Article Contents

Industry Insight: 3 Pin Led Connector

Introduction & Market Demand for 3-Pin LED Connectors in Commercial Lighting

The Critical Role of 3-Pin Connectors in Commercial Lighting Systems

In commercial and industrial lighting applications, 3-pin LED connectors serve as the backbone for reliable electrical connections in RGB strip lighting, DMX-controlled installations, and architectural lighting systems. Unlike residential applications, these environments demand connectors that maintain consistent performance under continuous operation, withstand environmental stressors, and comply with stringent safety regulations. Failure in such systems can lead to costly downtime, safety hazards, and project delays—making component reliability a non-negotiable factor.

Why Certification Compliance is Non-Negotiable for Importers

Global lighting distributors and project managers face significant risks when sourcing uncertified connectors. In North America, ETL certification (verified to UL 1598 for lighting equipment) is required for electrical products to meet NEC codes and pass inspections. Similarly, CE marking under the EU’s Low Voltage Directive is mandatory for market access. Non-compliant connectors may:

Trigger customs rejections or costly recalls

Increase liability exposure in case of electrical faults

Fail third-party testing during project commissioning

Beauty STC Lighting addresses these challenges through certified manufacturing processes and documented compliance for all connector products.

Beauty STC Lighting: Engineered Solutions for Global Markets

Established in 1998, Beauty STC Lighting has built a reputation for industrial-grade components through continuous investment in quality control and global market expertise. Our 3-pin LED connectors undergo rigorous testing to meet ETL (USA/Canada) and TÜV CE (Europe) standards, ensuring seamless integration into commercial projects worldwide. With OEM/ODM capabilities spanning 50+ countries, we provide tailored solutions for lighting architects and distributors seeking verified reliability.

| Specification | Beauty STC Specifications | Compliance Standards |

|---|---|---|

| Electrical Rating | 16A max current, 30V DC | ETL (UL 1598), CE (EN 60598) |

| Housing Material | V-0 Flame-Retardant PC | UL94 V-0 Certified |

| IP Rating | IP20 (Standard), IP66 (Waterproof) | IEC 60529 |

| Contact Material | Phosphor Bronze with Gold Plating | RoHS 2.0 Compliant |

| Operating Temperature | -20°C to +60°C | IEC 60068-2 |

| Termination | Solderless Clip / Crimp Terminal | Customizable for OEM Projects |

All connectors are manufactured in our Jiangmen facility with rigorous quality control processes aligned with international standards, ensuring traceability and consistency across bulk orders. Our engineering team works directly with clients to validate specifications against project requirements prior to production.

For technical specifications or custom configurations, contact our engineering team at [email protected] or +86 13902885704.

Technical Specs & Certifications (ETL/CE)

3-Pin LED Connector – Technical Specifications & Quality Standards

(Factory-direct data sheet – Beauty STC Lighting, Jiangmen, China)

1. Scope & Application

3-pin connectors are the critical “hand-off” point between Class III LED circuits and the outside world. When used with constant-voltage strips, wall-washers, or DMX-controlled fixtures they must preserve:

Signal integrity (PWM, DMX512-A)

Current continuity (up to 5 A per pin @ 24 Vdc)

Environmental sealing (IP20 → IP68 depending on zone)

Beauty STC integrates the connector specification into every luminaire design since 1998; all mating halves are factory-terminated and 100 % electrically tested before export.

