Article Contents

Industry Insight: Led Tape Power Supply

The commercial and industrial lighting sector demands exceptional reliability, stringent safety, and long-term operational efficiency from every component within an installation. Nowhere is this more critical than in the often-overlooked foundation of LED tape systems: the power supply. Far from being a simple accessory, the power supply is the essential heart that dictates system performance, lifespan, and crucially, compliance with rigorous international safety standards. In environments ranging from high-ceilinged warehouses and demanding retail spaces to sensitive healthcare facilities and outdoor architectural applications, the power supply must deliver stable, clean power under fluctuating loads and challenging conditions while meeting mandatory certifications. ETL listing for the North American market and CE marking for Europe are not optional checkboxes; they are non-negotiable requirements that validate electrical safety, electromagnetic compatibility, and adherence to regional regulatory frameworks, directly impacting project approval, insurance coverage, and end-user liability.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been a dedicated force in the professional lighting industry throughout this evolution. With over two decades of specialized engineering and manufacturing expertise, we understand the unique pressures and exacting standards of commercial and industrial projects. Our focus has always centered on developing robust, certified power solutions designed specifically for the demanding realities of professional LED tape applications, ensuring not just functionality, but enduring performance and uncompromised safety for specifiers, contractors, and facility managers worldwide.

Technical Specs & Certifications

The LED tape power supply is a critical component in any LED lighting system, ensuring stable and efficient operation of LED strips. While the power supply itself does not generate lumens, its compatibility and performance directly influence the efficiency and output of the connected LED tape. When integrating high-performance LED tapes—especially those designed for quality lighting in architectural, commercial, or residential settings—matching them with a reliable power supply is essential.

For LED tapes paired with Beauty (STC) Manufacturing Co., Ltd. power solutions, the focus is on maximizing system efficiency, with LED tapes typically delivering 90–120 lumens per watt depending on the LED density, chip type (e.g., 2835, 3014, 5050), and drive current. Beauty STC ensures that their compatible power supplies are engineered to support these high-efficiency LEDs without power loss or flicker, maintaining optimal lumen output over time.

A key requirement in premium lighting applications is high color fidelity, which is achieved through LED tapes with a Color Rendering Index (CRI) greater than 90. Beauty STC supports CRI >90 LED tapes by providing constant voltage (12V or 24V DC) power supplies with low ripple and high stability, minimizing color shift and ensuring consistent, natural light reproduction. These power supplies are designed to work seamlessly with high-CRI LED chips and phosphor coatings, preserving the integrity of the emitted light across extended operation.

Ingress Protection (IP) ratings are another critical factor, especially for installations in damp, outdoor, or high-dust environments. Beauty STC offers a range of IP-rated power supplies to match the LED tape’s protection level. Common options include IP65-rated drivers for partial weather resistance, suitable for covered outdoor areas, and IP67 or IP68-rated fully potted drivers for complete dust and water immersion protection. These ruggedized power supplies are ideal for landscape lighting, cove lighting, or industrial applications where environmental exposure is a concern.

Beauty (STC) Manufacturing Co., Ltd. is recognized for its commitment to quality, precision engineering, and compliance with international safety standards (including CE, RoHS, and UL). Their power supplies undergo rigorous testing for thermal management, surge protection, short-circuit prevention, and long-term reliability. This ensures not only the protection of the LED tape but also extended system lifespan and reduced maintenance costs. By combining high lumens-per-watt performance, support for CRI >90 lighting, and robust IP-rated protection, Beauty STC delivers a complete, high-quality LED lighting solution tailored for demanding applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as our primary production hub for LED lighting components and power solutions, strategically located within the Pearl River Delta’s robust electronics supply chain. The factory spans over 20,000 square meters and operates under strict ISO 9001 quality management protocols, with dedicated cleanroom environments for critical assembly processes. Regarding SMT capabilities, we deploy multiple high-speed Yamaha YS series automated placement lines featuring dual-lane configurations. These machines handle components down to 0201 package sizes with micron-level precision, supporting both reel-to-reel and tray feeding systems. Our SMT process incorporates automated optical inspection (AOI) stations after each placement stage and final automated X-ray inspection for BGA components, ensuring compliance with IPC-A-610 Class 2 standards for all lighting applications.

Aging test procedures represent a cornerstone of our quality assurance for power supplies. Every LED tape power supply undergoes mandatory 72-hour continuous burn-in testing under controlled thermal conditions within our environmental chambers. Units operate at 110% of rated load while subjected to temperature cycling between 25°C and 65°C, with real-time monitoring of output voltage stability, ripple current, and thermal performance via infrared thermal imaging. We maintain dedicated aging racks with automated data logging systems that flag any parameter deviation beyond ±3% tolerance, resulting in immediate unit quarantine for failure analysis. This rigorous process achieves a field failure rate below 0.15% for our power supply products.

