Article Contents

Industry Insight: Led Strip Lights And Transformer

The commercial and industrial lighting landscape has undergone a profound transformation, with LED strip lights emerging as a cornerstone solution for architectural accenting, task lighting, cove illumination, and functional workspace applications. Their flexibility, energy efficiency, and design versatility offer significant advantages over traditional linear fluorescent and halogen systems. However, the true performance, longevity, and safety of any LED strip installation hinge critically on the often-underestimated component: the transformer or driver. In demanding commercial and industrial environments where uptime, precise light output, and adherence to strict safety codes are non-negotiable, the driver is not merely a power supply but the essential guardian of system reliability. Rigorous certifications like ETL (verifying compliance with North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental requirements) are not optional extras; they are foundational prerequisites ensuring the driver can withstand harsh conditions, prevent fire hazards, and deliver stable, flicker-free operation over the long term. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, leveraging over 25 years of specialized engineering expertise to develop high-performance LED strip lights and, crucially, precision-engineered transformers designed specifically for the uncompromising demands of commercial and industrial projects worldwide. We understand that in professional lighting, where reliability isn’t optional, the quality of the power solution defines the entire system’s success.

Technical Specs & Certifications

LED strip lights and transformers are essential components in modern lighting systems, offering flexibility, energy efficiency, and high performance for both residential and commercial applications. At Beauty (STC) Manufacturing Co., Ltd., our LED strip lights are engineered to deliver superior illumination and reliability, meeting the highest industry standards.

Our LED strip lights achieve an efficacy of up to 130–150 lumens per watt, depending on the configuration and density of LEDs used. This high lumen-per-watt ratio ensures optimal energy savings without compromising brightness. We utilize high-grade SMD 2835, 3014, or 5050 LED chips, which are known for their consistent light output and thermal performance, contributing to long-term efficiency.

Color Rendering Index (CRI) is a critical factor in lighting quality, especially in environments where accurate color representation is essential, such as retail spaces, studios, and healthcare facilities. All our premium LED strip lights feature a CRI greater than 90, with select models reaching CRI 95+. This ensures vibrant, natural-looking colors and excellent visual clarity. The high CRI is achieved through carefully selected phosphor coatings and strict binning processes during manufacturing.

In terms of environmental protection, our LED strips are available in multiple IP (Ingress Protection) ratings to suit various installation conditions. IP20-rated strips are designed for dry, indoor environments with no exposure to dust or moisture. For damp or outdoor applications, we offer IP65-rated strips, which are protected against water jets and dust ingress, making them ideal for kitchens, bathrooms, and outdoor signage. For fully waterproof requirements, our IP67 and IP68-rated LED strips provide complete dust tightness and submersion protection up to 1 meter, suitable for pool lighting, landscaping, and marine environments.

