Article Contents

Industry Insight: Power Supply Led Light Strip

The commercial and industrial lighting sector continues to evolve with a growing emphasis on energy efficiency, durability, and regulatory compliance. Among the most transformative technologies driving this shift are LED light strips powered by integrated power supply systems. These solutions offer superior luminous efficacy, flexible installation options, and long-term cost savings—making them ideal for applications ranging from warehouse and factory lighting to retail displays and architectural accenting. Central to their reliability and safety are certifications such as ETL and CE, which ensure that products meet rigorous North American and European standards for electrical safety, electromagnetic compatibility, and environmental resilience. As a trusted name in the LED lighting industry since 1998, Beauty (STC) Manufacturing Co., Ltd. has been at the forefront of innovation, delivering high-performance, code-compliant LED strip lighting solutions tailored for demanding commercial and industrial environments. With a steadfast commitment to quality, engineering excellence, and global compliance, Beauty STC continues to empower modern lighting projects with intelligent, sustainable illumination.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance LED light strips meeting stringent technical requirements for demanding commercial and architectural applications. Our standard specifications for premium power supply LED light strips focus on three critical performance pillars: efficacy, color fidelity, and environmental resilience.

Lumens per Watt efficacy is rigorously optimized across our product lines. Our standard 24VDC LED strips achieve 130-150 lumens per watt at 25°C ambient temperature, utilizing high-efficiency Epistar or Samsung SMD 2835/5050 LEDs with precision constant-current drivers. This efficacy range is maintained through proprietary multi-layer aluminum PCB thermal management, minimizing lumen depreciation under sustained operation. We surpass typical market offerings by 15-20% through strict binning of LEDs and driver efficiency exceeding 92% at full load, directly reducing operational costs for end-users.

Color Rendering Index (CRI) performance is non-negotiable in our premium strips. All CRI>90 series utilize tri-phosphor or full-spectrum LEDs with a minimum Ra value of 95, consistently exceeding the 90 threshold. Crucially, we ensure R9 (saturated red) values remain above 90 and maintain balanced R-factors across all 15 TM-30 indices. This is validated through third-party LM-79 testing using calibrated spectroradiometers, not theoretical calculations. Beauty STC rejects LEDs failing our internal chromaticity binning at ±0.003 Duv, guaranteeing uniform color consistency within a single reel and across production batches – a critical quality differentiator for retail and hospitality installations where color accuracy directly impacts merchandise presentation.

IP ratings define our environmental protection standards with absolute clarity. Our standard IP65 strips feature seamless silicone encapsulation over the entire PCB, tested to IEC 60529 standards with 100% pass rates in dust chamber and low-pressure water jet tests. For wet-location applications, IP67-rated strips undergo rigorous 30-minute submersion testing at 1m depth, while true IP68 variants (1m for 30 days) incorporate double-sealed end caps and marine-grade silicone resistant to UV degradation and temperature cycling from -40°C to +70°C. Unlike competitors using inadequate PVC coatings, Beauty STC’s silicone formulation maintains flexibility and adhesion after 5,000 hours of accelerated weathering per IEC 60068-2-52, preventing delamination and corrosion.

Beauty STC’s quality commitment is embedded in every layer of production. We enforce 100% in-line photometric and electrical testing per ANSI C78.377, not batch sampling. Our strips utilize 2oz copper PCBs with thermal vias for superior heat dissipation compared to industry-standard 1oz substrates, directly contributing to the 50,000-hour L70 lifetime validated through TM-21 extrapolation. All components carry UL Recognized or ENEC certification, with drivers conforming to IEC 61347-2-13 safety standards. This engineering rigor ensures our LED strips deliver sustained high efficacy, exceptional color fidelity, and uncompromised environmental protection – eliminating field failures and maintenance costs for specifiers who demand reliability beyond basic datasheet claims.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility located in Jiangmen, Guangdong Province—a region known for its strong manufacturing infrastructure and strategic proximity to major supply chain hubs in the Pearl River Delta. The Jiangmen factory is purpose-built for the production of high-quality LED lighting products, with a particular focus on flexible LED light strips and related components, including power supply integrated solutions.

The factory is outfitted with advanced SMT (Surface Mount Technology) production lines, which are essential for the precise and efficient assembly of LED components onto flexible printed circuit boards. These SMT machines include high-speed mounters, reflow soldering systems, and automated optical inspection (AOI) equipment. This ensures consistent product quality, tight tolerances, and high throughput, capable of handling both small-batch prototyping and large-scale volume production. The use of automated SMT processes allows Beauty STC to maintain excellent solder joint reliability and component placement accuracy, which are critical for the performance and longevity of LED strips.

