Article Contents

Industry Insight: Led Tape Suppliers

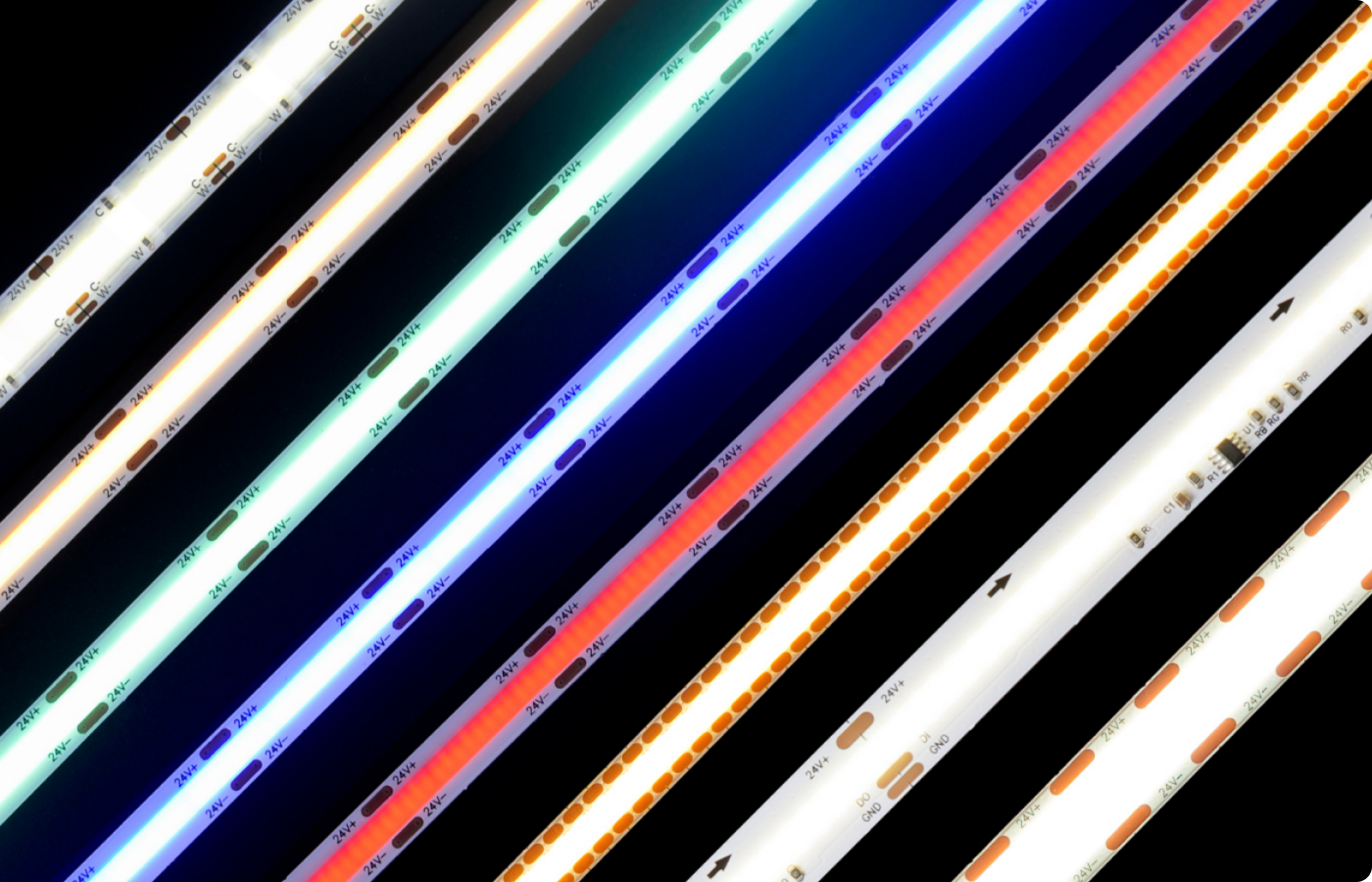

The commercial and industrial lighting sector continues to evolve with a growing emphasis on energy efficiency, durability, and design flexibility—key attributes that LED tape lighting delivers in abundance. As architects, engineers, and facility managers seek adaptable and high-performance illumination solutions, the demand for reliable LED tape suppliers has surged across applications ranging from retail environments and office spaces to manufacturing plants and cold storage facilities. In this competitive landscape, compliance with international safety and performance standards such as ETL and CE has become a critical differentiator, ensuring that products meet rigorous electrical, thermal, and environmental requirements for safe operation in demanding settings.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its founding in 1998. With over two decades of engineering excellence, Beauty STC has established itself as a leading supplier of high-quality LED tape solutions designed specifically for commercial and industrial applications. Combining robust construction, consistent lumen output, and full compliance with ETL and CE certifications, Beauty STC’s product lines offer system integrators and lighting designers the confidence of performance and reliability in even the most challenging environments. As the industry moves toward smarter, more sustainable lighting ecosystems, Beauty STC remains committed to advancing technology while maintaining the strict quality standards that global clients depend on.

