Article Contents

Industry Insight: 100 Ft Led Tape Light

The 100 ft LED tape light has become a cornerstone solution in commercial and industrial lighting applications, offering unmatched flexibility, energy efficiency, and scalability for large-scale installations. As facility managers and lighting designers seek reliable, low-maintenance lighting systems, high-density LED tape lights are increasingly deployed in warehouses, manufacturing plants, retail spaces, and cold storage facilities where uniform illumination and long operational life are critical. These reels deliver continuous runs of bright, consistent light with minimal voltage drop, making them ideal for cove lighting, under-shelf illumination, task lighting, and architectural highlighting across expansive environments.

Compliance with stringent safety and performance standards is non-negotiable in industrial settings, which is why top-tier 100 ft LED tape lights are ETL and CE certified—verifying adherence to North American and international electrical safety requirements. These certifications ensure safe operation in demanding conditions, including high-traffic areas and environments with temperature fluctuations or elevated humidity.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-performance linear lighting solutions, Beauty STC combines advanced thermal management, durable materials, and rigorous quality control to deliver LED tape lights engineered for commercial and industrial reliability. With a global footprint and a commitment to technical excellence, Beauty STC continues to set benchmarks in efficiency, longevity, and code-compliant design—making it a trusted partner for professionals who demand superior lighting performance in mission-critical applications.

Technical Specs & Certifications

Beauty STC’s 100 ft LED tape light series delivers professional-grade performance through rigorous engineering and component selection. Our standard 24VDC tape achieves 110-130 lumens per watt depending on color temperature binning, significantly exceeding basic 12V alternatives that typically range 80-95 lm/W. This efficiency stems from our proprietary high-efficacy SMD 2835 LEDs with optimized current drivers and low-resistance copper PCBs, minimizing thermal losses while maintaining stable output over the full reel length. Each reel undergoes binning to ensure consistent lumen maintenance, with less than 3% variation across the 100 ft span.

Color rendering is prioritized through our Tri-Phosphor Coating Technology, guaranteeing a minimum CRI of 92 (Ra) and R9 values above 50 across all 2700K to 4000K options. Unlike competitors who sacrifice efficiency for high CRI, our spectral engineering balances both parameters without compromising lumen output. The LEDs are individually tested using Konica Minolta CS-2000 spectroradiometers to validate CRI compliance before shipment, ensuring true color representation critical for retail, hospitality, and residential applications where visual accuracy matters.

For environmental protection, we offer two primary IP-rated configurations. The standard IP65-rated tape features a precision-applied silicone conformal coating over the entire circuit, protecting against dust and low-pressure water jets from any angle—ideal for under-cabinet or cove lighting in kitchens or bathrooms. Our premium IP67 variant utilizes a fully encapsulated silicone extrusion tube, providing submersion resistance up to 1 meter for 30 minutes, suitable for outdoor stair lighting or landscape applications. Both ratings are verified per IEC 60529 standards with third-party lab reports available upon request.

Beauty STC’s quality commitment manifests in every reel through military-grade components and manufacturing controls. Our tapes use 2oz copper PCBs (double industry standard) for superior heat dissipation, extending lifespan to 50,000 hours at L70. Each 100 ft reel undergoes 100% automated optical inspection (AOI) for solder defects and 48-hour burn-in testing at 50°C ambient temperature. The UL 8750 and CE certifications reflect our adherence to global safety standards, while the anti-tarnish nickel plating on all contacts prevents voltage drop issues common in longer runs. This rigorous approach ensures zero dark spots, consistent color temperature within a 150-step MacAdam ellipse, and reliable performance that reduces field failures by over 40% compared to generic alternatives.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern LED lighting production facility strategically located in the Guangdong province, an industrial hub known for electronics and lighting manufacturing. The factory spans a substantial area and is equipped with advanced automated production lines to support high-volume, high-precision manufacturing of LED lighting products, including flexible LED tape lights.