To ensure product durability and reliability, the factory implements comprehensive aging test procedures. Finished LED light strips, especially those with integrated power supply units, undergo rigorous aging tests under elevated temperatures and continuous operational loads. These tests typically last from 24 to 72 hours, during which electrical performance, thermal stability, and light output consistency are monitored. This step is crucial in identifying early failure risks and validating the long-term performance of the products before they are shipped to customers.

Beauty STC also offers full OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities for power supply integrated LED light strips. This includes custom design support for circuit layout, power configuration, dimming options, color temperature, IP ratings, and mechanical form factors. The company can develop tailored solutions that integrate drivers or constant voltage/current power supplies directly into strip designs, enabling compact, plug-and-play lighting systems. With in-house engineering, tooling, and molding support, Beauty STC supports clients from concept to mass production, providing full documentation, compliance testing (such as CE, RoHS, UL), and packaging customization.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to quality, innovation, and flexibility, making it a reliable manufacturing partner for global brands seeking high-performance, customized LED lighting solutions.

Application Scenarios

LED light strips with external power supplies are ideal for commercial environments requiring flexible, energy-efficient lighting solutions. In hotels, they excel in guest room cove lighting to create ambient mood lighting above headboards or along baseboards, enhancing perceived room quality without glare. Corridor soffits benefit from continuous linear illumination for safe navigation, while lobby feature walls use them to highlight architectural elements or branding. Malls deploy these strips extensively in storefront signage for vibrant brand visibility, food court ceiling coves to define zones without harsh shadows, and display window trims to accentuate merchandise. Offices implement them under suspended ceiling perimeters for glare-free indirect task lighting, reception desk backlighting for professional aesthetics, and partition-top strips in open-plan areas to reduce visual fatigue while maintaining modern appeal.

