Article Contents

Industry Insight: Led Light Strip Ws2812

The WS2812 LED light strip has emerged as a transformative solution in commercial and industrial lighting, offering dynamic color control, high energy efficiency, and seamless programmability for architectural accents, signage, and ambient environment design. Widely adopted in retail spaces, hospitality venues, and large-scale installations, the WS2812’s integrated control IC enables precise pixel-level addressing, making it ideal for creating immersive visual experiences and adaptive lighting environments. With increasing demand for reliable, code-compliant lighting systems, certified products bearing ETL and CE marks have become essential—ensuring electrical safety, electromagnetic compatibility, and adherence to North American and international standards. Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED innovation, delivering high-performance, rigorously tested lighting solutions to global markets. Leveraging over two decades of engineering expertise, Beauty STC combines cutting-edge technology with stringent quality control to provide WS2812 LED strips that meet the demanding requirements of commercial and industrial applications worldwide.

Technical Specs & Certifications

The WS2812 LED light strip, commonly referred to as NeoPixel, utilizes integrated RGB LED-driver ICs within a single 5050 SMD package. It is critical to clarify that lumens per watt, CRI, and IP ratings are not inherent specifications of the WS2812 control IC itself but are determined by the LED package design, phosphor formulation, and manufacturing construction employed by the strip producer. Beauty STC Manufacturing Co., Ltd. addresses these parameters through rigorous engineering choices in our WS2812-based product lines.

Lumens per watt for standard WS2812B strips typically range between 10-14 lm/W when operating at full white output. This efficiency is constrained by the fundamental design of the 5050 RGB LED package, which combines three separate diodes (red, green, blue) without a dedicated white channel. The inherent inefficiency arises from spectral gaps in RGB mixing and thermal limitations of densely packed diodes. Beauty STC optimizes thermal management through 2oz copper PCBs and high-conductivity adhesives, achieving the upper end of this range (13-14 lm/W) in our WS2812B-PRO series, though architectural-grade single-color strips remain significantly more efficient.

Achieving CRI >90 with standard RGB WS2812 strips is physically impossible due to the narrow spectral peaks of red, green, and blue diodes, which lack continuous spectrum coverage. Beauty STC overcomes this limitation in our WS2812B-PRO-WHITE variant by incorporating a fourth phosphor-converted white LED channel (2700K-6500K CCT options) alongside the RGB elements. This hybrid design enables tunable white light with Ra >90 and R9 >50 when operating in white mode, verified by第三方 Intertek LM-79 reports. RGB color mixing remains standard (CRI ~25-40), as is universal across all WS2812 implementations.

IP ratings for Beauty STC WS2812 strips are defined by our encapsulation processes. Our IP20 standard strips feature conformal coating for basic dust resistance. For demanding environments, we offer IP65 strips with silicone overmolding (0.8mm thickness) and IP67 strips with dual-layer TPU jackets, both pass MIL-STD-883H Method 1009.8 salt fog testing for 168 hours. All waterproof variants undergo 100% submersion testing at 1m depth for 24 hours prior to shipment. Critical for marine and outdoor architectural use, our IP67 strips maintain functionality after 500 freeze-thaw cycles (-40°C to 70°C).

Beauty STC differentiates through uncompromising quality controls absent in commodity strips. Every reel undergoes automated optical inspection for dead pixels and color binning to MacAdam Step 3 tolerances. We utilize Nichia and Epitex LED dies exclusively, with 50,000-hour L70 lifetime validation at 50°C ambient. Our strips feature fire-retardant PVC housings meeting UL 94 V-0 and pass IEC 62368-1 safety certification. Most critically, Beauty STC implements 100% functional testing at full brightness for 48 hours per reel, eliminating infant mortality failures common in budget alternatives. This commitment ensures consistent color fidelity, thermal stability, and longevity required for premium architectural and entertainment installations where reliability is non-negotiable.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, which serves as a key production base for its LED lighting products. The factory is designed to support high-volume, precision manufacturing with a strong emphasis on quality control and efficiency. It spans a large production area and integrates advanced automation technologies to meet international standards for electronics and LED product assembly.

