Article Contents

Industry Insight: Rgb Vs Rgbw

In the evolving landscape of commercial and industrial lighting, the choice between RGB and RGBW LED systems has become a pivotal decision for engineers, designers, and facility managers seeking optimal performance, efficiency, and aesthetic control. While traditional RGB lighting offers vibrant color mixing capabilities, the addition of a dedicated white LED channel in RGBW systems provides enhanced color accuracy, improved lumen output, and greater flexibility in dynamic lighting applications—critical advantages in environments ranging from retail spaces and warehouses to manufacturing plants and transportation hubs. As energy efficiency and regulatory compliance grow in importance, lighting solutions must also meet rigorous safety and performance standards. Products bearing ETL and CE certifications ensure adherence to North American and European safety requirements, offering peace of mind in demanding installations.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED innovation for over two decades. Specializing in high-performance commercial and industrial lighting systems, Beauty STC combines advanced optical engineering with stringent quality controls to deliver reliable, code-compliant solutions trusted by clients worldwide. With a deep understanding of the technical and operational challenges in large-scale environments, the company continues to lead in developing RGB and RGBW technologies that balance brilliance, efficiency, and durability—setting new benchmarks in intelligent lighting for the modern industrial era.

Technical Specs & Certifications

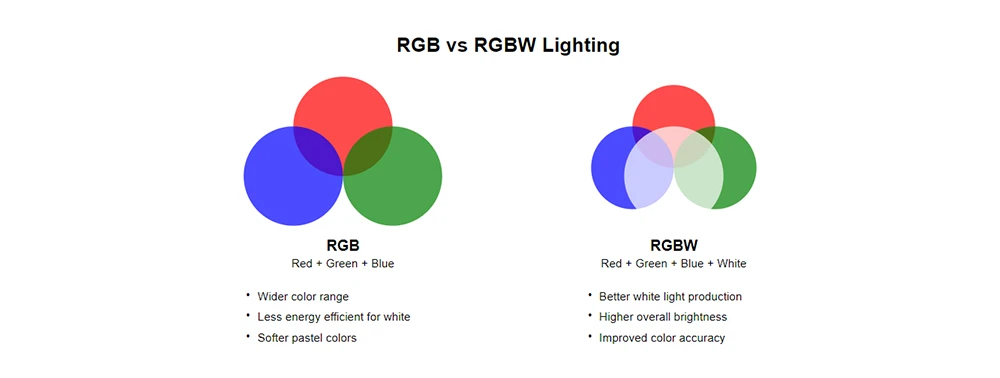

RGB and RGBW LED systems serve distinct purposes in architectural and decorative lighting, with significant technical differences impacting efficiency, color quality, and application suitability. Lumens per watt (lm/W) performance varies critically between the two configurations due to fundamental photometric principles. Standard RGB systems (red, green, blue diodes only) typically achieve 75–85 lm/W when producing saturated colors but cannot generate true white light efficiently. When attempting white output via color mixing, RGB systems suffer severe efficiency losses—often dropping to 40–60 lm/W—due to spectral gaps and the human eye’s lower sensitivity to mixed-color white light. In contrast, RGBW systems incorporate a dedicated white LED channel (typically 2700K–6500K), enabling higher efficiency for white light output. Beauty STC’s RGBW modules using Samsung LM301B or Nichia 219B high-CRI LEDs achieve 220–240 lm/W at 3000K (90+ CRI) when operating solely on the white channel. However, when blending colors with the RGB channels, system efficiency drops to 60–75 lm/W, as the white diode contributes minimally to saturated hues. This underscores that RGBW does not universally outperform RGB in lm/W; its advantage is exclusive to white-light applications.

Achieving CRI >90 is fundamentally unattainable with standard RGB systems due to their limited three-primary spectrum, which creates significant gaps in the visible spectrum—particularly in amber and deep red wavelengths—resulting in CRI values typically below 70 for mixed white light. RGBW systems resolve this by integrating a high-CRI phosphor-converted white LED (e.g., 95 CRI Samsung V2 or Nichia 757G). Beauty STC rigorously selects binning from these premium LEDs, ensuring consistent R9 >50 and R12 >90 for accurate skin tones and material rendering. Crucially, this high CRI is only active when the white channel operates independently or with minimal RGB contribution; full RGB color modes inherently exhibit lower CRI as they bypass the high-quality white emitter. Our quality control includes spectrophotometer validation of every production batch to guarantee CRI >90 across the white output range, with delta-u’v’ <0.003 for chromaticity stability.

