Article Contents

Industry Insight: Ribbon Light Diffuser

Ribbon light diffusers have become an essential component in modern commercial and industrial lighting applications, where uniform illumination, energy efficiency, and aesthetic integration are paramount. As LED technology continues to evolve, the demand for high-performance optical solutions that enhance light distribution while minimizing glare and hotspots has grown significantly. Diffusers play a critical role in achieving these goals—particularly in linear lighting systems such as ribbon lights—where seamless light output is required across large architectural surfaces, retail displays, warehouse facilities, and production environments.

In commercial and industrial settings, compliance with rigorous safety and performance standards is non-negotiable. That’s why leading installations specify ribbon light diffusers that are ETL and CE certified, ensuring they meet North American and international electrical safety requirements. These certifications not only validate product reliability but also provide peace of mind for facility managers, architects, and electrical contractors tasked with long-term operational performance and code compliance.

Since 1998, Beauty STC Manufacturing Co., Ltd. has been at the forefront of innovative LED lighting solutions, specializing in high-quality diffusers and optical components designed for demanding commercial and industrial environments. With decades of engineering expertise and a commitment to precision manufacturing, Beauty STC delivers diffuser systems that combine superior light diffusion, durability, and regulatory compliance—helping global partners build safer, more efficient, and visually consistent lighting installations.

Technical Specs & Certifications

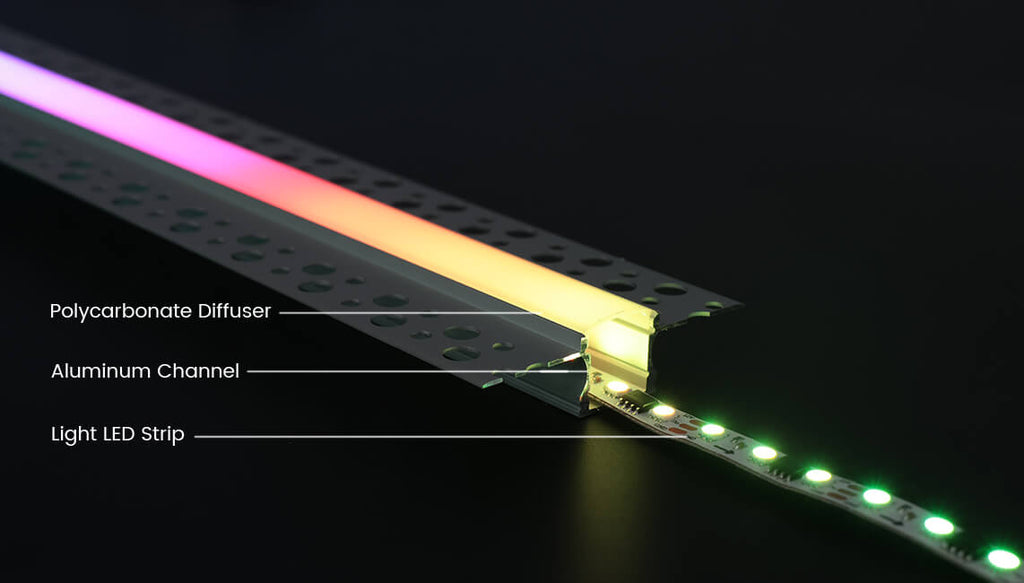

Beauty STC Manufacturing Co., Ltd. provides high-performance linear LED lighting solutions where the diffuser is a critical component for achieving optimal optical performance and environmental protection. While the term “ribbon light diffuser” typically refers to the optical cover used with flexible or rigid LED strip modules (commonly called LED tape or ribbon lights), the requested specifications pertain to the complete integrated luminaire system incorporating our precision-engineered diffusers. Our diffusers are not standalone components but are designed and manufactured in-house as part of the overall product architecture to ensure seamless performance.

Luminous Efficacy (Lumens per Watt) is a core focus in our linear lighting systems. Beauty STC’s premium ribbon light products with integrated diffusers achieve system efficacies ranging from 130 to 150 lumens per watt under standard operating conditions at 25°C ambient temperature. This high efficiency is maintained through our proprietary diffuser formulations which utilize advanced micro-prismatic or optimized opal structures. These designs maximize light extraction while minimizing internal absorption and back-reflection losses that commonly plague lower-quality diffusers. Crucially, we report system efficacy including the diffuser’s impact, not just bare LED performance, ensuring realistic field expectations. Thermal management within the extrusion and diffuser interface is rigorously engineered to prevent efficacy droop at higher operating temperatures.

