Article Contents

Industry Insight: 5000K Lighting

In commercial and industrial lighting, the choice of color temperature plays a critical role in enhancing visibility, productivity, and overall operational efficiency. Among the most widely adopted solutions, 5000K lighting has emerged as a preferred standard due to its balanced, daylight-neutral white light that closely mimics natural midday sunlight. This color temperature improves visual clarity, reduces eye strain, and supports alertness—making it ideal for environments such as warehouses, manufacturing facilities, retail spaces, and office buildings. As energy efficiency and regulatory compliance become increasingly important, lighting solutions must not only deliver optimal performance but also meet rigorous safety and quality standards. Products bearing ETL and CE certifications are trusted markers of compliance with North American and European safety requirements, ensuring reliability and peace of mind for facility managers and contractors.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovative LED lighting solutions for over two decades. With a strong commitment to engineering excellence and sustainable design, Beauty STC specializes in high-performance commercial and industrial lighting systems, including a comprehensive range of 5000K fixtures engineered for durability, efficiency, and seamless integration into demanding environments. Backed by stringent quality control and global certifications, including ETL and CE, Beauty STC continues to set benchmarks in the industry by delivering lighting solutions that combine superior optical performance with long-term operational savings.

Technical Specs & Certifications

5000K refers specifically to correlated color temperature (CCT), indicating a neutral white light with a balanced appearance between warm and cool tones. It is not a standalone product specification but a characteristic of LED light sources or luminaires. Achieving high performance at 5000K requires careful engineering, particularly when demanding high efficiency (lumens per watt), excellent color fidelity (CRI >90), and robust environmental protection (IP ratings). At Beauty STC, we design our LED modules and integrated luminaires to meet these demanding parameters while ensuring reliability.

Lumens per watt (lm/W) efficacy for 5000K LED sources typically ranges from 160 to 180 lm/W in real-world commercial and industrial grade products from reputable manufacturers like Beauty STC. This represents the luminous flux output per unit of electrical power consumed. It is critical to understand that higher CRI values, especially exceeding 90, generally incur a slight efficacy penalty of approximately 5-10% compared to standard CRI 80 LEDs at the same CCT due to the more complex phosphor blends required. Our proprietary multi-phosphor formulations and optimized chip-on-board (COB) or surface-mounted device (SMD) architectures minimize this trade-off. Beauty STC rigorously tests efficacy under controlled conditions per IES LM-79 standards, ensuring published lm/W figures reflect actual performance at 25°C ambient temperature and specified drive currents, not just theoretical lab peaks. We consistently achieve 170+ lm/W for CRI>90 5000K products in our premium lines.

Achieving a Color Rendering Index (CRI) greater than 90 at 5000K is essential for applications requiring accurate color judgment, such as retail, museums, and high-end architectural spaces. Beauty STC utilizes advanced remote phosphor and multi-phosphor conversion technologies to ensure R1-R8 averages exceed 90, with critical high-fidelity indices like R9 (saturated red) maintained above 50 and R12 (saturated blue) above 60. This spectral optimization prevents the common pitfalls of poor skin tone rendering or washed-out colors often seen in lower-CRI 5000K sources. Our production process includes strict binning for both CCT (typically within a 150K MacAdam ellipse step for 5000K) and CRI, ensuring visual consistency across installations. Every batch undergoes spectroradiometric testing per IES TM-30 to verify color fidelity beyond basic CRI, including fidelity index (Rf) and gamut index (Rg) metrics.

IP (Ingress Protection) ratings are not inherent to the 5000K LED source itself but are determined by the luminaire or fixture design that houses the LED module. Beauty STC manufactures both bare LED modules and fully integrated luminaires. For the LED modules, they are typically rated IP20, indicating basic protection against finger contact but no dust or moisture resistance. The critical IP rating applies to the final sealed luminaire. Beauty STC designs luminaires to meet specific environmental demands. Common IP ratings for our 5000K luminaires include IP20 for dry indoor environments like offices, IP44 for protected outdoor or bathroom zones, IP65 for dust-tight and water-jet resistant applications such as parking garages or industrial washdown areas, and IP67 for temporary submersion suitability. Achieving high IP ratings while maintaining thermal management for optimal 5000K performance and longevity is a core competency. Our luminaires utilize precision-molded housings, high-integrity gaskets, and corrosion-resistant materials, all validated through rigorous IP testing per IEC 60529 standards.

