Article Contents

Industry Insight: Adhesive Stripes

The commercial and industrial LED lighting sector continues to prioritize installation efficiency and long-term reliability, driving significant innovation in mounting solutions. Adhesive stripes, specifically engineered pressure-sensitive tapes pre-applied to LED strips and modules, have become a critical enabler for rapid, clean, and secure fixture integration across demanding environments like warehouses, retail spaces, manufacturing floors, and cold storage facilities. Moving beyond basic convenience, today’s high-performance adhesive systems must deliver exceptional thermal stability, UV resistance, and consistent bond strength across diverse substrates and challenging conditions, from extreme temperatures to high-vibration settings. Crucially, compliance with stringent safety standards is non-negotiable; adhesive stripes integrated into lighting products must support the overall fixture’s certification under recognized marks such as ETL for North American markets and CE for Europe, ensuring electrical safety and mechanical integrity are never compromised by the mounting method. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution. With over 25 years of specialized expertise in LED lighting components and systems, we understand that the adhesive is not merely an accessory but a fundamental element of the lighting solution’s performance and safety lifecycle. Our commitment lies in developing and supplying adhesive stripe technologies that meet rigorous global certification requirements while delivering the robust, dependable mounting essential for professional-grade commercial and industrial applications.

Technical Specs & Certifications

Adhesive LED stripes from Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance and reliability in both residential and commercial lighting applications. These flexible LED strips are designed with precision to deliver optimal efficiency, color accuracy, and environmental protection.

In terms of efficiency, Beauty STC’s adhesive LED stripes typically achieve a luminous efficacy range of 110 to 130 lumens per watt, depending on the specific configuration and density of LEDs per meter. This high lumen-to-watt ratio ensures energy-efficient operation without compromising brightness, making them ideal for long-term use where power savings and illumination quality are critical.

Color Rendering Index (CRI) is a key focus in Beauty STC’s product development. All premium adhesive stripes are manufactured with LEDs that deliver a CRI greater than 90, with select models reaching CRI 95+. This ensures exceptional color fidelity, allowing objects and surfaces to appear in their true, natural colors under the light—essential for retail displays, art galleries, kitchens, and healthcare environments.

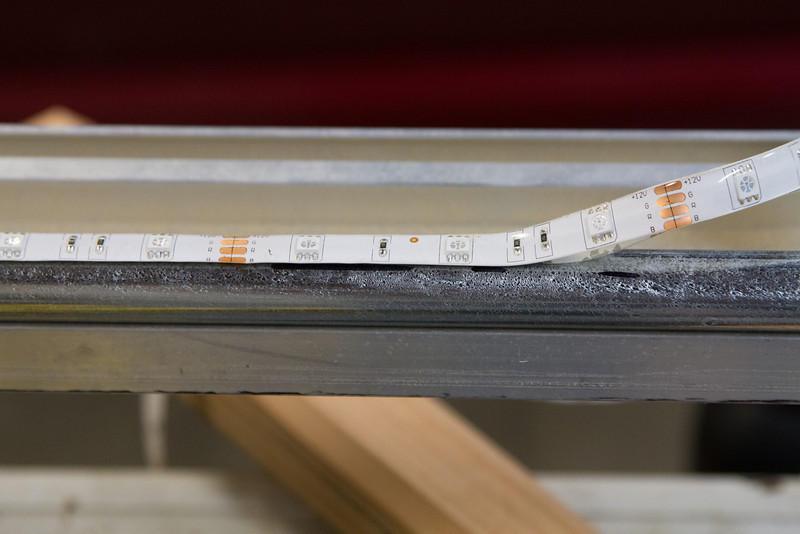

Regarding environmental protection, Beauty STC offers adhesive LED stripes in multiple Ingress Protection (IP) rated variants to suit diverse installation conditions. The standard non-encapsulated strips (IP20) are suitable for dry indoor environments. For damp or outdoor applications, silicone-coated versions are available in IP65 rating, providing protection against water jets and dust ingress. Fully encapsulated strips are offered in IP67 and IP68 ratings, enabling submersion in water up to 1 meter for extended periods, making them ideal for outdoor architectural lighting, signage, and landscape installations.

