Article Contents

Industry Insight: 2835 Led

The 2835 LED package has cemented itself as a fundamental workhorse within the commercial and industrial lighting sector, driven by its exceptional balance of performance, thermal management, and cost-effectiveness for high-output applications. Its compact footprint and robust design make it the preferred choice for demanding environments like warehouses, manufacturing facilities, retail spaces, and parking structures, where consistent, high-lumen output, long operational life, and reliable performance under continuous use are non-negotiable requirements. Crucially, for any product deployed in these professional settings, adherence to stringent safety and performance standards is paramount. Compliance with ETL (Intertek) certification for the North American market and CE marking for Europe is not merely a regulatory formality but a critical assurance of electrical safety, photobiological safety, and overall product reliability that facility managers and lighting specifiers demand to mitigate risk and ensure code compliance. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of developing and manufacturing high-performance 2835 LED components specifically engineered to meet and exceed these rigorous commercial and industrial demands. Our deep expertise in thermal management, optical control, and stringent quality assurance processes ensures our 2835 LEDs deliver the sustained lumen maintenance and operational stability essential for professional lighting solutions, positioning Beauty STC as a trusted partner for manufacturers building the next generation of efficient, durable, and certified luminaires.

Technical Specs & Certifications

The 2835 LED is a widely used surface-mount device (SMD) LED package named for its physical dimensions—2.8 mm by 3.5 mm. It is commonly employed in LED strips, linear lighting, downlights, and panel lights due to its compact size, efficient thermal performance, and high lumen output relative to power consumption.

In terms of efficiency, high-quality 2835 LEDs typically deliver between 100 to 130 lumens per watt (lm/W), depending on the drive current, thermal management, and binning of the LED chips. At Beauty (STC) Manufacturing Co., Ltd., our 2835 LEDs are engineered to consistently achieve luminous efficacy in the upper range of this spectrum—often exceeding 120 lm/W—ensuring energy-efficient lighting solutions suitable for both residential and commercial applications.

Color Rendering Index (CRI) is a critical metric for applications requiring accurate color representation. Beauty STC’s premium 2835 LEDs are available with a CRI greater than 90 (Ra > 90), and select high-end variants reach Ra > 95. This high CRI performance is achieved through advanced phosphor coating technology and strict chip selection, enabling natural and vibrant color reproduction ideal for retail lighting, museums, healthcare facilities, and high-end residential environments.

Regarding environmental protection, the 2835 LED itself is a component and does not carry an IP (Ingress Protection) rating independently. However, when integrated into luminaires or LED strips, the overall product can achieve various IP ratings based on the fixture’s design and encapsulation. Beauty STC offers 2835-based lighting solutions in configurations rated from IP20 for indoor dry locations to IP65, IP67, and even IP68 for outdoor, damp, or submersible applications. These ratings are achieved through precision silicone coating, conformal sealing, and robust housing designs that protect against dust, moisture, and mechanical damage.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process, from chip bonding to final assembly. Our 2835 LEDs undergo extensive testing for lumen maintenance (L70/L90), thermal stability, and chromatic consistency, ensuring long service life—typically rated at 50,000 hours—and reliable performance under continuous operation. With ISO-certified manufacturing standards and a focus on innovation, Beauty STC delivers 2835 LED solutions that combine high efficiency, superior color quality, and durable construction for demanding lighting applications worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern, vertically integrated manufacturing facility in Jiangmen, Guangdong Province, strategically positioned within the Pearl River Delta to leverage strong supply chain logistics and technical talent. The factory spans over 20,000 square meters and is equipped with advanced automation specifically tailored for high-volume, precision LED lighting production.

Our surface-mount technology (SMT) line features multiple high-speed Yamaha YS series placement machines, including the YS12F and YSM20 models, capable of handling components from 0201 imperial size up to large power LEDs. These machines achieve placement accuracy of ±25μm and throughput exceeding 80,000 components per hour per line. The SMT process for 2835 LED packages utilizes nitrogen-reflow soldering to ensure void-free thermal joints critical for lumen maintenance, with automated optical inspection (AOI) systems verifying every solder joint and component placement. The lines are optimized for the stringent tolerances required by 2835 LEDs, including precise control of phosphor layer application and binning consistency.

Aging and reliability testing is conducted in dedicated environmental chambers across a 1,500-square-meter quality assurance zone. All 2835 LED modules undergo mandatory 72-hour aging tests at 85°C/85% RH per IEC 60068-2-66 standards, with real-time lumen and chromaticity monitoring. We implement accelerated life testing (ALT) protocols using TM-21 projections, subjecting samples to 5,000+ hours of stress testing at elevated temperatures. Each batch receives comprehensive photometric validation via integrating spheres and goniophotometers to verify LM-80 compliance, with thermal imaging used to identify potential failure points in the thermal management system.

