Article Contents

Industry Insight: Led Strip Lights Corners

The commercial and industrial lighting sector demands precision, reliability, and seamless integration, especially when navigating the critical transitions inherent in modern architectural and functional designs. LED strip lights have become fundamental for cove lighting, task illumination, signage, and accenting structural elements, but their effectiveness is often compromised at corners and bends. Achieving truly seamless illumination around 90-degree turns or complex angles without visible gaps, color shifts, or hotspots remains a significant engineering challenge in professional installations. Poorly executed corners not only detract from the intended aesthetic but can create shadows in retail displays, uneven light distribution on production lines, or safety hazards in warehouses – issues unacceptable in demanding commercial and industrial environments. Furthermore, compliance with stringent safety standards like ETL and CE certification is non-negotiable for these applications, ensuring electrical safety, performance reliability, and adherence to regional regulations for liability and code compliance. Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over 25 years to solving these precise challenges. We bring deep expertise in advanced thermal management, optical engineering, and robust construction specifically for professional-grade LED solutions, ensuring our corner connectors and flexible strip systems deliver the flawless, certified performance required by architects, engineers, and facility managers worldwide.

Technical Specs & Certifications

LED strip light corners are critical components in seamless lighting installations, especially where directional changes are required without compromising light output or aesthetics. At Beauty (STC) Manufacturing Co., Ltd., our LED strip light corner connectors and compatible strip systems are engineered to maintain high performance through bends and turns, ensuring uniform illumination across linear and angular runs.

Our high-quality LED strip lights deliver an industry-leading efficiency of 120–140 lumens per watt, depending on the color temperature and density configuration. This high lumen-to-watt ratio ensures energy savings without sacrificing brightness, making our strips ideal for both residential and commercial applications where efficiency and longevity are paramount.

Color Rendering Index (CRI) is a key focus in our product development. All our premium LED strip lights feature a CRI greater than 90, with select models achieving CRI >95. This exceptional color fidelity ensures that illuminated environments reflect true-to-life colors, which is essential in retail displays, art galleries, kitchens, and makeup areas where accurate color representation is critical.

In terms of environmental protection, Beauty STC offers LED strip lights with multiple IP (Ingress Protection) ratings to suit various installation conditions. Our standard non-protected strips are rated IP20, suitable for indoor dry locations. For damp or outdoor use, we provide IP65-rated strips, which are protected against water jets and dust, making them ideal for kitchens, bathrooms, and outdoor signage. For fully submersible or harsh environment applications, our IP67 and IP68-rated strips offer complete dust protection and resistance to temporary or continuous immersion in water, respectively.

Beauty (STC) Manufacturing Co., Ltd. is committed to superior build quality and rigorous testing. Our LED strips use high-purity phosphor coatings, consistent binning of LEDs, and premium flexible PCB materials to ensure even light distribution and minimal color shift over time. The corner connectors are designed with precise alignment features to maintain electrical continuity and mechanical stability, reducing the risk of flickering or failure at bends.

All products undergo stringent quality control, including thermal cycling, humidity resistance, and photometric testing. This dedication to excellence ensures long operational life—typically 50,000 hours or more—and consistent performance across installations involving multiple corners and complex layouts.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China, serves as our primary production hub for LED lighting solutions, strategically positioned within the Pearl River Delta for efficient logistics and access to skilled technical labor. The factory is a modern, ISO 9001-certified operation designed for high-volume, precision manufacturing with stringent quality control protocols integrated throughout the production flow.

Our Surface Mount Technology (SMT) line is a cornerstone of the facility, featuring advanced Yamaha YS series placement machines. These systems handle components down to the 0201 metric package size, ensuring precise placement of LEDs, resistors, capacitors, and ICs onto flexible and rigid PCBs used in LED strips. The line includes automated solder paste printing, high-speed pick-and-place units, and nitrogen-reflow ovens, enabling consistent assembly for both standard and high-density LED strip designs. This capability supports the production of complex multi-channel strips, including those requiring intricate corner sections where board flexibility or specialized connectors are needed.