2. Pin Configuration & Electrical Rating

| Parameter | Beauty STC Spec | Generic Market Offer |

|---|---|---|

| Pole count | 3 (GND, DATA/+, –) | 3 (sometimes 2+blank) |

| Rated current | 5 A per pin, 60 Vdc max | 3 A, 24 Vdc typical |

| Contact resistance | ≤3 mΩ (initial) | 5–10 mΩ |

| Dielectric withstanding | 1 500 Vac, 1 min | 500 Vac |

| Wire range | 0.5 mm² – 1.0 mm² (18–20 AWG) | 0.3 mm² max |

| Temp class | –40 °C … +105 °C (TUV) | –20 °C … +80 °C |

| Mating cycles | ≥ 50 (gold flash) ≥ 500 (selective Au) | 25 cycles typical |

3. Material & Build Integrity

| Component | Beauty STC Certified | Generic Market |

|---|---|---|

| Housing | V-0 PC, UV-stabilised, halogen-free | V-2 PA66 |

| Contact | Cu-alloy, Ni under-layer, 3 µ″ Au selective | Cu, 1 µ″ Sn |

| Wire seal | Silicone, IP66/68 variants | PVC, IP20 only |

| PCB header | 1 oz Cu, 1.6 mm FR-4, white mask | 0.5 oz Cu, paper phenolic |

| Cable jacket | 105 °C VW-1, 300 V, 18 AWG, 3C | 80 °C, 300 V, 22 AWG |

All plastics are RoHS/REACH and halogen-free; UL 94 V-0 file E358258 applies.

4. IP & Environmental Matrix

| IP Code | Test Condition | Beauty STC Part Number | Typical Use |

|---|---|---|---|

| IP20 | Indoor, dry | STC-3P-10-J | Strip-to-strip jumper |

| IP65 | Dust, water jet | STC-3P-65-S | Kitchen cove |

| IP67 | 1 m, 30 min | STC-3P-67-M | Façade outline |

| IP68 | 3 m, 24 h | STC-3P-68-D | Pool perimeter |

Each sealed version is double O-ring with over-moulded strain relief; salt-spray 48 h per ASTM B117.

5. System-Level Compatibility (Luminaire Side)

| LED Strip Metric | Beauty STC Guarantee | Notes |

|---|---|---|

| Lumens/Watt | Up to 210 lm/W (strip level) | Connector loss <1 % @ 5 A |

| CRI | >90 (98 typ. for Skin-tone strip) | No chromatic shift through connector |

| PCB Copper | 2 oz base, 3 oz on request | Prevents trace burnout at connector pad |

| Binning | 3 SDCM, 1 500 K – 6 500 K | MacAdam ellipse maintained end-to-end |

6. Certification & Traceability

ETL/cETL to UL 2108 & CSA C22.2 #9 (file 5016290)

TUV CE, EN 61347-2-13, EN 60598-2-20

RoHS 2.0, REACH 223 SVHC, PAHs <0.1 %

ISO 9001:2015 production lot codes laser-marked on every shell—full backward traceability to copper mill lot.

7. Factory QC Flow (Connector Focus)

- Incoming crimp height & pull-force (≥ 50 N)

- 100 % hi-pot & continuity on harness

- IP66/68 units pressure-decay tested (0.2 bar, 30 s)

- Salt-spray & thermal-shock (–40 ↔ +105 °C, 100 cycles) on qualification batch

- Random cross-section—plating thickness verified by X-ray fluorescence

8. Quick-Reference Table – Generic vs. Beauty STC Certified

| Attribute | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Certifications | Self-declared CE | ETL, TUV CE, RoHS, REACH |

| Current headroom | 3 A | 5 A |

| Contact plating | Sn (1 µ″) | Au over Ni (3 µ″) |

| IP rating offered | IP20 only | IP20, IP65, IP67, IP68 |

| Flammability | UL 94 V-2 | V-0, CTI ≥ 250 V |

| Warranty | 1 year | 5 years (connector & strip) |

| OEM tooling | N/A | In-house mould shop, 25 days lead |

9. Ordering Codes (OEM/ODM Ready)

| Code | Description |

|---|---|

| STC-3P-10-J-100 | 3-pin 10 cm jumper, IP20, 100 pcs bag |

| STC-3P-67-M-500 | 3-pin 0.5 m lead, IP67, 500 pcs carton |

| STC-3P-68-D-CU | Custom underwater length, IP68, per drawing |

Engineering drawings (.STEP), DMX512 continuity report, and ETL certificate pdfs supplied within 12 h.

