Article Contents

Industry Insight: Led On The Floor

In the evolving landscape of commercial and industrial lighting, efficiency, durability, and compliance are paramount. One solution gaining significant traction is LED on the floor—low-profile, high-output lighting systems designed to provide optimal illumination in high-traffic and demanding environments such as warehouses, manufacturing facilities, cold storage units, and distribution centers. These fixtures combine robust construction with energy-efficient LED technology, offering reduced maintenance costs and long-term operational savings. As industry standards become more stringent, certifications such as ETL and CE have become essential markers of safety, performance, and regulatory compliance, ensuring that lighting solutions meet rigorous North American and European requirements.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its founding in 1998. With over two decades of engineering excellence, Beauty STC has established itself as a leading manufacturer of industrial-grade LED luminaires, specializing in rugged, code-compliant lighting solutions tailored for commercial and industrial applications. Combining cutting-edge optical design with rigorous testing protocols, the company delivers products that not only meet but exceed ETL and CE standards, providing customers with reliable, sustainable, and future-ready lighting systems.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and manufactures high-performance LED floor lighting solutions, including recessed step lights, stair lights, and surface-mounted floor luminaires, specifically engineered for demanding architectural and commercial applications where safety, aesthetics, and durability are paramount. Our technical specifications consistently exceed industry benchmarks, ensuring optimal performance and longevity.

Luminous efficacy for Beauty STC’s LED floor lighting fixtures typically ranges from 110 to 130 lumens per watt at the system level. This high efficiency is achieved through the strategic selection of premium mid-power or high-density LED packages coupled with proprietary optical designs and advanced thermal management systems utilizing extruded aluminum heat sinks integrated directly into the fixture housing. Crucially, these lm/W figures represent complete fixture output under real-world operating conditions at 25°C ambient, not just bare LED chip performance, accounting for driver losses and optical efficiency. This ensures specifiers receive accurate, achievable performance data for energy modeling and sustainability certifications.

All Beauty STC LED floor lights targeting architectural and high-end commercial use maintain a minimum Color Rendering Index (CRI) of 90, with Ra values typically between 90 and 95. We achieve this through the use of carefully selected tri-phosphor or multi-phosphor LED packages combined with stringent binning processes during manufacturing. This high CRI ensures accurate and vibrant color representation, critical for retail environments, museums, hospitality settings, and any application where visual clarity and ambiance are essential. We further offer options with R9 >50 to guarantee faithful rendering of saturated red tones, a common weakness in lower-CRI LEDs.

IP (Ingress Protection) rating is non-negotiable for floor-mounted luminaires subject to foot traffic, cleaning, and potential moisture exposure. Beauty STC standardizes IP67 as the minimum rating across our core floor light product lines. This signifies complete protection against dust ingress (6) and the ability to withstand temporary immersion in water up to 1 meter depth for 30 minutes (7). Many models, particularly those designed for outdoor plazas, pool decks, or wet interior zones, achieve IP68 certification, guaranteeing protection against continuous submersion under manufacturer-specified conditions. Robust stainless steel or marine-grade aluminum housings, precision-machined sealing grooves, and high-grade silicone gaskets are fundamental to achieving and maintaining these rigorous ratings throughout the fixture’s lifespan.

The exceptional performance metrics in lumens per watt, CRI, and IP rating are direct results of Beauty STC’s unwavering commitment to quality engineering and manufacturing excellence. We implement rigorous ISO 9001-certified quality control processes, including 100% in-line photometric testing, accelerated life testing (ALT) simulating 50,000+ hours of operation, and comprehensive environmental stress screening for every batch. Our fixtures utilize only Tier-1 LED components from globally recognized suppliers, coupled with constant current drivers featuring >94% efficiency and 5-year warranties. This systematic approach ensures that every Beauty STC LED floor light delivers not only the specified photometric and environmental performance but also exceptional reliability and consistent light output maintenance (L90/B10) over its rated lifetime, minimizing maintenance costs and ensuring long-term customer satisfaction in critical installations.

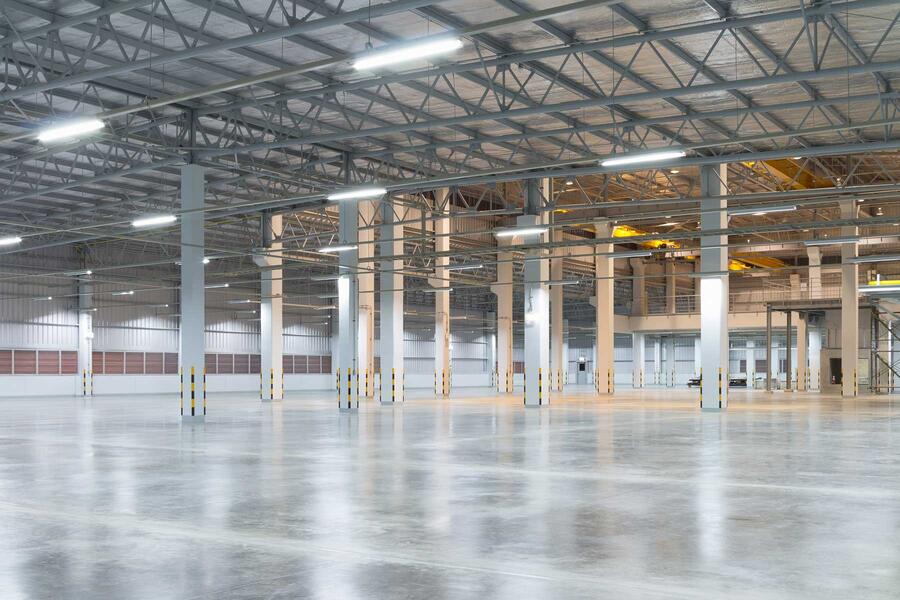

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control, efficiency, and flexibility to meet diverse customer demands.

