Article Contents

Industry Insight: Rgbw Led Tape

RGBW LED tape lighting has emerged as a transformative solution in commercial and industrial lighting, offering unparalleled flexibility in color control, energy efficiency, and design adaptability. As architects, engineers, and facility managers seek smarter and more customizable lighting systems, RGBW technology—integrating red, green, blue, and white LEDs into a single strip—delivers dynamic ambient lighting, high-quality white light output, and precise color tuning for a wide range of applications. From retail environments and hospitality spaces to manufacturing facilities and architectural highlights, RGBW LED tapes provide a scalable and low-maintenance lighting option that supports both aesthetic vision and operational performance.

In regulated commercial and industrial markets, compliance is critical. Leading RGBW LED tape products are certified to meet rigorous safety and performance standards, including ETL listing and CE marking, ensuring they adhere to North American and European electrical, safety, and electromagnetic compatibility requirements. These certifications not only validate product reliability but also facilitate seamless integration into large-scale installations where code compliance and long-term durability are paramount.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovation in LED lighting solutions for over two decades. Specializing in high-performance flexible LED tapes, including advanced RGBW systems, Beauty STC combines engineering excellence with stringent quality control to serve global commercial and industrial clients. With a commitment to sustainability, product longevity, and regulatory compliance, Beauty STC continues to set industry benchmarks through technically superior, code-compliant lighting solutions trusted by professionals worldwide.

Technical Specs & Certifications

RGBW LED tape represents a sophisticated evolution beyond standard RGB systems by incorporating a dedicated white LED channel alongside the traditional red, green, and blue channels. This configuration enables precise, high-fidelity white light output and expanded color mixing capabilities, critical for professional architectural and commercial applications where color accuracy and light quality are paramount. At Beauty STC Manufacturing Co., Ltd., our RGBW LED tape products are engineered to exceed industry benchmarks, with particular emphasis on efficiency, color rendering, and environmental resilience.

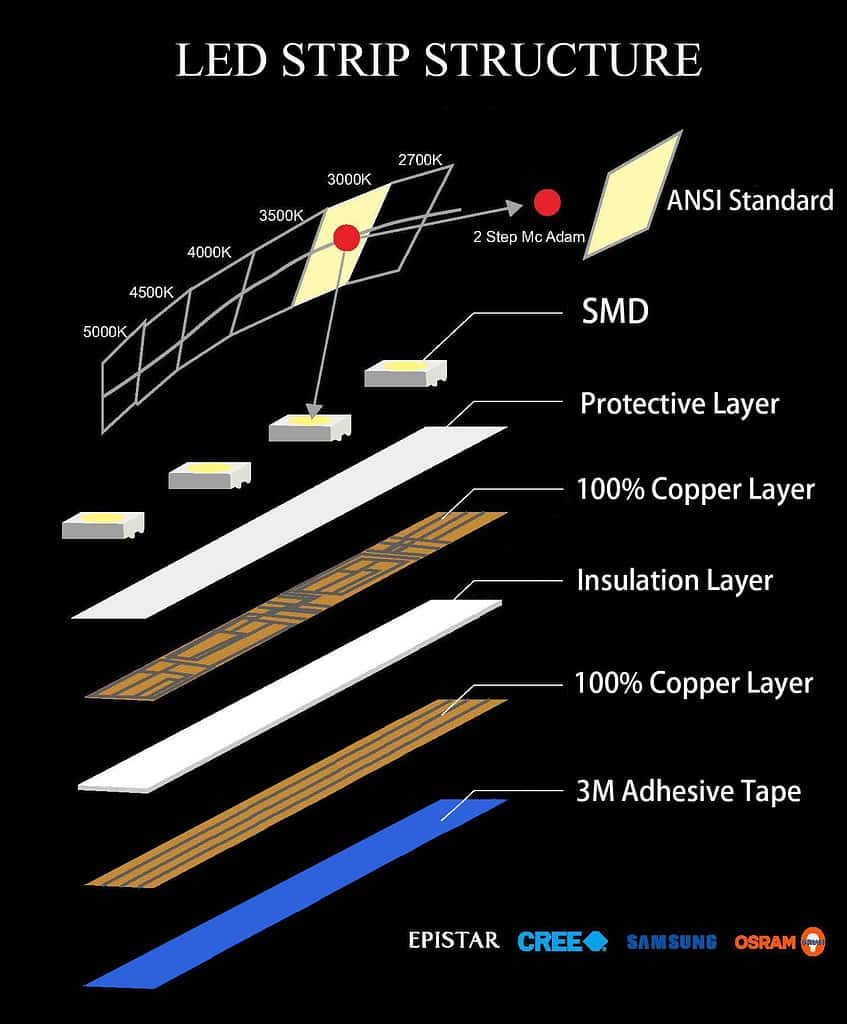

Lumens per Watt (lm/W) performance in RGBW tape requires careful interpretation due to the dual-light-source nature. The white channel (typically 2700K to 6500K CCT) operates independently from the RGB channels, resulting in distinct efficiency metrics. Beauty STC’s high-CRI white channels achieve 85-100 lm/W at 25°C ambient, utilizing premium 2835 or 3535 SMD LEDs with optimized phosphor blends. The RGB channels inherently exhibit lower efficacy (typically 40-70 lm/W) due to spectral conversion losses, especially in deep red and blue wavelengths. Crucially, published lm/W figures often reference only the white channel; our technical documentation transparently specifies efficacy for both white and full-color operation under standardized testing conditions (IEC 62612), ensuring realistic project planning. System-level efficiency is further enhanced through our proprietary constant-current drivers and low-resistance copper PCB designs, minimizing thermal derating even at 5-meter reel lengths.