Our OEM capabilities for LED tape power supplies encompass comprehensive turnkey solutions from initial concept to mass production. We support custom engineering of both constant voltage (12V/24V/48V) and constant current drivers with power ranges from 15W to 600W, featuring specialized designs for indoor, outdoor, and wet-location applications. The engineering team utilizes Altium Designer for schematic development and thermal simulation, while our tooling department maintains in-house mold fabrication for custom housings. Production flexibility includes UL, CE, and CCC certified platform modifications with lead times as short as 15 days for pre-qualified designs. All OEM projects undergo full regulatory compliance verification in our on-site EMC/EMI lab prior to shipment, with documentation packages including IEC 61347-2-13 test reports and photometric data for integrated lighting systems. This integrated approach allows us to deliver fully certified, application-specific power solutions meeting global market requirements.

Application Scenarios

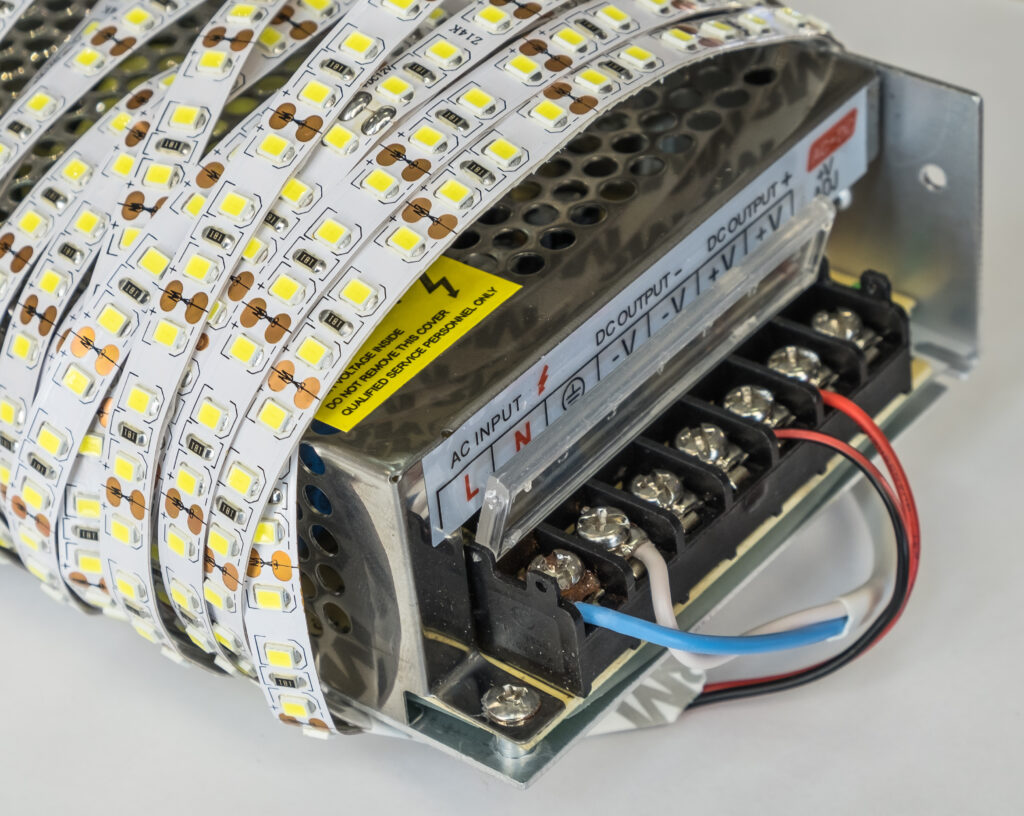

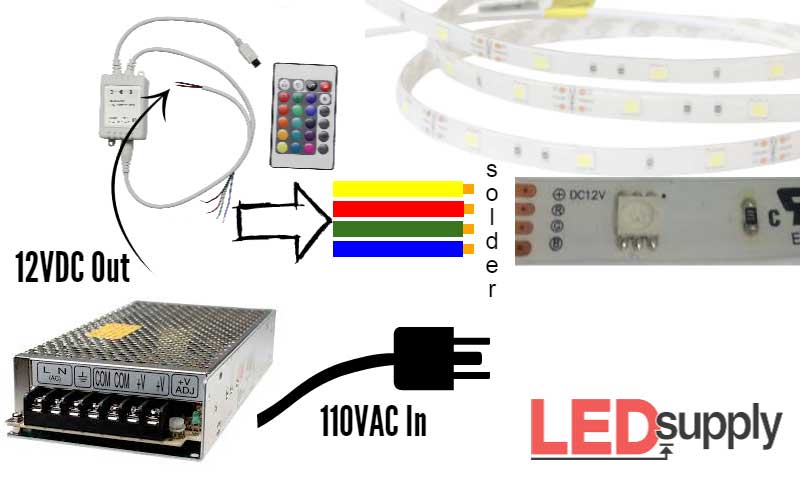

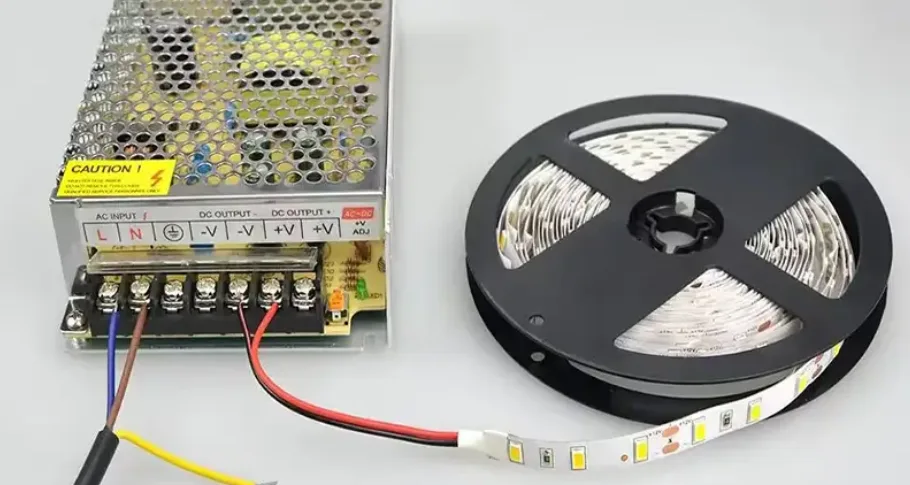

LED tape power supplies are essential components in low-voltage LED tape lighting systems, converting mains voltage (typically 110V or 230V AC) to a safe, usable DC voltage—commonly 12V or 24V—required by LED tapes. Their application spans various commercial and hospitality environments including hotels, malls, and offices, where flexible, energy-efficient, and aesthet-ically pleasing lighting is a priority.

In hotels, LED tape power supplies are commonly used to power lighting in guest room cove lighting, under-bed or headboard accents, bathroom mirrors, and wardrobe interiors. They also support ambient lighting in lobbies, corridors, and feature walls. The low-profile nature of LED tapes allows for discreet integration into architectural details, and the power supply ensures stable, flicker-free illumination, enhancing guest comfort and luxury appeal.

In shopping malls, LED tape power supplies drive lighting in display windows, signage backlighting, ceiling coves, escalator handrails, and decorative feature installations. The ability to create continuous runs of light with minimal visible fixtures makes them ideal for modern retail environments. Power supplies must be appropriately sized and often installed in accessible ceiling voids or service areas to support long tape runs across expansive spaces.