Contact the OEM team

[email protected] | +86-13902885704

41th Caihong Road, Jianghai Hi-Tech Zone, Jiangmen, Guangdong, China

Factory Tour: Manufacturing Excellence

Precision Manufacturing Process & OEM Capabilities

Advanced Production Line Overview

Beauty STC Lighting’s Jiangmen facility leverages 25+ years of industrial expertise to deliver consistent, high-precision 3-pin LED connector production. Our manufacturing process integrates automated systems with rigorous engineering controls to ensure repeatability and reliability:

SMT (Surface Mount Technology) Assembly: Fully automated pick-and-place machines with 0.01mm positional accuracy for PCB component placement.

Precision Molding: High-tolerance injection molding for connector housings (±0.05mm dimensional tolerance), ensuring perfect fit with LED strips and wiring systems.

Automated Soldering: Wave and reflow soldering lines compliant with IPC-A-610 standards, eliminating human error in critical electrical joints.

Integrated Production Flow: Closed-loop manufacturing from raw material processing to final assembly, all within our ISO 9001-certified Jiangmen facility (established 1998).

Rigorous Quality Control Protocols

Every 3-pin connector undergoes multi-stage validation to meet global safety and performance standards:

24–48 Hour Burn-In Testing: Units operated at 110% rated load to verify thermal stability and long-term durability.

IP Rating Verification: Water ingress testing per IEC 60529 (e.g., IP65 spray test, IP67 immersion test for waterproof variants).

Electrical Safety Compliance: Dielectric strength testing (1.5kV AC for 1 minute), insulation resistance checks (>100MΩ), and creepage/clearance validation per ETL/CE requirements.

100% Visual & Functional Inspection: Automated optical inspection (AOI) for solder defects, followed by manual checks for physical integrity and pin alignment.

All testing protocols align with ETL (USA/Canada) and TUV CE (Europe) certification frameworks, ensuring seamless market access for global clients.

Tailored OEM/ODM Solutions

Beauty STC Lighting provides end-to-end customization for 3-pin LED connectors, enabling precise alignment with project-specific requirements. Our ODM capabilities include:

Custom Physical Dimensions: Length adjustments from 30mm to 300mm for space-constrained installations.

IP Rating Customization: From standard IP20 indoor use to IP68 submersible ratings for harsh environments.

Material Specifications: Copper alloy contacts with gold-plating options; PC housing with UL94-V0 flame resistance.

Packaging Solutions: Private label retail packaging, bulk shipping containers, or project-specific configurations (e.g., anti-static trays for sensitive installations).

| Parameter | Standard Options | Customizable Range |

|---|---|---|

| Connector Length | 50mm, 100mm, 150mm | 30mm to 300mm |

| IP Rating | IP20, IP65, IP67 | Up to IP68 |

| Wire Gauge | 22–20 AWG | 18–24 AWG |

| Contact Material | Copper alloy | Gold-plated copper |

| Housing Material | PC (UL94-V0) | Custom polymers |

| Packaging | Standard retail | Private label, bulk |

All custom solutions undergo full certification testing to meet regional safety standards for global deployment. Whether integrating with RGB, RGBW, or tunable-white LED strips, our connectors deliver consistent performance across diverse applications.

For technical specifications or project-specific OEM requirements, contact our engineering team at [email protected] or +86 13902885704.