The production floor is anchored by advanced SMT (Surface Mount Technology) lines, which enable precise and automated placement of electronic components onto PCBs (printed circuit boards). These SMT machines are capable of handling high-speed assembly with tight tolerances, ensuring consistent performance and reliability of LED modules. The use of automated optical inspection (AOI) systems integrated into the SMT process allows for real-time defect detection, significantly enhancing product quality and yield rates.

To ensure long-term reliability, the Jiangmen factory implements comprehensive aging tests as part of its quality assurance protocol. Finished LED products undergo extended burn-in periods under controlled thermal and electrical conditions, simulating real-world operating environments. This aging process helps identify early failures and ensures that only stable, durable products are shipped to customers. Environmental testing chambers are also used to evaluate performance under varying temperatures and humidity levels, further validating product robustness.

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities and actively supports custom projects, including specialized products such as LED lights designed for floor installations—commonly referred to in the industry as “LED on the floor” applications. These can include recessed floor luminaires, step lights, or decorative LED floor panels used in architectural, commercial, and hospitality settings. The company works closely with clients to develop tailored solutions, from initial design and prototyping to full-scale production. This includes custom optics, mechanical housing, thermal management, and control systems integration, all backed by in-house engineering and tooling support.

Overall, the Jiangmen factory combines advanced automation, rigorous testing, and flexible manufacturing practices to deliver high-quality, customized LED lighting solutions for global markets.

Application Scenarios

LED on the floor installations, typically referring to recessed in-floor linear LED systems or low-profile floor-mounted luminaires, serve specific functional and aesthetic purposes in high-traffic commercial environments. Their application requires careful consideration of location, purpose, and robust installation practices to ensure safety, durability, and effectiveness. Below is a breakdown of suitable applications across hotels, malls, and offices, followed by critical installation guidance.

In hotels, in-floor LED lighting is most effectively deployed in lobbies and main entrances to create a welcoming, modern ambiance while subtly guiding guest flow toward reception or elevators. Corridor pathways benefit significantly from low-level linear in-floor lighting, especially near stairwells or elevator banks, enhancing wayfinding in low-light conditions without disrupting guest rest. High-end spas or wellness areas may use discreet, IP68-rated in-floor strips within wet zones for atmospheric lighting, though strict adherence to local electrical codes for wet locations is non-negotiable. Avoid installing such systems in guest room corridors where frequent cleaning or luggage traffic could cause damage or safety hazards.

Shopping malls utilize in-floor LED systems primarily at main entry portals to draw attention and establish visual identity, often integrated with branding elements. Perimeters of food courts or central gathering zones employ linear in-floor lighting to define spaces and manage crowd movement safely. Critical emergency egress paths may incorporate photoluminescent or low-voltage LED floor markers where local fire codes permit, but this requires explicit approval from authorities having jurisdiction. Exercise extreme caution in high-traffic thoroughfares; any in-floor installation must use heavy-duty, anti-slip rated lenses (minimum R12 slip resistance) and robust housings designed for constant pedestrian and potential trolley impact. Avoid placement directly under storefronts where frequent tenant changes necessitate floor alterations.

Office environments see strategic use in corporate lobbies for directional guidance toward reception or meeting areas, creating a professional first impression. Defined pathways leading to conference centers or executive suites can benefit from subtle in-floor lighting for evening or low-occupancy hours. Some modern collaborative zones use minimal in-floor strips to delineate activity areas without physical barriers, though overuse in open-plan workspaces is discouraged as it may cause visual distraction. Emergency exit routes in lobbies or near stairwells might incorporate code-compliant floor-level lighting, but standard office work floors rarely justify the cost and maintenance complexity of in-floor systems due to lower ambient light needs and higher risk of damage from furniture movement.

Installation demands rigorous attention to detail. Structural integrity is paramount; never cut into structural slabs, post-tensioned concrete, or load-bearing elements without explicit engineering approval. Trenching must follow precise depth and width specifications per the luminaire manufacturer, typically requiring a minimum 50mm wide trench for standard linear systems. Waterproofing is critical: use marine-grade silicone sealant around conduit entries and ensure the entire trench assembly has a continuous waterproof membrane, especially in areas prone to moisture like mall entrances or hotel spas. Voltage drop management is essential for long runs; calculate required wire gauge meticulously and consider 24V systems with distributed power injection points every 5-8 meters. Always install luminaires within dedicated aluminum or stainless-steel channels with removable lenses for maintenance access, never direct-embedding strips into concrete. Slip resistance must meet local standards; specify textured or ribbed polycarbonate lenses. Finally, coordinate closely with architects and flooring contractors to align with final floor levels and ensure seamless integration with surrounding materials like stone, tile, or epoxy finishes. Post-installation, conduct thorough photometric validation to confirm uniformity and avoid glare or hotspotting that could compromise safety.

Why Choose Beauty STC Lighting

Transform your space with innovative LED floor solutions. Partner with Beauty STC, a trusted leader in advanced LED lighting technology, to bring stunning, energy-efficient illumination to any environment. Our high-performance LED lighting systems are engineered for durability, style, and optimal brightness. To learn more and explore collaboration opportunities, contact us today at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.