Article Contents

Industry Insight: Power Supply For Led Lighting

The commercial and industrial LED lighting sector continues to evolve rapidly, driven by increasing demands for energy efficiency, durability, and regulatory compliance. At the heart of every high-performance LED lighting system lies a critical component—the power supply. More than just a source of electrical conversion, the power supply determines system reliability, longevity, and performance under varying environmental conditions. In commercial and industrial applications—ranging from warehouses and manufacturing facilities to office complexes and retail spaces—the power supply must deliver consistent, stable output while meeting stringent safety and electromagnetic compatibility standards. Certifications such as ETL and CE have become essential benchmarks, ensuring that power supplies comply with North American and international safety, emissions, and performance requirements. These certifications are not just regulatory checkboxes; they reflect a commitment to quality and safety in demanding environments.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the design and production of high-quality LED power solutions. With over two decades of engineering expertise, Beauty STC specializes in developing reliable, certified, and energy-efficient power supplies tailored specifically for commercial and industrial LED lighting systems. The company’s dedication to innovation, rigorous testing, and global compliance—including full ETL and CE certification across its product lines—has positioned it as a preferred partner for lighting manufacturers seeking performance-driven, code-compliant solutions. As the industry moves toward smarter, more sustainable lighting infrastructures, Beauty STC continues to set the standard for excellence in power supply technology.

Technical Specs & Certifications

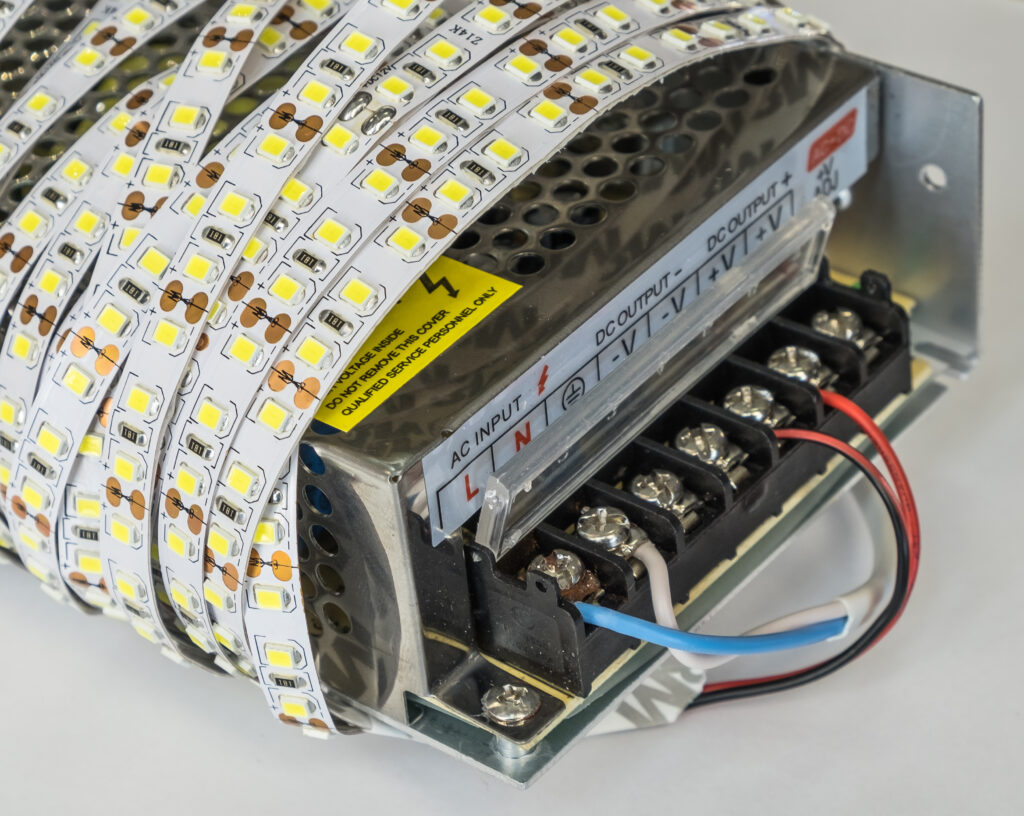

LED power supplies, more accurately termed LED drivers, are critical components that convert incoming AC line voltage to the precise DC current or voltage required by LED modules. It is essential to clarify that metrics such as lumens per watt (lm/W) and Color Rendering Index (CRI) are characteristics of the complete LED luminaire (fixture), not the driver itself. The driver’s role is to enable and sustain these performance levels through stable, efficient power delivery. Beauty STC Manufacturing Co., Ltd. designs and manufactures drivers specifically engineered to support high-performance luminaires meeting stringent efficiency and quality benchmarks.