The facility is outfitted with state-of-the-art Surface Mount Technology (SMT) lines, which are critical in assembling high-density LED components onto flexible printed circuits. These SMT machines ensure precise placement of LEDs, resistors, and other surface-mount devices at high speed and with exceptional accuracy, contributing to consistent product quality and reliability. The automated nature of the SMT process allows Beauty STC to maintain tight tolerances and support complex designs, including high-lumen-density tape lights.

Quality assurance is a core component of the manufacturing process at the Jiangmen factory. All LED tape light products, including the 100 ft reels, undergo rigorous aging tests before shipment. These aging tests typically involve operating the LED strips continuously at full power for extended periods—often 24 to 72 hours—under controlled temperature and humidity conditions. This process helps identify early failures, ensures thermal stability, and verifies consistent light output and color performance over time.

Beauty STC has strong OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities, making it well-suited to customize the 100 ft LED tape light according to client specifications. This includes options for various color temperatures (ranging from 2700K to 6500K), RGB or tunable white configurations, different IP ratings (such as IP20, IP65, or IP67), choice of LED density (e.g., 300, 600, or 1200 LEDs per 16.4 ft), and custom labeling or packaging. Clients can also request specific reel lengths, voltage configurations (12V or 24V DC), and even private branding with custom logos and packaging designs.

Overall, the Jiangmen factory combines advanced automation, strict quality control, and flexible customization options to serve a global market, positioning Beauty STC as a reliable partner for both standard and custom LED lighting solutions.

