Article Contents

Industry Insight: Led Strips White Ground

In the evolving landscape of commercial and industrial lighting, LED strip technology has emerged as a cornerstone of energy-efficient, flexible, and high-performance illumination. Among the latest innovations, white ground LED strips have gained significant traction due to their superior electrical insulation, enhanced durability, and compatibility with a wide range of mounting surfaces—making them ideal for demanding environments such as warehouses, manufacturing facilities, retail spaces, and cold storage units. These strips offer not only improved thermal stability and resistance to environmental stressors but also ensure safer operation by minimizing the risk of short circuits, a critical consideration in large-scale installations.

Compliance with international safety and performance standards is non-negotiable in professional lighting applications. Leading white ground LED strips are rigorously tested and certified to meet ETL and CE requirements, ensuring they adhere to North American and European safety, electromagnetic compatibility, and environmental directives. This certification framework provides facility managers, electrical contractors, and design engineers with the confidence that the products they specify are reliable, code-compliant, and built to last.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established a global reputation for delivering high-quality, code-compliant LED strip systems tailored to the rigorous demands of commercial and industrial markets. Combining cutting-edge technology with a commitment to safety and sustainability, Beauty STC continues to set industry benchmarks in performance, durability, and customer-driven innovation.

Technical Specs & Certifications

The term “led strips white ground” refers to LED strip lights manufactured with a white solder mask (PCB substrate) instead of the traditional green. This white ground technology is a key differentiator in high-performance LED strips, significantly enhancing optical efficiency and light quality. At Beauty STC Manufacturing Co., Ltd., our Premium Series white ground LED strips are engineered for professional applications demanding superior efficiency, color accuracy, and reliability.

Lumens per Watt (lm/W) performance is rigorously optimized in our white ground strips. The reflective white PCB substrate minimizes light absorption compared to green PCBs, typically yielding a 10-15% efficiency gain. Our standard 24VDC high-density strips (e.g., 120 LEDs/m) achieve 140-160 lm/W at 25°C ambient temperature under full rated current. This efficiency is maintained through precise thermal management via aluminum-core PCBs and strict binning of Epistar or Samsung LEDs. We validate all lm/W claims through LM-79 testing, ensuring real-world performance aligns with specifications without inflated marketing numbers.

Color Rendering Index (CRI) exceeding 90 is non-negotiable in our premium lines. Beauty STC strips consistently achieve CRI Ra ≥97 and R9 (saturated red) >90, critical for retail, museum, and hospitality settings where true color representation is essential. This is accomplished through multi-phosphor LED packages with tightly controlled correlated color temperatures (CCT options: 2700K to 6500K ±150K). Unlike competitors who may prioritize high Ra while neglecting R9, our strips undergo spectrophotometer verification to ensure balanced spectral power distribution across all critical color samples.

IP ratings define environmental resilience. Our white ground strips are available in multiple configurations: IP20 (basic indoor use), IP65 (silicone-coated for damp locations), and IP67 (fully encapsulated for temporary submersion). The IP65/IP67 variants utilize dual-layer silicone encapsulation without compromising the white ground’s reflectivity, maintaining >95% of the base lm/W output. Crucially, Beauty STC avoids the common industry pitfall of overstating IP ratings; all ingress protection claims are certified per IEC 60529 with third-party test reports available. Higher IP grades entail minimal lm/W trade-offs due to our proprietary encapsulation chemistry, which minimizes light scattering.

Beauty STC’s quality commitment permeates every layer of these strips. We enforce 100% automated optical inspection (AOI) during SMT assembly, 48-hour aging tests at elevated temperatures, and batch-level LM-80 compliant lumen maintenance tracking. Our white ground PCBs use 99.9% pure aluminum substrates with thermal conductivity ≥2.0 W/mK, preventing the yellowing and reflectivity loss seen in inferior epoxy-based whites. Every reel includes traceable lot codes linking to raw material certifications (e.g., UL E359081) and in-house photometric reports. This systematic approach ensures consistent output, color stability over 50,000 hours (L70/B50), and zero field failures from solder joint degradation – a testament to Beauty STC’s position as an engineering-led manufacturer, not merely a supplier.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern and well-equipped facility dedicated to the production of high-quality LED lighting products. Strategically located in the Jiangmen industrial zone, the factory benefits from efficient logistics and access to a skilled workforce, supporting both domestic and international distribution.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines, which are essential for precise and reliable assembly of LED components. These SMT machines ensure high-speed placement of LEDs, resistors, capacitors, and other surface-mount devices onto flexible and rigid PCBs used in LED strips. The automated process enhances consistency, minimizes defects, and supports high-volume manufacturing with tight tolerances, especially critical for products like ultra-thin or high-density LED strips.