Lumens per watt represents the overall efficacy of the luminaire, indicating how much visible light (lumens) is produced per unit of electrical power (watts) consumed by the entire fixture. While the driver does not generate light, its efficiency directly impacts the system-level lm/W. Beauty STC drivers achieve typical efficiencies of 90-94% across a wide load range, minimizing energy loss as heat. High-efficiency drivers are essential for luminaires targeting 150+ lm/W system efficacy, as driver losses directly reduce the net lumens delivered per input watt. Our drivers incorporate advanced topologies like active PFC and resonant LLC converters, coupled with low-loss semiconductor components and optimized thermal management, to maintain peak efficiency even under varying line voltages and ambient temperatures. This ensures the luminaire consistently achieves its designed high lm/W output over its operational life.

CRI, specifically requiring values greater than 90 (Ra >90), is a photometric property determined solely by the spectral power distribution of the LED light source itself. However, the driver plays a vital role in maintaining stable CRI performance over time. Poor driver regulation, excessive current ripple, or thermal runaway can cause LED junction temperature fluctuations or drive current instability, leading to chromaticity shift and reduced CRI. Beauty STC drivers feature ultra-low output current ripple (<5% typically), precise constant current regulation (±3% accuracy), and robust thermal protection circuits. These characteristics prevent LED stress, ensuring the high-CRI phosphor-converted white LEDs operate within their optimal thermal and electrical parameters. This stability is critical for applications like retail, healthcare, and museums where accurate color representation is non-negotiable, and Beauty STC drivers are rigorously tested to guarantee consistent CRI performance throughout the luminaire’s rated lifetime.

IP (Ingress Protection) ratings define the level of protection against solid objects and moisture for the entire luminaire enclosure. The driver’s own IP rating is a key factor, especially for outdoor or harsh environment fixtures. Beauty STC offers a comprehensive range of drivers with IP ratings from IP20 (basic indoor use) up to IP67 and IP68 (suitable for submersion). Our higher IP-rated drivers utilize fully potted construction with thermally conductive, optically clear silicone compounds, eliminating internal air gaps and providing superior resistance to moisture, dust, and corrosive elements. Conformal coating on internal PCBs and gasketed enclosures with robust UV-stable polycarbonate or aluminum housings further enhance environmental resilience. For instance, our IP67-rated drivers undergo stringent 30-minute submersion testing at 1 meter depth and continuous operation validation in 95% RH environments at 40°C, ensuring reliability in demanding applications like street lighting, industrial facilities, and marine settings.

Beauty STC’s commitment to quality is embedded in every driver. We adhere to rigorous internal standards exceeding IEC 61347-1 and IEC 61347-2-13, with comprehensive 100% automated production testing for safety, functionality, and performance parameters. Our drivers feature industrial-grade components sourced from verified suppliers, multi-stage thermal management systems, and extensive protection mechanisms including short-circuit, over-voltage, over-temperature, and open-circuit protection. This focus on reliability translates to industry-leading MTBF figures exceeding 100,000 hours at 25°C ambient and full-load conditions, backed by a standard 5-year warranty. Beauty STC drivers are not merely power converters; they are engineered enablers that ensure luminaires consistently deliver high lm/W efficacy, stable >90 CRI color quality, and the environmental resilience demanded by the IP rating specified for the fixture, forming the foundation of our reputation for premium, long-lasting LED lighting solutions.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility located in Jiangmen, Guangdong Province, a region well-known for its robust electronics and lighting industry ecosystem. The factory is equipped with advanced Surface Mount Technology (SMT) production lines, which are critical for the high-precision assembly of electronic components used in LED lighting power supplies. These SMT machines include fully automated pick-and-place systems, reflow soldering ovens, and automated optical inspection (AOI) equipment, ensuring consistent quality, high efficiency, and reliability in component placement and soldering processes.