Achieving CRI >90 is non-negotiable for Beauty STC’s professional-grade RGBW tape. This specification applies exclusively to the dedicated white channel, as CRI is undefined for saturated RGB colors. Our solution employs rigorously binned 90+ CRI (Ra≥92) and R9≥50 white LEDs, predominantly utilizing Nichia or Seoul Semiconductor diodes with violet-pump technology for superior spectral continuity. The R9 value (saturated red rendering) is prioritized above industry averages, critical for retail and hospitality settings where skin tones and merchandise appear natural. RGB channel performance is validated through MacAdam Ellipse steps (≤3 SDCM) to ensure color consistency across reels. Every production batch undergoes spectroradiometric verification per CIE 15:2018, with calibration against NIST-traceable equipment, guaranteeing that the Ra>90 specification is consistently met in real-world installations—not just under ideal lab conditions.

IP ratings for RGBW tape are intrinsically linked to installation methodology and material integrity. Beauty STC offers IP20 (basic insulation), IP65 (silicone-jacketed for damp locations), and IP67 (fully potted for temporary submersion) variants. Our IP65/IP67 tapes utilize dual-layer silicone encapsulation: a primary conformal coating over the PCB followed by an extruded silicone jacket with UV stabilizers. This prevents delamination and moisture ingress at cut points—addressing a common industry failure point—while maintaining flexibility. Rigorous validation includes 500-hour salt spray testing (ASTM B117) and thermal cycling (-40°C to +70°C) to simulate 5+ years of harsh environmental exposure. It is critical to note that IP67 integrity requires proper end-cap sealing during installation; our kits include patented silicone end seals with integrated strain relief, certified to maintain rating after 10+ mating cycles.

Beauty STC’s quality differentiation stems from vertical integration and uncompromising process control. We source semiconductor dies directly from tier-1 LED manufacturers, implement automated optical inspection (AOI) at 30-micron resolution during SMT assembly, and enforce 72-hour pre-aging burns at 60°C. Our thermal management strategy—featuring 2oz copper PCBs and thermally conductive adhesives—ensures lumen maintenance of L90/B10 >50,000 hours at 45°C ambient, significantly outperforming competitors reliant on thinner substrates. Every reel ships with a traceable quality passport detailing bin codes, test reports, and compliance certificates (UL 8750, CE, RoHS). Backed by a 5-year warranty—the industry’s most robust commitment—Beauty STC RGBW tape delivers the reliability demanded by high-end projects where lighting is integral to brand experience, not merely illumination. This holistic approach to engineering, from semiconductor selection to field validation, defines our leadership in professional LED solutions.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The factory is designed to support high-efficiency manufacturing processes with a strong focus on quality control, automation, and scalability to meet both domestic and international market demands.

At the core of the production line are advanced SMT (Surface Mount Technology) machines that ensure precise and reliable placement of LED components onto flexible printed circuits used in LED tapes. These SMT lines are fully automated, featuring high-speed pick-and-place machines, precision stencil printers, reflow soldering systems, and AOI (Automated Optical Inspection) units. This setup allows for consistent production of high-density, high-performance LED strips, including complex configurations such as RGBW (Red, Green, Blue, White) variants, where multiple LED types are integrated on a single tape for tunable white and full-color output.

To ensure long-term reliability and performance, all LED tape products undergo rigorous aging tests within the Jiangmen facility. These tests involve subjecting finished and partially assembled products to extended operation under elevated temperatures and continuous power cycling—typically 24 to 72 hours depending on product specifications. This process helps identify early-life failures, validates thermal management, and confirms color consistency and brightness stability before products are released for shipment.

Beauty STC also has strong OEM (Original Equipment Manufacturer) capabilities, particularly for RGBW LED tape products. The company supports custom solutions including tailored lumen output, color temperature options, PCB widths (e.g., 10mm, 12mm), silicone jacketing (milky or clear), voltage configurations (12V or 24V), and cut points. Clients can provide specifications for branding, packaging, reel lengths, and even IC-controlled addressable versions. The in-house engineering team collaborates closely with customers to develop prototypes, perform testing, and scale to mass production efficiently.

Overall, the Jiangmen factory combines automated precision, comprehensive quality assurance, and flexible customization to serve a global client base requiring high-quality, reliable RGBW LED tape solutions under OEM arrangements.

