Article Contents

Industry Insight: Strip Led Cob

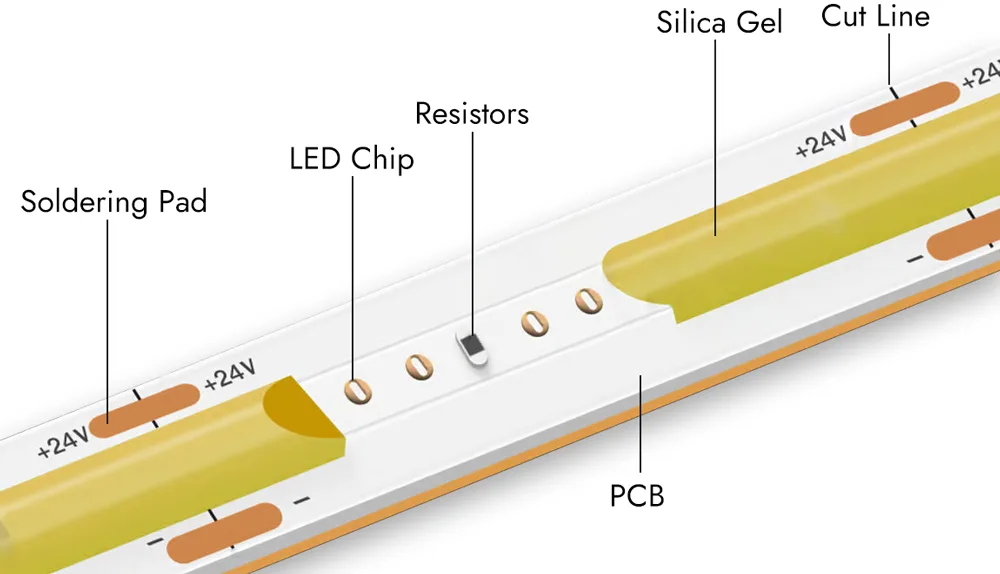

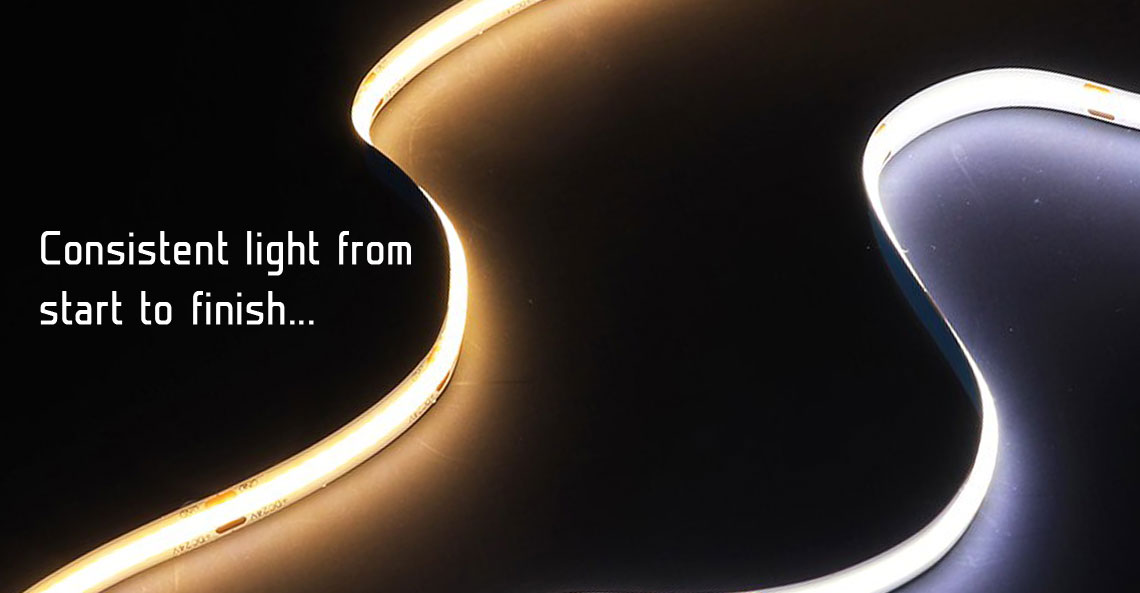

The commercial and industrial lighting landscape is undergoing a significant transformation, driven by the relentless pursuit of superior light quality, operational efficiency, and long-term reliability. Within this evolution, COB (Chip-on-Board) LED strip technology has emerged as a critical solution, moving far beyond simple decorative applications to become a cornerstone for demanding professional environments. Unlike traditional SMD LED strips, COB strips integrate multiple LED chips directly onto a single substrate, creating a seamless, high-density light source that eliminates the distracting dotting effect. This delivers exceptionally uniform illumination crucial for tasks in retail displays, high-bay warehouse lighting, precision manufacturing areas, and architectural cove lighting where visual comfort and accurate color rendition are non-negotiable. The inherent thermal management advantages of COB designs also translate directly to sustained lumen output and extended service life in the continuous-operation scenarios typical of industrial facilities, significantly reducing maintenance costs and downtime.