To ensure product durability and performance under real-world conditions, the Jiangmen factory conducts comprehensive aging tests on all power supply units. These tests simulate extended operation under varying electrical loads, temperatures, and humidity levels. Units are typically run continuously for 4 to 8 hours or longer under elevated temperatures to identify early failures and verify thermal management, component stability, and overall circuit integrity. This rigorous testing protocol supports product reliability and longevity, meeting international safety and performance standards.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities tailored specifically for power supplies used in LED lighting applications. The company offers customized design and manufacturing services, including circuit design, component sourcing, thermal management optimization, and compliance testing (such as CE, RoHS, UL, and CCC). With in-house engineering support, the factory can develop power supplies ranging from low-voltage DC drivers to high-efficiency AC-DC constant current and constant voltage drivers, suitable for commercial, industrial, and residential LED lighting systems. The OEM process is flexible, supporting small-batch prototyping as well as large-scale mass production with strict quality control throughout.

Overall, the Jiangmen factory combines automated manufacturing, rigorous quality assurance, and tailored engineering support to deliver reliable, high-performance LED power supply solutions for global clients under OEM arrangements.

Application Scenarios

Power supplies for LED lighting are critical components in commercial environments like hotels, malls, and offices, where reliable, efficient, and high-quality illumination is essential. In hotels, LED power supplies are deployed extensively in guest rooms for dimmable ambient and task lighting, ensuring smooth dimming performance without flicker to enhance guest comfort. They are equally vital in lobbies, corridors, and restrooms, where consistent operation and long lifespan reduce maintenance disruptions. For malls, these power supplies drive high-output retail lighting in storefronts and display areas, requiring robust thermal management to handle continuous operation under high ambient temperatures from密集 foot traffic and adjacent equipment. They also support architectural lighting in atriums and common areas, where weather-resistant or high-IP-rated units may be needed near entrances or skylights. Offices utilize LED power supplies in suspended ceiling grids for uniform task lighting at workstations, demanding flicker-free operation to prevent eye strain and productivity loss, while conference rooms and executive suites often require precision dimming compatibility with building management systems.

Installation demands meticulous attention to maximize performance and longevity. Always verify the power supply’s input voltage range matches the local mains supply and confirm output specifications—voltage, current, and wattage—align precisely with the connected LED load, including a 20% safety margin to prevent overloading. Mount units in well-ventilated areas away from direct heat sources like HVAC ducts or enclosed ceiling voids; for high-ambient environments like mall retail spaces, select units rated for at least 60°C or use external heatsinks. Ensure proper grounding is implemented at both the mains input and the power supply chassis to mitigate electrical noise and safety risks, particularly in older hotel buildings with inconsistent wiring. In damp locations such as hotel pool areas or mall restrooms, use power supplies with a minimum IP65 rating and avoid installing them below the LED fixtures to prevent condensation ingress. For dimmable systems common in hotel lobbies and offices, match the power supply’s dimming protocol—0-10V, DALI, or phase-cut—with the control system and maintain separate low-voltage wiring from mains cables to avoid interference. Finally, conduct thorough pre-commissioning tests under full load to verify stable output and thermal behavior, as field failures often stem from overlooked voltage drops or inadequate heat dissipation during initial setup. Always adhere to local electrical codes and manufacturer guidelines to ensure safety and warranty validity.

Why Choose Beauty STC Lighting

Looking for a reliable power supply for your LED lighting projects? Partner with Beauty STC, a trusted leader in high-quality LED solutions. Our advanced power supply systems are engineered for performance, durability, and energy efficiency, ensuring optimal results for every application. Backed by years of manufacturing expertise, we deliver products that meet international standards and exceed customer expectations.

Take the next step in your lighting projects by collaborating with a partner you can trust. Contact us today at [email protected] to discuss your requirements and discover how Beauty STC can power your success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.