Article Contents

Industry Insight: 12 Volt Led Vehicle Lights

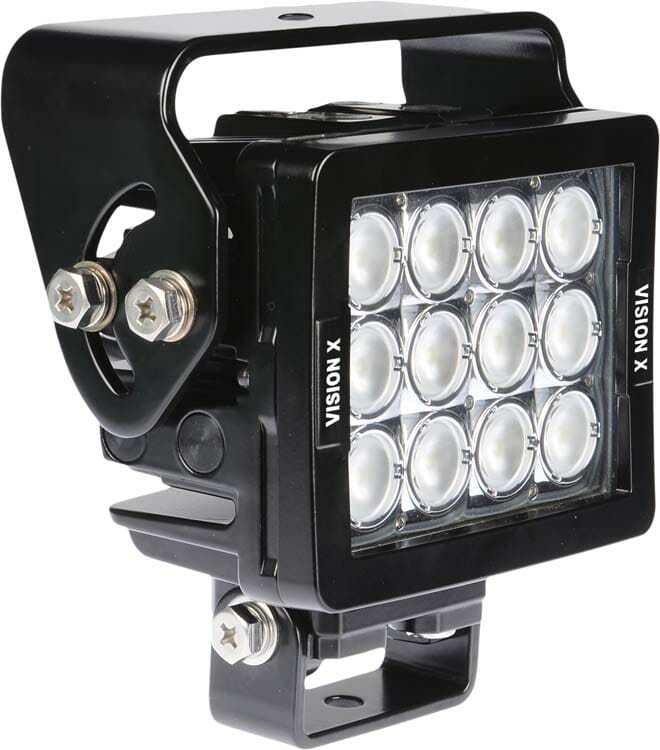

The commercial and industrial vehicle lighting sector is undergoing a decisive shift toward 12 volt LED technology, driven by the relentless demand for operational efficiency, enhanced safety, and reduced lifecycle costs across demanding work environments. Unlike consumer automotive applications, commercial fleets, construction equipment, agricultural machinery, emergency response vehicles, and material handling systems require lighting solutions engineered for extreme durability, consistent high-output performance under vibration and harsh conditions, and seamless integration with complex vehicle electrical systems. This transition is not merely about energy savings; it is a critical operational imperative where lighting reliability directly impacts productivity, worksite safety compliance, and maintenance downtime. Crucially, specifying 12 volt LED vehicle lights for these professional applications mandates adherence to rigorous international safety and performance standards. ETL certification for the North American market and CE marking for Europe are non-negotiable requirements, ensuring products meet essential electrical safety, electromagnetic compatibility, and environmental regulations, providing fleet managers and OEMs with the assurance of compliance and operator protection. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, leveraging over 25 years of specialized engineering expertise to develop robust, certified 12 volt LED lighting systems specifically designed to meet the uncompromising demands of commercial and industrial vehicle operations worldwide.

Technical Specs & Certifications

LED vehicle lights operating at 12 volts are widely used across automotive, marine, and off-road applications due to their energy efficiency, durability, and compact design. At Beauty (STC) Manufacturing Co., Ltd., our 12-volt LED vehicle lighting solutions are engineered to meet the highest standards of performance and reliability, ensuring optimal visibility and safety in demanding environments.

A key performance metric for LED lighting is luminous efficacy, measured in lumens per watt (lm/W). Our 12-volt LED vehicle lights typically deliver an efficacy range of 90 to 120 lumens per watt, depending on the specific model and optical configuration. This high efficiency ensures maximum light output with minimal power draw, reducing strain on the vehicle’s electrical system while providing bright, consistent illumination.

Color Rendering Index (CRI) is another critical factor, especially in applications where accurate color representation enhances safety and visibility. All premium models in our 12-volt LED lineup feature a CRI greater than 90, enabling drivers to distinguish objects, terrain, and signals more clearly under various lighting conditions. High CRI LEDs contribute to reduced eye fatigue and improved night-time visibility, making them ideal for emergency vehicles, work trucks, and off-road use.

Ingress Protection (IP) ratings are essential for ensuring durability in harsh environments. Beauty STC’s 12-volt LED vehicle lights are designed with robust sealing and are typically rated at IP67 or IP68. An IP67 rating indicates complete protection against dust and the ability to withstand immersion in water up to 1 meter for 30 minutes, while IP68 offers extended submersion protection. These ratings ensure reliable operation in wet, muddy, or dusty conditions commonly encountered in off-road, agricultural, and industrial applications.

Quality is at the core of Beauty STC’s manufacturing philosophy. Our LED vehicle lights are built using high-grade aluminum heat sinks for superior thermal management, automotive-grade polycarbonate lenses for impact resistance, and rigorously tested driver circuits for stable performance across voltage fluctuations. Each product undergoes extensive environmental and electrical testing, including thermal cycling, vibration, and salt spray resistance, to ensure long service life and consistent performance under real-world conditions.

With a strong commitment to innovation and reliability, Beauty (STC) Manufacturing Co., Ltd. continues to set industry benchmarks in LED lighting technology, delivering 12-volt solutions that combine high lumens per watt, excellent color rendering, and superior ingress protection for professional and consumer applications alike.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as a core production hub for our automotive lighting solutions, specifically engineered to meet the rigorous demands of the global vehicle lighting market. The factory is purpose-built for high-volume, precision manufacturing of LED products, with a significant focus on 12-volt LED vehicle lights including work lights, spotlights, floodlights, and auxiliary lighting systems.

