Article Contents

Industry Insight: Led Stripe Dmx

In the rapidly evolving landscape of commercial and industrial lighting, LED stripe DMX technology has emerged as a transformative solution, combining dynamic color control, energy efficiency, and architectural adaptability. Widely deployed in retail environments, hospitality venues, manufacturing facilities, and large-scale installations, DMX-controllable LED stripes offer precise lighting management through industry-standard protocols, enabling synchronized effects, zoning, and automation that elevate both ambiance and functionality. As demand grows for reliable, code-compliant lighting systems, certifications such as ETL and CE have become essential markers of safety, performance, and regulatory adherence—ensuring these products meet rigorous North American and international standards.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in professional LED lighting since its founding in 1998. With over two decades of engineering excellence, Beauty STC has built a reputation for delivering high-performance, code-compliant LED solutions tailored to the demanding requirements of commercial and industrial applications. Their LED stripe DMX系列产品 reflect this commitment—combining robust construction, precise DMX512 control, and full ETL and CE certification to ensure seamless integration and long-term reliability in mission-critical environments. As the industry moves toward smarter, more sustainable lighting infrastructures, Beauty STC continues to lead with innovation grounded in quality and compliance.

Technical Specs & Certifications

LED stripe lighting with DMX control refers to flexible LED tape lights incorporating DMX512 or RDM protocol for precise pixel-level addressing and dynamic color or intensity control. At Beauty STC Manufacturing Co., Ltd., our engineered DMX-controllable LED stripes prioritize performance metrics critical for professional applications. Lumens per watt efficiency varies significantly based on LED density, drive current, and binning. Our standard DMX addressable strips achieve 90-110 lumens per watt at 25°C ambient temperature under nominal drive conditions. Higher-density configurations (e.g., 60 LEDs/meter) typically operate at 85-100 lm/W due to thermal constraints, while optimized 30-48 LED/meter variants reach 100-115 lm/W. We achieve this through efficient SMD 2835 or 3535 LED packages with low thermal resistance substrates and precision constant-current drivers designed to minimize conversion losses.

Color Rendering Index (CRI) exceeding 90 is non-negotiable for applications demanding accurate color representation. Beauty STC utilizes high-CRI LED bins with Ra ≥ 92 and R9 ≥ 50, achieved through multi-phosphor formulations and rigorous spectral tuning. Our strips undergo spectrophotometric validation to ensure consistency across production batches, with CRI measured at 3000K, 4000K, and 6500K CCT options. This guarantees faithful rendering of saturated reds and skin tones critical in retail, museum, and broadcast environments where color integrity is paramount.

IP ratings for DMX LED stripes depend on the construction method. Beauty STC offers multiple configurations: IP20 for indoor dry locations with bare PCB strips, IP65 for protected outdoor use with silicone-jacketed strips (resistant to dust and low-pressure water jets), and IP67/IP68 for full submersion applications using fully potted silicone encapsulation. Our IP68-rated strips withstand continuous immersion up to 1 meter for 72 hours, validated through IEC 60529 testing. Critical attention is paid to connector integrity and end-cap sealing to maintain the rated protection level across the entire assembly.

Beauty STC’s commitment to quality is embedded in our ISO 9001-certified manufacturing processes. We implement strict binning protocols for LEDs and drivers to ensure lumen maintenance (L70 > 50,000 hours at 25°C), conduct 72-hour accelerated life testing on every production batch, and utilize automated optical inspection for solder joint and component placement accuracy. Our DMX protocols undergo rigorous EMI/EMC validation per IEC 61000-6 standards to prevent signal interference in complex installations. This systematic approach delivers reliability, consistent photometric performance, and seamless integration into professional lighting control systems, distinguishing our products in demanding architectural and entertainment applications.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen is a modern, well-equipped facility specializing in the production of high-quality LED lighting products. Strategically located in the Jiangmen industrial zone in Guangdong Province, the facility benefits from strong infrastructure, a skilled labor force, and proximity to major supply chain networks, enabling efficient manufacturing and logistics.

The factory is outfitted with advanced Surface Mount Technology (SMT) production lines that ensure precision and consistency in assembling LED components. These SMT machines are capable of handling a wide range of LED strip types, including high-density and fine-pitch designs, allowing for reliable soldering of small components such as RGB LEDs, ICs, and resistors onto flexible and rigid PCBs. The automated nature of the SMT process enhances production speed, minimizes human error, and supports high-volume output while maintaining excellent quality standards.

To ensure long-term reliability and performance, all LED products undergo rigorous aging tests before shipment. The aging process typically involves operating the LED strips at elevated temperatures and full power for extended periods—usually 24 to 72 hours—monitoring for defects such as flickering, color inconsistency, or component failure. This step is critical in identifying early-life failures and verifying product durability under continuous use, especially for demanding applications like stage lighting, architectural installations, and entertainment environments.

Beauty STC has robust OEM capabilities and is well-equipped to support customized LED stripe DMX solutions. The company can develop and manufacture DMX-controlled LED strips according to client specifications, including custom PCB layouts, IC selection (such as WS2811, WS2812B, or TM1814), voltage configurations (5V, 12V, or 24V), IP ratings, and mechanical dimensions. Their engineering team works closely with clients to integrate DMX512 protocols, ensuring seamless compatibility with professional lighting control systems. In addition, they offer custom labeling, packaging, and branding services to meet specific market or project requirements.

Overall, the Jiangmen factory combines automation, strict quality control, and flexible manufacturing to deliver reliable, high-performance LED stripe DMX products tailored to the needs of global OEM partners.