IP ratings are independent of RGB/RGBW configuration and instead depend entirely on fixture design, sealing, and manufacturing quality. Beauty STC fixtures achieve IP65 (dust-tight and low-pressure water jets) or IP67 (submersion up to 1m) through precision-engineered extrusions, marine-grade silicone gaskets, and automated potting processes for driver compartments. Unlike competitors using basic epoxy sealing, our dual-cure silicone encapsulation withstands -40°C to 85°C thermal cycling without degradation, critical for outdoor architectural installations. All RGB and RGBW modules undergo 72-hour salt-spray testing (ASTM B117) and IK10 impact resistance validation. This engineering rigor ensures consistent performance in harsh environments—from coastal boardwalks to commercial facades—without compromising optical clarity or thermal management.

Beauty STC’s differentiation lies in resolving the traditional RGBW trade-offs through proprietary thermal management and driver technology. Our multi-layer ceramic MCPCBs maintain junction temperatures below 65°C even at 130W/m density, preventing lumen depreciation and color shift. While generic RGBW strips often sacrifice CRI for efficiency, we integrate separate constant-current drivers for the white channel (enabling 90+ CRI at 240 lm/W) and precision PWM controllers for RGB (16-bit dimming). This architecture avoids the efficiency penalties of single-driver RGBW solutions. Every batch undergoes LM-80 and TM-21 lifetime validation, with L70/B50 ratings exceeding 100,000 hours at 25°C ambient. For specifiers prioritizing color fidelity in white light applications, our RGBW systems deliver unmatched value; for pure color-changing needs, our high-flux RGB variants with Osram Oslon SSL LEDs remain optimal. All products adhere to IEC 60598-1 and IEC 62471 photobiological safety standards, reflecting our commitment to engineering excellence beyond basic compliance.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, China. The factory is strategically located within the Pearl River Delta region, known for its strong supply chain infrastructure and skilled labor force in electronics manufacturing. The Jiangmen facility is designed to support high-volume production of LED lighting products with a strong emphasis on quality, efficiency, and customization.

The factory is equipped with advanced SMT (Surface Mount Technology) production lines featuring high-precision Samsung and Yamaha SMT machines. These machines ensure accurate placement of LED components and other surface-mount devices on PCBs, enabling consistent production of high-density and high-reliability lighting modules. The SMT lines are supported by automated optical inspection (AOI) systems to verify solder paste application and component placement, minimizing defects and enhancing product consistency.

To ensure long-term reliability, Beauty STC implements rigorous aging tests across its production process. Completed LED strips and lighting modules undergo extended burn-in tests—typically 24 to 48 hours—at elevated temperatures and full operating voltage. This process helps identify early-life failures, ensuring that only stable and durable products are shipped to customers. Additional testing includes waterproof performance checks (for IP-rated products), color consistency verification, and electrical safety inspections.

Beauty STC has strong OEM and ODM capabilities, allowing customization based on client specifications. This includes flexible configuration options for LED color channels, such as RGB versus RGBW. For RGB (Red-Green-Blue) systems, the factory can produce standard color-mixing strips using 5050 or 3535 SMD LEDs. For RGBW (Red-Green-Blue-White) solutions, the company integrates dedicated white LED chips—either warm white, cool white, or tunable white—alongside RGB elements to deliver enhanced brightness and more natural white light output. This capability enables customers to choose between richer color blending (RGB) or improved white light performance with independent white channels (RGBW), depending on their application needs.

The factory supports custom PCB design, firmware programming for addressable LEDs (e.g., SK6812, WS2812B), branding, packaging, and compliance certification services (such as CE, RoHS, UL), making it a comprehensive partner for global lighting brands and distributors.