At the core of the production line are multiple high-speed SMT (Surface Mount Technology) machines. These machines are capable of placing tiny LED components, drivers, and resistors with high accuracy and speed onto flexible and rigid PCBs used in LED light strips. The SMT lines are fully automated, featuring automatic optical inspection (AOI) systems that detect soldering and component placement errors in real time, ensuring consistent product quality and reliability.

For the production of the ‘LED light strip ws2812’—a popular individually addressable RGB LED strip—the factory has dedicated SMT lines optimized for WS2812B and compatible ICs. The process includes precise stencil printing, component placement, reflow soldering, and post-soldering inspection. The facility also supports both 5V and 12V configurations, various densities (such as 30, 60, or 144 LEDs per meter), and different waterproofing options (IP20, IP65, IP67).

A critical part of quality assurance at the Jiangmen factory is the aging test process. All LED light strips, including the ws2812 models, undergo a 24 to 48-hour continuous aging test under full load and elevated temperature conditions. This ensures early failure detection, stabilizes performance, and verifies the longevity and thermal management of the final product. The aging racks are monitored automatically, with any underperforming units flagged for rework or removal.

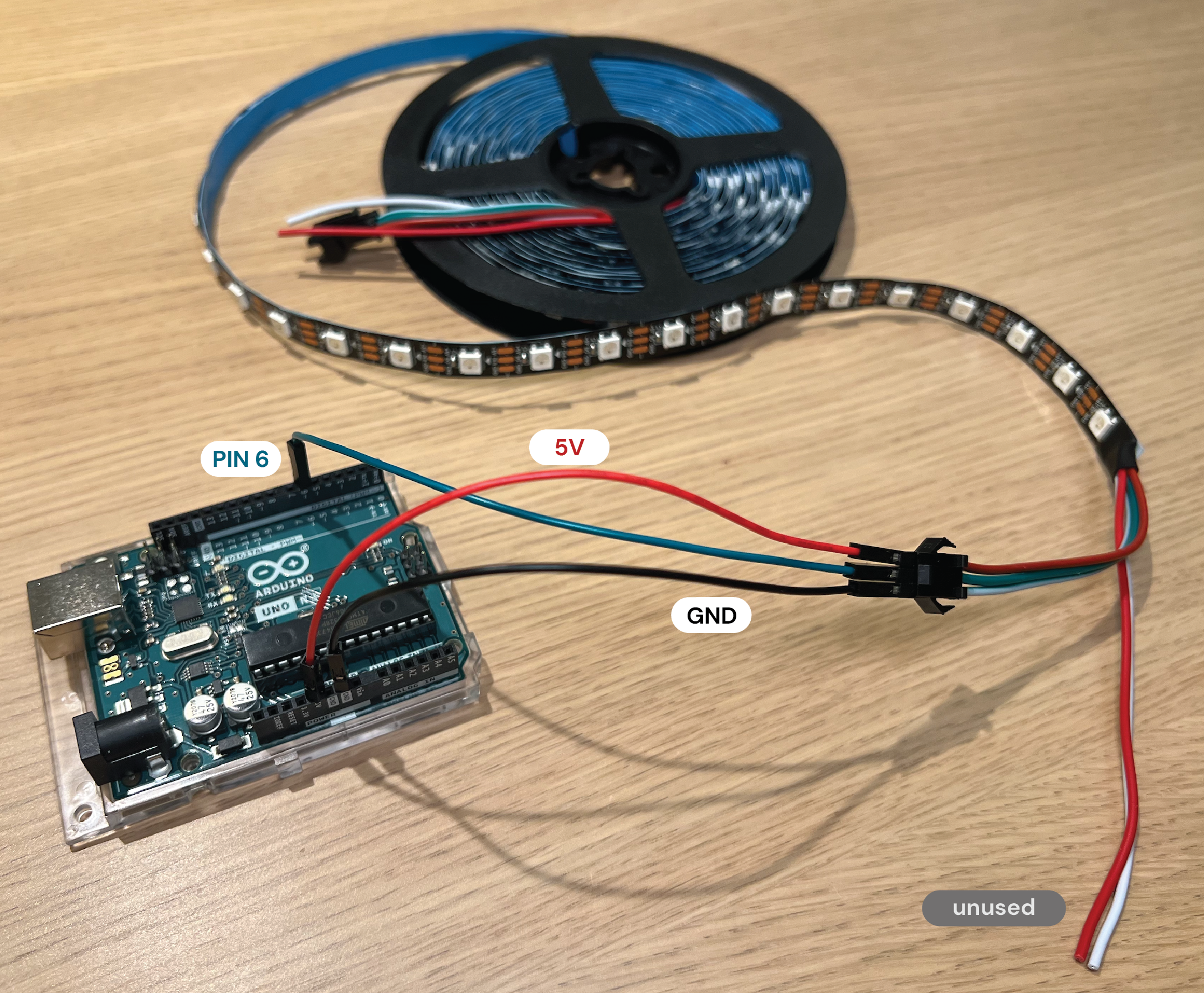

Beauty STC has strong OEM and ODM capabilities for the ‘led light strip ws2812’. The company can customize PCB color, length, density, silicone jacket type, connector types, packaging, and branding per client requirements. Clients can also request firmware customization for addressing protocols, color mixing, or integration with control systems such as Arduino, Raspberry Pi, or commercial lighting controllers. The factory supports small to large MOQs and provides full turnkey solutions from design and prototyping to mass production and logistics.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to advanced manufacturing, scalability, and reliability in the competitive LED lighting market.

Application Scenarios