Application Scenarios

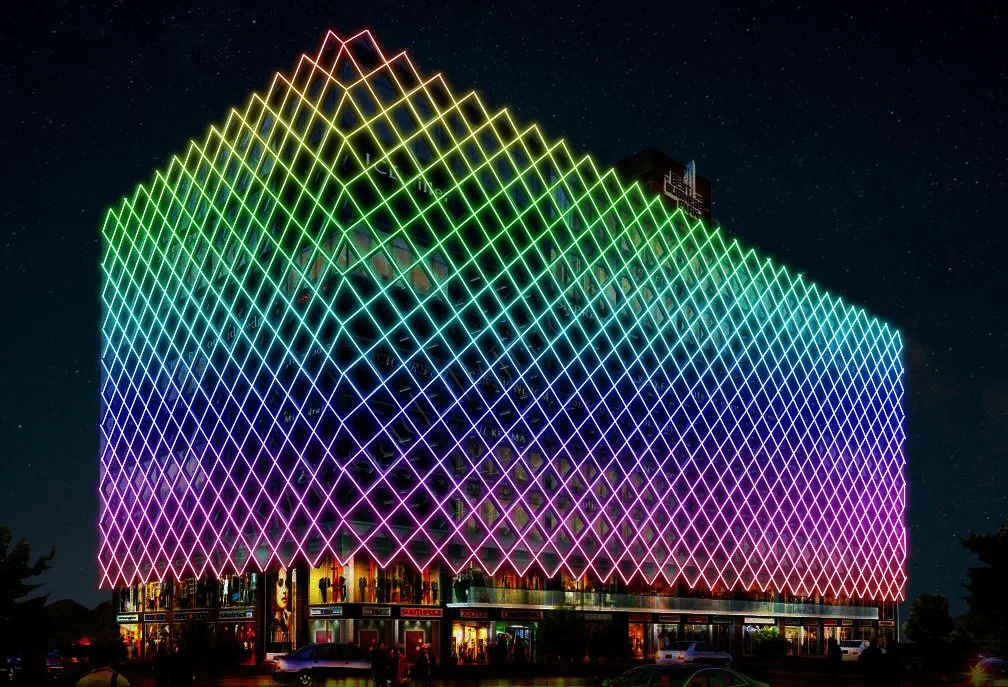

LED stripe DMX systems are specifically designed for dynamic, addressable lighting control where precise color tuning, animation, and synchronization are required. In hotels, malls, and offices, they serve distinct purposes beyond basic illumination, enhancing aesthetics, branding, and functionality.

In hotels, LED stripe DMX is ideal for high-impact guest experience zones. Install it along architectural coves in lobbies to create immersive welcome environments that shift from warm sunrise hues in the morning to vibrant tones for evening events. Use it underwater in pool perimeters for color-changing safety accents during swim sessions or ambient effects at night. Feature walls in premium suites or bars benefit from programmable scenes that align with seasonal themes or guest preferences, while corridor soffits can display subtle directional lighting that transitions intensity based on time of day. Avoid using it in standard guest room ceilings where simple warm dimming suffices, as DMX complexity adds unnecessary cost.

Malls leverage DMX LED stripes primarily for tenant flexibility and experiential marketing. Install them within storefront headers where retailers can dynamically update colors to match seasonal campaigns or sales events without physical modifications. Central atrium columns or suspended sculptural elements become digital canvases for synchronized holiday displays or branded content. Critical areas include food court perimeter coves that shift from energetic whites during lunch rushes to relaxing ambers in evenings, and wayfinding strips along handrails that pulse gently toward exits during emergencies. Do not deploy DMX strips in standard corridor lighting; reserve them for high-visibility brand zones where motion-triggered effects drive foot traffic.

Offices apply DMX LED stripes strategically for wellness and adaptive environments. Implement them above workstation partitions to deliver circadian lighting—gradually shifting from 6500K cool white at 9 AM to 3000K at 5 PM to reduce eye strain. Conference room perimeter coves can transition to neutral 4000K during presentations then to calming blues post-meeting. Reception desks use subtle under-counter DMX strips to signal meeting status (e.g., red for busy, green for available). Avoid overuse in open offices; limit to collaboration zones where animated color zones can energize brainstorming sessions. Never install DMX strips in areas requiring task lighting consistency, like drafting tables or labs.

Installation requires meticulous planning to avoid signal degradation. Always terminate the final DMX node with a 120-ohm resistor across data lines to prevent reflection errors—this is non-negotiable for stable operation. Power injection is critical: for 24V strips, inject power every 10 meters; for 12V, every 5 meters. Route data cables separately from power lines with at least 30cm clearance to avoid interference, using shielded CAT5e for runs exceeding 15 meters. Test signal integrity with a DMX tester before final mounting, as daisy-chaining beyond 32 fixtures per universe risks packet loss. Crucially, never connect DMX strips directly to standard controllers—always use a dedicated DMX decoder matched to the strip’s protocol (e.g., DMX512, Art-Net). Finally, document all universe/channel mappings during installation; reprogramming 200 fixtures post-commissioning wastes billable hours.

Why Choose Beauty STC Lighting

Discover the full potential of dynamic lighting with our premium LED stripe DMX solutions designed for professional applications. At Beauty (STC) Manufacturing Co., Ltd., we specialize in high-performance, customizable LED lighting that delivers precision, reliability, and stunning visual impact. Whether you’re working on architectural projects, stage designs, or immersive environments, our DMX-enabled LED stripes offer seamless integration and superior control.

Partner with Beauty STC to benefit from OEM/ODM support, rigorous quality standards, and dedicated technical expertise. We are committed to delivering innovative lighting solutions that meet the demands of global markets.

For inquiries and collaboration opportunities, contact us today at [email protected]. Let’s illuminate your next project together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.