Article Contents

Industry Insight: Leds In Room

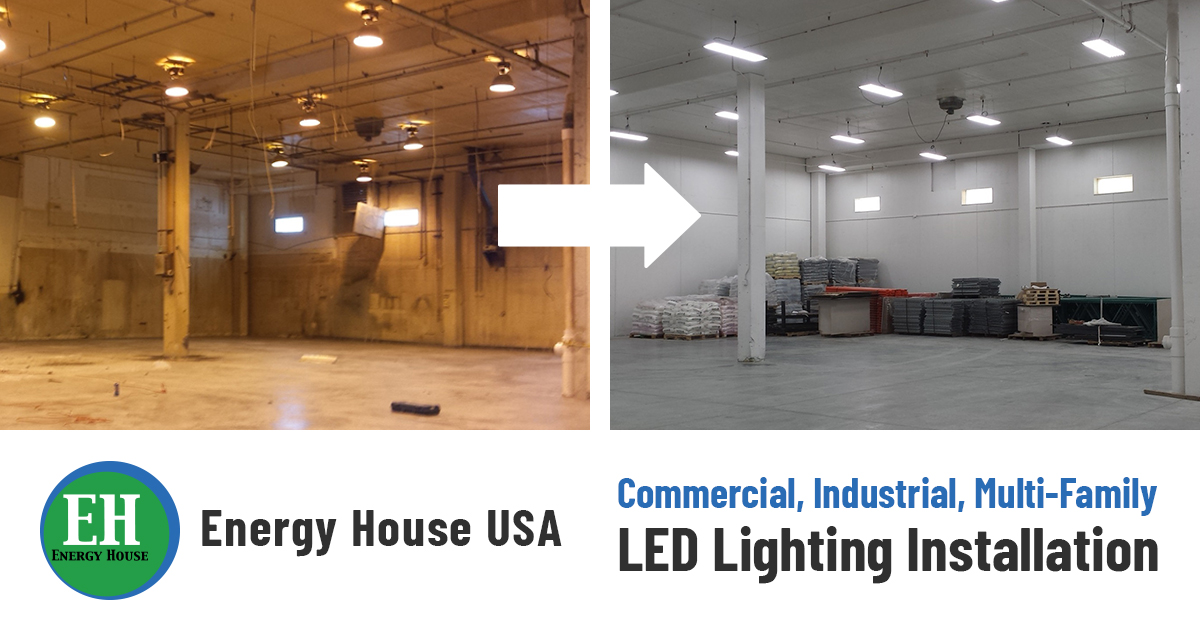

The commercial and industrial lighting sector is undergoing a profound transformation, driven by the relentless adoption of LED technology within built environments. Moving far beyond basic illumination, modern LED solutions are now fundamental infrastructure components, directly impacting operational efficiency, occupant well-being, and the bottom line for businesses ranging from expansive warehouses and manufacturing plants to sophisticated offices and retail complexes. Energy savings remain a primary driver, but the focus has decisively shifted towards intelligent systems offering superior light quality, precise controllability, extended lifespans under demanding conditions, and seamless integration with building management systems. Crucially, in this professional sphere, compliance is non-negotiable. Rigorous safety certifications like ETL for the North American market and CE marking for Europe are not merely checkboxes; they are essential assurances of product reliability, electrical safety, and adherence to stringent regional regulations, mitigating liability risks and ensuring installations meet code requirements from day one.

Beauty STC Manufacturing Co., Ltd. has been at the forefront of this evolution since our establishment in 1998. With over 25 years of dedicated engineering expertise, we specialize in designing and manufacturing high-performance LED lighting solutions engineered specifically for the rigorous demands of commercial and industrial applications. Our commitment extends beyond innovation to uncompromising quality and global compliance, ensuring every fixture we produce meets or exceeds critical standards like ETL and CE, providing facility managers and contractors with the confidence that their lighting infrastructure is both future-proof and safely certified.

Technical Specs & Certifications

When specifying LEDs for room lighting applications, several critical technical parameters must be considered to ensure optimal performance, energy efficiency, and visual comfort. At Beauty (STC) Manufacturing Co., Ltd., our LED lighting solutions are engineered to meet and exceed industry standards, combining high performance with long-term reliability.

