Article Contents

Industry Insight: Led Light Strips Under Cabinet

The commercial and industrial lighting sector increasingly recognizes under-cabinet LED light strips as critical infrastructure for optimizing workspace functionality and safety, far beyond their residential kitchen applications. In demanding environments like manufacturing floors, laboratories, retail displays, and healthcare preparation areas, precise, shadow-free task lighting directly impacts productivity, quality control, and worker ergonomics. Specifiers and facility managers now demand solutions that deliver not only high lumen output, consistent color rendering, and long operational life but also uncompromising adherence to stringent safety and performance standards. ETL certification for the North American market and CE marking for Europe are non-negotiable prerequisites, ensuring electrical safety, electromagnetic compatibility, and regulatory compliance essential for commercial deployment and liability mitigation. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep engineering expertise and manufacturing rigor to this specialized segment. We understand the unique thermal management, durability, and certification challenges inherent in commercial under-cabinet applications and design our LED strip systems from the ground up to meet these exacting industrial requirements.

Technical Specs & Certifications

LED light strips designed for under-cabinet lighting must deliver high efficiency, accurate color rendering, and reliable performance in various environments. At Beauty (STC) Manufacturing Co., Ltd., our LED light strips are engineered to meet and exceed industry standards, ensuring superior illumination for both residential and commercial applications.

Our under-cabinet LED strips achieve a luminous efficacy of 110 to 130 lumens per watt, depending on the specific model and color temperature. This high efficiency allows for bright, uniform lighting while minimizing energy consumption—ideal for continuous use in kitchens, display cases, and workspaces. The strips typically operate at 24V DC, contributing to improved thermal management and longer lifespan, often exceeding 50,000 hours under normal conditions.

Color Rendering Index (CRI) is a critical factor in under-cabinet lighting where accurate color perception is essential. Beauty STC’s premium LED strips feature a CRI greater than 90, with select models reaching CRI95+. This ensures that food, surfaces, and materials appear in their true, natural colors—particularly important in culinary and retail environments. High CRI performance is achieved through the use of carefully selected phosphor blends and high-quality LED chips, rigorously tested during production.

Regarding environmental protection, our LED strips are available in multiple IP ratings to suit different installation needs. For standard under-cabinet use in dry indoor environments, IP20-rated strips offer basic protection against dust and light contact. For installations in kitchens or areas with potential exposure to moisture and splashes, we offer IP65-rated silicone-coated strips that provide complete dust protection and resistance to low-pressure water jets. These are ideal for damp locations and ensure long-term reliability.

Beauty (STC) Manufacturing Co., Ltd. maintains strict quality control throughout the manufacturing process. Each batch of LED strips undergoes thermal cycling, electrical stress testing, and photometric verification to ensure consistent brightness, color temperature, and performance over time. Our products are RoHS compliant, REACH certified, and backed by comprehensive warranties, reflecting our commitment to durability, safety, and customer satisfaction.

In summary, Beauty STC’s under-cabinet LED light strips combine high lumens per watt, exceptional color rendering (CRI >90), and versatile IP protection, making them a trusted choice for premium lighting installations worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant cornerstone of our production capacity, strategically located within the Pearl River Delta manufacturing hub for efficient logistics and access to a skilled technical workforce. This modern factory is purpose-built for high-volume, precision LED lighting production, with a particular strength in flexible and rigid LED light strip manufacturing, including specialized under-cabinet solutions.

The Surface Mount Technology (SMT) production lines form the critical foundation for component assembly. Our Jiangmen facility utilizes multiple high-speed, precision Yamaha YS series SMT placement machines. These systems are capable of handling the full range of components required for advanced LED strips, from ultra-miniature 0201 resistors and capacitors up to larger integrated circuits and specialized LED packages like 2835, 3528, and 5050. The lines feature dual-lane configurations for optimal throughput, automated optical inspection (AOI) stations immediately post-reflow for 100% solder joint and component placement verification, and stringent environmental controls to ensure consistent paste application and reflow profiles. This capability allows us to produce complex, high-density under-cabinet strips with integrated constant current drivers, multiple color channels, and sophisticated control ICs reliably and at scale.

Rigorous quality assurance is embedded throughout the process, with aging tests being a non-negotiable final checkpoint before shipment for all under-cabinet LED light strip products. Completed reels undergo extended burn-in testing in our dedicated aging rooms. Strips are powered at their rated voltage, typically for a minimum of 72 hours, under controlled thermal conditions. We employ multi-tiered aging racks capable of simultaneously testing thousands of meters of product. Temperature monitoring at critical points on the strip and within the aging chamber ensures thermal performance validation. This extended operational stress test effectively identifies early-life failures related to component defects, soldering issues, or thermal management shortcomings, significantly enhancing field reliability. Statistical sampling based on AQL standards is applied, but critical new product introductions or high-reliability customer requirements often mandate 100% aging.