Color Rendering Index (CRI) performance is paramount for applications demanding accurate color representation, such as retail, beauty salons, and high-end residential spaces. All Beauty STC ribbon light systems featuring our signature diffusers deliver a minimum CRI Ra value of 92, with typical production units achieving Ra 94-96. We exceed the basic CRI >90 requirement by also ensuring strong deep red (R9 > 50) and high-fidelity color rendition across the visible spectrum. This is validated through independent third-party LM-79 testing. Our diffusers utilize UV-stable, color-neutral materials that do not introduce spectral shifts or yellowing over time, preserving the high CRI performance of the underlying LEDs throughout the product’s lifespan. For critical applications, we offer versions meeting TM-30-15 standards with Rf > 85 and Rg > 98.

IP Rating capabilities are integral to our product design philosophy, ensuring suitability for diverse environments. Beauty STC ribbon light systems are available in multiple configurations. Standard indoor variants feature IP20-rated diffusers made from high-clarity polycarbonate or PMMA, providing basic protection against finger contact. For damp or outdoor locations, we utilize seamless silicone diffusers or co-extruded polycarbonate profiles achieving IP65 or IP67 ratings. These diffusers undergo stringent testing per IEC 60529 standards, including submersion tests for IP67 variants. The silicone diffusers, in particular, offer superior flexibility, UV resistance, and thermal stability, maintaining optical clarity even under harsh conditions. It is important to note that higher IP-rated diffusers may exhibit a slight reduction in system efficacy (typically 3-5%) compared to IP20 versions due to increased light diffusion, but our engineering minimizes this trade-off.

Beauty STC’s commitment to quality is evident in every diffuser we produce. Our vertically integrated manufacturing process begins with material selection using only virgin-grade, UL-listed polymers free from recycled content that could cause yellowing or haze. Diffusers are precision injection-molded or extruded under controlled cleanroom conditions to ensure consistent wall thickness, optical clarity, and dimensional accuracy. Each batch undergoes rigorous in-house photometric testing for transmittance, haze, and color shift, alongside accelerated life testing including 5,000-hour UV exposure and thermal cycling. This meticulous approach, supported by our ISO 9001-certified quality management system, guarantees that Beauty STC diffusers maintain their optical properties and structural integrity far beyond standard industry expectations, providing reliable, high-fidelity illumination for the product’s rated lifetime. We prioritize real-world performance consistency over merely meeting minimum specifications.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The factory is equipped with advanced production infrastructure designed to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control and operational efficiency.

At the core of the production line are state-of-the-art SMT (Surface Mount Technology) machines, which enable accurate and rapid placement of electronic components onto printed circuit boards. These SMT lines are fully automated, ensuring consistent soldering quality and high throughput, essential for manufacturing reliable LED strip lights and related products. The facility maintains strict environmental controls in the SMT area to prevent contamination and ensure optimal performance of sensitive electronic assemblies.

Quality assurance is reinforced through comprehensive aging tests. After assembly, LED products undergo extended burn-in procedures under controlled thermal and electrical conditions. These aging tests typically run for 24 to 72 hours, allowing the team to identify early failures, verify thermal management performance, and ensure long-term reliability before products are shipped to customers. Additional testing includes luminance consistency checks, color temperature verification, and waterproof performance validation for applicable products.