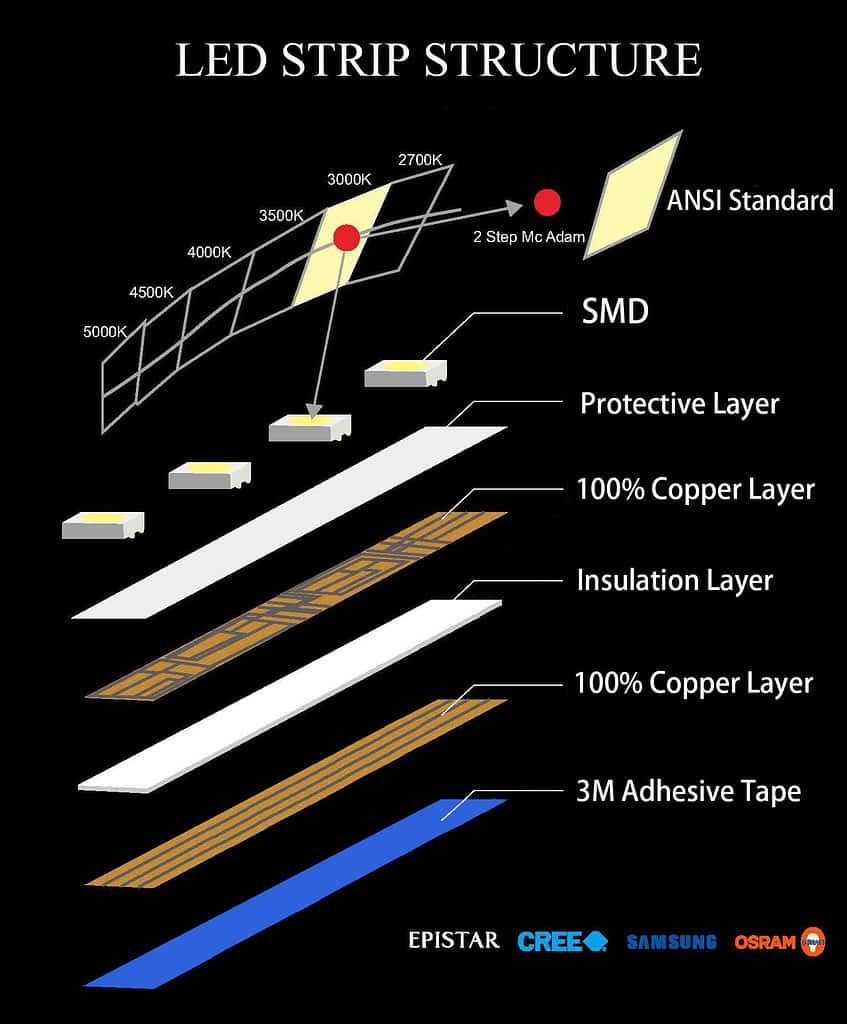

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process. Utilizing high-grade SMD LEDs, consistent phosphor coating, and robust FPC (flexible printed circuit) materials, Beauty STC ensures uniform light output, minimal lumen depreciation over time, and excellent thermal management. Their adhesive stripes undergo extensive testing for solder joint integrity, peel adhesion strength, and long-term operational stability, reflecting the company’s commitment to durability and performance in real-world conditions.

All products are compliant with international standards including RoHS and REACH, and many carry CE and UL certifications. With over two decades of manufacturing expertise, Beauty STC has established a reputation for producing reliable, high-quality LED lighting solutions trusted by clients worldwide.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern, vertically integrated manufacturing facility in Jiangmen, Guangdong Province, serving as our primary production hub for LED lighting solutions. This facility spans over 20,000 square meters and is designed to stringent international quality standards, holding ISO 9001 certification. The factory environment emphasizes controlled production conditions, rigorous process validation, and comprehensive in-house testing capabilities to ensure product reliability and performance consistency for global markets.

Our Surface Mount Technology (SMT) production lines form the core of PCB assembly operations. The Jiangmen factory houses eight high-speed Yamaha YS series SMT lines, capable of placing components as small as 0201 metric packages with precision. These lines feature fully automatic pick-and-place machines, nitrogen-reflow soldering systems for optimal joint integrity, and integrated 3D Automatic Optical Inspection (AOI) stations after each critical process step. This setup supports high-volume production of complex LED driver and module boards, achieving placement accuracies within ±25µm and throughput rates exceeding 80,000 components per hour per line. The SMT area operates under strict electrostatic discharge (ESD) controls and environmental monitoring to maintain yield rates above 99.2%.

Aging and reliability testing are conducted in a dedicated 500-square-meter environmental testing zone. All LED light engines and finished luminaires undergo mandatory 72-hour continuous aging tests at 50°C ambient temperature with full-load operation, simulating accelerated real-world conditions. This chamber utilizes forced-air circulation systems and real-time electrical parameter monitoring to detect early failures or lumen depreciation trends. We also perform extended 168-hour aging for critical client projects and integrate thermal imaging during testing to identify potential hotspot issues. Products must maintain luminous flux within ±5% of initial readings and exhibit zero catastrophic failures to pass this stage, ensuring only units meeting our stringent reliability benchmarks advance to final packaging.

