Article Contents

Industry Insight: Addressable Led Tape

The commercial and industrial lighting landscape is undergoing a significant transformation, driven by the demand for intelligent, adaptable, and energy-efficient solutions. Addressable LED tape has emerged as a pivotal technology within this shift, moving far beyond basic illumination to enable dynamic, controllable, and highly customizable lighting scenarios. In environments ranging from high-end retail displays and corporate lobbies to demanding industrial facilities and architectural facades, the ability to precisely program individual LEDs for color, intensity, and animation sequences unlocks unprecedented design flexibility, enhances occupant experience, and supports functional lighting requirements like wayfinding or task-specific zones. This capability is no longer a luxury but a strategic asset for forward-thinking projects seeking differentiation and operational efficiency.

Critical to the successful deployment of addressable LED tape in professional settings is rigorous adherence to safety and performance standards. Compliance with certifications such as ETL (for the North American market) and CE (for Europe) is non-negotiable. These marks are essential assurances for contractors, facility managers, and end-users, verifying that the products meet stringent electrical safety, electromagnetic compatibility, and operational reliability requirements. Specifying addressable tape without these certifications introduces significant risk, including potential safety hazards, project delays, and costly non-compliance issues, making certified solutions a fundamental prerequisite for any reputable commercial or industrial installation.

Beauty STC Manufacturing Co., Ltd., established in 1998, stands at the forefront of this evolution in professional LED lighting. With over 25 years of dedicated expertise in precision-engineered LED solutions, we understand the exacting demands of commercial and industrial applications. Our focus has always been on developing robust, high-performance addressable LED tape systems that not only deliver exceptional optical quality and control sophistication but are also rigorously tested and certified to meet global standards, including ETL and CE. We partner with lighting designers, specifiers, and contractors to provide reliable, innovative, and code-compliant lighting technology that forms the intelligent foundation for modern built environments.