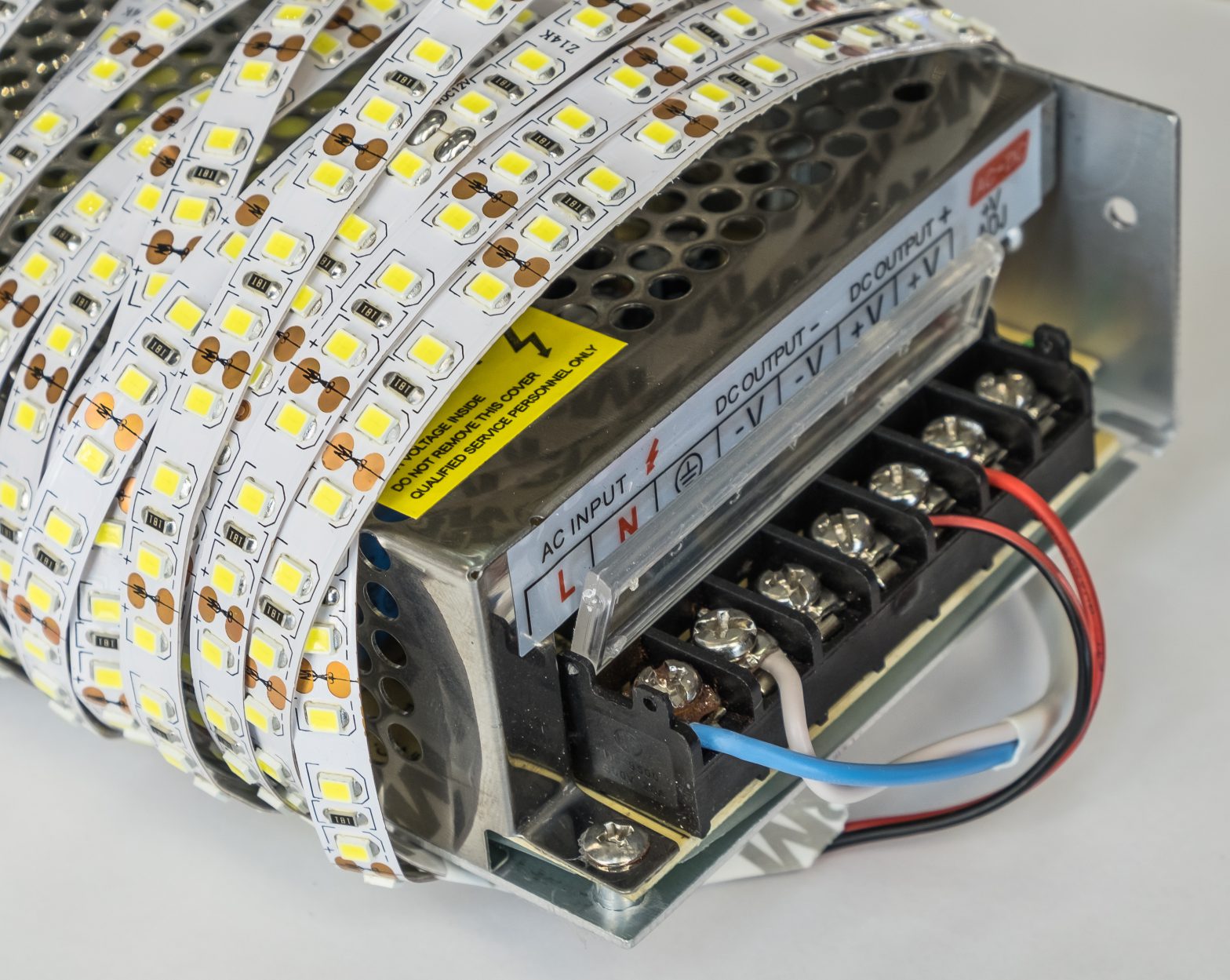

The transformers, or LED drivers, used with our strip lights are constant voltage types (typically 12V or 24V DC) and are designed to match the power requirements of the LED strips precisely. They feature high efficiency (up to 92%), wide input voltage range (100–240V AC), and built-in protections against overvoltage, overcurrent, and overheating. Many of our drivers are also IP67-rated for outdoor or concealed installations, ensuring durability and long service life.

Beauty (STC) Manufacturing Co., Ltd. is committed to quality and innovation. Our production processes follow strict ISO9001 standards, and all products undergo rigorous testing for electrical safety, thermal management, and photometric performance. We use lead-free, RoHS-compliant materials and conduct aging tests on every batch to ensure consistent performance over time. With over two decades of expertise in LED lighting, Beauty STC delivers reliable, high-performance lighting solutions trusted by clients worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern, purpose-built manufacturing facility in Jiangmen, Guangdong Province, strategically located within the Pearl River Delta region to leverage excellent supply chain access and logistics infrastructure. This factory serves as our primary production hub for LED lighting solutions, featuring advanced automation and stringent quality control systems designed specifically for high-volume, precision manufacturing of LED strip lights and associated drivers.

The Surface Mount Technology (SMT) production area is a cornerstone of our Jiangmen facility. We utilize multiple high-speed SMT lines equipped with state-of-the-art placement machines from leading manufacturers, capable of handling components down to 0201 package sizes with exceptional accuracy. These machines feature multi-nozzle heads and advanced vision systems to ensure precise component placement on flexible and rigid PCBs used for LED strips. The lines integrate seamlessly with automated solder paste printers and nitrogen-reflow soldering ovens, maintaining strict thermal profiles critical for the reliability of densely populated LED circuits. This SMT capability allows us to efficiently produce a wide range of LED strip configurations, from standard density to high-power, high-CRI variants, with consistent solder joint integrity essential for thermal management and longevity.

