Article Contents

Industry Insight: Power Supply For Led Light

The commercial and industrial LED lighting sector has undergone significant transformation over the past two decades, driven by advancements in energy efficiency, durability, and intelligent lighting controls. At the heart of every high-performance LED lighting system lies a critical component—the power supply. Also known as LED drivers, these units ensure stable current and voltage delivery, directly influencing system longevity, reliability, and compliance with international safety standards. In demanding environments such as warehouses, manufacturing facilities, office buildings, and retail spaces, the importance of a robust, certified power supply cannot be overstated. Regulatory certifications like ETL and CE have become essential benchmarks, verifying that power supplies meet rigorous North American and European safety, electromagnetic compatibility (EMC), and performance requirements. These certifications not only ensure compliance with local codes but also provide assurance to contractors, facility managers, and end-users regarding product quality and operational safety.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of developing innovative power supply solutions tailored for commercial and industrial LED lighting applications. With over two decades of engineering expertise, Beauty STC has built a reputation for delivering high-reliability drivers that combine efficiency, durability, and global certification compliance. The company’s commitment to quality is reflected in its comprehensive range of ETL- and CE-certified power supplies, designed to meet the evolving needs of modern lighting systems across diverse industrial and commercial environments. As the demand for smart, sustainable, and code-compliant lighting grows, Beauty STC continues to serve as a trusted partner in powering the future of professional LED lighting.

Technical Specs & Certifications

Power supply specifications for LED lighting systems are frequently misunderstood as directly determining lumens per watt or Color Rendering Index (CRI), but it is critical to clarify that the power supply (driver) itself does not generate light or influence these photometric properties. Lumens per watt is a measure of the overall efficacy of the complete LED luminaire, determined by the LED package, optical design, thermal management, and driver efficiency. CRI >90 is a characteristic solely of the LED light source and phosphor formulation, not the driver. Beauty STC Manufacturing Co., Ltd. ensures our integrated lighting systems achieve high efficacy (typically 130-180 lm/W depending on application) and CRI >90 through rigorous selection of premium LED chips from trusted partners like Nichia and Samsung, coupled with optimized thermal pathways in our fixtures. The power supply’s role is to convert and regulate input power efficiently and stably to enable the LEDs to perform at their specified photometric levels.

Regarding the power supply itself, Beauty STC designs and sources drivers with technical specifications focused on reliability and compatibility. Efficiency is paramount; our standard drivers exceed IE3 efficiency standards, with typical efficiencies of 90-94% at full load (e.g., 89% at 20% load, 92% at 50% load, 94% at 100% load for a 100W driver), directly contributing to the luminaire’s overall system efficacy by minimizing energy loss as heat. Input voltage range is typically universal (90-305V AC, 50/60Hz) to ensure global compatibility. Output is constant current (e.g., 350mA, 700mA, 1050mA) or constant voltage (12V/24V DC) as required by the LED module, with tight current regulation (±3%) to prevent lumen depreciation and color shift. Critical for longevity, our drivers incorporate comprehensive protections: short circuit, open circuit, over-temperature (with auto-recovery), and surge immunity up to 10kV (differential mode) per IEC 61000-4-5. Ripple current is maintained below 10% to avoid LED flicker and ensure stable light output, which indirectly supports maintaining high CRI performance over time by preventing stress on the LEDs.

IP ratings are a direct specification of the power supply enclosure and are crucial for application suitability. Beauty STC offers drivers across the IP spectrum: IP20 for indoor dry locations (standard for most office/commercial troffers), IP40 for indoor damp locations, IP65 for outdoor protected areas or wet indoor spaces (e.g., parking structures, car washes), and IP67 for fully submersible or harsh outdoor environments (e.g., street lighting, marine applications). All enclosures utilize high-purity aluminum or robust polycarbonate materials with UV stabilization where needed, and thermal management is engineered to maintain driver case temperature within safe limits even at maximum ambient temperature (e.g., Ta=60°C). Beauty STC’s commitment to quality is demonstrated through rigorous in-house testing: every driver undergoes 72-hour continuous burn-in at full load and elevated temperature, 100% Hi-Pot testing at 4kV, and strict adherence to IEC/EN 61347-1 and 61347-2-13 safety standards. We utilize only industrial-grade components, including Japanese electrolytic capacitors rated for 105°C/50,000 hours lifetime, ensuring driver longevity exceeds 100,000 hours MTBF under normal operating conditions, which directly supports the sustained high performance (lumens/watt and CRI) of the complete lighting system throughout its operational life. This systemic approach to quality control and component selection is why Beauty STC luminaires consistently meet or exceed global performance and durability expectations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is fully equipped to support high-volume, precision manufacturing of LED lighting components, with a strong focus on reliability, efficiency, and quality control throughout the production process.