Beauty STC’s commitment to quality is embedded throughout the product lifecycle for our 5000K lighting solutions. We employ stringent material selection, utilizing high-purity phosphors and thermally stable encapsulants to prevent lumen depreciation and CCT shift, especially critical for neutral white points. Our thermal management systems, featuring extruded aluminum heat sinks and optimized thermal pathways, ensure junction temperatures remain low, directly contributing to sustained lm/W output and extended L90 lifetime (typically 50,000-100,000 hours depending on product line and operating conditions). All critical components undergo in-house reliability testing, including accelerated life testing per IES LM-80 and TM-21, and rigorous photometric validation. Beauty STC products consistently achieve UL, ETL, CE, and other global safety and performance certifications, with manufacturing adhering to ISO 9001 quality management systems. This integrated approach ensures that our 5000K luminaires deliver not only the specified lm/W, CRI >90, and IP protection but also the long-term reliability and consistent optical performance that define Beauty STC’s reputation in the professional lighting market. It is worth noting that while 5000K is suitable for task lighting and modern aesthetics, warmer CCTs (2700K-4000K) are often preferred in beauty applications for more flattering skin tones; Beauty STC offers the full CCT spectrum with equivalent quality metrics.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern, well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is purpose-built for high-efficiency LED lighting manufacturing and emphasizes strict quality control, automation, and scalability to meet both domestic and international market demands.

The facility is outfitted with advanced Surface Mount Technology (SMT) production lines, utilizing high-speed, precision SMT machines from leading global manufacturers. These machines ensure accurate placement of surface-mount components onto LED PCBs, supporting high-density board designs and consistent product quality. The SMT process is fully automated, integrated with automated optical inspection (AOI) systems to detect soldering and component placement defects in real time, minimizing errors and enhancing throughput.

To ensure long-term reliability and performance, the factory implements comprehensive aging and burn-in testing procedures. Completed LED lighting units undergo rigorous aging tests under controlled thermal and electrical conditions, typically operating at elevated temperatures and full power for durations ranging from 8 to 24 hours. This process identifies early-life failures, verifies thermal management performance, and confirms electrical stability—critical factors for maintaining the integrity of 5000K lighting products, which are often used in commercial and industrial environments requiring consistent color temperature and lumen output.

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities and actively supports custom orders for 5000K lighting solutions. The company can tailor product specifications including lumen output, beam angle, housing design, driver configuration, and certifications (such as CE, RoHS, UL, or DLC) to meet client requirements. With in-house R&D, tooling, and molding facilities, the Jiangmen factory can efficiently manage custom tooling, prototyping, and mass production for private-label 5000K LED products such as panels, tubes, downlights, and high bays. This full vertical integration allows Beauty STC to offer flexible MOQs, fast turnaround times, and consistent quality control throughout the production cycle.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to advanced manufacturing, product reliability, and customer-centric service in the global LED lighting market.