Aging and reliability testing are rigorously conducted in dedicated environmental chambers. Completed LED strip reels undergo a minimum 72-hour burn-in test at 60°C, significantly exceeding typical industry standards of 24 hours. During this process, strips operate at rated voltage while monitored for thermal performance, light output stability, and electrical integrity. Any units exhibiting lumen depreciation beyond acceptable thresholds, color shift, or component failure are automatically rejected. This extended aging protocol ensures only units meeting our stringent 50,000-hour L70 reliability target reach customers, directly addressing field failure risks common in lower-tier products.

Regarding OEM capability for LED strip light corners, the Jiangmen factory excels in full customization. We manufacture not only the linear LED strips themselves but also produce integrated corner solutions as part of bespoke OEM projects. This includes engineering and fabricating specialized bent sections, right-angle connectors, or custom-molded corner housings designed to maintain consistent light distribution and mechanical durability at installation turns. Our tooling department rapidly develops molds for unique corner profiles, while our engineering team collaborates with clients to validate thermal management and electrical continuity at these critical junctions. Clients provide specific corner geometry requirements, bend radii, or connector types, and we deliver fully integrated strip-corner assemblies under their branding, complete with custom packaging and compliance documentation for global markets. This end-to-end control from SMT assembly through corner integration ensures seamless performance in complex lighting installations.

Application Scenarios

LED strip light corners are critical transition points when installing flexible LED strips around bends, edges, or directional changes in architectural features. Proper handling of these corners ensures uniform illumination, prevents damage to the strip, and maintains aesthetic continuity. Their application varies across different environments such as hotels, malls, and offices, each with distinct lighting requirements and design goals.

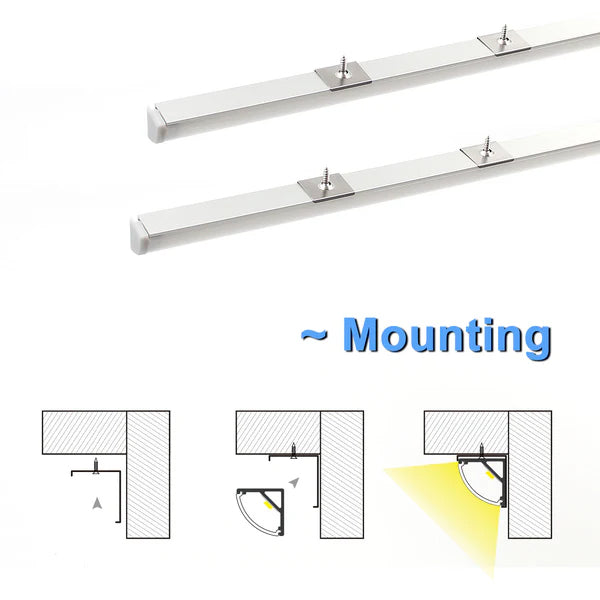

In hotels, LED strip light corners are commonly used in reception areas, hallways, cove lighting in lobbies, under handrails along staircases, and within guest room headboards or bathroom vanities. These spaces often feature curved walls, recessed niches, or angular cabinetry where corners must be navigated seamlessly. The warm or tunable white color temperatures enhance ambiance and create a welcoming environment. When installing in hotel settings, it’s essential to maintain visual consistency—ensure the corner bend does not cause shadowing or hot spots. Use corner connectors or gently bend the strip with a minimum radius of 15–20 mm, depending on the strip model, to avoid solder point damage.

