Article Contents

Industry Insight: Neon Diffuser

The commercial and industrial lighting sector continues its decisive shift from traditional glass neon signage towards advanced LED-based solutions, driven by demands for energy efficiency, durability, and versatile design. Central to this evolution is the critical role of the neon diffuser – the specialized optical component that transforms discrete LED points into the smooth, continuous, and visually appealing glow synonymous with the neon aesthetic. Modern commercial applications, from retail storefronts and hospitality venues to large-scale architectural installations and industrial wayfinding, require diffusers engineered not just for visual quality but for rigorous performance under demanding conditions. Safety and compliance are paramount in these settings, making ETL certification for North American markets and CE marking for Europe non-negotiable requirements, ensuring products meet stringent electrical safety and electromagnetic compatibility standards. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this transition. We leverage over two decades of dedicated expertise in optical engineering and LED system integration to develop neon diffuser solutions specifically tailored for the exacting needs of commercial and industrial lighting professionals, prioritizing consistent light distribution, material longevity, and seamless compliance with global safety directives.

Technical Specs & Certifications

The neon diffuser lighting solutions manufactured by Beauty (STC) Manufacturing Co., Ltd. are engineered to deliver high-performance illumination with an emphasis on energy efficiency, color accuracy, and environmental protection. These linear LED diffused systems are designed to emulate the soft, continuous glow of traditional neon while offering modern solid-state lighting advantages.

In terms of efficiency, Beauty STC’s neon diffuser products achieve a luminous efficacy ranging from 100 to 130 lumens per watt, depending on configuration and color temperature. This high lumen-to-watt ratio ensures optimal energy consumption, making them ideal for both commercial and architectural lighting applications where long operating hours demand efficiency without compromising brightness.

Color quality is a hallmark of Beauty STC’s neon diffusers, with all premium models featuring a Color Rendering Index (CRI) greater than 90. This high CRI ensures accurate and vibrant color representation, making these lights suitable for retail environments, art installations, and hospitality settings where visual appeal is critical. Some variants are also available with R9 values exceeding 50, further enhancing red tone rendering for a more natural light spectrum.

Regarding environmental protection, Beauty STC offers neon diffuser systems with IP65 and IP67 ratings as standard. The IP65 rating provides complete dust protection and resistance to low-pressure water jets from any direction, making it suitable for indoor and semi-outdoor environments. The IP67 rating extends protection to temporary immersion in water up to 1 meter, allowing reliable performance in demanding outdoor or high-moisture areas such as signage, facade lighting, and under-canopy installations.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout production, utilizing high-grade polycarbonate or silicone diffusers that ensure uniform light distribution without hotspots. Combined with high-quality LED chips and robust driver integration, their neon diffusers offer long lifespans exceeding 50,000 hours with minimal lumen depreciation. All products undergo stringent photometric, thermal, and environmental testing, reflecting Beauty STC’s commitment to durability, safety, and consistent optical performance in real-world conditions.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is located in the Jiangmen National High-Tech Industrial Development Zone in Guangdong Province, China. This strategically positioned factory spans over 50,000 square meters and serves as the company’s central hub for LED lighting production, integrating advanced automation with stringent quality control systems under ISO 9001 and ISO 14001 certifications. The facility is designed for high-volume output while maintaining flexibility for custom OEM projects, featuring dedicated cleanrooms for sensitive electronics assembly and climate-controlled testing environments.

The surface mount technology (SMT) production lines form the backbone of our electronics manufacturing capability. We operate eight fully automated SMT lines, primarily utilizing Yamaha YS series placement machines known for their precision and speed. These lines handle components down to 0201 package size and support multi-layer PCB assembly for complex LED drivers and control systems. Each line integrates automatic optical inspection (AOI) stations immediately post-reflow to verify solder joint integrity and component placement accuracy, ensuring defect rates remain consistently below industry benchmarks. The SMT capacity supports daily production of over 1.5 million LED modules, with real-time data monitoring tracking process parameters like reflow thermal profiles and pick-and-place nozzle performance.

