Article Contents

Industry Insight: Thin Led Light Strips

The commercial and industrial lighting sector is undergoing a significant transformation driven by the demand for versatile, space-efficient, and high-performance illumination solutions. Thin LED light strips have emerged as a critical enabler within this evolution, moving far beyond simple decorative applications. Their ultra-slim profiles and flexible form factors are now essential for addressing complex architectural constraints in retail displays, seamless integration into machinery for task lighting, precise highlighting in high-end hospitality environments, and critical illumination within tight spaces of manufacturing facilities and clean rooms. This shift underscores a fundamental requirement: modern commercial and industrial projects necessitate lighting that delivers exceptional optical control and reliability without compromising valuable physical real estate or installation timelines.

Achieving widespread adoption in these demanding settings, however, hinges on rigorous adherence to safety and performance standards. ETL and CE certifications are not merely optional checkboxes; they are fundamental prerequisites for project approval and long-term operational safety. These certifications validate that thin LED light strips meet stringent electrical safety, electromagnetic compatibility, and environmental requirements mandated by building codes and industry regulations across North America and Europe. Specifiers and facility managers rely on these marks to mitigate liability risks, ensure worker safety, and guarantee that lighting installations will perform reliably under continuous industrial operation, avoiding costly delays or retrofits due to non-compliant products.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of this specialized lighting revolution for over 25 years. We understand that commercial and industrial applications demand more than just thinness; they require engineered solutions built for durability, consistent lumen maintenance, thermal management under load, and seamless integration with control systems. Leveraging decades of focused R&D and manufacturing expertise, Beauty STC develops and produces thin LED light strips specifically engineered to exceed the rigorous demands of professional environments. Our commitment to quality is embedded from substrate selection through to final assembly, ensuring every product bearing the Beauty STC name delivers the certified performance, reliability, and safety that facility managers and lighting professionals depend on for mission-critical installations worldwide.

Technical Specs & Certifications

Thin LED light strips from Beauty (STC) Manufacturing Co., Ltd. are engineered for high efficiency, excellent color rendering, and reliable performance in a variety of residential, commercial, and architectural lighting applications. These ultra-slim profile strips are designed to deliver superior optical quality while maintaining energy efficiency and durability.

In terms of efficiency, Beauty STC’s thin LED light strips typically achieve luminous efficacy ranging from 100 to 130 lumens per watt, depending on the specific configuration, LED density, and color temperature. This high lumen-per-watt ratio ensures minimal energy consumption while providing bright, consistent illumination. The use of high-grade SMD LEDs—such as 2835, 3528, or 5050—combined with optimized PCB design and driver integration contributes to this efficiency.

Color rendering is a key strength of Beauty STC’s LED strips. All premium-grade strips are available with a Color Rendering Index (CRI) greater than 90, with select models offering CRI values of 95 or higher. This ensures accurate and natural color representation, making them ideal for environments where visual clarity and color fidelity are critical—such as retail displays, art galleries, kitchens, and high-end residential interiors. High CRI is achieved through the use of phosphor-coated diodes and rigorous binning processes during manufacturing.

Regarding environmental protection, Beauty STC offers thin LED light strips in multiple IP (Ingress Protection) ratings to suit various installation conditions. IP20-rated strips are suitable for dry, indoor environments where protection from dust and moisture is not a concern. For damp or outdoor applications, IP65-rated strips are available, featuring a silicone coating that protects against water jets and dust ingress. Fully encapsulated IP67 and IP68 variants are also offered for installations requiring submersion resistance or use in high-humidity areas such as bathrooms, under-cabinet lighting, or outdoor signage.

Beauty STC’s commitment to quality is evident in every stage of production. The company adheres to strict quality control standards, including 100% aging tests, solder joint inspections, and batch consistency checks. Their LED strips are RoHS compliant, LM-80 tested for lumen maintenance, and designed for long operational life—typically rated at 50,000 hours or more under proper operating conditions. With precision manufacturing, consistent color temperature options (2700K to 6500K), and excellent thermal management, Beauty STC’s thin LED light strips stand out for reliability, performance, and optical quality in the competitive lighting market.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility is strategically located in Jiangmen, within Guangdong Province’s Pearl River Delta region. This location provides significant advantages, including excellent logistics infrastructure, proximity to key component suppliers, and access to a skilled technical workforce, all essential for efficient LED lighting production. The factory occupies a modern 20,000 square meter purpose-built facility designed for high-volume, precision manufacturing with a strong emphasis on quality control and process efficiency.

Our Surface Mount Technology (SMT) production lines are the core of our thin LED light strip manufacturing capability. We operate multiple state-of-the-art Yamaha YS series SMT placement machines, renowned for their speed, accuracy, and reliability in handling the demanding requirements of LED assembly. These machines are configured specifically for the challenges of thin flexible PCBs used in our light strips, capable of placing ultra-small 0201 and even 01005 LED components with micron-level precision. The lines feature fully automated solder paste printing, high-speed pick-and-place, nitrogen-reflow soldering for superior joint quality, and comprehensive Automated Optical Inspection (AOI) systems after reflow to detect any placement or soldering defects before the strips move to the next stage. This advanced SMT capability ensures consistent, high-density component placement critical for the performance and longevity of our thin LED strips.

Rigorous aging and reliability testing is a non-negotiable part of our quality assurance process, particularly for thin LED light strips where thermal management and component stress are critical factors. Every production batch undergoes mandatory aging tests in our dedicated environmental chambers. Strips are subjected to continuous operation at elevated temperatures, typically 50°C, for a minimum of 72 hours, significantly exceeding standard industry practice. During this period, we monitor performance parameters like forward voltage, light output maintenance, and color consistency in real-time. Crucially, we implement a 10% overvoltage aging test protocol specifically designed to accelerate potential failure modes and identify any weak components or solder joints before products leave the factory. Only strips that pass this stringent burn-in without degradation or failure are cleared for final inspection and shipment.