Technical Specs & Certifications

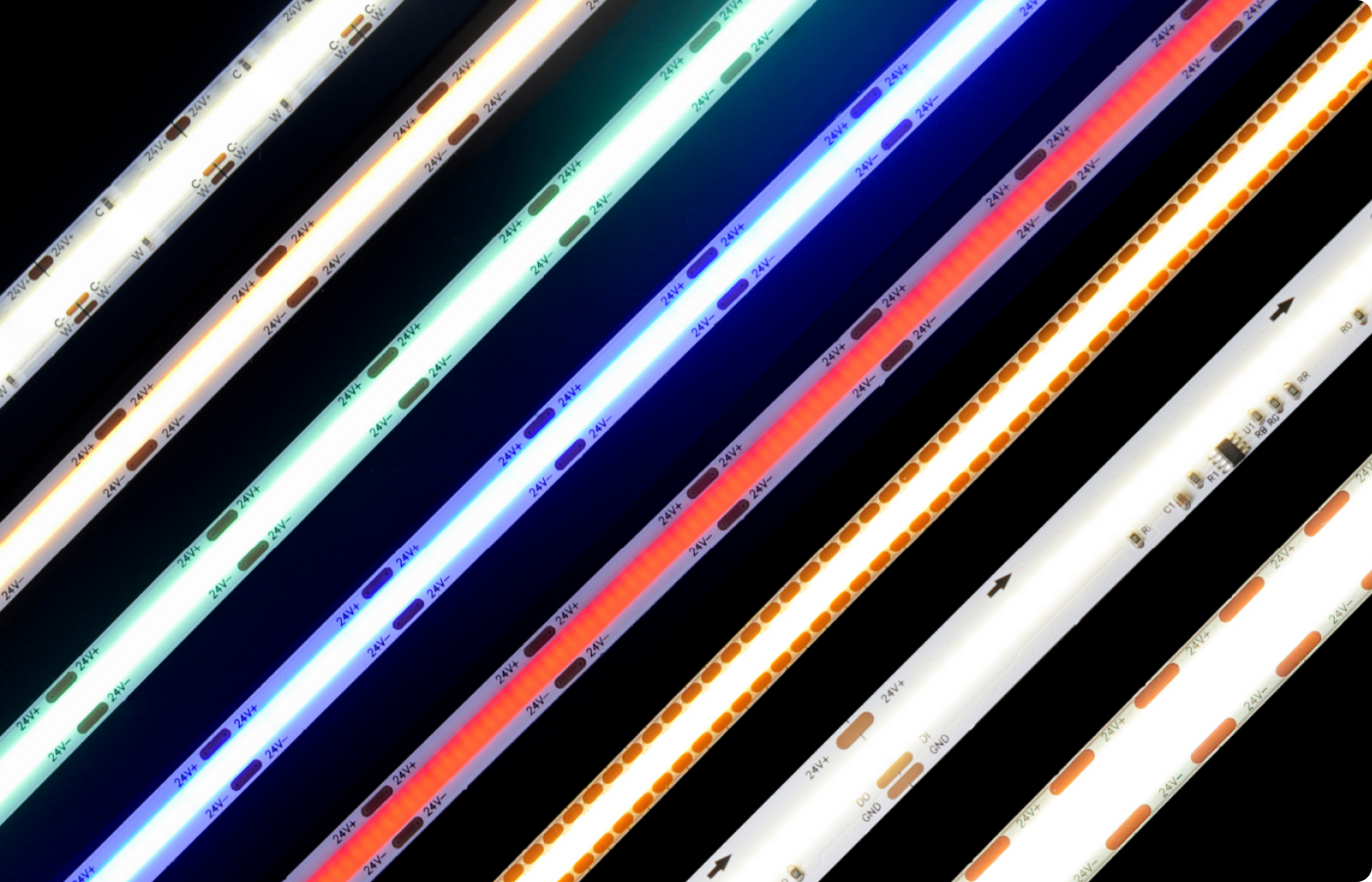

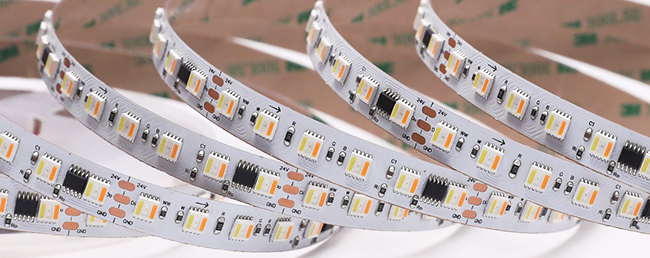

Addressable LED tape from Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability in both residential and commercial lighting applications. These advanced LED strips feature individually controllable LEDs, enabling dynamic color changing, precise dimming, and programmable lighting effects via protocols such as WS2812B, SK6812, or DMX512, depending on the model.

In terms of efficiency, Beauty STC’s addressable LED tapes deliver an industry-competitive luminous efficacy ranging from 18 to 23 lumens per watt. While this is lower than some non-addressable LED tapes due to the integrated control circuitry, the trade-off is fully justified by the enhanced functionality and design flexibility. The actual lumen output varies by density—typically available in 30, 60, or 144 LEDs per meter—with higher-density tapes offering greater brightness and smoother color gradients.

A key hallmark of Beauty STC’s addressable LED tape is its high Color Rendering Index (CRI >90), ensuring accurate and vibrant color representation. This makes the product ideal for applications where true color fidelity is critical, such as retail displays, architectural accent lighting, and hospitality environments. The LEDs are available in multiple color temperatures (2700K to 6500K) and support RGBW or RGBWW configurations, combining rich color control with warm and cool white channels for superior tuning capability.

Regarding environmental protection, Beauty STC offers addressable LED tapes in multiple IP ratings to suit diverse installation conditions. The standard non-coated version is IP20, suitable for dry, indoor environments. For damp or outdoor applications, silicone-coated variants are available in IP65, providing resistance to water jets and dust ingress, making them ideal for cove lighting, signage, and outdoor façades. Fully encapsulated IP67 and IP68 rated tapes are also offered, enabling submersion in water up to 1 meter for extended periods, perfect for pool lighting, marine applications, and harsh environments.

