Article Contents

Industry Insight: Led Lamp Diode

The term “LED lamp diode” requires precise technical clarification: commercially and industrially, the fundamental light-emitting component is the LED chip, packaged into a robust semiconductor device known as an LED package or module, which is then integrated into complete luminaires. This distinction is critical as the performance, longevity, and reliability of commercial and industrial LED lighting systems hinge directly on the quality and engineering of these core semiconductor components. The global shift from legacy lighting technologies to solid-state LED solutions in demanding environments like warehouses, manufacturing facilities, retail spaces, and office buildings is now well-established, driven overwhelmingly by the imperative for significant energy savings, reduced maintenance costs, and enhanced operational uptime. Success in this sector demands LED diodes engineered for high lumen output per watt, exceptional thermal management under continuous operation, and resilience against environmental stressors such as temperature extremes, humidity, and electrical fluctuations.

For facility managers and lighting specifiers, the selection of LED technology transcends mere illumination; it is a strategic operational decision impacting total cost of ownership and productivity. This is where internationally recognized safety and performance certifications like ETL (indicating compliance with North American safety standards, often mirroring UL requirements) and CE (demonstrating adherence to European health, safety, and environmental protection legislation) become non-negotiable prerequisites. These certifications are not merely regulatory checkboxes but vital assurances that the LED diodes and the luminaires built around them have undergone rigorous independent testing for electrical safety, electromagnetic compatibility, and operational reliability. In the high-stakes commercial and industrial landscape, where system failure can halt production lines or compromise safety, specifying ETL/CE certified components is fundamental to mitigating risk and ensuring long-term, trouble-free performance.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of specialized expertise to this exacting market. We are not just a component supplier but a solutions partner deeply embedded in the commercial and industrial LED lighting ecosystem. Our engineering focus has always centered on developing and manufacturing high-performance LED packages and modules engineered specifically for the rigorous demands of professional lighting applications. From our inception, we have prioritized rigorous in-house testing protocols that consistently meet and often exceed ETL, CE, and other global certification benchmarks, ensuring our diodes form the dependable heart of luminaires trusted by businesses worldwide to illuminate critical operations efficiently and safely. Our legacy is built on delivering semiconductor-level reliability that translates directly into real-world lighting system performance for our industrial and commercial clients.

Technical Specs & Certifications

The LED lamp diodes manufactured by Beauty (STC) Manufacturing Co., Ltd. are engineered to deliver high performance and reliability for a wide range of residential, commercial, and industrial lighting applications. Central to their design is an emphasis on energy efficiency, color fidelity, and environmental resilience.

In terms of efficiency, Beauty STC’s LED diodes achieve luminous efficacy ratings typically ranging from 110 to 140 lumens per watt (lm/W), with select high-performance models exceeding 150 lm/W under optimal thermal and drive current conditions. This high lumens-per-watt ratio ensures minimal energy waste and reduced operational costs, aligning with global energy-saving standards and sustainability goals.

Color Rendering Index (CRI) is a critical quality metric for lighting, and Beauty STC ensures that its premium LED diodes consistently deliver a CRI greater than 90. This high CRI enables accurate representation of colors, making these diodes ideal for applications where visual clarity and color discrimination are essential—such as retail displays, art galleries, medical facilities, and high-end residential interiors. The use of advanced phosphor coatings and tightly binned LED chips contributes to superior color consistency and rendering across production batches.

Regarding environmental protection, Beauty STC integrates robust Ingress Protection (IP) ratings into its LED lamp systems. While the diode itself is a component, the complete lamp assemblies incorporating these diodes are rated to meet various IP standards depending on application needs. Common configurations include IP65 for dust-tight and water-jet resistance, suitable for outdoor and damp locations, and IP67 for temporary submersion protection, often used in landscape and industrial environments. The diodes are mounted on thermally efficient, sealed PCBs and encapsulated when necessary to support these IP ratings and ensure long-term reliability.

Beauty STC’s commitment to quality is evident in its rigorous manufacturing processes, adherence to international standards (including ISO 9001 and IEC certifications), and comprehensive in-house testing for thermal management, lumen maintenance (L70/L90), and electrical safety. Each LED diode undergoes stringent quality control to ensure uniform performance, longevity, and resistance to lumen depreciation over time. This focus on precision engineering and material integrity positions Beauty STC as a trusted provider of high-end LED solutions in competitive global markets.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as a primary production hub for the company’s LED lighting solutions. Strategically located within the Pearl River Delta manufacturing cluster, the Jiangmen factory occupies a significant footprint exceeding 50,000 square meters. It operates under stringent ISO 9001 quality management systems and maintains a controlled environment essential for precision electronics manufacturing, including dedicated cleanroom areas for critical processes. The facility is designed for high-volume output while adhering to international safety and environmental standards, featuring modern infrastructure for efficient material flow and production line management.