Aging and reliability testing represent a critical phase in our quality assurance protocol. All finished LED products undergo mandatory aging procedures in our dedicated environmental testing wing. Standard aging involves continuous operation at 110% of rated voltage for 24 hours under controlled 40°C ambient conditions, with automated systems monitoring lumen output, color consistency, and thermal performance. For premium product lines and specific client requirements, we implement extended 48-hour aging cycles with periodic photometric measurements. Our aging chambers incorporate thermal imaging cameras to detect localized overheating issues, and we maintain detailed failure mode databases to drive continuous process improvement. This rigorous testing ensures field failure rates remain below 0.3% across our product portfolio.

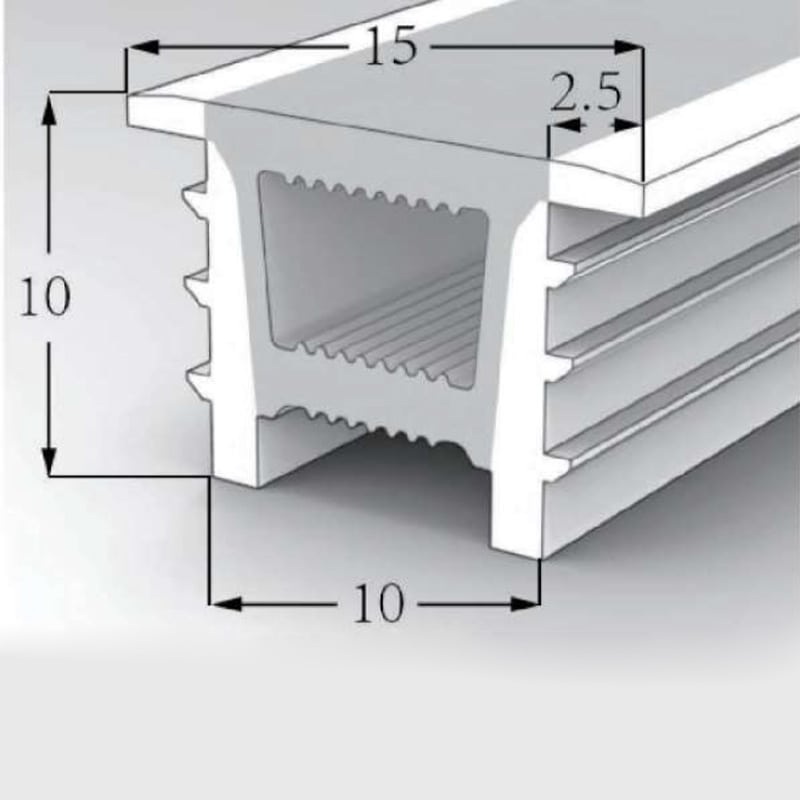

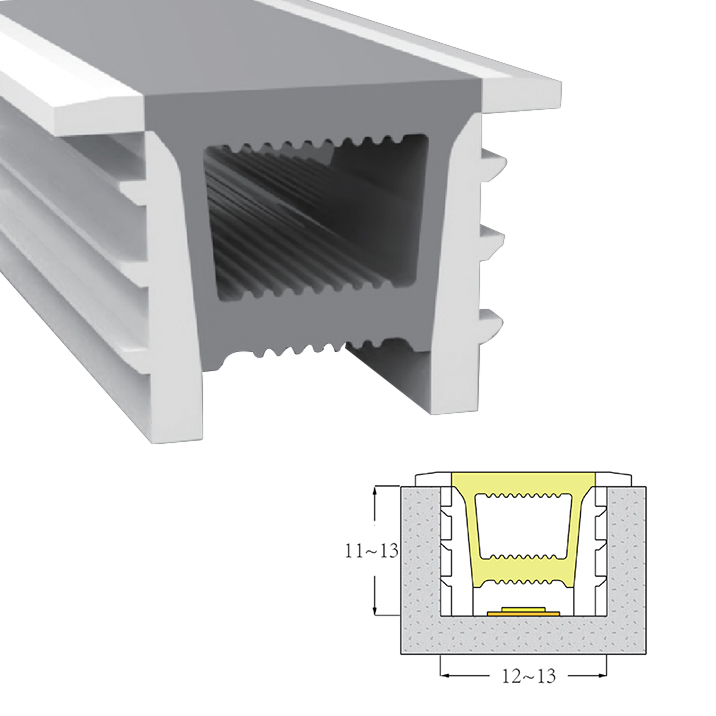

Regarding OEM capabilities for neon diffusers, our Jiangmen factory excels in custom linear lighting solutions. We possess in-house extrusion capabilities for producing polycarbonate and acrylic diffuser profiles in various cross-sections, including the signature flexible “neon” silicone alternatives. Our OEM service includes full customization of color temperature (1800K-6500K), CRI (Ra>90 standard), length (up to 5 meters continuous), and bending radius (minimum 50mm). The diffuser production process features spectral matching using Konica Minolta spectroradiometers to achieve precise color consistency, with custom diffuser opacities developed through proprietary particle dispersion techniques. We support clients from prototyping through volume production, providing UL/ETL-listed diffuser solutions with IP65-rated options and integrated mounting systems. Recent OEM projects include custom architectural cove lighting for hospitality chains and tunable-white diffusers for healthcare applications, all manufactured under our documented change control procedures.

Application Scenarios

Neon diffusers are commonly used in environments where aesthetic lighting design plays a crucial role in enhancing ambiance and visual appeal. They are ideal for concealing LED neon flex or strip lights while providing a soft, uniform glow that mimics traditional glass neon signage. Here are typical applications across different settings:

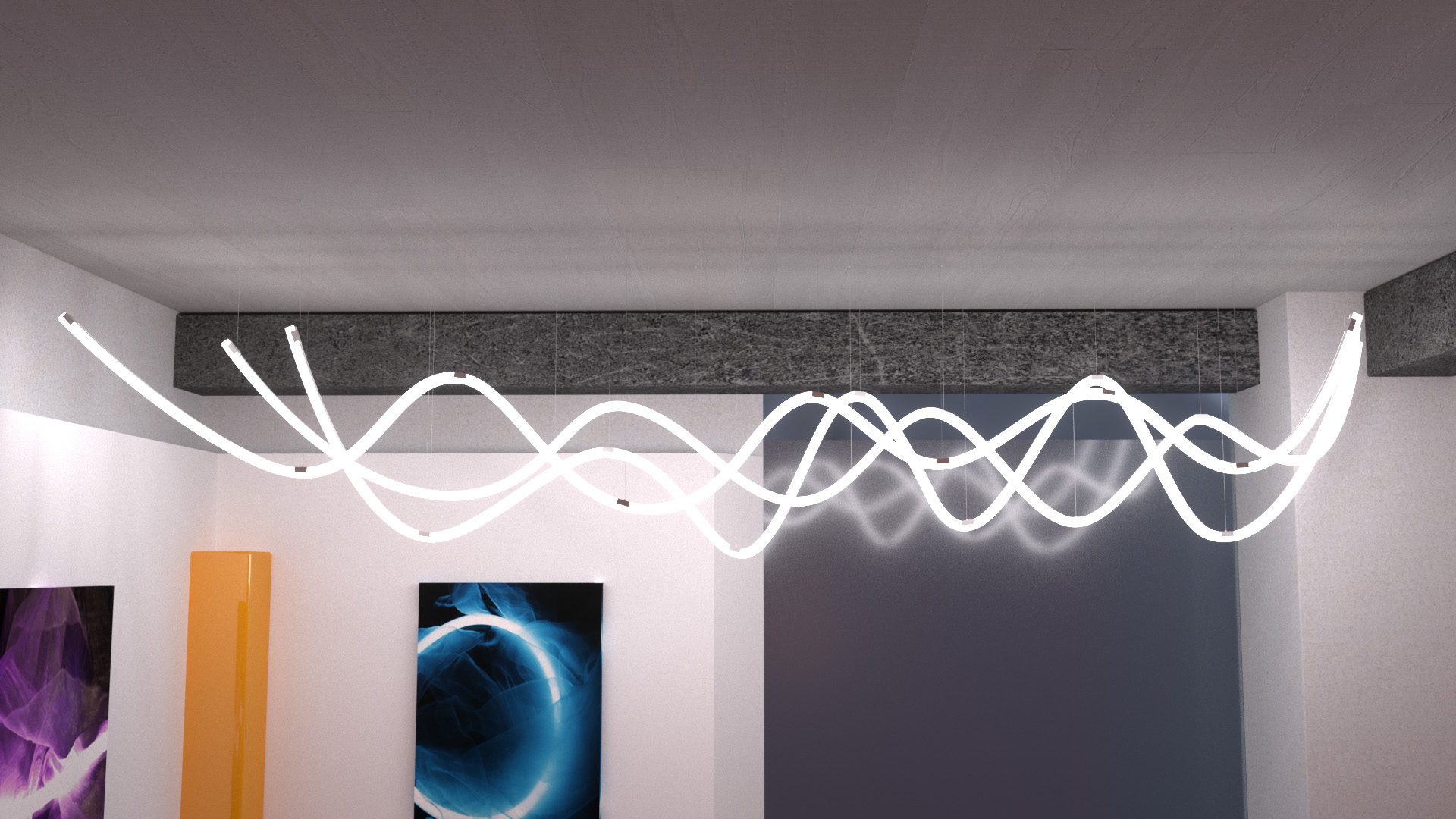

In hotels, neon diffusers are frequently used in lobbies, lounges, bars, hallways, and guest corridors to create a warm and inviting atmosphere. They are often integrated into architectural features such as coves, recessed ceilings, or custom signage to highlight branding or design elements. The diffuser helps eliminate hotspots from individual LEDs, ensuring a seamless light output that enhances the luxury feel of the space.

Shopping malls utilize neon diffusers in signage for retail stores, food courts, and directional wayfinding systems. The diffuser enables consistent brightness and color rendering, which is essential for brand visibility and attracting foot traffic. They are also used in decorative ceiling installations and feature walls to create dynamic lighting effects that contribute to the overall shopping experience.

In office environments, neon diffusers are typically applied in reception areas, conference rooms, and breakout zones to add a modern, professional touch. While general office lighting prioritizes functionality, neon diffusers allow for creative accent lighting that reflects company culture without causing glare or visual discomfort. They can be used to illuminate logos or brand colors subtly.