For any lighting solution deployed in commercial or industrial settings, adherence to stringent safety and performance standards is not optional; it is a fundamental requirement. Products must demonstrably comply with regional regulations to ensure user safety, facilitate smooth project approvals, and provide liability protection. Certifications such as ETL (indicating compliance with North American safety standards) and CE (signifying conformity with European health, safety, and environmental requirements) are essential benchmarks. These certifications validate rigorous testing for electrical safety, electromagnetic compatibility, and thermal performance, providing specifiers, contractors, and facility managers with the confidence that the installed lighting systems meet the highest levels of reliability and safety expected in professional installations. Selecting COB LED strips bearing these critical marks is a primary consideration for risk mitigation and project success.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this professional LED lighting evolution for over 25 years. We specialize in engineering and manufacturing high-performance LED solutions specifically designed to meet the exacting demands of commercial and industrial applications. Our deep expertise in thermal management, optical control, and robust construction methodologies ensures that our COB LED strip products deliver not only the superior light quality professionals require but also the certified reliability and durability essential for mission-critical environments. From precision optical lenses to advanced thermal substrates and rigorously tested driver integration, Beauty STC focuses on providing engineered lighting systems that solve real-world challenges, reduce total cost of ownership, and support the evolving standards of modern commercial and industrial spaces.

Technical Specs & Certifications

The strip LED COB (Chip-on-Board) technology offered by Beauty (STC) Manufacturing Co., Ltd. represents a high-performance lighting solution designed for both commercial and residential applications where uniform illumination, efficiency, and color quality are critical. These COB strip lights integrate multiple LED chips directly onto a flexible circuit board, enabling a continuous line of light with minimal dotting effect, making them ideal for cove lighting, under-cabinet installations, display lighting, and architectural accenting.

In terms of efficacy, Beauty STC’s COB LED strips deliver an impressive lumen output ranging from 100 to 130 lumens per watt, depending on the color temperature and drive current. This high lumens-per-watt ratio ensures energy-efficient operation, reducing power consumption while maintaining bright, consistent light output. The efficiency is achieved through advanced thermal management design and the use of high-quality phosphor coating on the COB array, which enhances light extraction and minimizes lumen depreciation over time.

Color Rendering Index (CRI) is a key focus for Beauty STC, and their COB strip LEDs consistently achieve a CRI greater than 90, with select high-end variants reaching CRI 95+. This ensures accurate and natural color representation, which is essential in retail, hospitality, and art gallery environments where true-to-life color is paramount. The high CRI is supported by a tightly binned selection of LED chips and precise control over the spectral power distribution during manufacturing.

Regarding environmental protection, Beauty STC offers COB LED strips in multiple IP (Ingress Protection) ratings to suit various installation conditions. The standard non-protected version is available as IP20, suitable for dry indoor environments. For damp or outdoor applications, silicone-coated versions are offered in IP65, providing protection against water jets and dust ingress. Fully encapsulated COB strips are available in IP67 and IP68 ratings, making them submersible and ideal for outdoor signage, landscape lighting, and marine environments. These high IP-rated versions utilize durable silicone overmolding that maintains flexibility while ensuring long-term reliability under harsh conditions.

Beauty STC is recognized for its stringent quality control processes, utilizing automated SMT (Surface Mount Technology) production lines and rigorous in-line testing for electrical performance, color consistency, and thermal stability. Each batch undergoes aging tests and photometric verification to ensure compliance with international standards such as IEC, RoHS, and REACH. The company’s commitment to quality is further reflected in the extended lifespan of their COB strips—typically rated at 50,000 hours (L70), even under continuous operation.

In summary, Beauty STC’s COB LED strip lights combine high efficiency (100–130 lm/W), exceptional color fidelity (CRI >90, up to 95+), and robust environmental protection (IP20 to IP68), backed by consistent manufacturing quality and reliability. These attributes position their products as a premium choice in the competitive LED lighting market.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as our primary production hub for advanced LED lighting solutions. Strategically located within the Pearl River Delta industrial corridor, the Jiangmen factory spans over 20,000 square meters and operates under strict ISO 9001 and ISO 14001 certified processes. The facility is engineered for high-volume precision manufacturing with a strong emphasis on quality control and flexible production capabilities tailored to global market demands.

Our surface mount technology (SMT) production lines feature state-of-the-art Yamaha YSM20 and YSM10 placement machines, which form the backbone of our component assembly process. These systems deliver exceptional precision with placement accuracy of ±25 micrometers and speeds reaching 0.035 seconds per component, critical for handling the fine-pitch requirements of modern LED chips. The dual-lane configuration allows simultaneous production of multiple product lines, including specialized setups dedicated to COB (Chip-on-Board) substrates. Advanced vision systems ensure perfect alignment of LED dies during placement, while nitrogen-reflow soldering environments minimize oxidation for superior thermal and electrical reliability in the final assemblies. All SMT processes are monitored in real-time through our MES (Manufacturing Execution System) for traceability and immediate process correction.