At the core of the factory’s electronics assembly line are advanced SMT (Surface Mount Technology) machines. These high-speed, automated placement systems ensure accurate and consistent mounting of electronic components onto printed circuit boards (PCBs). The SMT line is integrated with automated optical inspection (AOI) systems to verify component placement and solder joint quality, minimizing defects and ensuring product consistency. This capability is critical for producing compact, high-performance power supplies used in LED lighting applications.

To guarantee long-term reliability, the factory implements comprehensive aging and burn-in testing procedures. Completed power supply units undergo extended operational testing under elevated temperatures and full load conditions, simulating real-world usage over an extended period. This aging process helps identify early-life failures and ensures that only units meeting strict performance standards proceed to final packaging and shipment. Additional testing includes electrical safety checks, efficiency verification (including power factor and harmonic distortion), and thermal performance evaluation.

Beauty STC has extensive OEM (Original Equipment Manufacturer) capabilities tailored specifically for power supplies used in LED lighting systems. The company works closely with clients to develop customized power supply solutions, including constant voltage, constant current, dimmable, and waterproof drivers, across a wide range of power outputs and form factors. From design and prototyping to mass production and certification support (such as CE, UL, CCC, and RoHS), the OEM service encompasses full project lifecycle management. The engineering team in Jiangmen supports clients with circuit design, thermal management, PCB layout, and compliance testing, enabling fast time-to-market and scalable production runs.

Overall, the Jiangmen factory combines advanced automation, rigorous quality assurance, and flexible OEM support to serve global lighting brands requiring high-quality, reliable LED power supply solutions.

