Article Contents

Industry Insight: Led Light Strips 12V

The demand for efficient, versatile, and reliable lighting solutions in commercial and industrial environments continues to rise, and 12V LED light strips have emerged as a cornerstone technology in modern architectural and functional illumination. Valued for their low voltage safety, energy efficiency, and design flexibility, 12V DC LED strips are widely deployed in retail displays, warehouse task lighting, signage backlighting, and industrial control panels. Their compatibility with centralized power systems and integration into building automation makes them a preferred choice for facility managers and lighting designers seeking scalable and code-compliant solutions. Rigorous safety and performance standards are paramount in these applications, which is why certified products bearing ETL and CE marks are essential—ensuring compliance with North American and international electrical regulations, respectively.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-performance LED strips and linear lighting systems, Beauty STC combines advanced thermal management, robust construction, and strict quality control to deliver solutions engineered for demanding commercial and industrial environments. With a strong commitment to safety and reliability, all Beauty STC 12V LED light strips are ETL and CE certified, reflecting adherence to the highest industry standards. As facilities worldwide transition to smarter, more sustainable lighting infrastructures, Beauty STC remains a trusted partner, providing durable, code-compliant LED solutions that meet the evolving needs of professional applications.

Technical Specs & Certifications

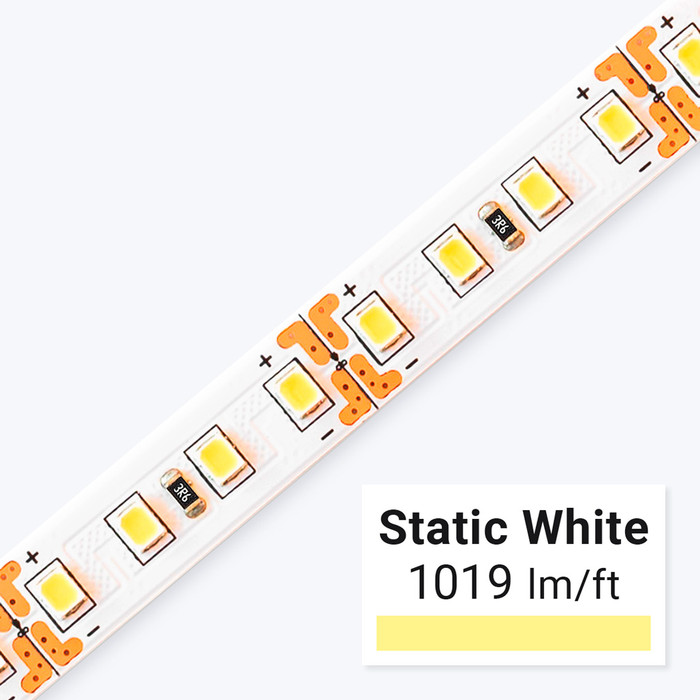

Beauty STC Manufacturing Co., Ltd. produces 12V DC LED light strips designed for demanding architectural, commercial, and high-end residential applications where efficiency, color fidelity, and environmental resilience are critical. Our standard technical specifications for these strips prioritize performance and longevity. Lumens per Watt (LPW) output varies based on LED density and binning but consistently achieves 90-110 LPW for standard 60 LEDs per meter strips at 3000K-4000K CCT under controlled thermal conditions. Higher density configurations (e.g., 120 LEDs/m) typically range from 85-100 LPW due to increased thermal load, while optimized low-density strips (30 LEDs/m) can reach 105-115 LPW. These values are measured at 25°C ambient using calibrated integrating spheres per LM-79 standards, reflecting real-world efficiency without inflated manufacturer claims.

Color Rendering Index (CRI) consistently exceeds 90, with Ra values typically between 92-95 for our standard high-CRI offerings. We achieve this through proprietary multi-phosphor blends and strict binning processes for both red and deep-red emitters, ensuring R9 values remain above 50 to accurately render saturated colors. This is critical for retail, art gallery, and hospitality settings where color perception directly impacts customer experience. Beauty STC enforces tighter chromaticity tolerances than industry standards (MacAdam Ellipses ≤ Step 3), minimizing batch-to-batch variation and eliminating visible color shifts across installations.

