Article Contents

Industry Insight: Waterproof Light Strips Led

The commercial and industrial lighting sector increasingly demands robust, versatile illumination solutions capable of withstanding demanding environments without compromising performance or safety. Waterproof LED light strips have emerged as a critical workhorse in this landscape, moving far beyond simple accent lighting to become essential for exterior architectural features, industrial facility task lighting, cold storage, marine applications, and harsh process environments where moisture, dust, or chemical exposure are persistent challenges. For facility managers and lighting specifiers, selecting the right solution hinges not only on luminous efficacy and longevity but on rigorous adherence to international safety and performance standards. Certifications like ETL (verifying compliance with North American safety standards) and CE (indicating conformity with European health, safety, and environmental requirements) are non-negotiable prerequisites, providing essential assurance that these flexible lighting systems operate reliably and safely under continuous stress, reducing fire hazards and liability risks while minimizing costly maintenance and replacement cycles in critical operations. As a trusted partner in this demanding field, Beauty STC Manufacturing Co., Ltd., established in 1998, leverages over 25 years of specialized expertise in high-performance LED lighting engineering. We focus intensely on developing waterproof LED strip solutions specifically engineered for the uncompromising realities of commercial and industrial settings, where proven durability, certified safety, and consistent output are fundamental requirements for operational success.

Technical Specs & Certifications

Waterproof LED light strips from Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance and reliability in both indoor and outdoor applications. These strips are designed to deliver excellent luminous efficacy, accurate color rendering, and robust environmental protection.

In terms of efficiency, our waterproof LED light strips achieve a luminous output of 110 to 130 lumens per watt, depending on the specific model and LED density. This high lumens-per-watt ratio ensures energy-efficient operation, reducing power consumption while maintaining bright, consistent illumination across installations. The efficiency is maintained across various color temperatures, from warm white (2700K) to cool white (6500K), without compromising output quality.

Color Rendering Index (CRI) is a critical factor in lighting quality, especially for applications where true color representation is essential. Beauty STC’s premium waterproof LED strips feature a CRI greater than 90, ensuring that colors appear natural and vibrant under the light. This high CRI performance makes them ideal for retail displays, architectural accent lighting, under-cabinet kitchen lighting, and hospitality environments where visual clarity and ambiance are paramount.

Regarding environmental protection, our waterproof LED strips are available with IP65, IP67, and IP68 ratings. IP65-rated strips are protected against low-pressure water jets and dust ingress, making them suitable for damp indoor areas or covered outdoor spaces. IP67-rated versions are dust-tight and can withstand temporary immersion in water up to 1 meter for 30 minutes, ideal for outdoor signage, garden lighting, or marine applications. The IP68 rating offers the highest level of protection, with continuous submersion resistance beyond 1 meter, perfect for underwater pool lighting or harsh industrial environments.

Beauty (STC) Manufacturing Co., Ltd. maintains strict quality control throughout the production process. Our LED strips use high-grade SMD LEDs, durable flexible PCBs, and premium silicone or PVC encapsulation to ensure long-term performance and resistance to UV, temperature fluctuations, and moisture. All products undergo rigorous testing for electrical safety, thermal management, and waterproof integrity before leaving the factory. With over two decades of lighting expertise, Beauty STC delivers reliable, high-performance LED solutions trusted by clients worldwide.