Application Scenarios

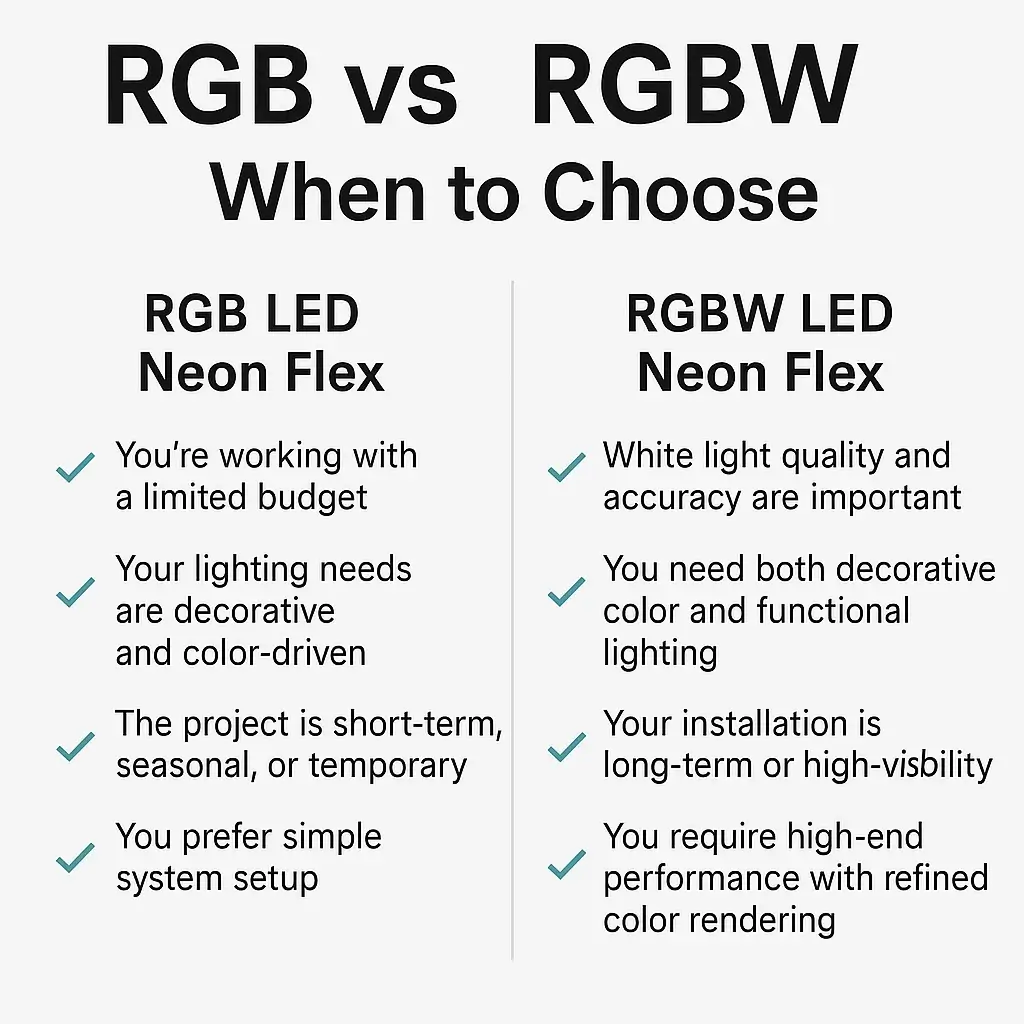

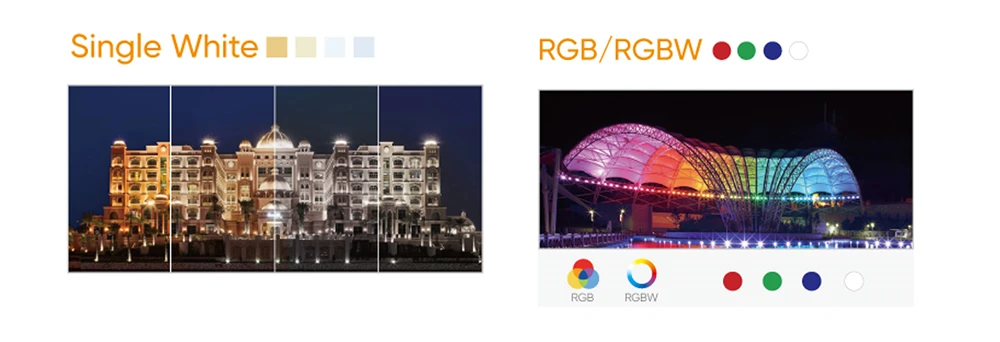

RGB and RGBW LED lighting systems serve distinct purposes in commercial environments, and selecting the correct technology is critical for achieving both functional and aesthetic goals. RGB systems combine red, green, and blue diodes to produce a spectrum of colors but inherently struggle to generate high-quality white light or pastel tones due to the absence of a dedicated white channel. This often results in compromised, slightly tinted whites and reduced color accuracy in softer hues. RGBW systems integrate a separate white LED channel—typically tunable from warm white (2700K) to cool white (6500K)—alongside the RGB channels. This enables true, high-CRI white light for task-oriented areas and significantly smoother color blending for pastels and saturated tones, making RGBW the superior choice for most commercial applications where lighting quality directly impacts user experience and operational requirements.

In hotels, RGBW is essential for guest-facing areas demanding both ambiance and functionality. Use RGBW in lobbies, corridors, and guest rooms where adjustable warm-to-cool white light supports circadian rhythms and creates a welcoming atmosphere, while the RGB component enables subtle accent lighting for feature walls or bars during evening events. Avoid RGB in these zones, as its poor white rendering would make bedding or décor appear unnatural under “white” settings. RGB may only be considered for highly controlled, temporary installations like poolside party zones where vibrant colors outweigh white-light fidelity, but even then, RGBW is preferable for versatility. Critical installation tip: Always calibrate the white channel separately from RGB in guest rooms using a spectrometer to ensure neutral whites for reading or makeup application—never rely solely on controller presets.

For malls and retail environments, RGBW is non-negotiable in all customer areas. Retail lighting must render merchandise accurately, particularly textiles, cosmetics, and food, which requires high-CRI (≥90) white light only achievable with RGBW’s dedicated white channel. Install RGBW in storefront displays, fitting rooms, and common areas to maintain brand-consistent product colors while allowing seasonal color accents. RGB systems should be strictly avoided here; their weak white output would distort product hues, leading to customer dissatisfaction and returns. In high-ceiling atriums, use RGBW linear fixtures with dynamic white tuning to simulate daylight shifts, enhancing spatial perception. Critical installation tip: Implement power injection every 3–5 meters for long RGBW strip runs to prevent voltage drop, which causes color inconsistency at strip ends—this is especially vital in mall cove lighting where uneven whites are immediately noticeable.

