Article Contents

Industry Insight: Diffusing Led Light Strips

The commercial and industrial lighting sector demands more than just functional illumination; it requires solutions that enhance productivity, ensure safety, and create visually comfortable environments. Within this critical space, the effective diffusion of LED light strips has emerged as a fundamental engineering challenge and opportunity. Poorly diffused linear LED sources create harsh glare, uneven illumination, and distracting shadows – issues that directly impact worker concentration in manufacturing facilities, compromise the visual appeal of retail displays, and undermine the professional ambiance of office spaces. Achieving truly uniform, glare-free light output is not merely an aesthetic concern but a core performance metric for modern installations. Crucially, any solution deployed in these demanding environments must meet rigorous safety and performance standards. ETL certification for the North American market and CE marking for Europe are not optional checkboxes; they are essential validations that the product, including its diffuser system and thermal management, operates safely and reliably under continuous industrial use, mitigating fire risks and ensuring long-term performance consistency. Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over 25 years to solving precisely these complex lighting challenges. We engineer high-performance diffusing LED light strips specifically for the unforgiving realities of commercial and industrial applications, where reliability, optical quality, and certified safety are non-negotiable requirements driving successful project outcomes.

Technical Specs & Certifications

Diffusing LED light strips are engineered to deliver uniform, glare-free illumination by incorporating a milky white or frosted silicone or PVC cover over the LED array. This diffusion layer effectively blends individual LED points into a continuous line of light, making them ideal for architectural accenting, cove lighting, under-cabinet installations, and retail displays where visual comfort and aesthetic appeal are critical.

In terms of performance, high-quality diffusing LED light strips from Beauty (STC) Manufacturing Co., Ltd. achieve luminous efficacies ranging from 100 to 130 lumens per watt, depending on the LED density and binning. This efficiency is attained through the use of premium 2835 or 5050 SMD LEDs paired with optimized driver configurations and thermally efficient flexible PCBs. These values place Beauty STC’s strips at the higher end of the market spectrum, ensuring energy savings without sacrificing brightness.

Color Rendering Index (CRI) is a key focus for applications requiring accurate color representation. Beauty STC’s diffusing LED strips consistently achieve a CRI greater than 90, with Ra values typically between 92 and 95. This is accomplished using high-CRI LED chips and phosphor coatings that enhance spectral distribution across the visible spectrum. As a result, illuminated surfaces appear more natural and vibrant, making these strips suitable for museums, retail environments, and high-end residential projects.

Regarding environmental protection, Beauty STC offers diffusing LED strips in multiple IP ratings to suit diverse installation conditions. IP20-rated strips are designed for dry, indoor environments with no exposure to dust or moisture. For damp or outdoor use, IP65-rated strips feature a conformal coating on the PCB and a fully sealed silicone diffuser, providing protection against dust and low-pressure water jets. For fully submersible or high-humidity applications, IP67 and IP68 variants are available, with robust encapsulation ensuring long-term reliability even in challenging conditions.

Beauty (STC) Manufacturing Co., Ltd. maintains strict quality control throughout production, including automated optical inspection, thermal cycling tests, and photometric validation. Components are sourced from trusted suppliers, and all strips undergo 100% aging and burn-in testing prior to shipment. This commitment to excellence ensures consistent color temperature, long lifespan (typically 50,000 hours L70), and reliable performance across all batches. Beauty STC’s diffusing LED light strips are certified to international standards including UL, CE, and RoHS, reflecting their suitability for global deployment in both commercial and residential applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen is a cornerstone of our production capacity, strategically located within the Jiangmen National High-Tech Industrial Development Zone. This modern plant spans approximately 30,000 square meters and is purpose-built for the efficient, high-volume manufacturing of advanced LED lighting solutions, including our specialized diffusing LED light strips. The factory integrates cutting-edge automation with stringent quality control processes throughout its production flow, ensuring consistent output that meets global standards.