Installation & Application Scenarios

Application Scenarios for 3-Pin LED Connectors

(Factory-direct view from Beauty STC Lighting, ETL & TÜV CE certified since 1998)

Where 3-Pin Connectors Add Value to Commercial Projects

| Segment | Typical Lighting Task | Why 3-Pin (vs. 2- or 4-P) | Key Specs* | Installer Notes |

|---|---|---|---|---|

| Upscale Hotels | CCT-tunable cove & headboard strips | Dual-white strip needs 3 conductors (V+, CW, WW) | 16 A, 300 V, 12–24 V DC, IP65 | Route through aluminium profile; keep connector outside concrete pour to avoid alkali attack on PC housing |

| Shopping Malls | Continuous 24 V RGBW façade runs | 3-pin splits power & data cleanly—one pin for common anode, two for DMX signal pair | IP66, -30…+80 °C, Cu ≥ 0.75 mm² | Use one connector every 5 m to limit voltage drop below 5 %; torque M8 gland to 0.8 N·m |

| Spec Offices | 3000–5000 K tunable linear fixtures | Central dimming via 0–10 V on third pin | 250 V, 10 A, flame class UL94 V-0 | Keep 3-pin separate from 230 V trunk in partition trunking; maintain 8 mm creepage as per EN 60598-1 |

| Façade Media | DMX512 pixel dots | XLR-style 3-pin carries balanced data + shield | 120 Ω characteristic impedance, TPE jacket -40 °C | Terminate last node with 120 Ω resistor inside male shell; verify with cable tester before façade lift |

*All connector families quoted are ETL-listed and TÜV CE certified by Beauty STC Lighting; 25-year OEM/ODM records on file.