WS2812 LED light strips excel in commercial environments where dynamic, customizable, and attention-grabbing visual effects are required, rather than general illumination. Their individually addressable RGB pixels make them ideal for creating immersive experiences, brand reinforcement, and architectural accents. In hotels, they are particularly effective for under-cabinet lighting in premium bars or minibars, behind headboards in luxury suites for ambient mood lighting, outlining swimming pool perimeters for color-changing water features, and integrated into reception desk edges or feature walls to create a signature welcome experience. The programmability allows for scenes matching guest preferences or time of day, enhancing perceived value without overwhelming guests with brightness.

Within malls and retail environments, WS2812 strips shine in high-impact visual merchandising applications. Install them inside glass display cases to dynamically highlight featured products with color shifts or chase effects, along the undersides of escalator handrails for safety and visual flow, within column wraps for seasonal campaign animations, and integrated into interactive floor installations where foot traffic triggers color responses. Their precision enables synchronized lighting across large facades or storefronts for events, though careful power management is critical for these expansive runs. Avoid using them for general pathway lighting as their point-source nature creates uneven illumination unsuitable for safe navigation.

Offices present more limited but strategic opportunities for WS2812 technology, primarily confined to branding and reception areas. Implement them subtly within logo backlighting at the main entrance, along the underside of executive lounge bar counters, or as a thin accent line within high-end conference room cove details to signal room status via color. Crucially, avoid any installation in standard workspaces as the RGB capabilities and potential for animation are highly distracting and non-compliant with ergonomic lighting standards for task performance. The focus here should be on static, low-intensity white or brand-color accents only, never dynamic effects in functional areas.