One of the primary performance metrics is luminous efficacy, measured in lumens per watt (lm/W). Our LED luminaires for indoor room applications typically deliver between 110 and 140 lumens per watt, depending on the optical configuration and thermal management design. This high efficacy ensures significant energy savings over conventional lighting while maintaining excellent light output. Advanced driver technology and high-efficiency LED chips contribute to this performance, allowing our fixtures to provide bright, uniform illumination with minimal power consumption.

Color Rendering Index (CRI) is another essential factor, particularly in environments where accurate color perception is vital—such as retail spaces, studios, healthcare facilities, and high-end residential interiors. All Beauty STC LED products designed for indoor room lighting feature a CRI greater than 90, with many options offering CRI values of 95 or higher. This ensures that colors appear natural and vibrant under the light, enhancing visual clarity and occupant comfort. We achieve this through the use of high-quality phosphor-coated LEDs and rigorous binning processes during manufacturing.

Regarding environmental protection, Ingress Protection (IP) ratings are crucial for determining a fixture’s resistance to dust and moisture. For standard indoor room applications, our LED fixtures typically carry an IP20 rating, which provides protection against solid objects larger than 12mm and no protection against water—suitable for dry, controlled indoor environments. However, for areas such as bathrooms, kitchens, or utility rooms where moisture may be present, we offer fixtures with higher IP ratings, including IP44 and IP54, which provide protection against splashing water and dust ingress. These higher-rated luminaires are ideal for damp locations while maintaining aesthetic appeal and performance.

Beauty STC prides itself on superior build quality, rigorous quality control, and compliance with international standards such as IEC, EN, and UL. Our LED products undergo extensive thermal, electrical, and photometric testing to ensure longevity, with typical L70 lifespans exceeding 50,000 hours. The use of premium drivers, robust heat sinks, and high-transmission optical materials further enhances reliability and performance consistency across diverse operating conditions.

In summary, Beauty STC’s LED lighting solutions for rooms deliver high lumens per watt, excellent color rendering with CRI >90, and appropriate IP ratings tailored to the application environment. These features, combined with our commitment to engineering excellence and quality manufacturing, make our products a trusted choice for professional and residential lighting projects worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as a core production hub for our LED lighting solutions, strategically located within Guangdong Province’s robust electronics manufacturing ecosystem. The factory occupies a modern, climate-controlled industrial building designed specifically for precision electronics assembly, featuring dedicated cleanrooms for critical processes and streamlined workflow zones to maximize efficiency and quality control throughout the production cycle.

Our Surface Mount Technology (SMT) production lines represent a significant investment in automation and precision. The facility operates multiple high-speed SMT lines equipped with advanced placement machines from leading global manufacturers. These machines handle components ranging from ultra-fine pitch ICs to larger power LEDs and passive components with exceptional accuracy, typically achieving placement precision within ±25 microns. The lines integrate fully automated solder paste printing, multi-camera optical inspection (SPI) for paste verification, reflow ovens with precise thermal profiling capabilities, and automated optical inspection (AOI) stations post-reflow to ensure solder joint integrity and component placement before moving to subsequent assembly stages. This capability supports the high-density, multi-layer PCBs common in modern LED drivers and intelligent lighting modules.

Rigorous aging and burn-in testing is a non-negotiable phase for all LED luminaires produced at the Jiangmen factory, particularly critical for room lighting applications where reliability and consistent light output are paramount. Completed fixtures undergo extended operational aging tests under controlled environmental conditions, typically spanning 48 to 72 hours. During this period, units operate continuously at elevated temperatures and full rated power within specialized environmental chambers. We meticulously monitor key parameters including lumen maintenance, color consistency (CCT and CRI), driver stability, thermal performance at critical junctions, and overall electrical safety. Any unit exhibiting performance drift beyond stringent internal thresholds or functional anomalies is automatically flagged for root cause analysis and corrective action, ensuring only units meeting our durability standards advance to final packaging.