Our Surface Mount Technology (SMT) capabilities form the critical foundation for producing high-reliability LED light strips. The Jiangmen factory operates multiple dedicated SMT lines featuring state-of-the-art Samsung SM481 Plus and Yamaha YSM20 placement machines. These systems handle components with exceptional precision, down to 00505 package sizes and 0.3mm pitch, essential for densely populated flexible and rigid LED strip PCBs. With a combined placement capacity exceeding 8 million components per day across twelve fully automated lines, we achieve high throughput while maintaining accuracy. Integrated automated optical inspection (AOI) using 3D solder paste inspection (SPI) and post-reflow AOI systems ensures solder joint integrity and component placement accuracy before strips proceed to subsequent assembly stages. Material handling is streamlined through automated systems, minimizing human intervention and reducing the risk of contamination or error.

Rigorous aging and reliability testing is a non-negotiable phase in our production process, directly contributing to the long lifespan our customers expect. Within the Jiangmen facility, we maintain extensive dedicated aging chambers capable of simultaneously testing over 5,000 meters of finished LED light strips. Products undergo controlled aging cycles at elevated temperatures, typically 45°C ±2°C, and often at 110% of rated voltage for durations ranging from 48 to 72 hours. This accelerated stress testing effectively identifies infant mortality failures and validates thermal management performance under sustained operation. Automated monitoring systems continuously log critical parameters such as forward voltage, luminous flux, and color consistency throughout the test period. Only strips that demonstrate stable performance and meet our strict luminous decay thresholds after aging are cleared for final packaging and shipment, providing tangible assurance of field reliability.

Beauty STC possesses comprehensive OEM capabilities specifically tailored for diffusing LED light strips, leveraging the full integration of our Jiangmen factory. We support extensive customization from initial concept through to finished goods. Our engineering team collaborates closely with clients to develop diffusing solutions meeting precise optical requirements, whether utilizing advanced silicone overmolding, specialized polycarbonate (PC) lenses, or integrated diffuser tapes. We offer a wide spectrum of color temperatures (2200K to 6500K), high CRI options (Ra>90), various beam angles, and multiple voltage configurations (DC12V, DC24V, AC). The factory handles all aspects of OEM production including custom PCB design and fabrication, tailored diffusion profiles, specific cutting lengths, connectorization, labeling, and branding. We accommodate flexible minimum order quantities starting from 500 meters for prototyping and ramp efficiently to high-volume production runs, managing every stage from component sourcing and SMT assembly through to final aging, packaging, and logistics. This end-to-end control within a single facility ensures quality consistency and rapid response to client specifications for diffused LED strip products.

Application Scenarios

Diffusing LED light strips are ideal for creating soft, uniform illumination without visible hotspots or individual LED dots, making them suitable for a wide range of commercial environments such as hotels, malls, and offices. Their versatility and aesthetic appeal make them a popular choice for both functional and decorative lighting applications.

In hotels, diffusing LED light strips are commonly used in guest rooms to highlight architectural features such as coves, headboards, or under cabinets. They provide ambient lighting that enhances comfort and luxury. In lobbies and hallways, these strips can be installed along ceiling perimeters or within recessed channels to create a welcoming, evenly lit environment. Bathrooms benefit from diffused lighting around mirrors, offering glare-free illumination that improves functionality while maintaining a high-end look.

Malls utilize diffusing LED light strips to enhance retail spaces and common areas. They are often integrated into cove lighting in walkways, accent lighting in storefront displays, and illuminated signage. The even glow helps draw attention to products and branding while contributing to a modern, upscale atmosphere. In food courts and rest areas, diffused lighting creates a pleasant, relaxing environment for visitors.

In office environments, diffusing LED light strips support both productivity and well-being. They are frequently installed in drop ceiling perimeters, under shelves, or within partition systems to provide indirect ambient lighting that reduces eye strain. Conference rooms and reception areas use diffused strips to create a professional yet inviting ambiance. Task lighting under cabinets or desks can also benefit from diffusion to minimize glare during long work hours.