Beauty STC possesses extensive OEM capabilities specifically tailored for thin LED light strips, making us a preferred partner for global brands. Our engineering team, comprising over 50 specialists, works closely with clients from the initial concept phase through to mass production. We offer comprehensive services including custom optical design, flexible PCB layout optimization for ultra-thin profiles (down to 8mm width), specialized thermal management solutions for constrained spaces, bespoke connector integration, and tailored packaging. Our factory is equipped to handle low-volume prototyping with rapid turnaround as well as high-volume production runs exceeding millions of meters annually. We excel at incorporating client-specific requirements such as unique color temperatures, dimming protocols (including DALI, 0-10V, PWM), special adhesives, custom labeling, and compliance with diverse international safety and performance standards. The entire OEM process, from design validation through SMT production, aging, final QC, and kitting, is managed under one roof with a typical lead time of 25-30 days for production orders, ensuring flexibility and responsiveness to client needs.

Application Scenarios

Thin LED light strips are versatile lighting solutions ideal for both decorative and functional applications across various commercial environments including hotels, malls, and offices. Their slim profile allows for discreet integration into architectural features, making them suitable for enhancing ambiance, guiding movement, and highlighting design elements.

In hotels, thin LED light strips are commonly used in guest rooms to backlight headboards, under cabinets, or along cove ceilings to create a soft, welcoming atmosphere. They are also effective in lobbies and corridors, where they can be installed along stair treads, handrails, or ceiling perimeters to provide gentle illumination that enhances safety and elegance. Bathrooms benefit from under-mirror or vanity lighting, offering even, glare-free illumination.

Malls utilize thin LED strips for accent lighting in signage, display windows, and feature walls to draw attention to retail spaces. They are frequently installed in escalator handrails, ceiling coves, and walkway edges to improve visibility and guide foot traffic. The flexibility of these strips allows them to be shaped around curved architectural details, adding dynamic visual interest to high-traffic areas.

In office environments, thin LED light strips can be used under desks, within shelving units, or above ceiling panels to add ambient or task lighting without overwhelming the workspace. They are especially useful in modern open-plan offices where subtle, indirect lighting helps reduce glare on computer screens while maintaining a professional and comfortable environment. Conference rooms often feature LED strips to highlight branding elements or architectural features.

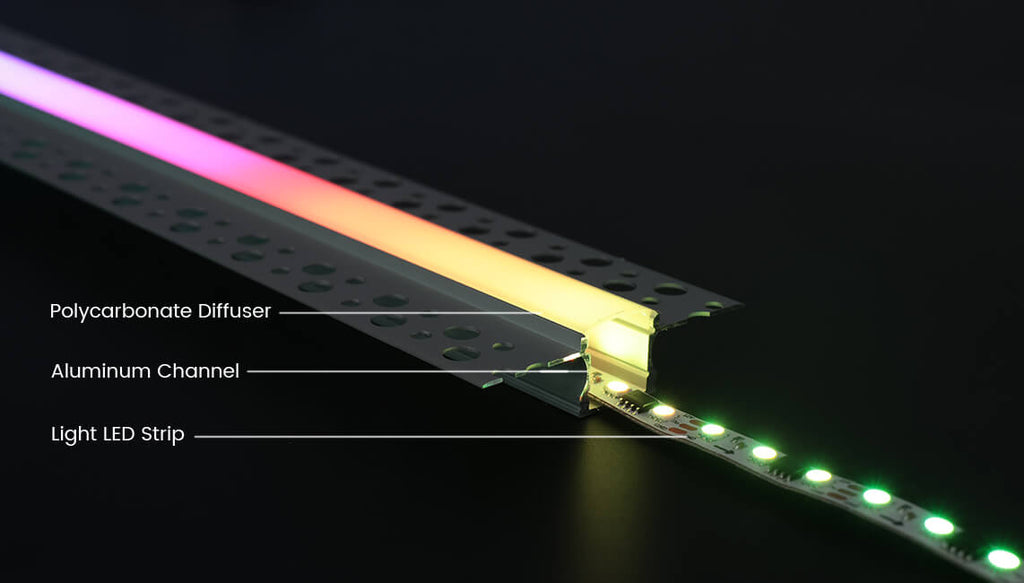

For successful installation, ensure the surface is clean, dry, and free of dust or grease before applying the adhesive backing. For long-term reliability, consider using mounting clips or aluminum channels, especially in high-temperature or high-traffic areas. Always verify voltage compatibility and use appropriate power supplies and connectors. Avoid sharp bends to prevent damaging the internal circuitry, and plan the layout to minimize visible connections or power sources. In humid areas such as bathrooms or outdoor-facing zones, select IP-rated waterproof strips to ensure durability and safety. Finally, test the strip before final installation to confirm color temperature, brightness, and functionality.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s precision-engineered thin LED light strips, designed for seamless integration into space-constrained installations without compromising on brightness or reliability. Our advanced manufacturing ensures consistent color rendering and thermal management, critical for demanding applications in retail displays, architectural accents, and high-end cabinetry. Partner with Beauty STC to access custom solutions tailored to your exact specifications, backed by rigorous quality control and engineering expertise that meets global safety standards.

Discover how our ultra-slim profiles and flexible configurations can solve your unique design challenges while reducing installation complexity. Contact our dedicated technical team at [email protected] to discuss your requirements and receive a detailed proposal for integrating Beauty STC’s thin LED light strips into your next project. Let us help you achieve flawless illumination with a partner committed to innovation and precision.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.