Aging and reliability testing represent a cornerstone of our quality assurance protocol at the Jiangmen facility. Every COB LED strip undergoes mandatory 24-hour continuous aging tests under controlled thermal conditions at 50°C, operating at 110% of rated current to accelerate early-life failure detection. We utilize fully automated aging racks with individual channel monitoring that logs voltage, current, and lumen maintenance data at 15-minute intervals. This rigorous burn-in process identifies potential weak components before shipment, significantly reducing field failure rates. For premium OEM projects or specialized applications requiring extended lifespan validation, we offer customized aging protocols up to 72 hours with thermal cycling between -20°C and 85°C. All test data is stored in our cloud-based quality management system for client access and continuous process improvement analysis.

Our OEM capability for strip LED COB products is a key differentiator at the Jiangmen factory. We specialize in fully customized COB strip solutions from initial concept through volume production. This includes engineering support for unique substrate designs, flexible or rigid configurations, custom color temperatures from 1800K to 6500K, and high-CRI options up to 98 Ra. The facility supports rapid prototyping with in-house PCB fabrication and 3D printing for mechanical validation, typically delivering first-article samples within 10-15 working days. For production, we accommodate order volumes ranging from 500 meters for niche applications to multi-kilometer runs for large-scale projects, with dedicated changeover protocols to maintain batch integrity. Our engineering team collaborates closely with clients on thermal management solutions, optical enhancements like secondary lenses, and specialized coatings for UV resistance or high-moisture environments. All OEM projects undergo the same stringent aging and photometric testing as standard products, with comprehensive reporting including IES files and LM-80 data packages to support client certification requirements. This turnkey capability has enabled successful partnerships with architectural lighting designers, medical equipment manufacturers, and retail display specialists requiring proprietary COB strip solutions.

Application Scenarios

Strip LED COB (Chip-on-Board) lighting is an advanced lighting solution known for its seamless, uniform light output and high lumen density. Due to its sleek design and excellent performance, it is increasingly used across commercial and hospitality environments such as hotels, malls, and offices. Below are the recommended applications and installation tips for each setting.

In hotels, strip LED COB lighting is ideal for creating ambient and accent lighting that enhances guest experience. It is commonly installed in reception areas to provide soft, glare-free illumination that sets a welcoming tone. Under-cabinet lighting in hotel kitchens and minibars benefits from the even light distribution of COB strips. Coves and alcoves in lobbies and hallways use COB strips to create indirect lighting that adds depth and elegance. Bathrooms and mirror surrounds also utilize COB strips for high-quality, shadow-free lighting. In guest rooms, they can be used in headboards or behind furniture to provide low-level ambient lighting.

Malls and retail spaces use strip LED COB lighting to highlight architectural features and merchandise. They are often installed in cove lighting along ceilings to wash walls with light, creating an open and inviting atmosphere. Display cases, signage backlighting, and shelving benefit from the uniform brightness and high color rendering of COB technology, ensuring products appear vibrant and true to color. Staircases and escalator edges can incorporate COB strips for both aesthetic appeal and improved safety. The continuous light beam without visible dots makes COB strips especially effective in high-end retail zones and fashion outlets.

Offices use strip LED COB lighting to enhance both functionality and visual comfort. They are frequently used in suspended ceiling coves to deliver indirect ambient lighting that reduces glare and eye strain. Under-cabinet lighting in workstations or meeting rooms provides focused illumination without harsh shadows. Reception desks and branding walls often use COB strips to create a modern, professional appearance. In open-plan offices, COB strips can be integrated into partition lighting systems or above drop ceilings to maintain a clean, minimalist aesthetic.

When installing strip LED COB lighting, several best practices should be followed to ensure optimal performance and longevity. Always ensure the mounting surface is clean, dry, and flat to allow proper adhesion of the adhesive backing. For long-term reliability, consider using aluminum channels with diffusers, which help dissipate heat and protect the strip from dust and physical damage. Proper heat management is critical because COB strips generate more heat than standard SMD LEDs; overheating can reduce lifespan and light output. Always adhere to the manufacturer’s recommended maximum run lengths and use appropriate power supplies with sufficient wattage capacity. For consistent brightness, especially in long runs, use constant voltage power supplies and consider injecting power at multiple points. Make sure all connections are secure and properly insulated, and use compatible dimmers if dimming functionality is required. Finally, test the installation before finalizing the setup to verify uniform illumination and correct operation.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC Manufacturing Co., Ltd.’s advanced COB LED strip solutions engineered for superior performance and seamless integration. Our proprietary Chip-on-Board technology delivers exceptional lumen density uniformity and thermal management critical for high-end architectural retail and hospitality applications where precision illumination matters. As your dedicated manufacturing partner we provide fully customizable OEM ODM services including bespoke color temperatures dimming protocols and IP-rated profiles backed by rigorous quality control and scalable production capacity.

Partner with Beauty STC to transform your design vision into reality through engineering excellence and responsive collaboration. Contact our technical sales management team directly at [email protected] to discuss your project specifications and receive a tailored solution proposal within 24 hours. Let us help you achieve competitive differentiation through lighting innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.