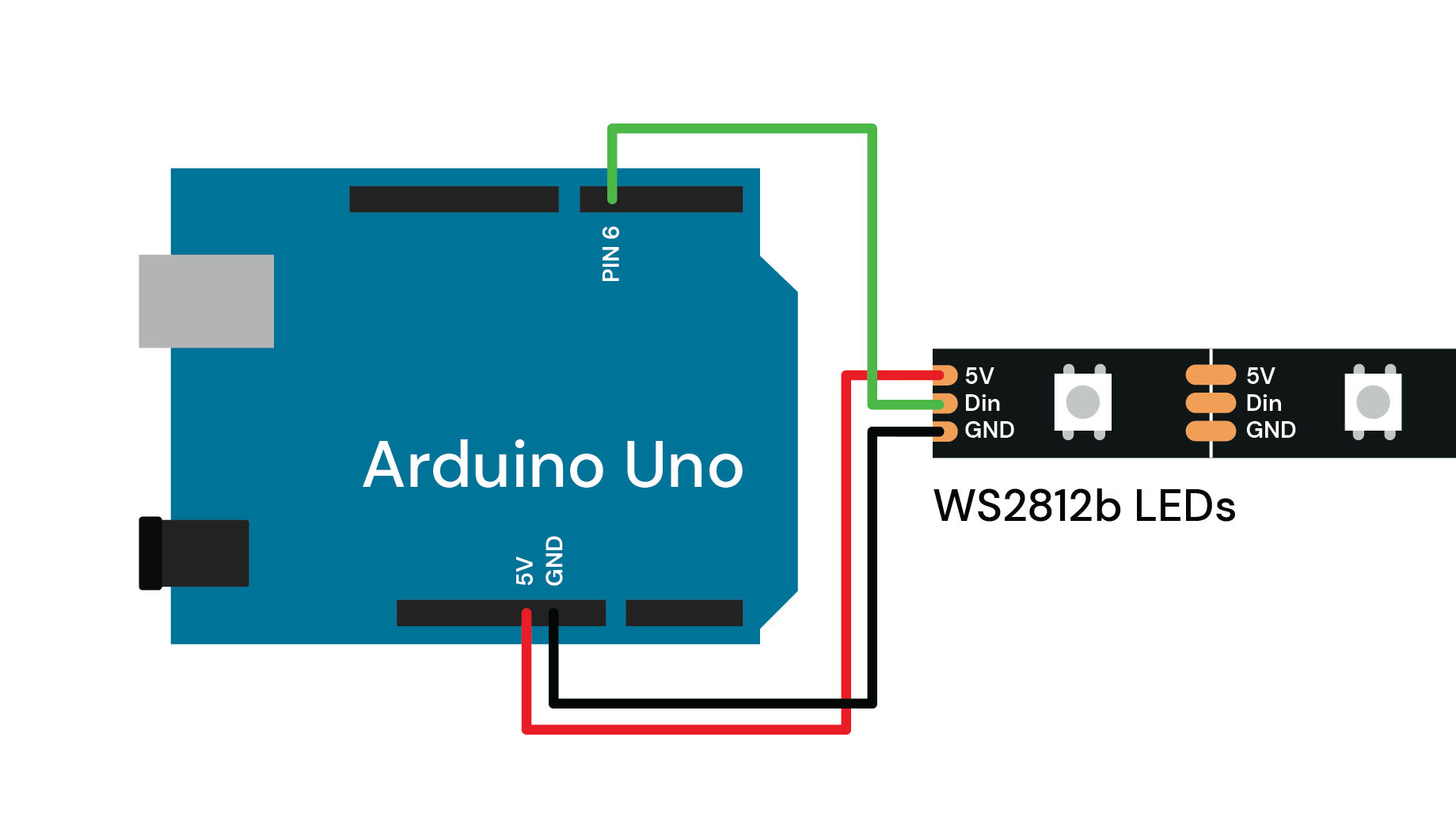

Installation demands meticulous planning to ensure reliability and performance. Always calculate voltage drop meticulously; for runs exceeding 2 meters, implement power injection at both ends and midpoints using 18AWG or thicker wires directly connected to the strip’s 5V and ground pads, never daisy-chained through the strip itself. Mount strips exclusively within aluminum channels with a diffuser to manage heat dissipation and prevent premature LED degradation, especially in enclosed spaces like under hotel headboards. In humid areas such as pool perimeters or mall entrances, use only IP67-rated strips with fully potted LEDs and seal all connector entry points with silicone. Before final mounting, conduct a full 24-hour burn-in test with your control system to identify any faulty pixels. Always pair with a high-quality, constant-voltage power supply rated at 20% above calculated maximum load and ensure all components carry relevant safety certifications like UL or CE for commercial occupancy compliance. Integrate with a robust controller platform that supports commercial protocols like DMX512 or Art-Net for centralized management across large installations.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality LED light strip WS2812 solutions from Beauty (STC) Manufacturing Co., Ltd. As a trusted partner in the LED industry, we deliver reliable, vibrant, and customizable smart lighting products designed to meet the demands of residential, commercial, and industrial applications.

Partner with Beauty STC to benefit from OEM/ODM support, competitive pricing, and dedicated engineering assistance. Whether you’re scaling up production or launching a new product line, our WS2812 LED strips offer superior performance, seamless integration, and consistent color control.

Contact us today to discuss your requirements and explore a long-term partnership. Reach our sales manager at [email protected] and take the first step toward brighter, smarter lighting solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.