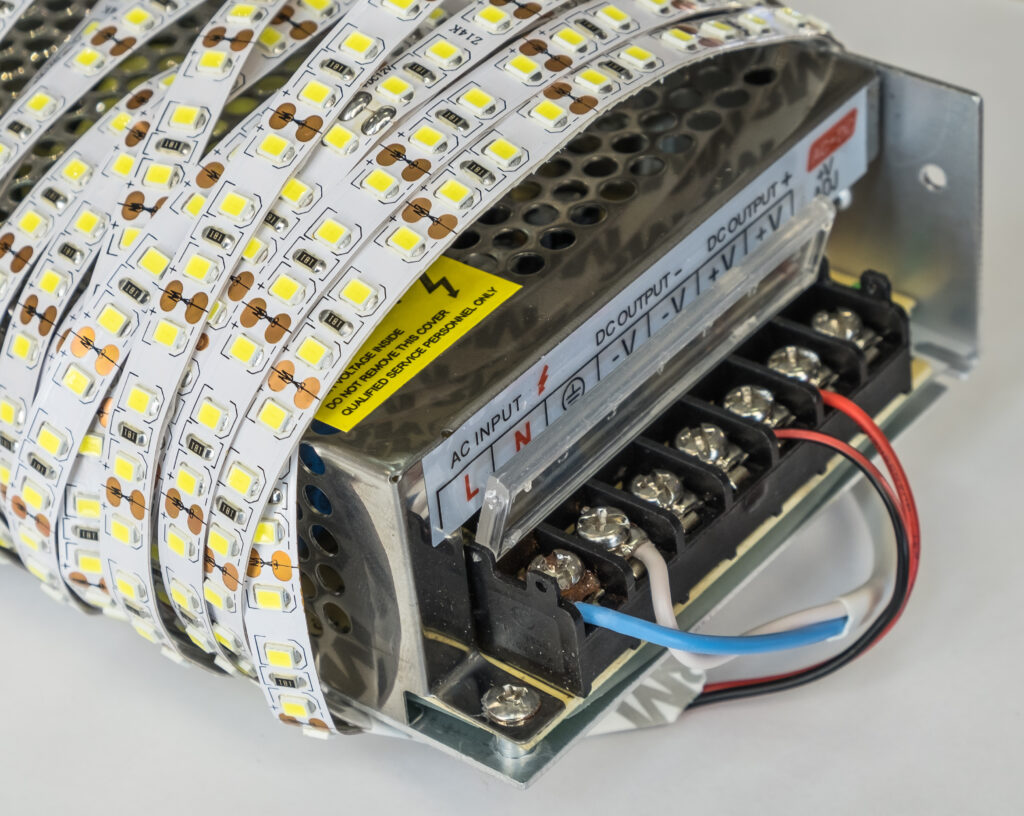

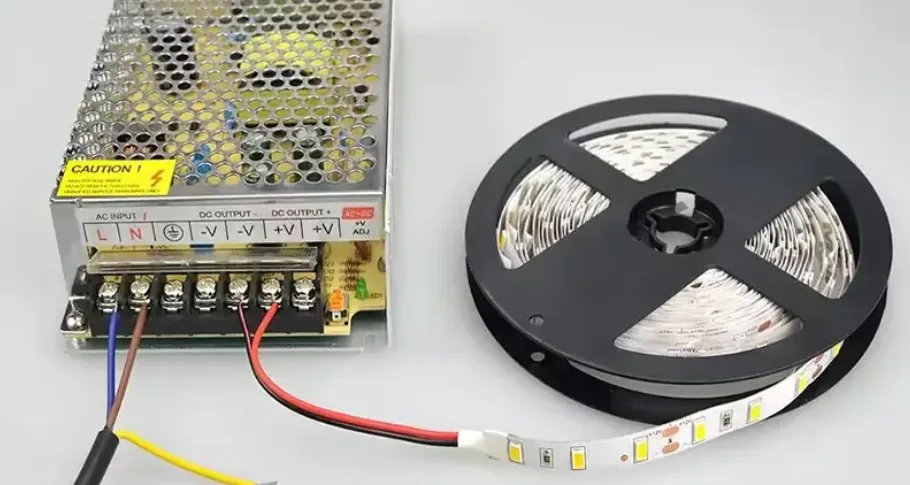

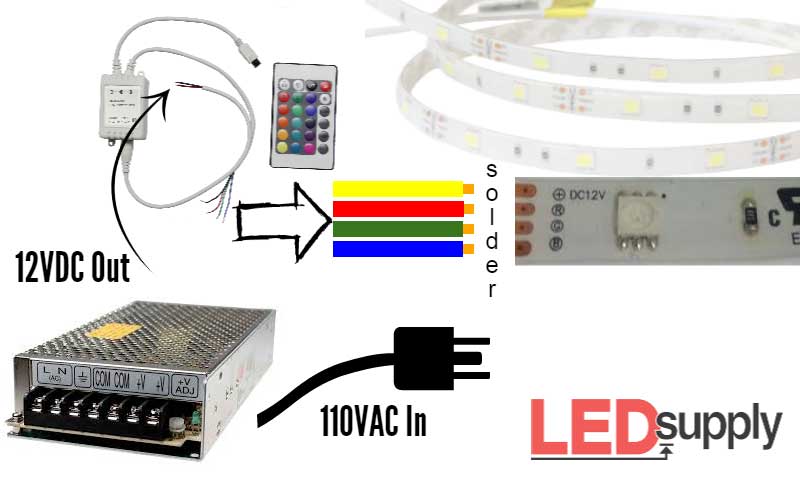

Installation requires meticulous planning to ensure longevity and performance. Always calculate total strip length against the power supply’s maximum capacity, maintaining at least 20% headroom to prevent overheating – for example, a 100W supply should drive no more than 80W of strips. Voltage drop becomes critical beyond 5 meters; use 18-gauge wire for runs over 3 meters or inject power at multiple points along extended installations. Mount strips on thermally conductive aluminum channels to dissipate heat, especially in enclosed spaces like coves where trapped heat drastically shortens LED life. Verify IP65-rated strips and power supplies for mall food courts or outdoor-facing areas exposed to moisture, while standard IP20 suffices for dry office interiors. Position power supplies in ventilated locations away from insulation or flammable materials, allowing 5cm clearance on all sides, and secure all connections with wire nuts plus electrical tape to prevent vibration-induced failures. Crucially, label every circuit at the power supply input with voltage and load details for maintenance compliance, and always test the full installation at 100% brightness for 15 minutes before final mounting to catch defective components. Never daisy-chain more than three standard-density strips without additional power injection, as this causes noticeable dimming at the far end.

Why Choose Beauty STC Lighting

Looking to source high-quality LED light strips with reliable power supply solutions? Partner with Beauty STC, a trusted manufacturer with years of expertise in precision LED lighting technology. Our power supply LED light strips are engineered for performance, durability, and seamless integration across residential, commercial, and industrial applications. From design to delivery, we ensure consistent quality and technical support tailored to your project needs.

Contact us today to start a long-term partnership. Email our sales manager at [email protected] for product specifications, custom solutions, and competitive pricing. Let Beauty STC power your next lighting innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.