Article Contents

Industry Insight: Solid Led Light Strip

The commercial and industrial lighting landscape is undergoing a fundamental transformation, driven by the relentless pursuit of energy efficiency, operational longevity, and adaptable illumination solutions. Within this evolution, solid-state LED technology has decisively moved beyond novelty to become the indispensable standard, particularly for flexible linear lighting applications. Solid LED light strips, distinguished by their robust construction, superior thermal management, and consistent optical performance, are now the preferred choice for demanding environments where reliability is non-negotiable. From illuminating vast warehouse aisles and enhancing retail merchandising with precise accent lighting to enabling sophisticated architectural cove details and critical task lighting in manufacturing facilities, these strips deliver the durability and controllability required for 24/7 operation. Crucially, their deployment in professional settings mandates rigorous adherence to safety and performance standards, making certifications like ETL (verifying compliance with North American safety standards) and CE (indicating conformity with European health, safety, and environmental requirements) essential markers of product integrity and market acceptance, not optional extras. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this shift. Leveraging over 25 years of specialized expertise in solid-state lighting engineering and precision manufacturing, we understand the exacting demands of commercial and industrial projects. Our commitment is to deliver Solid LED Light Strip solutions that not only meet but exceed these critical certification benchmarks, providing specifiers, contractors, and facility managers with the confidence of proven performance, lasting value, and seamless integration into the most challenging lighting infrastructures.

Technical Specs & Certifications

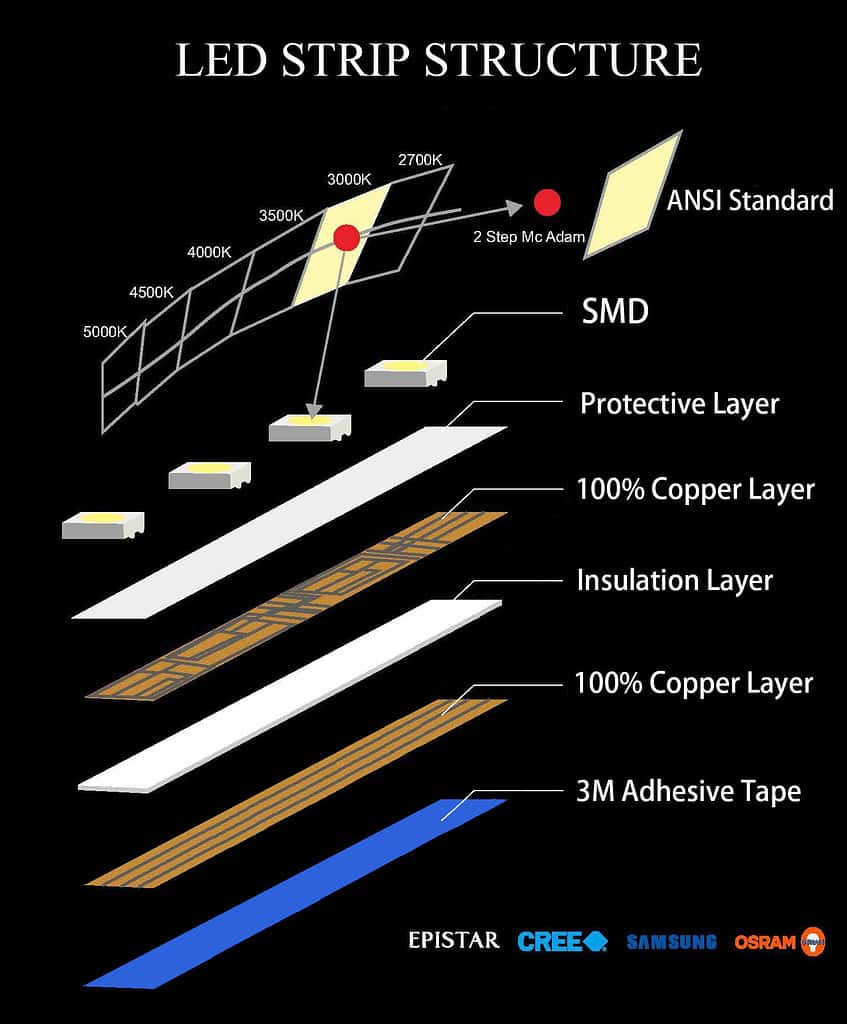

The solid LED light strip offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability across commercial, residential, and industrial lighting applications. These strips are designed with premium components to ensure consistent output, long service life, and excellent color fidelity.