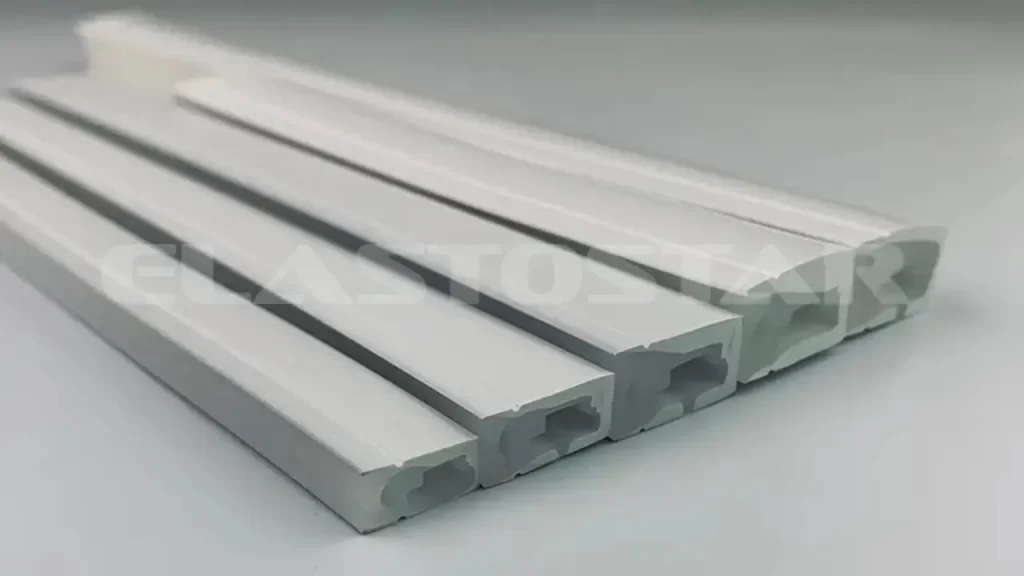

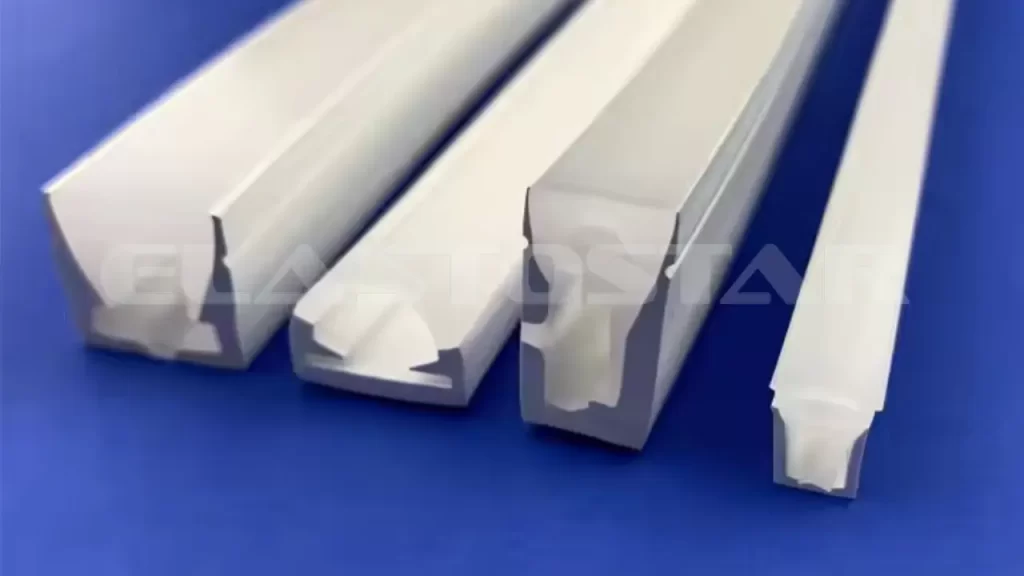

The Jiangmen factory has robust OEM capabilities, particularly tailored for customized LED solutions such as ribbon light diffusers. Beauty STC can support end-to-end OEM projects, from initial design and engineering to prototyping, tooling, and mass production. For ribbon light diffusers, the company offers customization in profile shape, length, material (such as PC or PMMA), light transmission levels, and color rendering properties. This flexibility allows clients to develop unique diffuser solutions optimized for specific applications, whether for architectural lighting, residential use, or commercial displays.

Overall, the Jiangmen facility reflects Beauty STC’s commitment to advanced manufacturing, quality assurance, and customer-driven innovation, making it well-suited to serve both domestic and international markets with reliable, high-performance LED lighting components.

Application Scenarios

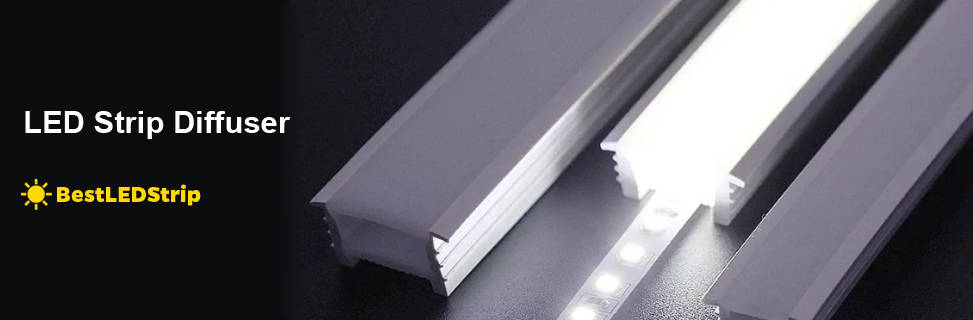

Ribbon light diffusers refer to the translucent cover components integrated into linear LED lighting systems, often called LED tape lights or flexible strips when used in architectural applications. These diffusers are not standalone products but essential elements within complete linear LED fixture assemblies designed for seamless, uniform illumination. Their primary function is to soften and evenly distribute light from discrete LED points, eliminating hotspots and creating a continuous glow. Within hospitality, retail, and commercial environments, strategic placement is critical for both aesthetics and functionality.