Contractor Installation Checklist

-

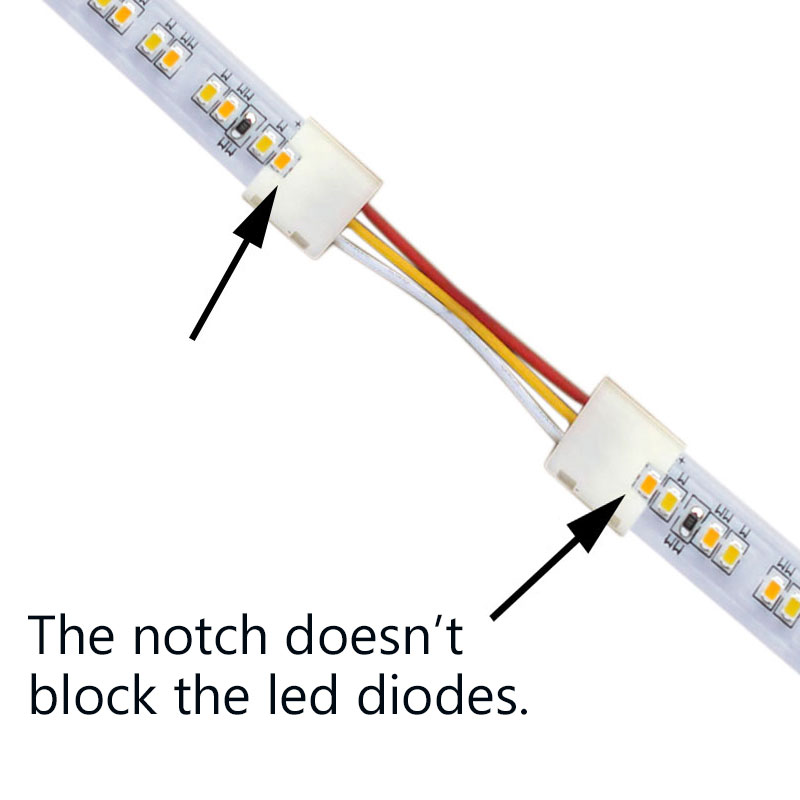

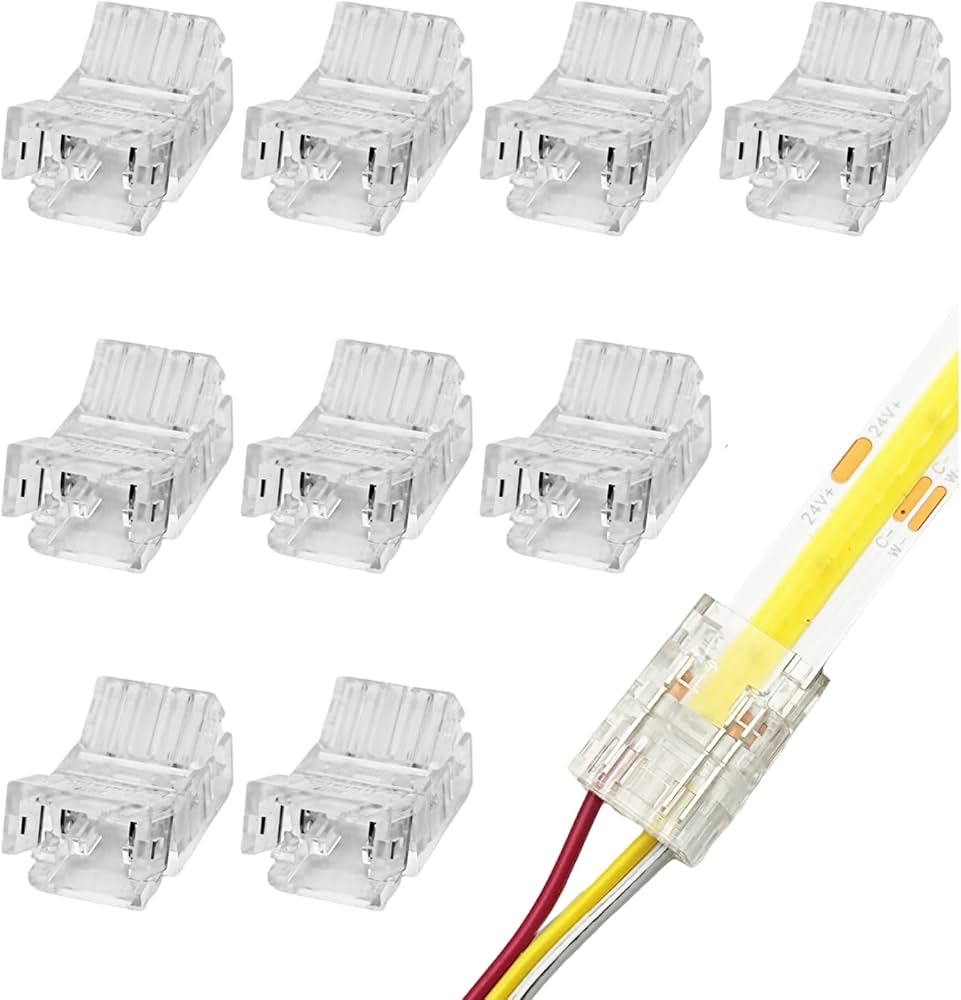

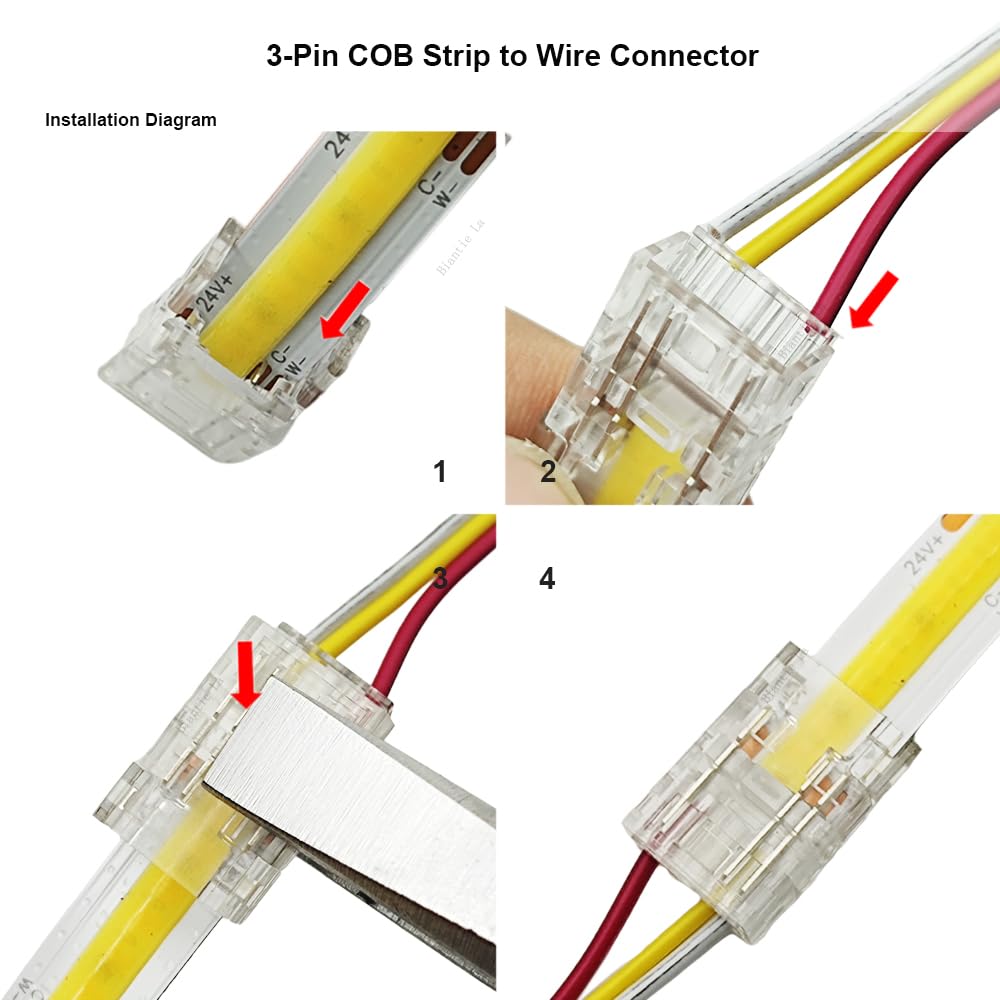

Strip-to-Wire Clip Type (10 mm PCB)

Strip copper pads must be 70 µm minimum; align dot-marked polarity before closing clamp.

After crimp, pull-test 2 kg × 15 s—no pad lift. -

IP66 Field-Solder Version

Slide heat-shrink before soldering; keep iron at 350 °C, 3 s max to avoid PC housing deformation.

Glue-lined shrink must overlap cable jacket ≥ 8 mm; cool under clamp for uniform seal. -