The Surface Mount Technology (SMT) production lines represent a core strength of the Jiangmen operation. We utilize multiple high-speed, fully automated SMT lines equipped with advanced machines from leading manufacturers such as Yamaha and Panasonic. These lines include state-of-the-art placement machines capable of handling components down to 0201 package sizes with exceptional placement accuracy, typically within ±25μm. Our SMT capacity supports high throughput, with machines achieving placement rates exceeding 80,000 components per hour per line. The process incorporates sophisticated pre-reflow solder paste inspection (SPI) systems and post-reflow automated optical inspection (AOI) to ensure solder joint integrity and component placement accuracy. This robust SMT infrastructure is critical for the reliable assembly of LED drivers, control modules, and directly for LED package integration onto substrates or MCPCBs.

Aging and reliability testing are rigorously implemented throughout the production process at the Jiangmen factory, particularly for LED light engines and complete luminaires. We maintain extensive aging test chambers capable of subjecting products to continuous operation under controlled thermal and electrical stress conditions for periods exceeding 1,000 hours, simulating extended real-world usage. These tests strictly follow international standards such as IEC 60598 and LM-80 where applicable. Parameters meticulously monitored include lumen maintenance, chromaticity shift, forward voltage drift, thermal performance, and overall electrical stability. Data collected during aging feeds directly into our reliability prediction models and continuous quality improvement programs, ensuring only products meeting our stringent durability criteria reach customers.

Regarding OEM capability specifically for LED lamp diodes, it is important to clarify terminology. Beauty STC Jiangmen factory does not manufacture the bare semiconductor LED chips (die) itself. However, we possess extensive OEM/ODM capabilities for finished LED lamp components and integrated LED light sources. This includes the design, engineering, and manufacture of complete LED packages, modules, and retrofit lamps incorporating LED diodes. Our OEM services encompass custom binning of purchased LED diodes to meet specific color temperature and flux requirements, thermal management solutions, optical design integration, driver compatibility, and final assembly into various lamp formats such as A19, GU10, PAR38, or specialized industrial modules. We offer full turnkey solutions from prototyping through mass production, handling custom specifications for lumen output, CCT, CRI, beam angle, and form factor, supported by our in-house SMT, aging, and quality control infrastructure. Minimum order quantities are flexible, accommodating both large-scale production runs and smaller, specialized batches based on client requirements.