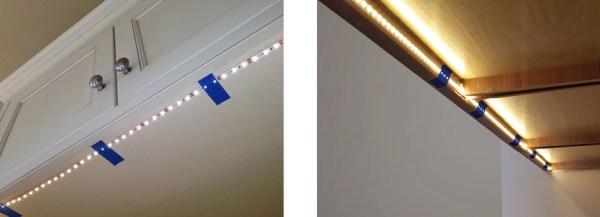

In hotel settings, ribbon light diffusers excel in creating inviting atmospheres. Install them beneath reception desk countertops to provide gentle uplighting that enhances the guest experience without glare. They are equally effective in corridor coves to guide movement with low-level ambient lighting, reducing harsh shadows. Within guest rooms, integrate diffused linear systems behind headboards for subtle backlighting or under wall-mounted cabinetry in bathrooms to eliminate dark zones while maintaining a clean visual line. For high-end suites, consider perimeter cove lighting in living areas where diffused ribbon lights can wash walls softly, adding perceived space and luxury. Always select diffusers with high color rendering index values above 90 for accurate skin tone representation in lobbies and guest areas.

Mall environments demand high visual impact and durability. Utilize diffused linear lighting within storefront display windows to highlight merchandise with even illumination that prevents distracting LED dots. Escalator handrails benefit significantly from integrated diffusers, providing continuous safety lighting that guides patrons smoothly. Suspended ceiling coves throughout common areas create expansive, airy feelings when diffused linear systems wash upper walls. For food court seating perimeters, low-level diffused lighting under benches adds warmth and defines spaces without overwhelming diners. In high-traffic zones, specify polycarbonate diffusers over acrylic for superior impact resistance, and ensure all fixtures meet IP65 ratings to withstand cleaning protocols and environmental fluctuations.

Office applications prioritize visual comfort and task performance. Integrate diffused linear systems into suspended ceiling grids as direct downlights, where the diffuser minimizes glare on computer screens compared to exposed LEDs. Under-cabinet task lighting in workstations benefits from tight-pitch diffusers that eliminate LED striations on documents. Perimeter cove lighting in conference rooms creates non-distracting ambient illumination that supports video conferencing. For modern open-plan offices, suspended linear pendants with high-quality diffusers provide focused task lighting while maintaining uniformity across large areas. Always maintain a minimum 5mm gap between diffuser ends and mounting surfaces to accommodate thermal expansion, especially in temperature-variable environments like atriums.

Critical installation considerations begin with thermal management: never compress diffusers against heat sinks as this causes premature yellowing and lumen depreciation. Maintain precise alignment between the diffuser profile and LED module to prevent visible gaps or dark bands. In all settings, verify that the diffuser’s beam angle matches the application—120-degree optics suit downward task lighting while 180-degree versions work best for indirect cove installations. For curved applications common in modern architecture, use flexible silicone diffusers with a minimum bending radius specified by the manufacturer. During commissioning, conduct a visual walkthrough under low-light conditions to identify any irregularities before final sealing. Crucially, select diffusers with UV stabilization for any space exposed to direct sunlight, such as mall atriums or hotel lobbies with large windows, to prevent hazing over time. Always adhere to local electrical codes regarding accessible fixture compartments, particularly in public spaces where maintenance access is required.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality ribbon light diffusers designed for seamless, uniform illumination. At Beauty STC, we specialize in precision-engineered diffusers that enhance the performance and aesthetics of LED ribbon lighting. Our advanced materials reduce hotspots and deliver consistent light output, ideal for architectural, commercial, and residential applications.

Partner with Beauty STC to benefit from custom sizing, superior optical clarity, and durable construction tailored to your project needs. As a trusted manufacturer, we are committed to innovation, quality, and on-time delivery.

For collaboration opportunities or technical inquiries, contact us today at [email protected] and discover how our ribbon light diffusers can elevate your next lighting solution.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.