Comprehensive aging and reliability testing is rigorously implemented before any product leaves the Jiangmen factory. We maintain dedicated aging chambers where finished LED strip lights and their matched transformers undergo extended burn-in tests, typically operating continuously for 24 to 72 hours at elevated temperatures simulating real-world stress conditions. This process occurs both at the component level for critical parts and, crucially, as fully integrated systems where strips are powered by their designated transformers. We monitor key parameters such as light output stability, color consistency, temperature rise at critical points, and driver performance throughout the aging cycle. This systematic approach allows us to identify and eliminate early-life failures, ensuring only units meeting our stringent reliability standards reach customers. The integration testing of strips with transformers is particularly vital, as it validates the compatibility and thermal performance of the complete lighting solution under sustained load.

Beauty STC possesses extensive OEM capabilities tailored specifically for LED strip lights and transformers at our Jiangmen facility. We offer full turnkey manufacturing services, starting from initial concept and custom engineering support through to mass production and logistics. Our engineering team works closely with clients to develop bespoke LED strip solutions, including custom lengths, densities, color temperatures, CRI values, flexible or rigid PCB formats, and various IP-rated constructions (from IP20 to IP68). Crucially, we design and manufacture compatible constant voltage or constant current transformers/drivers in-house, ensuring perfect electrical and thermal synergy between the strip and its power source. This integrated OEM approach allows us to provide clients with complete, validated lighting systems rather than just components. We support low to very high-volume production runs with flexible scheduling, rigorous quality documentation, and adherence to international standards including CE, RoHS, and UL recognition where required. Our Jiangmen factory’s infrastructure and expertise enable us to deliver high-quality, reliable, and fully customized LED strip lighting solutions efficiently under private label.

Application Scenarios

LED strip lights and transformers are widely used across various commercial and hospitality environments due to their flexibility, energy efficiency, and aesthetic appeal. Their applications in hotels, malls, and offices can significantly enhance both functionality and ambiance when properly installed.

In hotels, LED strip lights are commonly used in guest rooms to highlight architectural features such as cove ceilings, headboards, and under-cabinet lighting in minibars or desks. They are also ideal for accentuating reception desks, lobby areas, and corridors, where a warm and inviting atmosphere is desired. Waterproof LED strips are often installed in bathrooms, around mirrors, or in shower niches. The transformer, or LED driver, should be appropriately sized to match the total wattage of the strip and installed in a dry, ventilated location—often concealed within ceiling voids or behind panels.

In malls and retail environments, LED strip lights are used for cove lighting in walkways, under shelving, in display windows, and to highlight signage or architectural details. They help draw attention to products and create dynamic lighting schemes that enhance the shopping experience. Cold white or tunable white strips are often preferred in these settings for a bright, modern look. Transformers should be installed in accessible electrical enclosures or junction boxes to allow for maintenance and to ensure compliance with electrical codes. It is important to group circuits properly and avoid overloading transformers, especially in long continuous runs.

In offices, LED strip lights are frequently used for indirect lighting in suspended ceilings, under cabinets, or along stair edges for safety and modern design. They contribute to a well-lit, professional environment while reducing glare and eye strain. In conference rooms, they can be used to highlight branding or accent walls. Transformers must be selected based on the total load and dimming requirements—especially if integrated with building management or smart lighting systems. Always ensure that the transformer supports the dimming method being used, such as DALI, 0-10V, or phase dimming.

Installation tips include measuring the required length of LED strip accurately and cutting only at designated cut points. Ensure the surface is clean and dry before applying the adhesive backing. For longer runs, feed power from both ends to prevent voltage drop, which can cause dimming at the far end. Use aluminum channels to improve heat dissipation and protect the strips, especially in high-traffic or exposed areas. Always match the transformer’s output voltage (typically 12V or 24V DC) to the LED strip’s requirements and include a 20% safety margin in wattage capacity. Finally, follow local electrical codes and consider using a licensed electrician for final connections to ensure safety and compliance.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I emphasize our technical leadership in engineered lighting solutions. Our LED strip lights and compatible transformers are designed for superior performance, longevity, and seamless integration in demanding commercial and residential applications. Every component undergoes rigorous thermal and electrical validation to ensure reliability under continuous operation.

Partner with Beauty STC for OEM/ODM opportunities where precision engineering meets scalable manufacturing. We provide full technical collaboration from concept to certification, including custom voltage configurations and dimming protocols tailored to your market requirements. Our robust transformers eliminate flicker and compatibility issues that plague generic solutions, directly enhancing your end-product reputation.

Contact our engineering-led partnership team at [email protected] to discuss how our certified LED strips and purpose-built transformers can elevate your next project with measurable performance advantages. Let us handle the technical complexity while you focus on market growth.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.