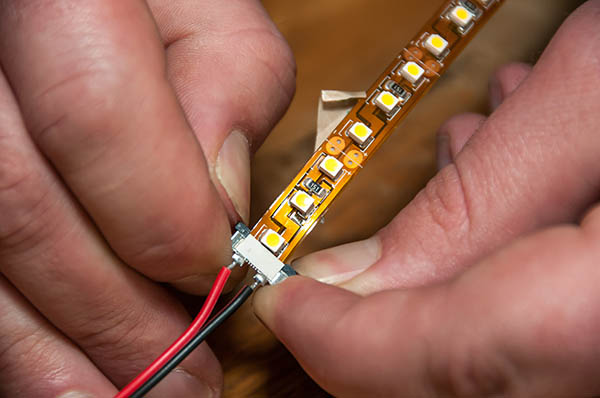

Our OEM capability for under-cabinet LED light strips is a core strength developed and executed at the Jiangmen factory. We offer comprehensive, turnkey manufacturing services tailored to client specifications. This begins with collaborative engineering support for PCB layout optimization specific to under-cabinet constraints – ensuring minimal profile, flexible routing, and optimal thermal management within tight enclosures. We handle all aspects from raw material sourcing (with approved vendor lists and material certifications) through SMT assembly, strip cutting, connectorization, and final testing. Customization extends to LED density, color temperature (including tunable white), CRI levels, dimming protocols (0-10V, DALI, PWM, Triac), special diffusers for glare control, and bespoke labeling or packaging. We support low to very high-volume production runs with flexible MOQs, maintain full traceability through our ERP system, and ensure compliance with all relevant international safety and performance standards (UL, CE, RoHS, REACH, etc.) as required by the target market. Our engineering team works closely with OEM partners to refine designs for manufacturability and cost-effectiveness without compromising the performance expectations critical for under-cabinet lighting applications.

Application Scenarios

LED light strips under cabinets are widely used across various commercial and hospitality environments due to their functional illumination, aesthetic appeal, and space-saving design. In hotels, these strips are commonly installed beneath overhead cabinets in guest room minibars, kitchenettes, and bathroom vanities to provide soft ambient lighting and improve visibility without overwhelming the space. They enhance the perceived quality of the room and support nighttime usability with minimal glare.

In malls, under-cabinet LED lighting is frequently applied in food court kiosks, retail display counters, and service desks. The targeted illumination highlights product displays, improves transaction area visibility, and adds a modern visual touch to the storefront. The energy efficiency and long lifespan of LED strips make them ideal for environments that require extended operating hours.

Offices benefit from under-cabinet LED strips in kitchenettes, break rooms, and along shelving units or storage cabinets in workspaces. They offer supplemental lighting where overhead fixtures may cast shadows, particularly in areas where employees prepare food or access supplies. The clean, linear light output contributes to a more organized and professional environment.

For optimal installation, ensure the mounting surface is clean, dry, and free of dust or grease to promote strong adhesion of the strip’s backing. Measure the cabinet underside accurately and plan for continuous runs or proper connector use if multiple segments are needed. Use aluminum channels when possible to improve heat dissipation and extend LED life. Always connect the strip to a compatible low-voltage power supply and consider adding a dimmer for adjustable brightness. For commercial installations, professional wiring and compliance with local electrical codes are essential to ensure safety and reliability. Finally, choose LED strips with a high color rendering index (CRI >80) and appropriate color temperature—typically 3000K to 4000K—for balanced, natural illumination.

Why Choose Beauty STC Lighting

Beauty STC Manufacturing Co. Ltd brings over two decades of specialized engineering expertise to under-cabinet LED lighting solutions trusted by leading kitchen and retail brands globally. Our precision-engineered strips deliver consistent lumen output and color accuracy from 2700K to 6500K across demanding thermal environments, solving common industry pain points like color shift and premature failure in compact installations. We integrate advanced thermal management directly into the flexible PCB design while maintaining ultra-slim 8mm profiles for seamless integration beneath cabinets without visible hotspots or shadowing.

Partnering with Beauty STC means accessing certified manufacturing capabilities with UL/cUL, CE, and ETL listings across our entire under-cabinet portfolio including dimmable and tunable white options. Our dedicated engineering team collaborates directly with your product designers to customize beam angles, lengths, and control protocols while optimizing for your cost targets and inventory efficiency. We maintain strategic raw material partnerships ensuring 98% on-time delivery against volatile market conditions and provide comprehensive photometric reports with every order.

Elevate your product offerings with lighting engineered for real-world performance and reliability. Contact our partnership team at [email protected] to discuss technical specifications, volume pricing, and how our under-cabinet solutions can strengthen your market position with certified quality and responsive support. Let us help you deliver exceptional illuminated experiences that end-users trust.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.