy savings and operational reliability. Waterproof LED strip lights have emerged as a critical technology for applications ranging from architectural facade highlighting and signage illumination to industrial facility perimeter lighting and outdoor retail displays. These demanding settings require more than basic weather resistance; they necessitate fixtures engineered for continuous exposure to moisture, temperature extremes, UV radiation, and physical stress, all while maintaining consistent lumen output and color fidelity over extended service life. Crucially, deploying such lighting in commercial and industrial projects mandates strict adherence to international safety and performance standards. Certifications like ETL (verifying compliance with North American safety standards) and CE (indicating conformity with European health, safety, and environmental requirements) are not optional extras but fundamental prerequisites for market access, liability mitigation, and ensuring the long-term safety and performance expected by professional specifiers and facility managers.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep engineering expertise specifically focused on solving complex commercial and industrial LED lighting challenges. We understand that waterproof outdoor strip lighting for professional applications requires far more than a simple silicone coating. Our commitment centers on rigorous in-house testing, advanced thermal management designs, and the use of premium components to achieve genuine, long-lasting waterproof integrity beyond basic IP ratings. We engineer our outdoor LED strip systems from the ground up to meet and exceed the stringent demands of ETL and CE certifications, providing specifiers and contractors with the confidence that our solutions deliver the durability, safety compliance, and performance reliability essential for successful, long-term commercial and industrial installations.

Technical Specs & Certifications

LED strip lights designed for outdoor use must meet stringent technical requirements to ensure durability, performance, and visual quality. For waterproof outdoor LED strip lights, key specifications include high lumens per watt (lm/W) efficiency, a Color Rendering Index (CRI) greater than 90, and a suitable Ingress Protection (IP) rating to withstand environmental exposure.

Lumens per watt is a critical measure of energy efficiency, indicating how much visible light is produced per unit of power consumed. High-performance outdoor LED strips typically deliver between 100 to 130 lumens per watt. Advanced SMD chip technologies such as 2835, 3528, or 5050 are commonly used to achieve this efficiency while maintaining stable thermal performance under prolonged operation. At Beauty (STC) Manufacturing Co., Ltd., our outdoor LED strips are engineered to consistently exceed 110 lm/W, ensuring bright illumination with minimal energy consumption.

Color fidelity is essential for both aesthetic and functional lighting applications. A CRI value greater than 90 ensures that colors appear natural and vibrant under the light source, which is particularly important for architectural lighting, landscape design, and retail exteriors. Beauty STC utilizes high-CRI LED chips paired with premium phosphor coatings to deliver consistent color accuracy across the entire length of the strip, minimizing color variance and maintaining excellent light quality in all outdoor conditions.

Ingress Protection (IP) ratings define the level of protection against dust and moisture. For outdoor applications, an IP65 rating or higher is recommended. IP65 provides complete dust protection and resistance to low-pressure water jets from any direction, making it suitable for covered outdoor installations. For direct exposure to rain or irrigation, IP67 (protection against temporary immersion) or IP68 (continuous submersion protection) are ideal. Beauty STC’s waterproof outdoor LED strips are manufactured with robust silicone encapsulation, seamless soldering, and high-quality flexible PCBs, ensuring long-term reliability at IP67 and IP68 ratings. Our production process includes rigorous testing for water resistance, thermal cycling, and UV stability to guarantee performance in harsh climates.

At Beauty (STC) Manufacturing Co., Ltd., quality is embedded in every stage of production. We adhere to international standards including RoHS, CE, and UL, and our LED strips undergo comprehensive in-house testing for electrical safety, photometric performance, and environmental resilience. The combination of superior materials, precision manufacturing, and strict quality control ensures that our waterproof outdoor LED strip lights deliver exceptional brightness, color accuracy, and longevity in demanding outdoor environments.