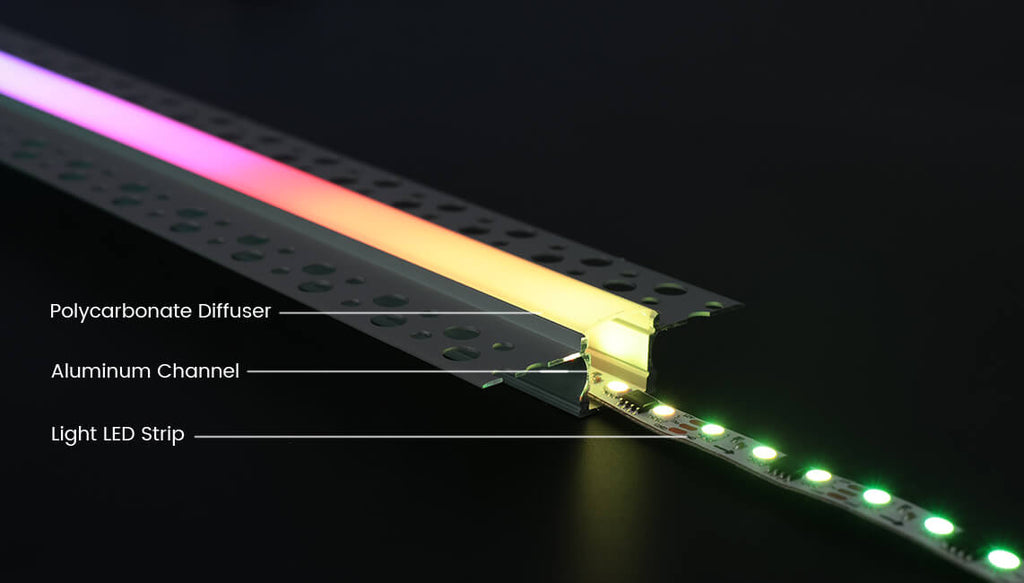

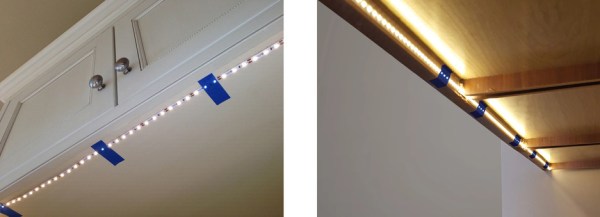

When installing diffusing LED light strips, several best practices should be followed. First, ensure the surface is clean, dry, and free of dust to promote strong adhesion of the strip’s backing. For optimal diffusion, use an aluminum channel or mounting track with a built-in diffuser lens—this not only protects the LEDs but also ensures even light distribution. Align the strip straight and avoid sharp bends, especially with rigid PCB strips, to prevent damage. If cutting is required, only cut at designated points to maintain electrical integrity.

Proper thermal management is essential; install the strips in well-ventilated areas or on thermally conductive surfaces to prevent overheating and extend lifespan. Connect the strips to a compatible constant-voltage power supply, and consider using a dimmer for adjustable lighting control. Finally, always follow local electrical codes and, when in doubt, consult a licensed electrician—especially for large-scale or permanent installations.

Why Choose Beauty STC Lighting

Transform your LED lighting projects with seamless, glare-free illumination through Beauty STC’s advanced diffusing LED light strip solutions. As industry leaders in optical engineering, we specialize in precision diffusion technology that eliminates hotspots and delivers uniform, professional-grade light output for architectural, retail, and hospitality applications. Partner with Beauty STC to access custom diffuser profiles, high-transmission materials, and rapid prototyping support tailored to your specific design requirements. Elevate your next installation with lighting that performs as beautifully as it looks. Contact our engineering team today at [email protected] to discuss your diffusion needs and discover how our expertise can enhance your product offerings.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.