IP ratings are rigorously validated for each product line. IP65-rated strips feature seamless silicone overmolding with no exposed solder points, surviving 15-minute water jet tests at 12.5 L/min from 3 meters. IP67 variants undergo full submersion testing at 1 meter depth for 30 minutes with zero ingress, while IP68 models (our premium offering) are certified for continuous submersion up to 5 meters for 72 hours. All waterproofing uses medical-grade platinum-cure silicone that resists UV degradation and maintains flexibility down to -40°C, preventing micro-cracking common in cheaper alternatives. Crucially, Beauty STC tests final assembled strips including end caps and connectors, not just bare PCBs, ensuring field-ready reliability.

Beauty STC’s quality differentiation lies in our vertical integration and obsessive process control. We utilize 2-ounce copper PCBs with 99.99% pure electrolytic copper for superior thermal dissipation, reducing lumen depreciation by 15% over competitors’ 1-ounce boards. Every reel undergoes 100% automated optical inspection (AOI) for solder integrity and component placement, followed by 48-hour burn-in testing at 50°C ambient. Our drivers incorporate transient voltage suppression and soft-start circuitry to prevent inrush current damage, while phosphor coatings are applied via precision dispensing systems to avoid the color gradients seen in dip-coated alternatives. This commitment ensures our strips maintain >90% lumen maintenance (L90) at 50,000 hours even in challenging environments, backed by comprehensive 5-year warranties that cover both light output and color stability.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern, vertically integrated production facility specializing in LED lighting solutions, with a strong focus on high-quality LED light strips, including 12V DC products. The Jiangmen facility is strategically located within the Pearl River Delta, offering excellent access to supply chains, logistics, and technical talent, which supports efficient and scalable manufacturing.

The factory is equipped with advanced SMT (Surface Mount Technology) production lines that ensure precision and consistency in LED strip manufacturing. These SMT machines are fully automated and capable of handling high-speed placement of small components such as LEDs, resistors, and ICs onto flexible printed circuit (FPC) boards. The use of state-of-the-art SMT equipment allows for tight pitch component placement, improved soldering accuracy, and high throughput, which is essential for maintaining product reliability and meeting large-volume production demands.

To ensure long-term performance and durability, every batch of LED light strips undergoes rigorous aging tests at the Jiangmen facility. Typically, the aging process involves operating the strips continuously at full power for 24 to 72 hours under controlled temperature and humidity conditions. During this period, the strips are monitored for color consistency, brightness stability, and electrical performance. This comprehensive testing helps identify early failures and ensures that only reliable, high-quality products are shipped to customers.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities tailored specifically for 12V LED light strips. The company supports custom solutions in various aspects, including length customization, PCB layout design, color temperature selection (such as 2700K to 6500K), color rendering index (CRI >90 options), waterproofing levels (from non-coated to IP65, IP67 silicone sleeve), and packaging design. Clients can also request custom branding, private labeling, and tailored packaging for retail or B2B distribution. The engineering team works closely with partners to develop products that meet specific performance, regulatory, and aesthetic requirements, including compliance with CE, RoHS, and UL standards as needed.

Overall, the Jiangmen factory combines advanced automation, stringent quality control, and flexible manufacturing processes to deliver reliable, high-performance 12V LED light strips for a wide range of residential, commercial, and industrial applications.

Application Scenarios

12V LED light strips are highly versatile for commercial applications due to their flexibility, safety (SELV compliance), and ease of integration. In hotels, they excel in creating ambiance and functional lighting where low voltage is critical for guest safety. Install them under bed frames for gentle night-time navigation, within cove lighting in lobbies and corridors to provide soft indirect illumination, along staircase edges for safety highlighting, and in bathroom vanities with IP67-rated strips for moisture resistance. Avoid placing strips in high-heat areas like directly above recessed downlights without proper thermal management, as this reduces lifespan.