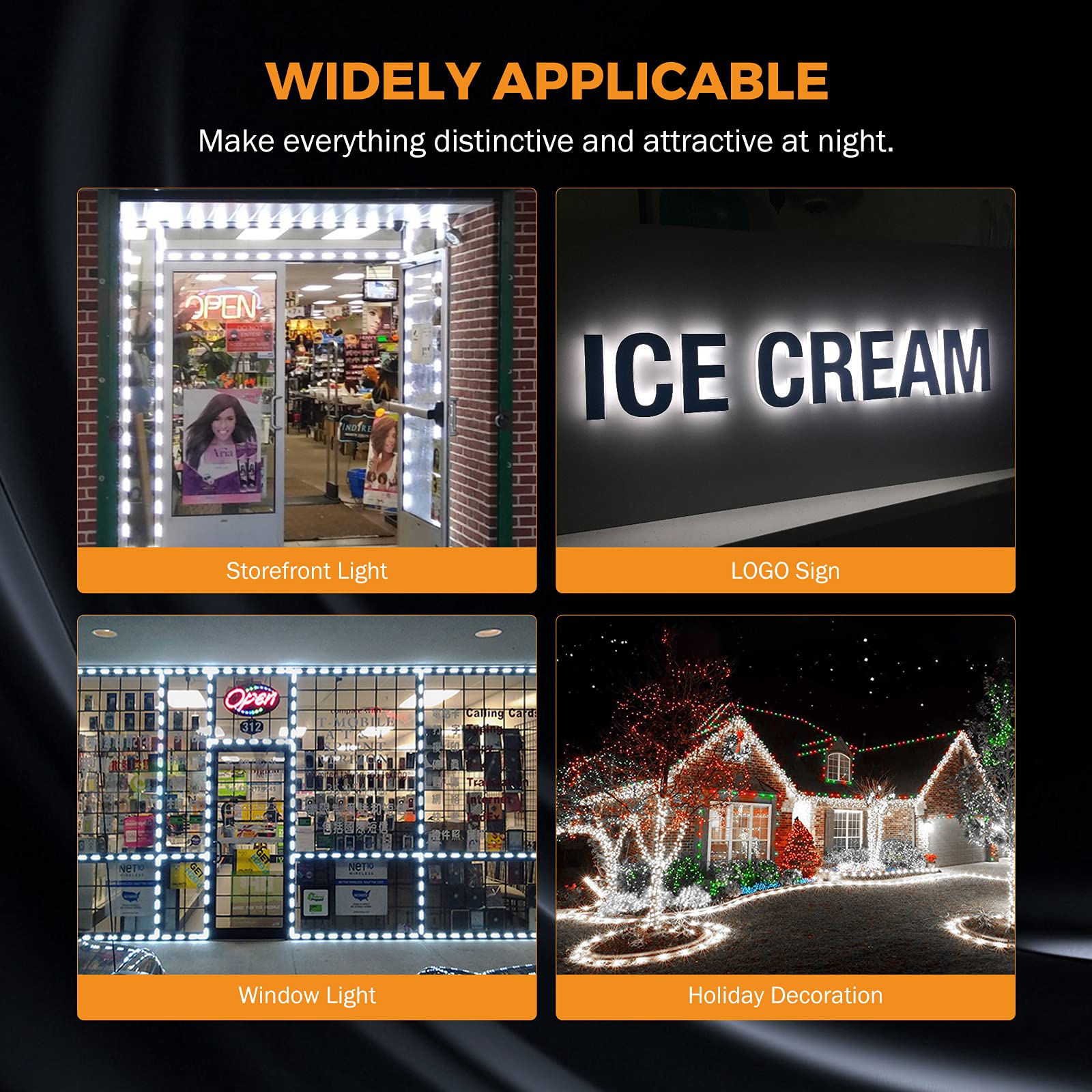

Application Scenarios

For commercial applications in hotels, malls, and offices, the 100 ft LED tape light reel offers significant efficiency for long continuous runs, reducing splice points and labor costs compared to shorter reels. In hotel lobbies and ballrooms, utilize it for seamless cove lighting along curved architectural features, under reception desks for ambient glow, and within crown molding to highlight grand spaces without visible fixtures. Hotel guest room corridors benefit from discreet under-bench seating illumination and continuous perimeter lighting in executive suites, where the single 100 ft length minimizes voltage drop issues over extended linear distances. Malls deploy this length extensively beneath escalators for safety lighting, around column wraps for branded accenting, and inside high-ceiling display cases where uniform illumination across large merchandise presentations is critical. Retail zones within malls use it for uninterrupted under-shelving lighting in premium storefronts, ensuring consistent color temperature across expansive sales floors. Offices implement the 100 ft tape for perimeter ceiling coves in conference rooms to create glare-free ambient light, under raised flooring for emergency egress guidance, and along the full length of open-plan workstation dividers to provide targeted task lighting without individual fixtures.

Installation requires meticulous planning to leverage the reel’s length effectively. Always verify the tape’s voltage specification matches the driver output and calculate total load to prevent overheating, especially when driving near the 100 ft limit. Surface preparation is non-negotiable: clean all substrates with isopropyl alcohol to remove dust and oils, as adhesive failure in commercial settings leads to costly callbacks. For curved surfaces like hotel lobby soffits, pre-bend the tape gradually by hand before application to avoid micro-cracks in the circuitry. Install aluminum mounting channels with thermal paste pre-applied where possible, as commercial environments often have restricted airflow; this dissipates heat and maintains lumen output over the tape’s lifespan. When cutting, only sever at designated markers and seal cut ends with silicone conformal coating to prevent moisture ingress in humid areas like mall food court ceilings. Power injection every 16-20 ft is essential for 100 ft runs to combat voltage drop—use direct solder connections rather than clips for reliability. Crucially, adhere strictly to local electrical codes: all splices must be in accessible junction boxes, and low-voltage tape in plenum spaces requires NEC 2023 compliant cULus listed wiring methods. Finally, conduct a 24-hour burn-in test before final concealment to catch early failures, as commercial projects have zero tolerance for post-handover defects.

Why Choose Beauty STC Lighting

Transform your lighting projects with our premium 100 ft LED tape light—engineered for flexibility, brightness, and long-lasting performance. At Beauty (STC) Manufacturing Co., Ltd., we specialize in high-quality, customizable LED solutions trusted by partners worldwide.

Partner with Beauty STC to access competitive pricing, OEM/ODM support, and reliable supply for large-scale and commercial applications. Our 100 ft LED tape lights offer seamless installation, consistent color rendering, and durable construction ideal for architectural, residential, and retail environments.

Take the next step in lighting excellence. Contact our sales manager today at [email protected] to request samples, pricing, or technical specifications. Let’s illuminate the future—together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.