Beauty STC possesses extensive OEM capabilities specifically tailored for LED room lighting solutions, encompassing a wide range of products such as downlights, panels, troffers, strip lights, and decorative fixtures. We offer comprehensive turnkey manufacturing services where clients provide specifications, designs, or performance requirements. Our engineering team collaborates closely with OEM partners from the initial design-for-manufacturability (DFM) review through to mass production, supporting customizations in optical distribution, thermal management solutions, driver configurations, dimming protocols, and mechanical form factors. We manage all aspects including component sourcing against approved vendor lists, full assembly, the aforementioned stringent aging protocols, final functional and safety testing, and custom branding. This includes applying client-specific labels, packaging configurations, and documentation to deliver finished products ready for the partner’s market under their brand identity, with flexible production volumes to accommodate diverse client needs.

Application Scenarios

LEDs are widely used across various indoor environments due to their energy efficiency, longevity, and design flexibility. In rooms within hotels, malls, and offices, LEDs serve both functional and aesthetic purposes, enhancing ambiance while reducing energy consumption.

In hotels, LEDs are commonly installed in guest rooms, lobbies, hallways, and restrooms. In guest rooms, warm white LEDs (2700K–3000K) create a cozy and inviting atmosphere, ideal for relaxation. LED strip lights under headboards or behind televisions add a modern touch. In lobbies and reception areas, brighter neutral white LEDs (3500K–4000K) provide a welcoming yet professional appearance. Recessed downlights, cove lighting, and pendant LEDs are popular choices. For hallways and corridors, motion-sensor LEDs ensure safety while conserving energy during low-traffic periods.

In malls, LEDs are used in retail spaces, corridors, restrooms, and food courts. Bright, high-color-rendering index (CRI >80) LEDs are essential in retail areas to accurately display product colors. Track lighting with adjustable LED spots highlights merchandise, while linear LED fixtures illuminate walkways and signage. In common areas, uniform lighting with cool white LEDs (4000K) enhances visibility and security. LED panels in suspended ceilings provide even illumination in food courts and lounges.

In offices, LEDs are installed in workspaces, meeting rooms, corridors, and reception areas. Cool white LEDs (4000K–5000K) are preferred in workspaces as they promote alertness and concentration. LED panel lights in grid ceilings offer glare-free, uniform illumination. In meeting rooms, dimmable LEDs allow adjustment based on presentation needs. Task lighting at desks complements general lighting. Reception areas benefit from decorative LED fixtures that reflect the company’s brand and professionalism.

Installation tips for LEDs in rooms include selecting the appropriate color temperature and brightness (measured in lumens) based on the room’s function. Ensure compatibility with existing dimmer switches if dimming is desired—use dimmable LED drivers and compatible controls. Always follow electrical safety standards and consider hiring a licensed electrician for complex installations. Position lights to minimize glare, especially in office and retail settings. Use LED strips or indirect lighting to create visual interest without over-illumination. Finally, consider smart LED systems with scheduling or occupancy sensors to further improve energy efficiency, particularly in low-occupancy areas like restrooms or storage rooms.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I understand the critical role that well-designed LED lighting plays in transforming any room’s functionality, ambiance, and energy efficiency. Whether you’re illuminating residential living spaces, commercial offices, retail environments, or hospitality settings, the right LED solution directly impacts user experience, productivity, and operational costs.

Beauty STC specializes in developing high-performance, customizable LED lighting systems engineered specifically for diverse room applications. Our products deliver superior color rendering, seamless dimming, thermal management, and long-term reliability—all while meeting stringent global safety and efficiency standards. We go beyond off-the-shelf fixtures to create tailored lighting experiences that align with architectural intent and human-centric needs.

Partner with Beauty STC to leverage our technical expertise, scalable manufacturing capabilities, and dedicated engineering support. We collaborate closely with designers, contractors, and brands to refine concepts, solve complex lighting challenges, and deliver solutions that exceed market expectations. Elevate your projects with lighting that performs as brilliantly as it looks.

Transform your room lighting vision into reality with Beauty STC. Contact our partnership team directly at [email protected] to discuss your project requirements and explore how our engineering-driven approach can add value to your offerings. Let’s innovate together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.