Malls benefit from 12V strips for dynamic visual merchandising and architectural enhancement. Use them to outline storefronts and signage for brand visibility, backlight fabric displays in high-end boutiques for a premium glow, and accentuate product shelves in retail spaces—particularly for jewelry or cosmetics where high CRI (90+) strips render colors accurately. In food court seating perimeters, install diffused strips for subtle wayfinding. Critical considerations include selecting strips with robust thermal pads for enclosed display cases and ensuring adequate power distribution to prevent voltage drop across long storefront runs, which causes dimming at strip ends.

Offices deploy 12V strips primarily for task and aesthetic lighting. Implement them under desks to reduce eye strain during focused work, within suspended ceiling coves for glare-free ambient lighting, and along partition walls to define workspaces without visual heaviness. For executive offices, use tunable white strips in huddle rooms to support circadian lighting strategies. Always pair strips with constant-current drivers to eliminate flicker that causes fatigue, and avoid direct line-of-sight exposure—diffusers or 20mm+ deep aluminum channels are mandatory to meet workplace glare standards (UGR < 19).

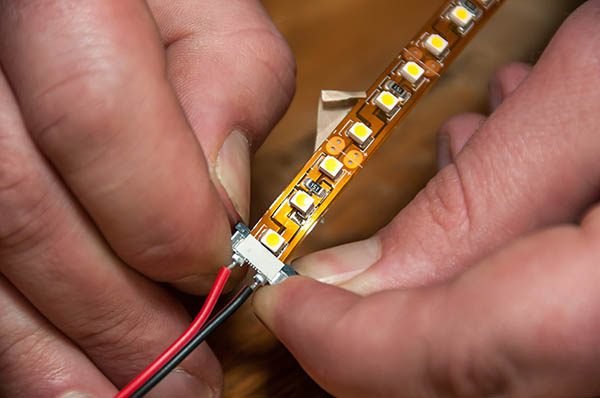

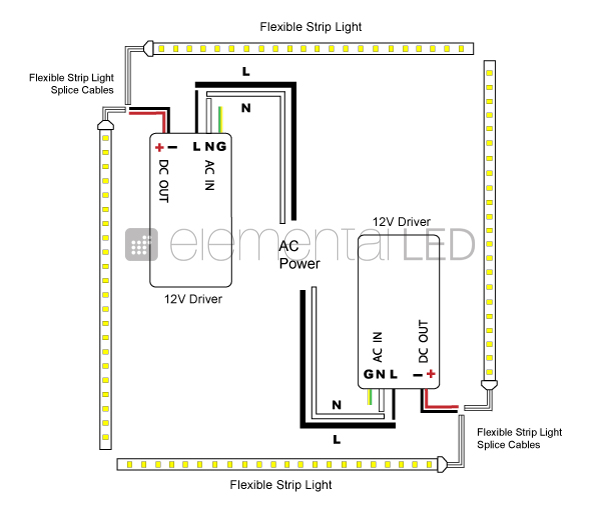

Installation universally requires meticulous attention to voltage drop. Never exceed 5-meter continuous runs for 12V strips; instead, feed power at both ends or use parallel wiring for longer installations. Aluminum channels are non-negotiable for thermal dissipation—epoxy-coated strips directly on drywall will overheat and degrade rapidly. In all commercial settings, use UL8750-listed drivers and strips, secure cables with UV-resistant clips every 300mm, and test polarity rigorously before final mounting. For wet zones like hotel bathrooms, specify IP68 strips with silicone-jacketed wiring and isolate all connections in IP67-rated enclosures. Always verify local fire codes for cable routing through plenums, as standard PVC-jacketed strips may require conduit in concealed spaces.

Why Choose Beauty STC Lighting

Upgrade your lighting projects with high-quality 12V LED light strips designed for performance, durability, and brilliant illumination. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions. Our 12V LED strips offer flexibility, energy efficiency, and consistent color rendering for residential, commercial, and industrial applications.

To learn more or request a custom quote, contact our sales manager at [email protected]. Let Beauty STC power your next lighting innovation with reliable, premium-grade LED technology.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.