In terms of efficiency, the solid LED light strips deliver a luminous efficacy ranging from 110 to 130 lumens per watt, depending on the specific configuration and color temperature selected. This high lumens-per-watt ratio ensures energy-efficient operation, reducing power consumption while maintaining bright, uniform illumination. The LEDs are typically driven at optimal currents to balance efficiency and thermal management, contributing to sustained performance over time.

Color Rendering Index (CRI) is a critical focus for Beauty STC’s lighting solutions. The solid LED strips feature a CRI greater than 90, with some variants reaching CRI95, ensuring accurate and vibrant color representation. This makes them ideal for environments where color precision is essential, such as retail displays, art galleries, photography studios, and high-end residential interiors. The high CRI is achieved through the use of top-bin LEDs and advanced phosphor coatings, ensuring minimal color deviation and excellent R9 (saturated red) values.

Regarding environmental protection, Beauty STC offers solid LED light strips in multiple IP (Ingress Protection) ratings to suit various installation conditions. The standard non-coated strip is rated IP20, suitable for dry indoor environments. For damp or outdoor applications, the strips are available with conformal coating or silicone encapsulation, achieving IP65, IP67, and even IP68 ratings. IP65-rated strips are protected against low-pressure water jets and dust, IP67 offers protection against temporary immersion in water up to 1 meter for 30 minutes, and IP68 provides continuous submersion protection under deeper water conditions, depending on the construction.

Beauty (STC) Manufacturing Co., Ltd. is recognized for its stringent quality control processes, adherence to international standards, and investment in R&D. Each solid LED light strip undergoes rigorous testing for electrical safety, thermal performance, color consistency, and aging. The use of high-quality flexible printed circuits (FPCBs), durable solder joints, and premium LED chips from trusted suppliers ensures long-term reliability and minimal lumen depreciation over time. Combined with competitive pricing and customizable options, Beauty STC’s LED strips stand out for their balance of performance, durability, and optical quality in the global lighting market.

Factory Tour: Manufacturing Excellence

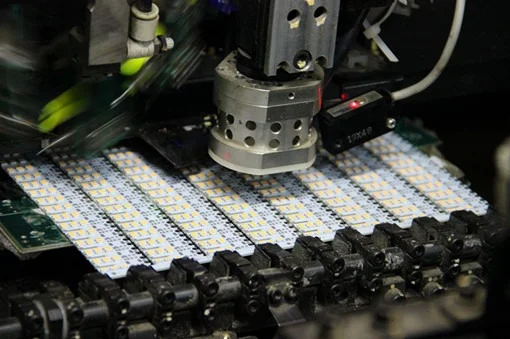

Beauty STC operates a modern 20,000 square meter manufacturing facility in Jiangmen, Guangdong Province, dedicated to high-volume LED lighting production with a strong emphasis on quality control and technical flexibility. The factory is strategically located within the Pearl River Delta’s industrial corridor, providing efficient access to supply chains and ports. Central to our production capability is a fully automated SMT line featuring multiple Yamaha YS24 and Siemens SX series machines. These systems handle components down to 0201 package size with precision placement accuracy of ±25μm, supporting high-density LED module assembly for rigid light strips. The line achieves a combined throughput of over 5 million components per day, utilizing nitrogen reflow soldering to ensure robust solder joints critical for thermal management in solid-state lighting applications.