Technical Specs & Certifications

LED tape suppliers must meet stringent technical specifications to serve high-end architectural, retail, and hospitality applications where color fidelity, efficiency, and durability are critical. For lumen output per watt (lm/W), industry-standard high-performance LED tapes with CRI >90 typically achieve 120–140 lm/W under controlled laboratory conditions at 25°C ambient temperature. This range balances efficacy with the optical and thermal compromises inherent in high-CRI binning. Suppliers claiming values exceeding 140 lm/W at CRI >90 should be scrutinized for test conditions, as pushing efficacy beyond this threshold often sacrifices color rendering or long-term lumen maintenance. Drive current density, thermal management in the tape design, and LED chip architecture directly influence this metric, with lower drive currents generally preserving CRI but reducing lm/W.

Color Rendering Index (CRI) exceeding 90 is non-negotiable for premium applications requiring accurate color representation. Suppliers must provide TM-30-19 metrics alongside CRI (Ra), particularly emphasizing R9 (saturated red) values above 50 and Rf (fidelity index) above 80. Achieving consistent CRI >90 requires tight binning of LEDs across all chromaticity quadrants, typically within a 3-step MacAdam ellipse (SDCM ≤3) for uniformity. Many budget suppliers achieve nominal CRI >90 but exhibit poor R9 or R12 values, resulting in unnatural skin tones or muted reds—a critical flaw in retail or beauty environments. Reputable suppliers validate CRI through third-party LM-79 testing and provide spectrometer reports, not just datasheet claims.

IP ratings define environmental resilience, with IP65 being the baseline for outdoor or high-moisture indoor use (e.g., cove lighting in bathrooms). True IP65 compliance requires full 360° silicone encapsulation, not just top-side coating, to prevent moisture ingress at solder joints or cut points. Suppliers must demonstrate compliance via IEC 60529 testing reports, as field failures often occur due to inadequate edge sealing or silicone delamination. For submerged applications (e.g., pool perimeters), IP67 or IP68 ratings are essential, demanding rigorous pressure testing at specified depths and durations. Note that IP ratings apply only to the tape itself; connectors and power supplies require separate certification.

At Beauty STC, we exceed these benchmarks through engineered quality control. Our Architectural Series LED tapes deliver 145+ lm/W at CRI >92 (with R9 >75 and Rf >85) using Samsung LM301H EVO or Nichia 219F chips, validated by Intertek LM-79 reports. We enforce SDCM ≤2 binning across production lots and subject every reel to 100% photometric verification. For IP protection, our double-layer silicone overmolding process—tested to 10,000 hours of 85°C/85% RH exposure—ensures IP65 integrity even after repeated flexing or cutting, eliminating the edge-peeling failures common in single-coat alternatives. This is backed by a 5-year warranty and LM-80/TM-21 lumen maintenance data projecting >90% output at 50,000 hours. Unlike commodity suppliers, Beauty STC integrates thermal vias in our flexible PCBs and uses 3 oz copper for optimal heat dissipation, directly enabling sustained high efficacy and color stability under real-world operating conditions.

Factory Tour: Manufacturing Excellence

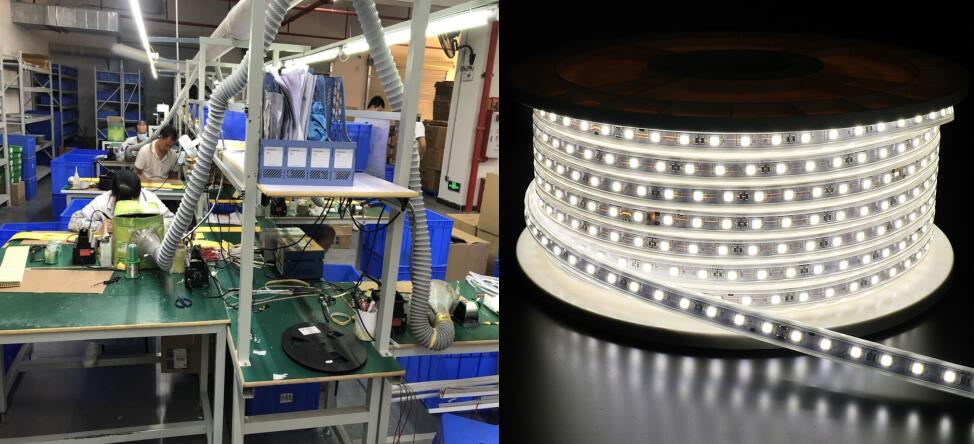

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial regions. The Jiangmen factory is purpose-built for the efficient and high-quality production of LED lighting products, with a strong focus on innovation, reliability, and scalability to meet both domestic and international market demands.

At the core of the factory’s production capabilities are advanced SMT (Surface Mount Technology) lines. These state-of-the-art SMT machines ensure precise and automated placement of LED components onto flexible and rigid PCBs used in LED tape production. The facility utilizes high-speed, multi-head SMT equipment capable of handling a wide range of component sizes and densities, supporting high-volume manufacturing while maintaining tight tolerances and consistent quality. These systems are integrated with automated optical inspection (AOI) to verify soldering accuracy and component alignment, minimizing defects and ensuring superior product reliability.