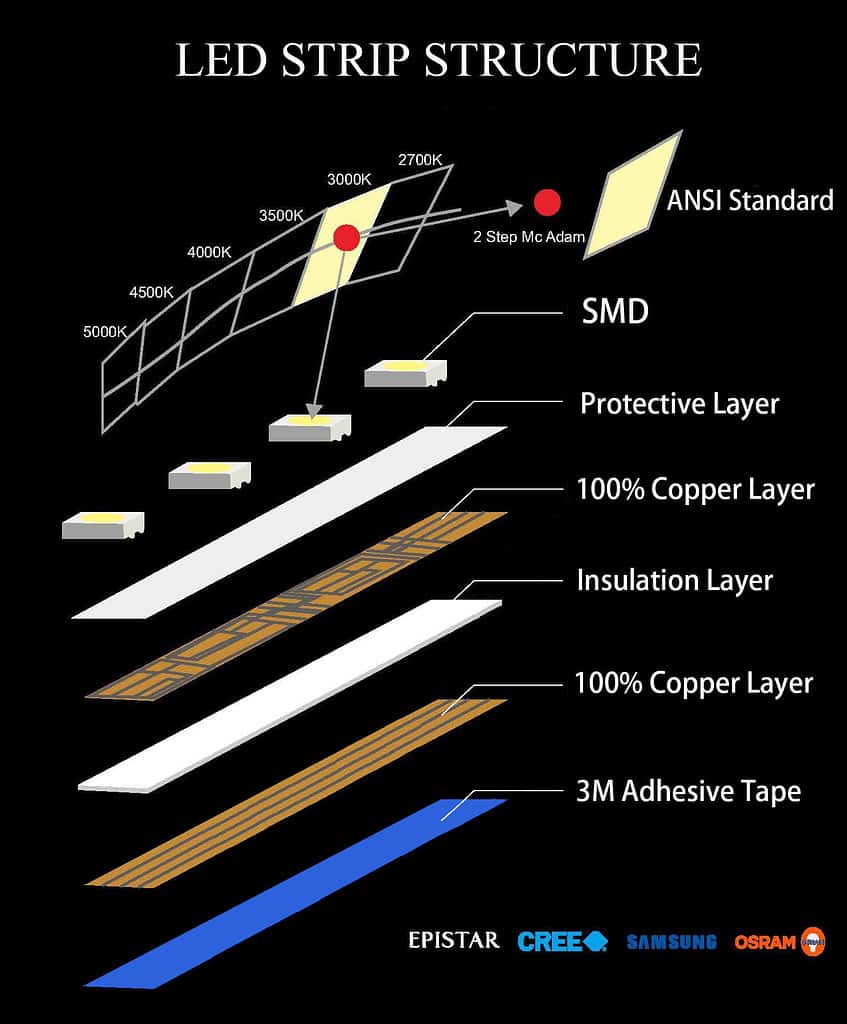

Beauty STC maintains rigorous quality control throughout the manufacturing process, using premium-grade SMD LEDs, stable IC drivers, and high-purity copper PCBs to ensure consistent performance, long lifespan (rated up to 50,000 hours), and minimal color shift over time. Their addressable LED tapes undergo extensive testing for signal integrity, thermal management, and moisture resistance, reflecting the company’s commitment to durability and customer satisfaction. With UL, CE, and RoHS certifications, Beauty STC’s addressable LED tapes stand out as a reliable, high-quality solution in the competitive smart lighting market.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China, serves as a core production hub for our advanced LED lighting solutions, including specialized addressable LED tape products. This modern factory is designed for precision manufacturing and stringent quality control, adhering to international standards such as ISO 9001. The facility integrates vertically controlled processes from component sourcing through final assembly and testing, ensuring consistency and reliability for our global clientele.

Our SMT production lines in Jiangmen are equipped with state-of-the-art machinery from leading manufacturers, primarily Yamaha and Siemens models. These high-speed, high-precision placement systems feature multiple heads capable of handling ultra-fine pitch components down to 0201 package sizes, with placement accuracy consistently maintained at ±25μm. Each line incorporates advanced automated optical inspection (AOI) systems immediately post-reflow to detect soldering defects, component misalignment, or missing parts, ensuring only flawless PCB assemblies proceed to the next stage. The SMT capacity supports high-volume production demands, with lines operating at speeds exceeding 80,000 components per hour while maintaining exceptional repeatability crucial for uniform LED performance.

Rigorous aging and reliability testing is a cornerstone of our quality assurance process at the Jiangmen site. Dedicated aging chambers subject finished addressable LED tape reels to a minimum 72-hour continuous burn-in cycle under controlled elevated temperatures typically ranging from 60°C to 70°C. During this period, automated monitoring systems continuously track critical parameters including light output flux, chromaticity coordinates, forward voltage stability, and individual pixel functionality across the entire reel length. Statistical process control methodologies are applied, with samples drawn according to AQL standards for comprehensive photometric and electrical validation. This extended stress testing effectively identifies infant mortality failures and validates long-term operational stability before products reach customers.

The Jiangmen factory possesses robust OEM capabilities specifically tailored for addressable LED tape solutions. We offer comprehensive customization from initial design through to mass production, supporting major IC platforms including WS2812B, SK6812, APA102, and DMX512 variants. Our engineering team collaborates closely with clients to modify PCB layouts for specific pixel densities, tape widths, and flexible substrate materials, while accommodating unique voltage requirements or signal protocols. Vertical integration allows us to manage all aspects in-house, including custom IC programming, specialized connector integration, and tailored waterproofing solutions such as silicone jacketing or IP67-rated profiles. We maintain strict IP protection protocols for proprietary designs and provide full documentation support, including IES files and programming libraries, enabling seamless integration of our addressable tape into diverse customer applications ranging from architectural lighting to entertainment installations. This end-to-end OEM service ensures clients receive a fully validated, market-ready product meeting exact performance and regulatory specifications.