Application Scenarios

RGBW LED tape offers significant advantages over standard RGB in commercial environments due to its dedicated warm white or tunable white channel, providing superior color rendering for whites and more natural illumination alongside vibrant color capabilities. In hotels, RGBW tape is ideal for creating adaptable ambiance in guest room cove lighting, allowing seamless transitions from energizing cool white during daytime to relaxing warm white in the evening, while the color channels enable subtle accent lighting for headboards or under-bed features. Lobby feature walls, reception desks, and corridor handrail undersides benefit from RGBW by maintaining high-quality, consistent white light for wayfinding and safety during operational hours, then shifting to branded colors or dynamic scenes for evening atmosphere without the poor color quality common in RGB white mixes. High-end hotel spas and pool areas utilize RGBW for therapeutic chromatherapy sessions with precise color control, combined with circadian-friendly white light programming to support guest well-being.

Malls extensively deploy RGBW LED tape for dynamic brand expression and enhanced shopper experience. Perimeter cove lighting in food courts and common areas uses RGBW to maintain bright, inviting warm white illumination during peak hours, transitioning to cooler whites for energy efficiency during off-peak times, while activating vibrant color schemes for holidays or sales events. Retail storefronts integrate RGBW within signage channels and window displays to ensure merchandise is lit with accurate, high-CRI white light critical for product presentation, then switch to attention-grabbing colors for promotions. Escalator handrails and feature columns employ RGBW for both functional illumination and interactive lighting effects that respond to foot traffic, leveraging the dedicated white channel for clarity and safety during normal operation.

Offices implement RGBW LED tape primarily for human-centric lighting strategies. Under-cabinet task lighting in collaborative zones uses tunable white capabilities to adjust correlated color temperature throughout the workday, supporting alertness with cooler light in mornings and reducing eye strain with warmer tones in afternoons, while color channels enable subtle zone identification or meeting status indicators. Conference room perimeter coving provides glare-free ambient light with precise white tuning for video conferencing, avoiding the green/magenta shifts inherent in RGB white. Reception areas utilize RGBW for brand-aligned accent lighting that maintains professional, high-quality white illumination during business hours, capable of shifting to branded colors for evening events without compromising visual comfort.

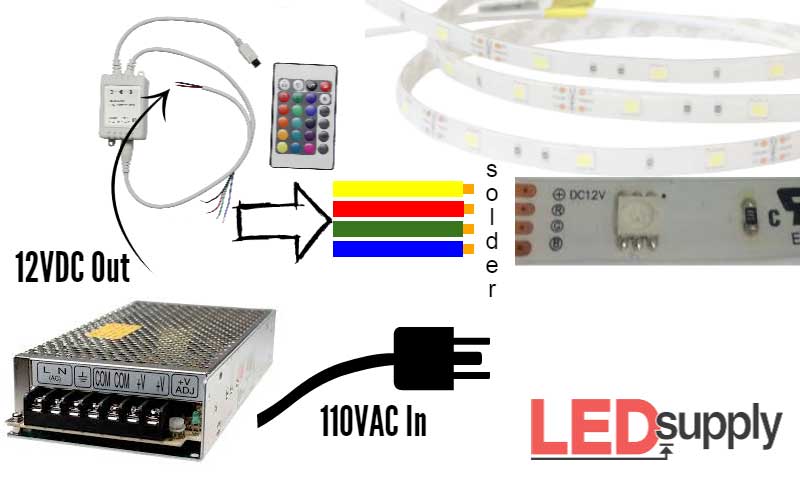

Installation requires careful planning for commercial success. Always use 24V DC systems for runs exceeding 5 meters to prevent voltage drop, which causes color shifting and dimming at the tape’s end; calculate power requirements meticulously and inject power at multiple points for long installations. Mount the tape exclusively within extruded aluminum channels with integrated diffusers to ensure even light distribution, prevent hotspots, and provide essential thermal management for sustained lumen output and longevity in continuously operated spaces. Maintain strict separation between the RGBW tape and any metallic building structures using non-conductive mounting clips to avoid short circuits, and verify all connections are waterproofed with silicone sealant even in indoor environments to protect against humidity-induced failures. For control, select professional-grade DMX512 or DALI systems compatible with building management systems, ensuring the controller supports separate dimming of the white channel for true tunable white functionality, and always install in-line fuses on every power feed for safety compliance. Finally, conduct rigorous pre-installation testing of each tape segment and controller channel to avoid field troubleshooting delays in occupied commercial settings.

Why Choose Beauty STC Lighting

Discover the full potential of customizable lighting with our high-quality RGBW LED tape. Designed for seamless color mixing and exceptional brightness, this versatile solution is perfect for residential, commercial, and architectural applications. Partner with Beauty STC, a trusted leader in innovative LED lighting solutions, and gain access to premium products, technical support, and reliable manufacturing. To learn more or request a sample, contact us today at [email protected].

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.