Comprehensive aging and reliability testing is a standard part of the manufacturing process at the Jiangmen plant. Completed LED tape reels undergo rigorous aging tests under controlled thermal and electrical conditions, typically running at full power for extended periods—commonly 24 to 72 hours. This process helps identify early-life failures, validates thermal management performance, and ensures long-term stability before products are shipped. Additional testing includes waterproof verification (for IP-rated tapes), color consistency checks, and photometric measurements using integrating spheres and spectrometers.

Beauty STC has strong OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities tailored specifically for LED tape suppliers and lighting brands. The company supports custom solutions including bespoke LED densities, color temperatures, CRI options, special coatings (such as silicone or PVC), and custom packaging formats. Clients can leverage Beauty STC’s in-house R&D team for circuit design, thermal engineering, and compliance testing to meet global standards (such as CE, RoHS, UL, and CCC). With flexible production runs, from small batches to large-scale orders, the Jiangmen factory is well-equipped to serve private-label partners seeking high-quality, reliable, and competitively priced LED tape solutions.

Application Scenarios

LED tape suppliers are critical partners for commercial lighting projects in hotels, malls, and offices, where specific aesthetic, functional, and durability requirements must be met. In hotels, LED tape is extensively used for cove lighting in lobbies and corridors to create welcoming ambient illumination, under-bar counter accents in restaurants and lounges for visual appeal, within wardrobe interiors for guest convenience, and along stair edges or pathways for subtle safety lighting. The emphasis here is on high color rendering for accurate skin tones and fabrics, smooth dimming for mood transitions, and consistent color temperature across vast installations to maintain a premium brand image. Suppliers must provide rigorously binned LEDs and robust IP-rated options for humid areas like spas or pool surrounds.

For malls and retail environments, LED tape applications focus on high-impact visual merchandising and architectural enhancement. Key uses include illuminating product displays within kiosks or window fronts to highlight textures and colors, creating dynamic ceiling features in food courts or common areas, outlining column wraps for wayfinding, and integrating into suspended signage for brand visibility. Malls demand suppliers capable of delivering large volumes with exceptional batch-to-batch color consistency, high lumen output for vibrant displays, and flexible configurations for curved or irregular surfaces. Durability against foot traffic vibrations and resistance to ambient heat from lighting fixtures are non-negotiable, alongside compliance with stringent fire safety standards like UL 2108 for enclosed installations.

Offices leverage LED tape for both functionality and well-being, primarily in under-cabinet task lighting in workstations to reduce eye strain, within partition walls to soften harsh lines and improve spatial perception, along ceiling perimeters for glare-free indirect lighting, and in meeting rooms for presentation accent zones. Here, suppliers must prioritize flicker-free performance to prevent fatigue, tunable white options for circadian rhythm support, and easy integration with building management systems. Offices also require clean, professional finishes with minimal visible joints, necessitating suppliers who offer precise cut points and reliable end-to-end connectors for seamless runs. Thermal management is crucial in confined office spaces, so aluminum channel compatibility and low-heat-output tapes are essential.

Installation in these settings requires meticulous planning beyond residential applications. Always verify the supplier’s technical documentation for voltage drop calculations over long runs, as commercial spaces often exceed 5-meter circuits; use constant-voltage power feeds at multiple points or step-up drivers to maintain brightness uniformity. Aluminum mounting channels are mandatory—not optional—to dissipate heat and prevent premature lumen depreciation, especially in enclosed coves or above false ceilings where ambient temperatures rise. For hotels and offices, ensure all tapes and power supplies carry the appropriate regional safety certifications like CE, UL, or CCC, with fire-rated tapes (e.g., IEC 60598-1 compliant) mandatory in mall ceiling voids. When cutting tapes, strictly adhere to the designated cut marks to avoid circuit damage, and use manufacturer-recommended solderless connectors to maintain IP ratings in humid zones. Finally, conduct thorough photometric validation post-installation; commercial projects require lux level consistency within 10% across large areas, which depends on the supplier’s binning accuracy and your adherence to spacing guidelines. Partnering with a supplier like Beauty (STC) Manufacturing Co., Ltd., which provides detailed installation support and project-specific engineering data, mitigates risks in these high-stakes environments.

Why Choose Beauty STC Lighting

Looking for reliable LED tape suppliers? Partner with Beauty STC, a trusted manufacturer with years of expertise in high-quality LED lighting solutions. We specialize in producing durable, efficient, and versatile LED tape lights for residential, commercial, and industrial applications. Our commitment to innovation and excellence ensures you receive products that meet international standards and exceed expectations.

As a global supplier, Beauty STC offers competitive pricing, custom OEM services, and consistent product performance. Whether you’re a distributor, contractor, or brand looking for a long-term manufacturing partner, we are ready to support your needs.

Contact us today to discuss your project and discover how we can help grow your business. Reach out to our sales manager at [email protected] for inquiries, quotes, or technical support. Let Beauty STC illuminate your success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.