In office environments, LED tape power supplies are used for under-cabinet task lighting, partition cove lighting, reception desk accents, and indirect ceiling lighting to improve visual comfort and reduce glare. They support well-distributed, glare-free illumination that contributes to a productive and professional atmosphere. In open-plan offices, LED tapes can also be used to define zones or highlight branding elements.

When installing LED tape power supplies, several best practices should be followed. First, ensure the power supply capacity exceeds the total wattage of the LED tape by at least 20% to prevent overloading and ensure longevity. For example, if the LED tape consumes 60 watts, use a power supply rated for at least 72 watts. Second, locate the power supply in a well-ventilated area, away from direct moisture and heat sources, as overheating reduces efficiency and lifespan. Enclosed power supplies with IP67 ratings are recommended for damp or concealed locations.

Proper wiring is critical. Use appropriately gauge cables to minimize voltage drop, especially for long runs. For installations exceeding 5 meters, consider feeding power from both ends of the tape or using amplifiers. Also, ensure all connections are secure and insulated, and use connectors or soldering as appropriate. Where multiple tape sections are used, avoid daisy-chaining beyond the manufacturer’s recommendations.

Lastly, always follow local electrical codes and safety standards. Mount the power supply securely using brackets or DIN rails where applicable, and ensure it is easily accessible for maintenance. In commercial settings, using modular or track-mounted power distribution systems can simplify future upgrades or repairs.

By carefully selecting and installing LED tape power supplies, hotels, malls, and offices can achieve reliable, efficient, and visually appealing lighting that supports both functionality and design intent.

Why Choose Beauty STC Lighting

Beauty STC delivers engineered LED tape power supply solutions designed for seamless integration, optimal performance, and long-term reliability in demanding lighting installations. Our power supplies undergo rigorous thermal and electrical validation to ensure stable voltage output across varying loads, eliminating flicker and extending tape lifespan while meeting global safety certifications. Partner with us to access customizable voltage and wattage configurations, bulk-order flexibility, and dedicated technical support from our in-house engineering team—turning complex project requirements into flawless, code-compliant implementations.

Elevate your next project with power supplies built for precision. Contact our partnership manager directly at [email protected] to discuss tailored solutions for your specific application needs.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.