For OEM production of 2835 LED solutions, Beauty STC provides end-to-end capability from optical design to finished goods. We support full customization of CCT, CRI (Ra>90 options available), lumen output, and beam angles for 2835-based strips, panels, and modules. Our engineering team collaborates on thermal management solutions using aluminum PCBs or ceramic substrates, and we offer proprietary phosphor formulations for specialty color points. The factory holds UL, CE, and TÜV certifications with ISO 9001 and IATF 16949 quality management systems, enabling turnkey manufacturing from prototype to mass production with minimum order quantities starting at 5,000 units. All OEM projects include full documentation for regulatory compliance and traceability through our ERP system.

Application Scenarios

The 2835 LED is a surface-mounted diode (SMD) package that measures 2.8mm by 3.5mm, known for its high luminous efficacy, compact size, and excellent thermal performance. Due to these characteristics, 2835 LEDs are widely used across various commercial and hospitality environments such as hotels, malls, and offices.

In hotels, 2835 LEDs are ideal for ambient and accent lighting in guest rooms, corridors, lobbies, and restrooms. Their high efficiency and consistent color rendering enhance the aesthetic appeal of interior spaces while reducing energy consumption. Strip lights using 2835 LEDs are often used under cabinets, behind headboards, or along architectural coves to create a warm and inviting atmosphere.

In malls, these LEDs are commonly used in cove lighting, signage backlighting, display lighting, and general illumination in walkways and common areas. The brightness and uniform light output of 2835 LEDs ensure that retail spaces are well-lit, helping to highlight products and improve the overall shopping experience. Their long lifespan also reduces maintenance costs in large, high-traffic areas.

In offices, 2835 LEDs are frequently integrated into panel lights, downlights, and linear fixtures. They provide bright, flicker-free illumination that supports productivity and reduces eye strain. The high color rendering index (CRI) options available with 2835 LEDs ensure accurate color representation, which is essential in workspaces requiring visual precision.

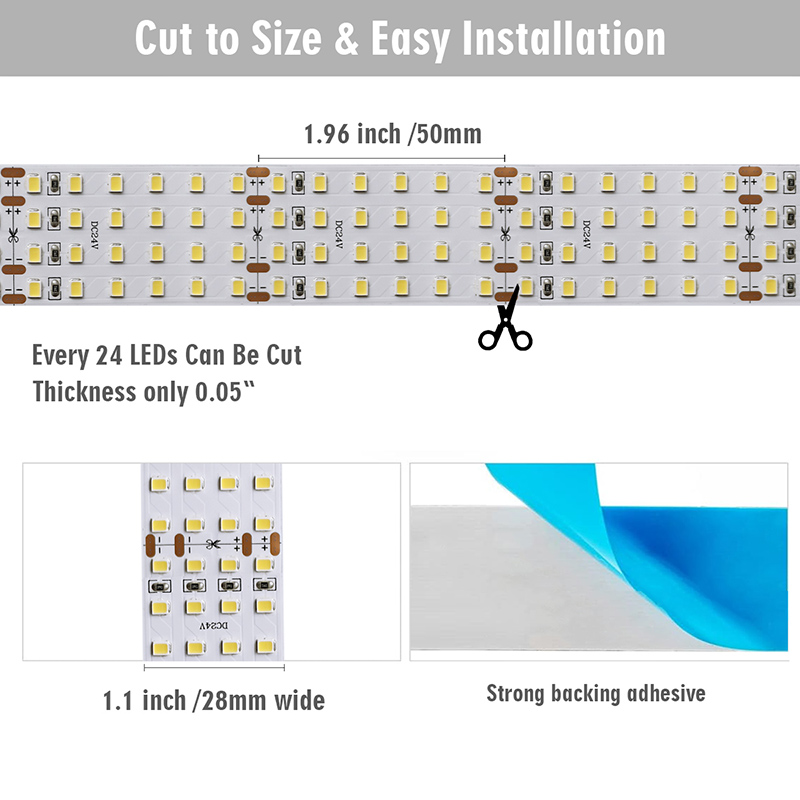

When installing 2835 LED strips or fixtures, ensure the surface is clean, dry, and free of dust to promote strong adhesion if using adhesive-backed strips. For optimal thermal management, install the LEDs on aluminum channels or heat-conductive surfaces, especially in enclosed or high-temperature environments. This helps dissipate heat and prolongs the LED’s lifespan. Always verify compatibility between the LED strip and power supply—match the voltage (typically 12V or 24V DC) and ensure the power supply has sufficient wattage capacity. Use proper connectors or solder joints for extensions, and avoid sharp bends in flexible strips to prevent damaging the circuit. In humid or outdoor-exposed areas, use IP65 or higher rated enclosures to protect against moisture and dust. Finally, follow local electrical codes and consider professional installation for permanent or hardwired applications to ensure safety and reliability.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s precision-engineered 2835 SMD LEDs, designed for superior luminous efficacy, thermal stability, and consistent color rendering across demanding applications. As your dedicated manufacturing partner, we deliver rigorously tested components that meet international quality standards while optimizing your production efficiency and end-product reliability. Our engineering team collaborates closely with clients to customize solutions for volume production, ensuring seamless integration into strips, modules, and fixtures. Partner with Beauty STC to leverage our advanced manufacturing capabilities and technical expertise in LED innovation. Reach out to our partnership manager today at [email protected] to discuss how our 2835 LEDs can enhance your product performance and market competitiveness.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.