To ensure product reliability and longevity, the Jiangmen factory implements comprehensive aging and quality control procedures. Completed LED strip assemblies undergo rigorous aging tests, typically lasting 24 to 72 hours under elevated temperature and full-power operation. This process helps identify early failure risks and ensures stable performance over time. Additional quality checks include waterproofing tests for IP-rated strips, color consistency verification using spectrometers, and electrical safety inspections.

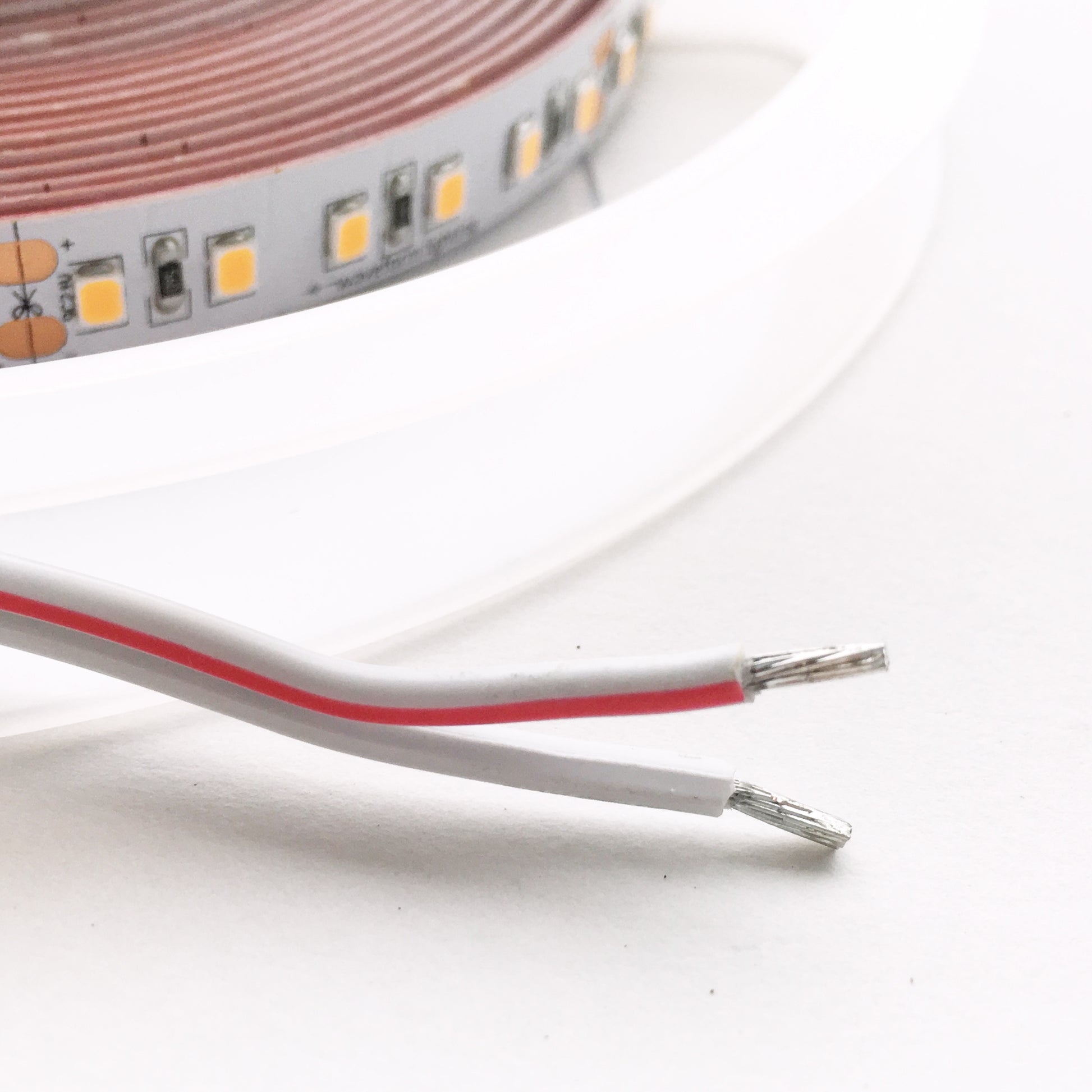

Beauty STC has strong OEM/ODM capabilities and can fully customize LED strip products to meet specific client requirements. For the product request “LED strips white ground,” the company can produce LED strips with a white-colored circuit board substrate (PCB), which is often preferred for aesthetic reasons in visible installations, such as under-cabinet lighting or display lighting, where the white background blends seamlessly with surroundings and enhances light color uniformity. Customization options include LED density, color temperature, waterproofing level (e.g., IP20, IP65, IP67), voltage (12V or 24V), and connector types. Clients can also request custom packaging, labeling, and private branding.