Regarding OEM capabilities for adhesive strips, commonly referred to in our context as flexible LED tape or strip lighting assemblies, the Jiangmen factory offers extensive customization. We possess specialized reel-to-reel production lines for manufacturing adhesive-backed LED strips with widths ranging from 8mm to 24mm. Our OEM service includes material selection from 15+ certified adhesive options, including high-bond acrylics for extreme temperatures (-40°C to +80°C) and UV-resistant silicones for outdoor use. Typical peel adhesion values range from 1.0 to 1.8 N/mm depending on substrate, all validated per ASTM D3330 standards. Clients specify PCB color, LED density (e.g., 60-240 LEDs/meter), IP rating (up to IP68 with silicone coating), and connector types, with our engineering team providing DFM support. All adhesive strip productions undergo 100% inline continuity testing and post-aging adhesion verification to guarantee performance under sustained thermal cycling and mechanical stress. This capability supports both low-volume prototyping and high-volume OEM orders exceeding 500,000 meters monthly.

Application Scenarios

Adhesive stripes are versatile lighting solutions that are ideal for accentuating architectural features, guiding foot traffic, and enhancing ambiance in commercial environments such as hotels, malls, and offices. In hotels, adhesive stripes are commonly used in guest rooms to highlight headboards, under cabinets, or along cove ceilings to create a soft, welcoming atmosphere. They are also effective in hallways and staircases for subtle wayfinding and safety lighting. In malls, adhesive stripes can be applied under handrails, along escalator edges, or within display fixtures to draw attention to key areas while maintaining a sleek, modern aesthetic. Offices benefit from adhesive stripes in reception areas, under desks, or along corridors to provide uniform, energy-efficient illumination that supports both functionality and design.

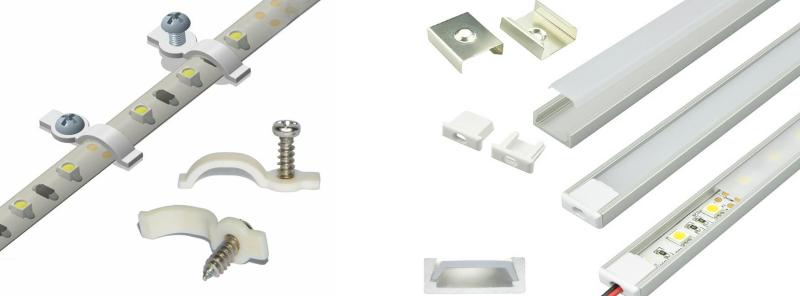

When installing adhesive stripes, it is essential to begin with a clean, dry, and grease-free surface to ensure strong adhesion. Wipe the mounting area with isopropyl alcohol and allow it to dry completely before application. Press the stripe firmly along its entire length to secure the bond, especially at the ends where lifting is more likely. For longer runs, consider using additional mechanical supports such as clips or brackets at intervals to prevent sagging. Always plan the layout in advance, taking into account power source location and whether the stripe will be controlled by a switch, dimmer, or controller. Avoid installing adhesive stripes on textured or porous surfaces, as these can compromise adhesion. In high-traffic or high-moisture areas, verify that the stripe has an appropriate IP rating for durability. Finally, disconnect power during installation and follow all manufacturer guidelines for electrical connections and compatibility with drivers or controllers.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s precision-engineered adhesive LED stripes, designed for seamless integration and lasting performance in architectural, retail, and residential applications. Our advanced peel-and-stick technology ensures secure mounting on diverse surfaces while maintaining optimal thermal management and luminous efficacy, eliminating common installation hurdles without compromising on durability or light quality. As a dedicated OEM/ODM partner with 15 years of specialized LED manufacturing expertise, we offer fully customizable solutions—from tailored lumen outputs and color temperatures to bespoke lengths and smart controls—all backed by rigorous in-house testing and global compliance certifications.

Partner with Beauty STC to transform your vision into reality with reliable, high-performance adhesive lighting systems that reduce labor costs and accelerate project timelines. Connect directly with our technical sales manager to discuss volume pricing, prototyping support, and dedicated engineering collaboration for your specific requirements. Reach out today at [email protected] to initiate a conversation about how our adhesive stripes can become a strategic asset for your business.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.