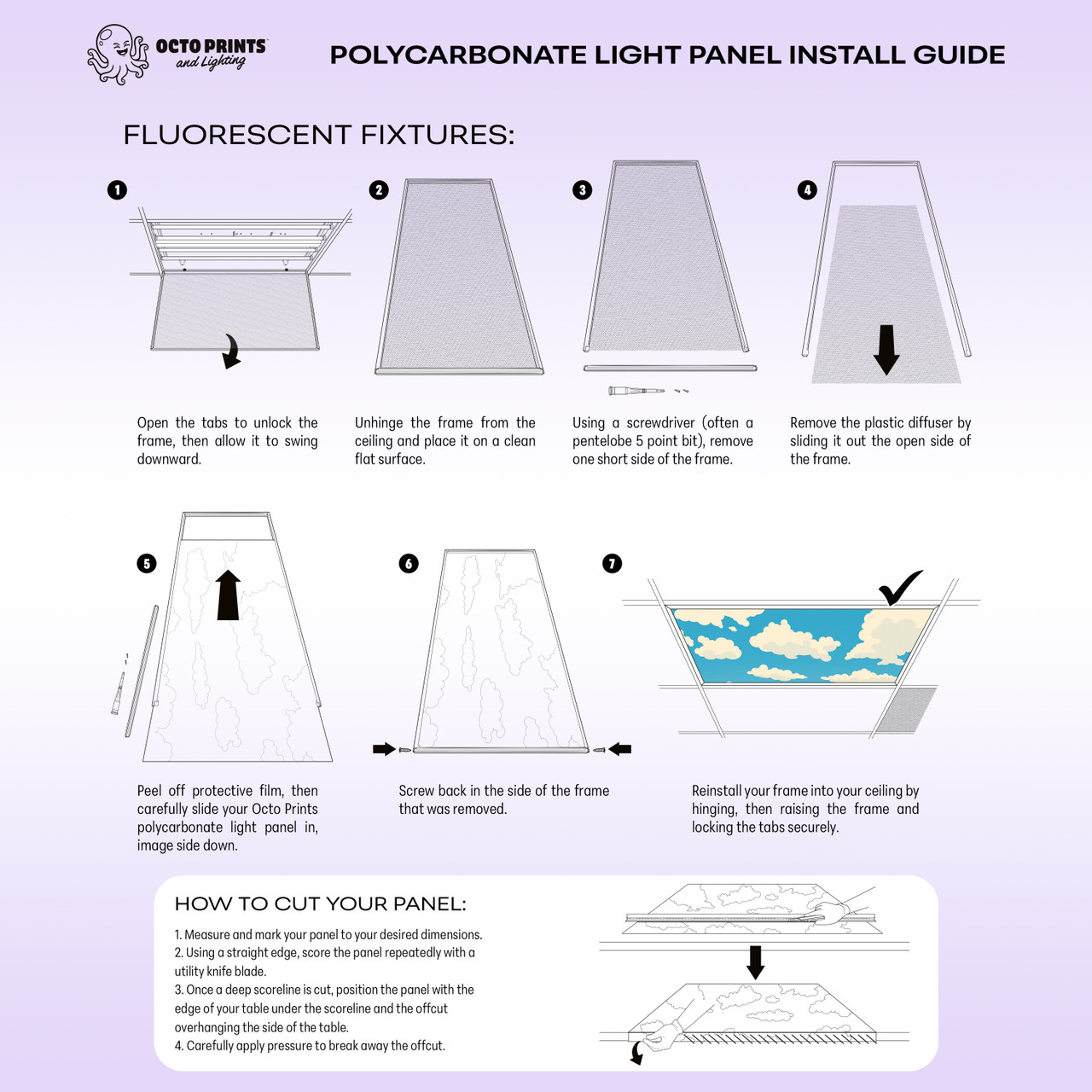

When installing neon diffusers, it is important to ensure the supporting structure is stable and properly aligned. Begin by measuring and cutting the diffuser profile to match the layout of the LED neon flex. Use compatible mounting clips or brackets at regular intervals—typically every 30 to 50 cm—to prevent sagging, especially in longer runs. Make sure the LED strip is centered within the diffuser to achieve even light distribution. For corner installations, heat the diffuser gently with a heat gun to bend it smoothly without cracking. Always clean the diffuser surface before final installation to avoid dust marks that could affect light clarity. Finally, ensure all electrical connections are secure and comply with local safety standards, particularly in public or high-traffic areas.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium neon diffuser solutions, engineered for exceptional performance and reliability in demanding commercial and architectural applications. Our advanced silicone-based diffusers deliver uniform, flicker-free illumination with a true neon aesthetic while maintaining superior durability against UV degradation, temperature fluctuations, and physical impact. As your dedicated manufacturing partner, we offer fully customizable profiles including precise color temperature matching, bespoke dimensions, and integrated mounting systems to seamlessly align with your design specifications and production timelines.

Partner with Beauty STC to leverage our 15 years of specialized LED extrusion expertise and ISO-certified manufacturing processes that ensure consistent optical clarity and thermal management. We collaborate closely with lighting designers and OEMs to solve complex challenges such as minimizing hotspots in curved installations or achieving IP67-rated weather resistance for outdoor signage without compromising light diffusion quality. Our engineering team provides comprehensive technical support from prototype validation through to volume production, guaranteeing your neon lighting products meet rigorous global safety and performance standards.

Contact our Lighting Solutions Manager today at [email protected] to discuss how our neon diffuser technology can enhance your next project with unmatched quality and innovation. Include your specific application requirements and volume expectations in your inquiry to receive a tailored technical consultation and sample kit within 48 hours. Let Beauty STC transform your vision into brilliantly illuminated reality.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.