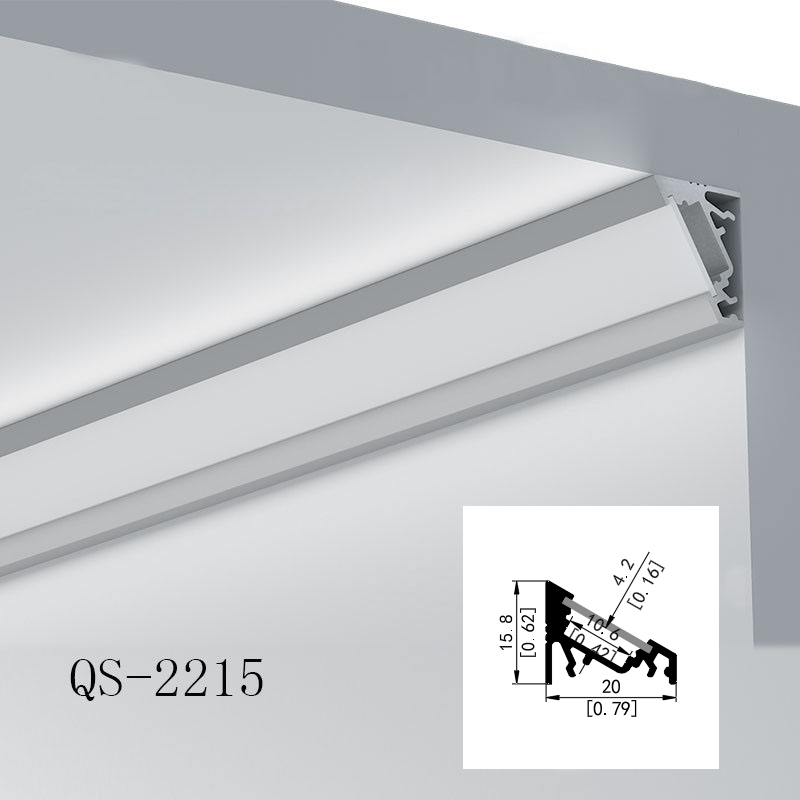

In malls and retail environments, LED strip light corners are frequently applied in display cases, ceiling coves, signage backlighting, and architectural feature walls. These areas often include sharp 90-degree turns or curved transitions where lighting must remain uninterrupted to highlight products or guide foot traffic. For such high-visibility applications, precision is key. Cut the strip only at designated cut points before and after the corner, and use L-shaped aluminum profiles to protect the strip and provide a clean, professional finish. Ensure the power supply is adequately sized to prevent voltage drop, especially in long runs with multiple corners.

In office spaces, LED strip light corners are typically found in suspended ceilings, under cabinets, around monitor backlighting, and along partition edges. The goal here is often functional ambient lighting or task lighting with a modern aesthetic. Installation should prioritize clean lines and minimal glare. When routing strips around corners in offices, consider using flexible aluminum channel bends or pre-formed corner brackets to maintain alignment. Maintain a consistent color temperature—usually 4000K neutral white—for visual comfort and productivity.

General installation tips for LED strip light corners include ensuring the strip is powered off during installation, cleaning the surface thoroughly for strong adhesive bonding, and avoiding sharp folds or kinks. For inside corners, fold the strip carefully, ensuring conductive pads do not short. For outside corners, use a small gap or a corner connector to bridge the turn. Always use compatible aluminum profiles when possible to dissipate heat and prolong strip life. Finally, test the strip before final mounting to confirm continuity and brightness through all corners.

Why Choose Beauty STC Lighting

Transform your LED strip lighting projects with Beauty STC’s precision-engineered corner solutions. Our specialized corner connectors and mounting systems eliminate the common installation challenges of awkward angles, ensuring seamless, professional, and durable results every time. Designed and rigorously tested by our in-house engineering team, these components deliver flawless light distribution and structural integrity for both residential and commercial applications. Partner with Beauty STC to access superior quality, innovative corner technology, and dedicated technical support that sets your projects apart.

Elevate your LED strip lighting offerings by collaborating with Beauty STC Manufacturing Co., Ltd. Contact our partnership manager directly at [email protected] to discuss custom corner solutions, bulk pricing, and how we can support your specific project requirements. Include “LED Corner Solution Inquiry” in your subject line for immediate attention and a streamlined response. Let us help you turn challenging installations into your most impressive work.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.