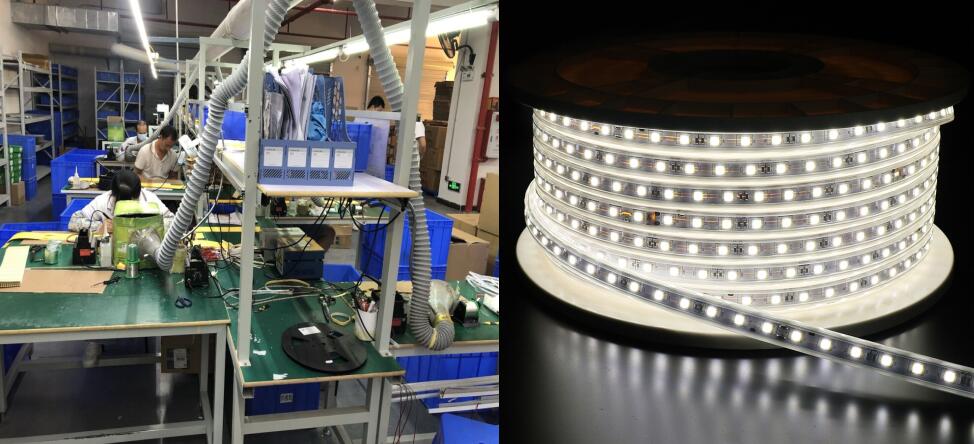

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as a core production hub for our LED lighting solutions, specifically engineered to handle high-volume, precision manufacturing with stringent quality control. This modern factory is strategically equipped to meet the demanding requirements of global markets, particularly for specialized products like waterproof outdoor LED strip lights.

The Surface Mount Technology (SMT) production lines within the Jiangmen facility are a cornerstone of our manufacturing capability. We operate multiple high-speed, high-precision SMT lines featuring advanced machines from leading manufacturers such as Panasonic and Yamaha. These lines include state-of-the-art placement machines like the Panasonic CM602 or Yamaha YS series, capable of placing components at speeds exceeding 60,000 components per hour with micron-level accuracy. This precision is critical for mounting the dense arrays of miniature LEDs, resistors, and capacitors onto flexible printed circuit boards (FPCBs) used in LED strips. The lines are fully automated, incorporating automated optical inspection (AOI) systems immediately after reflow soldering to detect and correct any placement or soldering defects in real-time, ensuring the foundational reliability of every strip produced, especially vital for outdoor applications where failure is not an option.

Rigorous aging and environmental testing are integral to our quality assurance process for waterproof outdoor LED strip lights, and the Jiangmen factory houses dedicated, extensive aging test chambers to fulfill this. Following assembly, all waterproof outdoor strips undergo multi-stage aging protocols. Initial burn-in tests run strips at elevated temperatures and full operating voltage for extended periods, typically 24 to 72 hours, to identify early-life failures. Crucially, for waterproof products, we conduct comprehensive environmental stress testing within specialized chambers. This includes thermal cycling tests that rapidly shift temperatures between extremes (e.g., -40°C to +85°C) while the strips are operating, simulating harsh outdoor conditions to expose weaknesses in materials or seals. Simultaneously, strips undergo continuous operation in high-humidity environments or even partial submersion tests per their rated IP level (such as IP65, IP67, or IP68) to verify the integrity of the silicone coating or extrusion and the robustness of end caps and connectors against moisture ingress over time. Performance metrics like lumen output, color consistency, and electrical parameters are continuously monitored throughout these aging cycles to guarantee long-term reliability and performance stability in real-world outdoor installations.