Application Scenarios

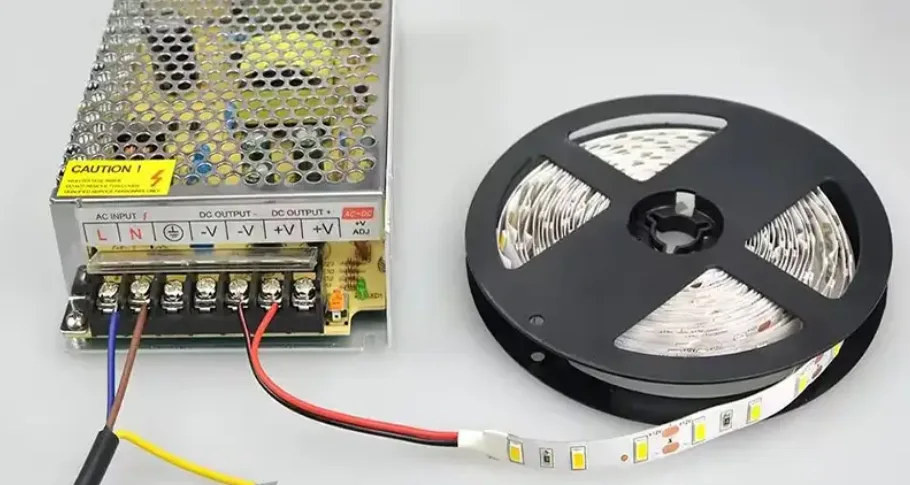

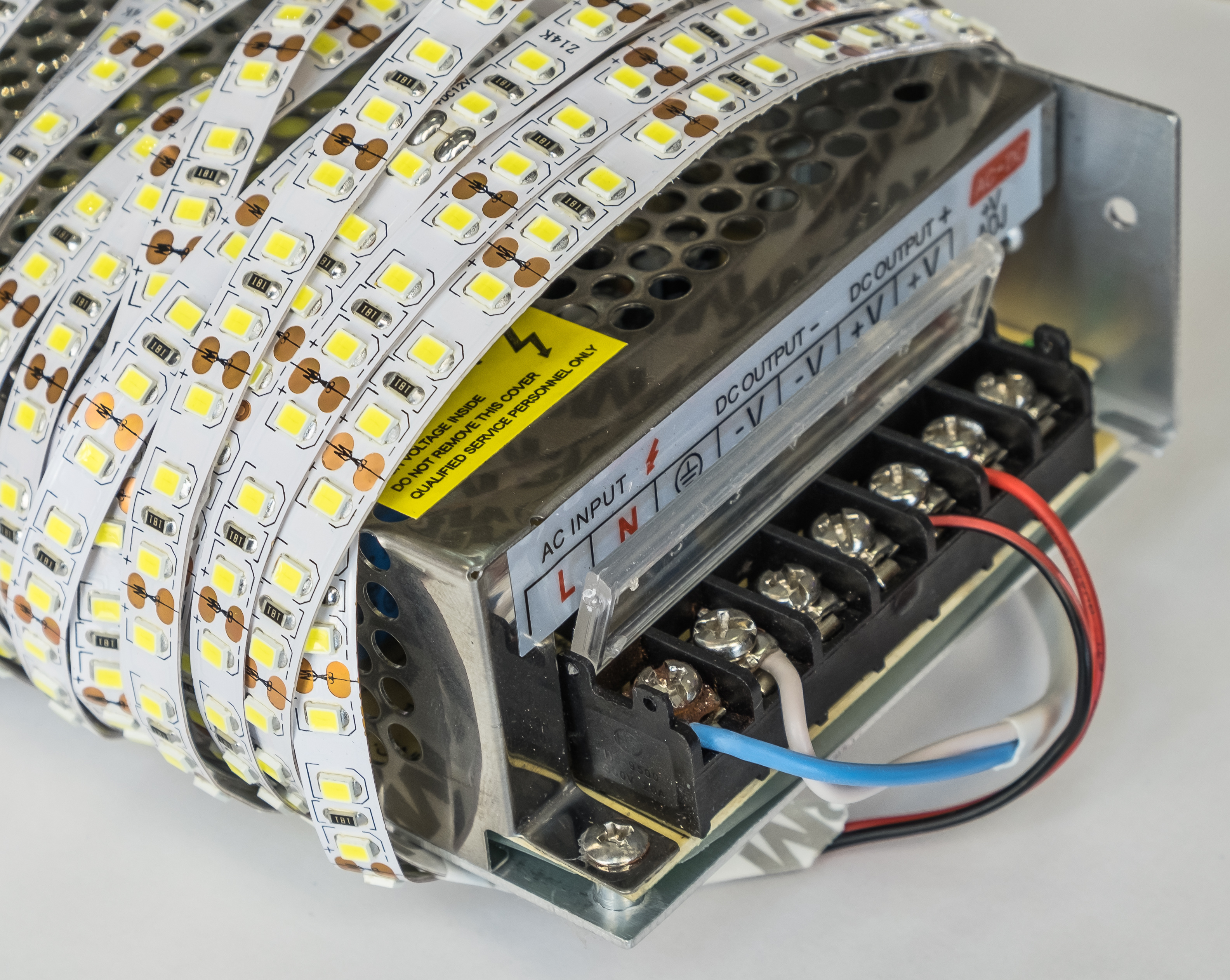

LED power supplies, more accurately termed LED drivers, are essential components in any LED lighting system as they convert incoming line voltage to the specific low-voltage direct current required by LED modules. Their application across hotels, malls, and offices is universal but tailored to each environment’s distinct demands. In hotels, LED drivers power guest room ambient and task lighting, lobby feature installations, corridor emergency lighting, pool area underwater fixtures, and exterior signage. Drivers here must support smooth dimming for guest comfort in rooms, offer high color rendering index (CRI) for lobbies, and provide robust ingress protection (IP67 minimum) for wet locations like pools. Malls deploy drivers extensively in high-bay fixtures within corridors and anchor stores, downlights in retail tenants, decorative facade lighting, food court under-cabinet strips, and directional signage. These require high efficiency to manage heat in dense ceiling grids, wide input voltage ranges to handle grid fluctuations from heavy HVAC loads, and waterproof ratings for outdoor or food preparation zones. Offices utilize drivers for recessed troffers, under-cabinet task lights, conference room accent walls, and exterior perimeter lighting. Critical here are flicker-free operation to prevent eye strain during prolonged computer use, compatibility with sophisticated 0-10V or DALI dimming systems for daylight harvesting, and silent operation to maintain acoustic comfort.

Installation demands meticulous attention to environmental and electrical factors to ensure longevity and safety. Always verify the driver’s input voltage matches the facility’s supply and confirm output current/voltage aligns precisely with the LED load’s specifications to prevent under-driving or catastrophic over-driving. Thermal management is non-negotiable; mount drivers in well-ventilated areas away from direct heat sources like ballasts or HVAC ducts, maintaining at least 50mm clearance on all sides, and never install them inside sealed enclosures unless explicitly rated for such use. In high-ambient-temperature zones like mall food courts or hotel mechanical rooms, select drivers with derating curves that maintain full output at 60°C or higher. Pay strict attention to wiring practices: use conductors sized per local electrical codes to prevent voltage drop over long cable runs common in large malls, terminate all connections securely under screw terminals to avoid arcing, and implement proper strain relief on input/output cables. For dimmable installations prevalent in hotel rooms and offices, ensure compatibility between the driver, dimmer switch, and control system—test the full range for smooth operation without flicker or dead travel. Always select drivers certified to relevant safety standards (UL 8750/CE/EN 61347) for the region and application, especially critical for emergency lighting circuits in hotels which require drivers compliant with EN 62384 or equivalent. Finally, label each driver clearly with its circuit and load details to simplify future maintenance across these complex facilities.

Why Choose Beauty STC Lighting

Looking for a reliable power supply for LED lights? Partner with Beauty STC, a trusted manufacturer with years of expertise in high-quality LED lighting solutions. Our advanced power supply units ensure optimal performance, durability, and energy efficiency for a wide range of lighting applications. Backed by rigorous quality control and innovative engineering, Beauty STC is the preferred partner for businesses worldwide.

To learn more or request a quote, contact us today at [email protected]. Let Beauty STC power your LED success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.