Application Scenarios

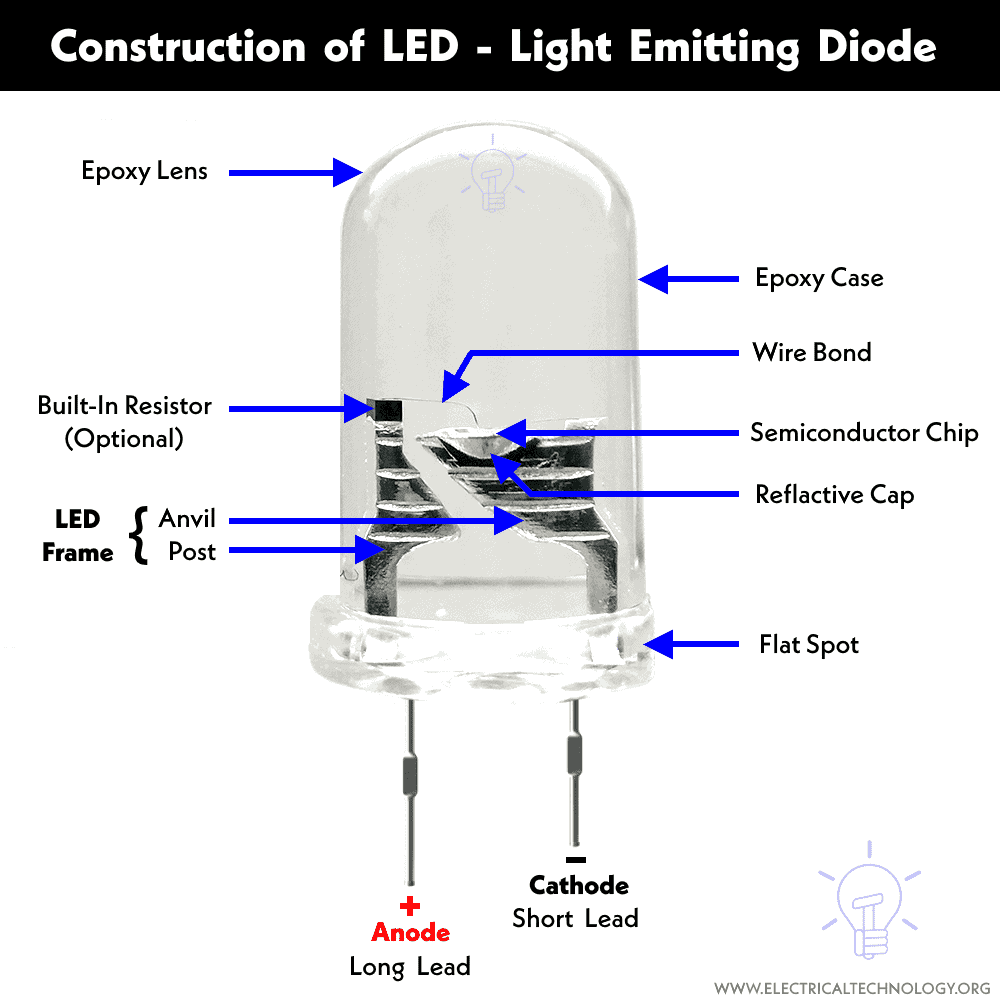

LED lamp diodes are semiconductor components that emit light when an electric current passes through them, and they serve as the core light source in modern LED lighting systems. While the term “LED lamp diode” typically refers to the individual diode chip itself, in practical applications it is usually integrated into complete LED lamps, bulbs, fixtures, or modules. These are widely used across commercial and public spaces due to their energy efficiency, long lifespan, and low maintenance.

In hotels, LED lighting is ideal for both functional and aesthetic purposes. They are commonly installed in guest rooms, hallways, lobbies, and outdoor areas. Warm white LEDs (2700K–3000K) create a welcoming and relaxing ambiance in guest rooms, while cooler temperatures can be used in workspaces or fitness centers. LED downlights, strip lighting under cabinets or headboards, and recessed fixtures in bathrooms offer both style and efficiency. Due to their low heat output, LEDs enhance guest safety and comfort.

In malls and retail environments, LED lighting plays a crucial role in highlighting merchandise and guiding foot traffic. High CRI (Color Rendering Index) LEDs, typically above 80 or 90, are preferred to ensure products appear vibrant and true to color. Track lighting, spotlights, and display case lighting often use high-intensity LED modules. Cold white or neutral white LEDs (3500K–5000K) are commonly used to create a bright and energetic shopping atmosphere. Energy savings are significant in large open spaces that require extended operating hours.

Offices benefit greatly from LED lighting due to their long operational periods and need for consistent illumination. LED panel lights or troffer fixtures are commonly used in drop ceilings to provide uniform, glare-free lighting. Daylight white LEDs (4000K–5000K) help maintain alertness and productivity. Installing dimmable LEDs or integrating with daylight sensors allows for dynamic lighting control, reducing energy consumption during daylight hours. Task lighting at workstations can also incorporate LEDs for focused illumination with minimal heat.

When installing LED lighting, several best practices should be followed. Ensure compatibility with existing electrical systems, especially if using dimmers—only use dimmers rated for LED loads to avoid flickering. Avoid enclosing non-enclosed-rated LED fixtures in airtight housings, as heat buildup can shorten lifespan. Always follow manufacturer guidelines for thermal management and ventilation. Use quality drivers and power supplies to ensure stable current, which is essential for diode longevity. In humid or outdoor areas, select fixtures with appropriate IP ratings to protect against moisture and dust. Finally, consider professional installation for large-scale projects to ensure optimal placement, wiring safety, and compliance with local electrical codes.

Why Choose Beauty STC Lighting

Elevate your lighting products with industry-leading LED lamp diode technology engineered for superior performance and reliability. At Beauty STC Manufacturing Co., Ltd., our senior engineering team specializes in optimizing diode efficiency, thermal management, and lumen maintenance to ensure your fixtures deliver exceptional brightness and longevity under demanding conditions. Partner with us to integrate precision-crafted diodes that meet rigorous global standards while reducing production costs and accelerating your time to market.

Contact our dedicated partnership manager today at [email protected] to discuss custom diode solutions tailored to your specific application requirements. Let Beauty STC become your trusted engineering ally in advancing next-generation LED lighting innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.