Application Scenarios

Addressable LED tape is a versatile lighting solution that allows individual control of each LED or segment along the strip, enabling dynamic color changes, patterns, and precise lighting effects. Its flexibility and programmability make it ideal for specific applications in Hotels, Malls, and Offices where aesthetic appeal, ambiance, and visual impact are important.

In hotels, addressable LED tape is commonly used in feature lighting applications such as behind headboards, under handrails in staircases, along cove lighting in lobbies, and within architectural details in ballrooms or VIP areas. It enhances guest experience by creating mood lighting that can be adjusted for different times of day or events. For example, warm white tones can be used in the evening for relaxation, while vibrant colors can energize a pool or bar area during events.

Malls benefit from addressable LED tape in decorative ceiling features, signage backlighting, display window accents, and along escalator handrails or walkway perimeters. The ability to create animated lighting sequences draws attention to retail spaces, promotes brands, and contributes to an engaging shopping environment. Programmable effects can also align with seasonal themes or promotional campaigns.

In office environments, addressable LED tape is typically used more subtly. It can be installed under shelves, in suspended ceiling coves, or along stair edges for wayfinding and ambient enhancement. While full color-changing effects may be limited in professional settings, the tape can support circadian lighting strategies by adjusting white tones throughout the day to improve occupant focus and comfort.

When installing addressable LED tape, several best practices should be followed. First, ensure the mounting surface is clean, dry, and smooth to guarantee proper adhesion of the tape’s backing. Use aluminum channels whenever possible to improve heat dissipation, extend LED life, and provide a clean, professional finish. Always observe the maximum run length specified by the manufacturer to prevent voltage drop, especially with longer installations. For extended runs, inject power at multiple points or use amplifiers.

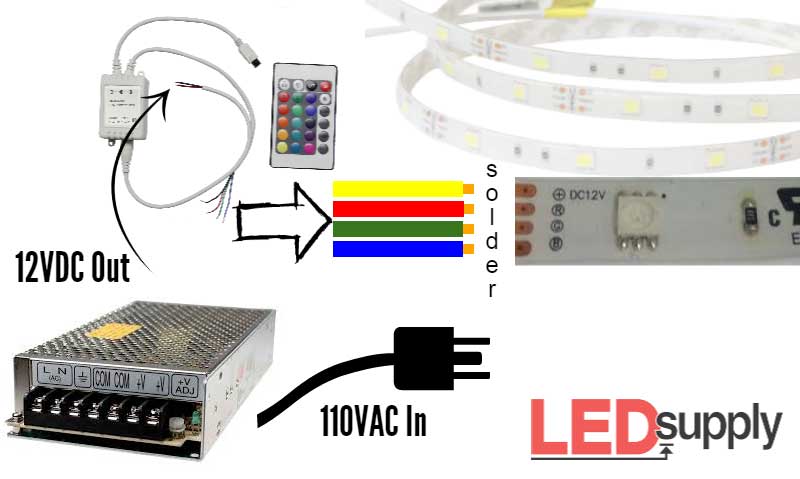

Proper planning of the data signal path is crucial—connect the data output of one strip to the input of the next in a daisy-chain configuration, avoiding long data runs that could degrade the signal. Use appropriate controllers and compatible software or DMX interfaces to manage the addressable functions effectively. Finally, protect all connections from dust and moisture with silicone caps or heat shrink tubing, and ensure all power supplies and controllers are installed in accessible locations for maintenance.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s cutting-edge addressable LED tape solutions designed for precision, versatility, and dynamic visual impact. As a trusted manufacturing partner with deep engineering expertise in advanced LED systems, we deliver fully customizable addressable tape that integrates seamlessly into architectural, entertainment, and retail applications while meeting stringent global quality and safety standards. Our dedicated technical team collaborates closely with partners to refine specifications, ensure optimal performance, and provide ongoing support from prototyping through volume production. Elevate your offerings with reliable, high-density pixel control and future-proof smart lighting technology engineered for exceptional longevity and color consistency. Partner with Beauty STC to access scalable manufacturing capabilities, rigorous quality assurance protocols, and responsive engineering collaboration tailored to your unique market demands. Contact our partnership manager today at [email protected] to discuss how our addressable LED tape can become a cornerstone of your product portfolio.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.