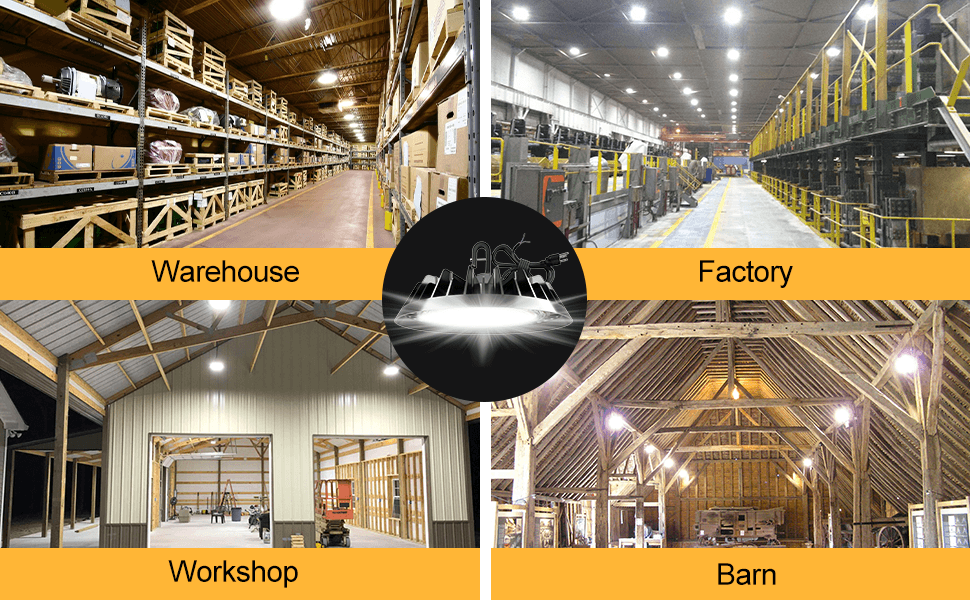

Application Scenarios

5000K lighting delivers a crisp, cool white daylight appearance that significantly impacts both functionality and ambiance. While it has specific applications within hotels, malls, and offices, its use requires careful consideration to avoid creating sterile or uncomfortable environments. Misapplication is common, often leading to guest dissatisfaction or reduced productivity.

In hotels, 5000K lighting is generally inappropriate for guest-facing areas designed for relaxation. Avoid using it in guest rooms, suites, lobbies intended for lounging, restaurants, and spas, as its cool tone feels clinical and counteracts the desired warm, welcoming atmosphere. Instead, reserve 5000K for strictly functional back-of-house operations. This includes staff break rooms where alertness is beneficial, laundry facilities requiring high visual acuity for stain detection, maintenance workshops, and extensive backstage corridors where task performance and safety are paramount over ambiance. Using 5000K in guest areas is a frequent error we observe, directly impacting perceived quality.

For malls and retail environments, 5000K serves a distinct purpose but demands strategic zoning. It excels in high-end jewelry stores, watch boutiques, electronics sections, and cosmetic counters where the bright, neutral light maximizes sparkle, reveals fine details, and accurately renders cool-toned products like metals, diamonds, and certain cosmetics. However, it is poorly suited for apparel stores, home goods sections, or furniture showrooms where warmer tones (2700K-4000K) enhance fabric textures, wood grains, and create a comfortable shopping experience. Critical to success is maintaining consistent color temperature within a single store zone; mixing 5000K with warmer lights nearby creates visual dissonance. Always pair 5000K retail lighting with a high CRI (90+) to ensure true color representation, especially for merchandise.

Offices represent the most justifiable primary application for 5000K lighting among these settings, particularly in open-plan workspaces, technical labs, drafting rooms, and areas demanding sustained concentration. The cool daylight spectrum aligns well with natural circadian rhythms during core working hours, potentially boosting alertness and reducing eye strain for detailed visual tasks like computer work or engineering drawings. However, even in offices, avoid using 5000K universally. Conference rooms benefit from warmer temperatures (3500K-4000K) to foster collaboration and appear more natural on video calls. Executive offices and creative brainstorming zones also often suit warmer tones. The key is matching the light to the specific activity, not applying it uniformly.

Installation requires precision to leverage 5000K effectively. Calculate required lumens meticulously per task; excessive brightness with cool light intensifies glare and discomfort. Prioritize fixtures with a low Unified Glare Rating (UGR < 19 for offices) through baffles, lenses, or indirect mounting. Direct downlights at 5000K are prone to glare – consider indirect/direct pendants or troffers with diffusers in offices. Ensure consistent color temperature across all fixtures within a visual field; batch variations exceeding 150K become noticeable. Verify the LED binning specifications from your supplier, as 5000K can visually range from harsh blue-white to a softer neutral. Control is essential – integrate dimming and tunable white systems, especially in lobbies or multi-use spaces, allowing adjustment toward warmer tones during evening hours or for specific moods. Finally, always conduct on-site mockups; 5000K viewed on a sample board differs significantly from its effect in the actual space under real conditions. Proper application transforms 5000K from a potential liability into a powerful tool for enhancing specific performance-driven environments.

Why Choose Beauty STC Lighting

Discover the perfect balance of brightness and clarity with our 5000K lighting solutions—ideal for commercial, industrial, and high-performance environments. At Beauty (STC) Manufacturing Co., Ltd., we specialize in premium LED lighting that delivers consistent color temperature, superior energy efficiency, and long-lasting performance.

Partner with Beauty STC to access custom lighting solutions tailored to your project needs. Our 5000K products are engineered for accuracy and reliability, ensuring optimal illumination across a wide range of applications.

For inquiries or to start a collaboration, contact our sales manager at [email protected]. Let us help you bring high-quality, professional lighting to your market.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.