Rigorous aging and reliability testing form a non-negotiable part of our production protocol. Every batch of solid LED light strips undergoes mandatory 72-hour continuous aging tests at 50°C ambient temperature, with real-time monitoring of luminous flux, color temperature, and forward voltage. We maintain dedicated aging chambers with a total capacity of 500 units simultaneously, allowing full batch validation before shipment. For critical OEM projects or high-reliability applications, we offer extended 1,000-hour accelerated life testing with detailed lumen maintenance reporting and thermal imaging verification of thermal pad performance on aluminum-backed rigid strips.

Our OEM capabilities for solid LED light strips are comprehensive and tailored to client specifications. We support full customization from initial optical design through to finished goods, including PCB layout optimization for aluminum substrates, thermal management solutions, and bespoke optical configurations. The factory handles all aspects of rigid strip production including SMT assembly, conformal coating, automated cutting, connectorization, and packaging. Clients can specify LED density, CCT ranges from 2200K to 6500K, CRI options up to 98, input voltages from 12V to 277V, and custom mechanical dimensions. We maintain UL, CE, and TÜV certified production lines with IPC-A-610 Class 2 compliance, offering rapid prototyping within 15 days and flexible order volumes from 500 meters for sampling to 50,000 meters monthly production capacity. All OEM projects include full documentation package with IES files, LM-79 reports, and thermal simulation data upon request.

Application Scenarios

Solid LED light strips are versatile and energy-efficient lighting solutions suitable for a wide range of commercial environments including hotels, malls, and offices. Their consistent illumination, long lifespan, and design flexibility make them ideal for both functional and decorative applications.

In hotels, solid LED light strips are commonly used in guest rooms to highlight architectural features such as cove ceilings, headboards, or under-cabinet lighting in minibars. They enhance ambiance and provide soft, indirect lighting that contributes to a relaxing atmosphere. In lobbies and hallways, LED strips can be installed along stair edges, reception desks, or wall niches to guide guests and create a welcoming environment. Back-of-house areas also benefit from their durability and low maintenance.

Malls utilize solid LED light strips in retail displays, signage backlighting, and pathway lighting to draw attention to storefronts and promote a modern, vibrant shopping experience. They are often integrated into coves above storefronts or used to accentuate product displays and escalator handrails. Their uniform light output ensures consistent brightness, which is essential in high-traffic commercial areas.

In office environments, solid LED light strips are effective for under-cabinet lighting, below desks, or within partition systems to reduce shadows and improve task lighting. They can also be used in conference rooms to highlight branding elements or create dynamic lighting scenes. Recessed ceiling coves with LED strips provide indirect ambient lighting that reduces glare and eye strain, contributing to a more comfortable and productive workspace.

When installing solid LED light strips, ensure the surface is clean, dry, and free of dust to promote strong adhesion of the strip’s backing. For best results, use aluminum channels which help dissipate heat, extend the lifespan of the LEDs, and provide a polished, professional finish. Always cut the strips only at the designated cut points to avoid damaging the circuitry. Use compatible LED drivers and controllers, and consider dimming options to adjust light levels based on time of day or function. In high-humidity areas such as restrooms or near entrances, select IP65-rated or higher waterproof strips. Finally, plan the layout in advance to minimize visible connections and ensure even light distribution, especially in continuous runs.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium solid LED light strips engineered for uncompromising performance and reliability. Our rigorously tested strips feature high-density LED placement on robust aluminum PCBs ensuring superior thermal management extended lifespan and consistent lumen output even under demanding conditions. Partner with Beauty STC to access customizable solutions tailored for architectural cove lighting retail displays or high-end residential installations where durability and precision matter most.

We provide comprehensive technical support including photometric data thermal validation and seamless integration assistance to streamline your design process. Our manufacturing excellence guarantees strict quality control adherence to international safety standards and flexible production capabilities for bulk orders without minimum quantity constraints.

Take the next step toward exceptional lighting outcomes by contacting our dedicated partnership team directly at [email protected]. Let us collaborate to deliver luminous results that exceed your clients’ expectations while strengthening your competitive edge in the market.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.