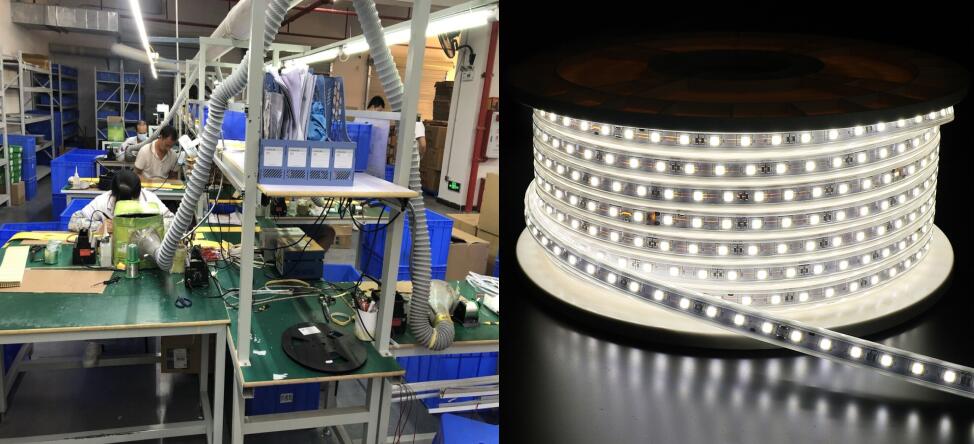

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant cornerstone of our production capacity, strategically positioned within one of China’s most advanced manufacturing clusters. The Jiangmen factory is a modern, purpose-built facility spanning over 20,000 square meters, designed specifically for high-volume, precision LED lighting production with a strong emphasis on quality control and process efficiency. Its location provides excellent logistics access to major ports and suppliers, ensuring streamlined material flow and timely delivery for global customers.

The Surface Mount Technology (SMT) production line at the Jiangmen plant is a key technological asset, featuring a robust configuration of six high-speed Yamaha YS series SMT placement machines. These machines operate with exceptional precision, capable of placing components down to 0201 package size at an aggregate throughput exceeding 1.2 million components per hour. The line integrates fully automated solder paste printers, nitrogen-reflow ovens for superior solder joint integrity critical for waterproof reliability, and advanced AOI (Automated Optical Inspection) systems performing real-time, multi-angle verification against IPC-A-610 Class 2/3 standards. This SMT capability is fundamental to producing the dense, reliable circuit boards required for high-performance waterproof LED light strips, ensuring consistent component placement essential for maintaining the integrity of the silicone encapsulation process.

Rigorous aging and reliability testing is a non-negotiable phase in our waterproof LED light strip production at Jiangmen. Every batch undergoes a comprehensive 72-hour continuous aging test under controlled environmental conditions. Strips are operated at 100% rated power within climate-controlled chambers that cycle through temperatures ranging from -20°C to +50°C and maintain 85% relative humidity, simulating years of real-world stress in a condensed timeframe. This extended burn-in process, conducted on dedicated racks with automated monitoring systems tracking voltage, current, and luminous output, effectively identifies infant mortality failures and verifies the long-term stability of the solder joints, LED chips, and the critical waterproof seal before products reach customers. This commitment to accelerated life testing directly translates to the field reliability our waterproof strips are known for.

Beauty STC possesses extensive OEM capabilities specifically tailored for waterproof LED light strips, fully operational at the Jiangmen facility. We support complete customization from the ground up, including but not limited to board-level design modifications for specific voltage, density, or color requirements, selection of varying IP65/IP67/IP68 rated silicone profiles and colors, integration of custom connectors, and tailored reel packaging with client-specific labeling and branding. Our engineering team collaborates closely with OEM partners during the NPI (New Product Introduction) phase, providing DFM feedback, prototyping, and certification support (including UL, CE, RoHS). The Jiangmen factory’s integrated production flow – from SMT assembly through silicone extrusion, cutting, connectorization, aging, and final inspection – allows us to efficiently manage low to high-volume OEM orders with flexible MOQs, maintaining strict adherence to the partner’s quality specifications and delivery schedules. This end-to-end control within a single facility ensures consistency and confidentiality for all OEM projects.

Application Scenarios

Waterproof LED light strips are versatile lighting solutions designed to withstand moisture and humidity, making them ideal for both indoor and outdoor applications where exposure to water is a concern. While hotels, malls, and offices are primarily indoor environments, there are still specific areas within these facilities where waterproof LED light strips are not only suitable but highly recommended.

In hotels, waterproof LED light strips are commonly used in bathrooms, around bathtubs and showers, under vanities, and along the edges of mirrors to create ambient lighting. They are also excellent for pool areas, spas, and outdoor patios or balconies where guests enjoy open-air spaces. Installing them under water features or in swimming pools (using submersible-rated strips) enhances visual appeal and safety. Coving and recessed lighting in wellness centers also benefit from moisture-resistant strips.

In malls, these light strips are best suited for restrooms, food courts with high humidity from cooking areas, and decorative water fountains or indoor water features. They can also be used in outdoor walkways, canopies, or entryways where weather exposure is likely. Retail display areas near windows or exterior doors may also benefit from the durability of waterproof strips, especially in regions with high humidity or frequent rain.

In offices, typical use cases include kitchenettes, restrooms, and server rooms where condensation might occur. While most office spaces are dry, using waterproof LED strips in these specific zones ensures longevity and reduces maintenance. Additionally, modern office designs incorporating indoor green walls or decorative water elements can utilize waterproof strips for accent lighting.