Our OEM capability for waterproof outdoor LED strip lights is a significant strength leveraged at the Jiangmen facility. We offer comprehensive, flexible OEM services tailored to partner specifications. This begins with collaborative design support, where our engineering team works with clients to develop custom strip configurations – determining optimal LED density, color temperature, CCT tuning, voltage requirements (12V/24V), and crucially, the appropriate waterproofing solution (e.g., silicone tube extrusion for IP67/IP68, or high-grade conformal coating for IP65). We source and utilize premium materials meeting international standards for UV resistance, flexibility, and thermal management essential for outdoor longevity. The factory’s scalable production capacity, supported by the SMT lines and robust supply chain management, allows us to efficiently handle OEM orders ranging from substantial volumes to smaller, specialized batches. Crucially, our integrated quality control, including the stringent aging and environmental testing protocols described, is applied rigorously to every OEM batch, ensuring the final product meets both the client’s exact specifications and the demanding durability requirements of outdoor environments, backed by necessary certifications.

Application Scenarios

LED strip lights designed for waterproof outdoor use are ideal in environments where exposure to moisture, weather elements, or high humidity is expected. While hotels, malls, and offices are primarily indoor spaces, there are specific outdoor or semi-outdoor areas within these facilities where waterproof LED strip lights are highly beneficial.

In hotels, waterproof LED strip lights are commonly installed along outdoor architectural features such as pool perimeters, exterior facades, garden pathways, balconies, and outdoor lounges. These lights enhance ambiance, improve nighttime visibility, and contribute to the aesthetic appeal of the property. Underwater lighting in swimming pools or fountains can also utilize fully waterproof strips rated for submersion (IP68).

Malls often feature expansive outdoor plazas, canopies, signage, and walkways. Waterproof LED strip lights are effectively used to illuminate signage, outline structural edges, highlight landscaping, or create dynamic lighting effects in open-air sections. They are also suitable for illuminating water features or outdoor seating areas, adding visual interest and safety after dark.

Offices with outdoor components—such as building exteriors, entryways, rooftop terraces, or covered parking areas—can utilize waterproof LED strips for both functional and decorative purposes. Accent lighting on columns, soffits, or stair risers improves visibility and creates a professional, modern appearance.

When installing waterproof LED strip lights outdoors, proper installation is critical for performance and longevity. Begin by selecting the correct IP rating: IP65 is suitable for protection against water jets, while IP67 or IP68 is recommended for temporary or full submersion. Ensure the power supply and all connections are housed in weatherproof enclosures and elevated above ground level to prevent water ingress. Use UV-resistant silicone coating or conduit if the strips are exposed to direct sunlight for extended periods. Always follow the manufacturer’s bending radius guidelines to avoid damaging the LEDs or waterproof jacket. Secure the strips using stainless steel clips or adhesive backing rated for outdoor use, and avoid stretching or compressing the strip during installation. Finally, test the system before finalizing the installation and conduct periodic inspections to maintain optimal performance and safety.

Why Choose Beauty STC Lighting

For contractors, architects, and lighting designers seeking reliable outdoor illumination solutions, Beauty STC delivers rigorously engineered waterproof LED strip lights built to withstand harsh environmental conditions. Our IP68-rated strips feature advanced silicone encapsulation, UV-resistant materials, and stable thermal management systems ensuring consistent performance across extreme temperatures and prolonged exposure to moisture. Unlike standard off-the-shelf options, Beauty STC products undergo 72-hour salt spray testing and 5,000-hour accelerated weathering cycles to guarantee longevity in coastal installations, landscape lighting, and architectural applications where failure is not an option.

Partner with Beauty STC to receive custom-cut lengths, tailored color temperatures, and seamless integration support for your specific project requirements. Our engineering team provides comprehensive technical documentation including photometric reports, thermal profiles, and compliance certifications to streamline your specification process. Avoid costly callbacks and rework by selecting outdoor LED strips designed for real-world durability from a manufacturer with 15 years of specialized lighting expertise.

Contact our technical sales manager directly at [email protected] to discuss your project parameters, request samples for validation testing, or obtain a formal quotation with volume pricing. Include your project location, required lumen output, and installation environment details to receive a solution engineered for your exact needs. Beauty STC stands behind every product with a 5-year warranty and dedicated field support to ensure your outdoor lighting investment performs flawlessly for years.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.