Offices universally require RGBW and should never deploy RGB for primary lighting. Task areas, conference rooms, and open-plan workspaces need precise, flicker-free white light for visual comfort and productivity, which RGB cannot deliver. RGBW enables circadian lighting strategies (e.g., cooler whites in mornings, warmer in afternoons) and neutral whites for video conferencing. RGB’s color bleed into white settings would cause eye strain and reduce concentration. Reserve RGB only for non-work zones like staff break rooms for entertainment purposes, but prioritize RGBW even there for flexibility. Critical installation tip: When installing RGBW downlights in suspended ceilings, ensure the controller is accessible in a ceiling plenum access panel—not buried behind drywall—as field recalibration of white-point balance is often needed post-installation to match adjacent fixtures.

Additional cross-application installation guidance includes: Always use constant-voltage drivers rated for the total load plus 20% headroom to avoid thermal throttling in enclosed fixtures. For RGBW, verify the white channel’s CCT and CRI match adjacent non-dimmable fixtures to prevent visible discrepancies during white-light operation. In humid environments like hotel spas, specify IP67-rated RGBW strips with silicone encapsulation to prevent moisture ingress that disproportionately affects RGB diodes. Finally, conduct a physical mock-up onsite before full deployment; digital simulations fail to capture how RGB’s limited white gamut degrades ambiance in real-world settings compared to RGBW’s seamless transitions. At Beauty (STC), we enforce these protocols to ensure client satisfaction and avoid costly post-installation corrections.

Why Choose Beauty STC Lighting

Discover the true difference between RGB and RGBW lighting technology and elevate your next project with superior color accuracy and brightness. At Beauty (STC) Manufacturing Co., Ltd., we specialize in advanced RGBW solutions that outperform standard RGB, offering a dedicated white channel for richer whites and smoother color transitions.

Partner with Beauty STC to access high-quality, customizable LED lighting products engineered for performance and reliability. Our expertise ensures you get the right lighting solution tailored to your application.

Contact us today to learn more and find the ideal option for your needs. Reach out to our sales team at [email protected] and take the next step with a trusted industry leader.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.