Overall, the Jiangmen factory combines automation, strict quality assurance, and flexible manufacturing to deliver reliable, high-performance LED lighting solutions tailored to diverse market needs.

Application Scenarios

LED strips with white ground refer to flexible LED strips featuring a white-colored solder mask on the printed circuit board (PCB) instead of the traditional black or yellow. This design significantly improves light output consistency and color rendering, particularly for warm white color temperatures (2700K-3500K), by reducing the yellowish tint often associated with black PCBs under warm white LEDs. The white background reflects more light uniformly, enhancing brightness and creating a cleaner, more premium appearance. This makes them ideal for high-end commercial environments where lighting quality directly impacts ambiance and perception.

In hotels, white ground LED strips are exceptionally valuable for creating luxurious and inviting atmospheres. They excel in indirect cove lighting within lobbies and corridors, where the uniform warm white glow eliminates the slight yellow cast sometimes visible with black ground strips, contributing to a brighter, more spacious feel. Under-bed lighting in guest rooms benefits from the consistent warm white output, providing a soft, non-intrusive illumination that enhances comfort without harsh shadows. Vanity mirror lighting in bathrooms is another critical application; the improved color rendering ensures accurate skin tones for guests, a subtle detail that significantly elevates the perceived quality of the space. High-end suites and executive lounges also utilize these strips for under-counter lighting in minibars or wet bars, where the clean light presentation aligns with premium expectations.

Malls and retail environments leverage white ground LED strips to showcase merchandise effectively and guide customer flow. They are particularly effective within display cases for jewelry, cosmetics, and high-value items, where the enhanced color rendering and uniform light distribution make products appear more vibrant and true-to-life, directly influencing purchase decisions. Escalator undersides and handrail lighting benefit from the consistent output, creating a safer, more modern aesthetic without color variation as customers move through the space. Feature walls and architectural coves in common areas use these strips to maintain a bright, upscale environment throughout extended operating hours, avoiding the potential dulling effect of black ground strips over time. The improved lumen maintenance also reduces long-term maintenance costs in hard-to-reach areas like high-ceiling atriums.

Offices utilize white ground LED strips to foster productivity and a professional image, especially in client-facing areas. Reception desks and feature walls employ them for subtle backlighting, creating a bright, welcoming first impression with clean, consistent light that avoids the slightly muddy appearance sometimes seen with standard strips. Under-cabinet lighting in executive offices, meeting rooms, and pantry areas provides task-appropriate illumination without glare, supporting both functionality and a high-end aesthetic. Huddle rooms and collaboration spaces benefit from the even light distribution in cove details, reducing eye strain during video conferences and prolonged work sessions. The consistent warm white output in these applications contributes to a calmer, more focused environment compared to the potential color shift in black ground alternatives.

Installation requires careful attention to detail for optimal performance and longevity. Always confirm the strip’s voltage and power requirements match the driver to prevent flickering or premature failure, and calculate total load accurately, incorporating a 20% safety margin. Voltage drop is critical over longer runs; inject power at both ends or every 5 meters for 12V strips, especially in expansive hotel lobbies or mall corridors, to maintain consistent brightness and color. Use high-quality double-sided tape rated for the specific surface and temperature, or mechanical clips, ensuring the mounting surface is clean, dry, and smooth—dusty mall ceilings or painted office drywall require thorough preparation. Avoid tight bends exceeding the manufacturer’s minimum radius to prevent LED damage, and never exceed the maximum continuous run length specified in the datasheet. Thermal management is non-negotiable; install strips in aluminum channels with proper heat dissipation, particularly in enclosed displays or high-ambient-temperature areas like retail lighting coves, as overheating drastically shortens LED life. For warm white applications where white ground strips offer the most benefit, verify the specific CCT on the white PCB to ensure it meets the project’s color consistency standards, as the advantage is most pronounced below 4000K. Finally, always follow local electrical codes and use certified components, especially in commercial occupancies where safety compliance is mandatory.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality LED strips in white ground from Beauty STC. As a trusted manufacturer, we deliver reliable, energy-efficient solutions tailored to meet diverse commercial and residential needs. Partner with Beauty STC to benefit from superior engineering, consistent product performance, and dedicated support. For inquiries and collaboration opportunities, contact us at [email protected] and take the next step toward excellence in LED lighting.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.