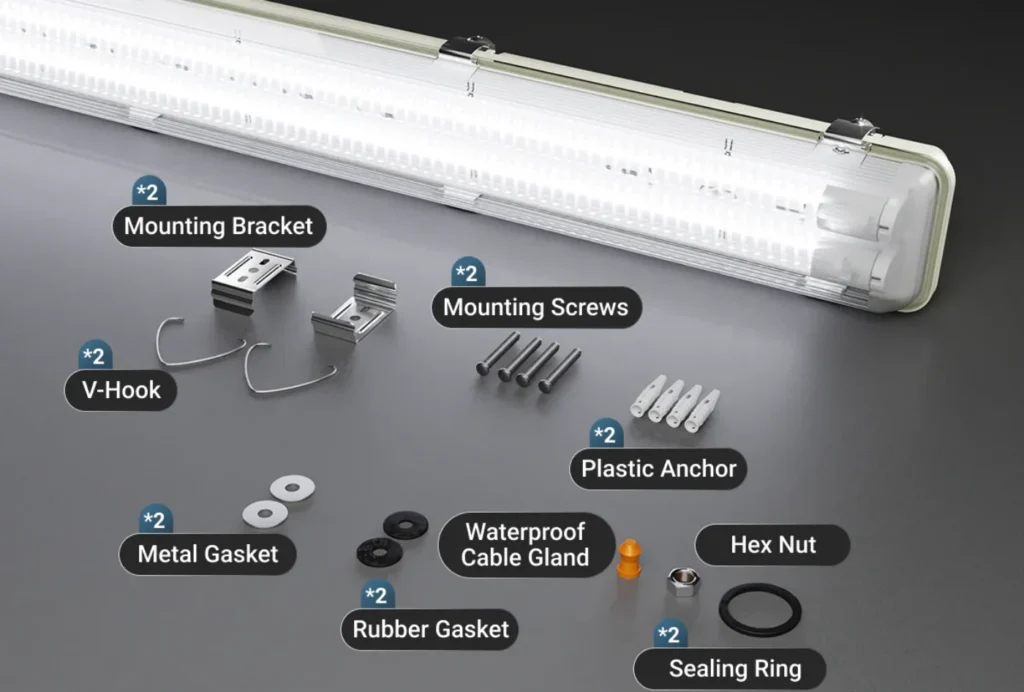

When installing waterproof LED light strips, several tips should be followed to ensure optimal performance and safety. First, always verify the IP rating—IP65 is suitable for splashes and damp environments, while IP67 or IP68 is required for submersion or heavy moisture exposure. Ensure the power supply and connectors are also rated for wet or damp locations and are properly sealed. Use compatible aluminum channels with diffusers to protect the strip, improve heat dissipation, and provide a clean, uniform glow. Avoid sharp bends in the strip to prevent damaging the internal circuitry. Make sure all cuts are made only at designated cut points. For outdoor or high-moisture areas, use silicone end caps and seal joints with waterproof silicone if necessary. Finally, connect the strip to a low-voltage power source and consider using a dimmer or controller compatible with waterproof installations for added functionality. Proper planning of the layout and power requirements will ensure a durable and visually appealing lighting solution.

Why Choose Beauty STC Lighting

Elevate your lighting projects with professionally engineered waterproof LED light strips designed for demanding environments. Beauty STC Manufacturing Co., Ltd. delivers superior IP65 and IP67 rated flexible LED strips built to withstand moisture, dust, and harsh conditions without compromising brightness or longevity. Our rigorously tested solutions ensure consistent performance for outdoor architectural accents, marine applications, landscape lighting, and industrial settings where reliability is non-negotiable.

Partner with Beauty STC to access cutting-edge waterproof LED technology backed by our in-house engineering expertise and stringent quality control processes. We specialize in customizing strip length, color temperature, lumen output, and voltage requirements to align precisely with your project specifications. Our manufacturing capabilities support scalable production without sacrificing the durability or energy efficiency that defines our products, providing you with a competitive edge in the market.

Secure your advantage in high-performance lighting by partnering with Beauty STC today. Contact our dedicated partnership manager directly at [email protected] to discuss your waterproof LED strip requirements and receive tailored engineering support for your next project. Let us deliver the robust, innovative lighting solutions your clients demand.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.