Our Surface Mount Technology (SMT) production lines are a cornerstone of the Jiangmen facility. We operate multiple state-of-the-art JUKI high-speed SMT lines capable of handling the full spectrum of components required for complex LED driver and control boards. These lines feature precise placement machines handling 0201 metric components and larger power devices essential for automotive-grade LED circuits. The process strictly adheres to lead-free soldering standards (IPC-J-STD-001) and incorporates comprehensive automated optical inspection (AOI) and automated X-ray inspection (AXI) stations after reflow soldering. This ensures exceptional solder joint integrity and component placement accuracy critical for the vibration resistance and longevity demanded in vehicle applications. The combined lines achieve a component placement throughput exceeding 600,000 components per hour while maintaining stringent quality control.

Aging and reliability testing for 12-volt LED vehicle lights is conducted under strictly controlled conditions within dedicated environmental chambers at the Jiangmen site. Every production batch undergoes a mandatory 72-hour continuous aging test at elevated temperatures (typically 65°C ambient) and at the nominal operating voltage of 13.8V DC, simulating real-world vehicle electrical system conditions including voltage spikes. During this burn-in period, lights are monitored for consistent lumen output, color stability, thermal performance, and any early failure modes. We utilize thermal imaging cameras to verify critical component temperatures remain within design limits and conduct photometric validation post-aging. Crucially, 100% of finished 12V LED vehicle lights pass through final functional testing, including waterproof ingress testing (IP67/IP68 verified), vibration simulation, and electrical safety checks before shipment.

The Jiangmen factory is fully equipped to provide comprehensive OEM services for 12-volt LED vehicle lights. Our engineering team collaborates directly with clients from initial concept through to mass production, offering custom optical design, thermal management solutions, robust mechanical housing development, and tailored electronic driver circuitry to meet specific voltage tolerances, dimming requirements, or CAN-bus compatibility needs. We support clients requiring custom branding, unique form factors, specific lumen outputs, or specialized beam patterns. The facility handles low-volume prototyping through to high-volume production runs with flexible line configurations. Our integrated supply chain management ensures control over critical components like LEDs, drivers, and optics. We provide full documentation including IEC/SAE-compliant test reports, DFMEA support, and adhere strictly to automotive quality standards such as IATF 16949. Clients benefit from our expertise in design for manufacturability, ensuring cost-effective production without compromising the ruggedness required for off-road, trucking, and marine environments, with no minimum order quantity constraints for established partners.

Application Scenarios

The use of 12-volt LED vehicle lights is primarily designed for automotive and mobile applications, not for permanent installation in fixed commercial or hospitality environments such as hotels, malls, or offices. These lights are engineered to operate on low-voltage direct current (DC) power systems typically found in cars, trucks, RVs, boats, and other vehicles. As such, their application in stationary buildings is limited and generally not recommended unless specific conditions are met.

However, there may be niche or decorative uses in hotels, malls, or offices where a themed or temporary lighting effect is desired—for example, in a retro automotive-themed restaurant within a mall, a lobby display in a hotel showcasing vintage vehicles, or an experiential retail space in an office complex. In these cases, 12-volt LED vehicle lights could be used creatively for accent or ambient lighting, but only if integrated safely into a compatible power setup, such as a converted DC power system or via an appropriate AC-to-DC power adapter.

For proper and safe installation, consider the following tips:

Always verify the voltage requirements of the LED lights and ensure compatibility with the power source. In non-vehicle settings, a reliable 12V DC power supply or transformer must be used to convert standard AC mains power (e.g., 120V or 230V AC) to 12V DC.

Use waterproof or sealed connectors when installing in environments with potential moisture exposure, even indoors, to prevent corrosion and short circuits.

Secure wiring neatly and protect it from foot traffic or physical damage using conduit or cable management systems, especially in high-traffic areas like malls or hotel corridors.

Ensure all electrical installations comply with local building and fire safety codes. In commercial spaces, work with a licensed electrician to avoid safety hazards and code violations.

Avoid daisy-chaining multiple lights beyond the recommended load capacity of the power supply, as this can lead to voltage drops, reduced light output, or overheating.

Ground the system properly if the fixture or housing is metal to prevent electrical shock risks.

Test the lighting setup before finalizing the installation to confirm consistent brightness and functionality across all units.

While 12-volt LED vehicle lights offer energy efficiency, durability, and compact design, their optimal use remains in transportation and mobile applications. For permanent architectural lighting in hotels, malls, and offices, it is better to use LED fixtures specifically designed for commercial lighting with appropriate safety certifications, lumen output, and beam angles suited for those environments.

Why Choose Beauty STC Lighting

Upgrade your vehicle lighting performance with Beauty STC’s precision-engineered 12 volt LED vehicle lights designed for exceptional durability and brightness in demanding conditions. Our rigorously tested solutions deliver superior visibility, energy efficiency, and longevity for commercial fleets, emergency vehicles, and off-road applications while meeting stringent automotive safety standards. Partner with Beauty STC to integrate reliable, high-output lighting systems that reduce maintenance costs and enhance operational safety across your vehicle portfolio. Contact our engineering team directly at [email protected] to discuss custom specifications, volume pricing, and technical support tailored to your requirements. Let us help you illuminate the road ahead with confidence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.