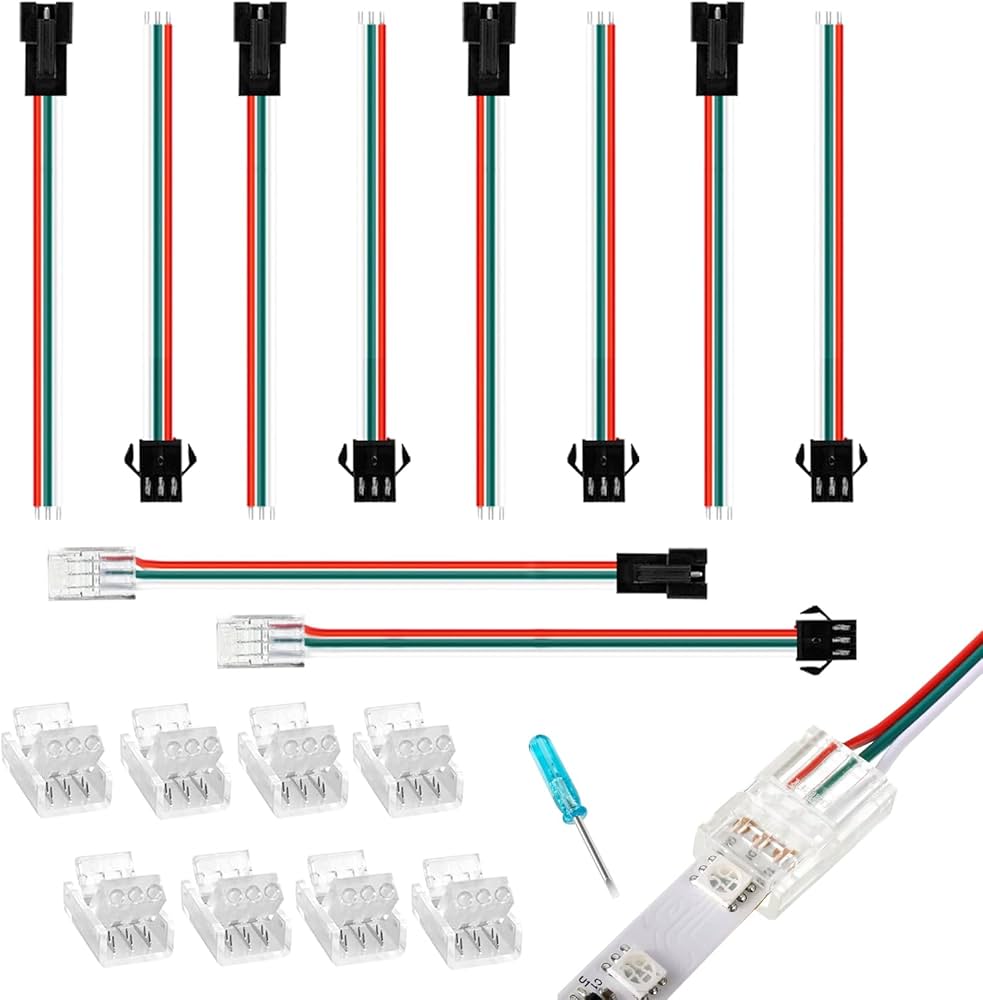

DMX XLR 3-Pin

Use 22 AWG twisted pair (≥ 30 twists/m) plus drain; avoid star topology—daisy chain only.

Pin-1 chassis bond to fixture housing; earth loop resistance < 1 Ω measured with micro-ohmmeter. -

High-Bay Retrofit (Factory Aisles)

3-pin feed-through splitter rated 16 A/600 V for 200–480 W UFO fixtures; mount splitter box minimum 0.5 m above ceiling to stay clear of HVAC vibration. -

Documentation Hand-Over

Record node map, draw DMX address list, and include Beauty STC batch QR code for future traceability.

Need project-specific connector kits, custom cable lengths, or matched LED modules?

Email: [email protected] | Tel: +86-13902885704

Beauty (STC) Manufacturing Co., Ltd—ETL & CE certified production since 1998.

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting for Industrial-Grade 3-Pin LED Connectors

Precision Engineering for Global LED Installations

Since 1998, Beauty STC Lighting has delivered reliable LED components to 50+ countries worldwide. Our 25+ years of manufacturing expertise ensures every 3-pin connector meets stringent safety, durability, and performance standards for mission-critical lighting applications. As a factory-direct supplier, we eliminate intermediaries to provide consistent quality and transparent supply chain control.

Technical Specifications & Certifications

Our 3-pin LED connectors are engineered for demanding industrial and commercial environments. All products undergo rigorous testing to comply with international safety regulations:

| Specification | Detail |

|---|---|

| Contact Material | Phosphor Bronze, Gold-Plated for Low Resistance & Corrosion Resistance |

| Rated Current | 16A |

| Voltage Rating | 300V |

| Housing Material | UL94 V-0 Flame-Retardant PC (RoHS Compliant) |

| IP Rating | IP20 (Standard), IP67/IP68 (Custom Options) |

| Operating Temperature | -40°C to +85°C |

| Certifications | ETL (USA/Canada), TUV CE (Europe) |

OEM/ODM Capabilities for Custom Integration

We specialize in turnkey solutions tailored to your project requirements:

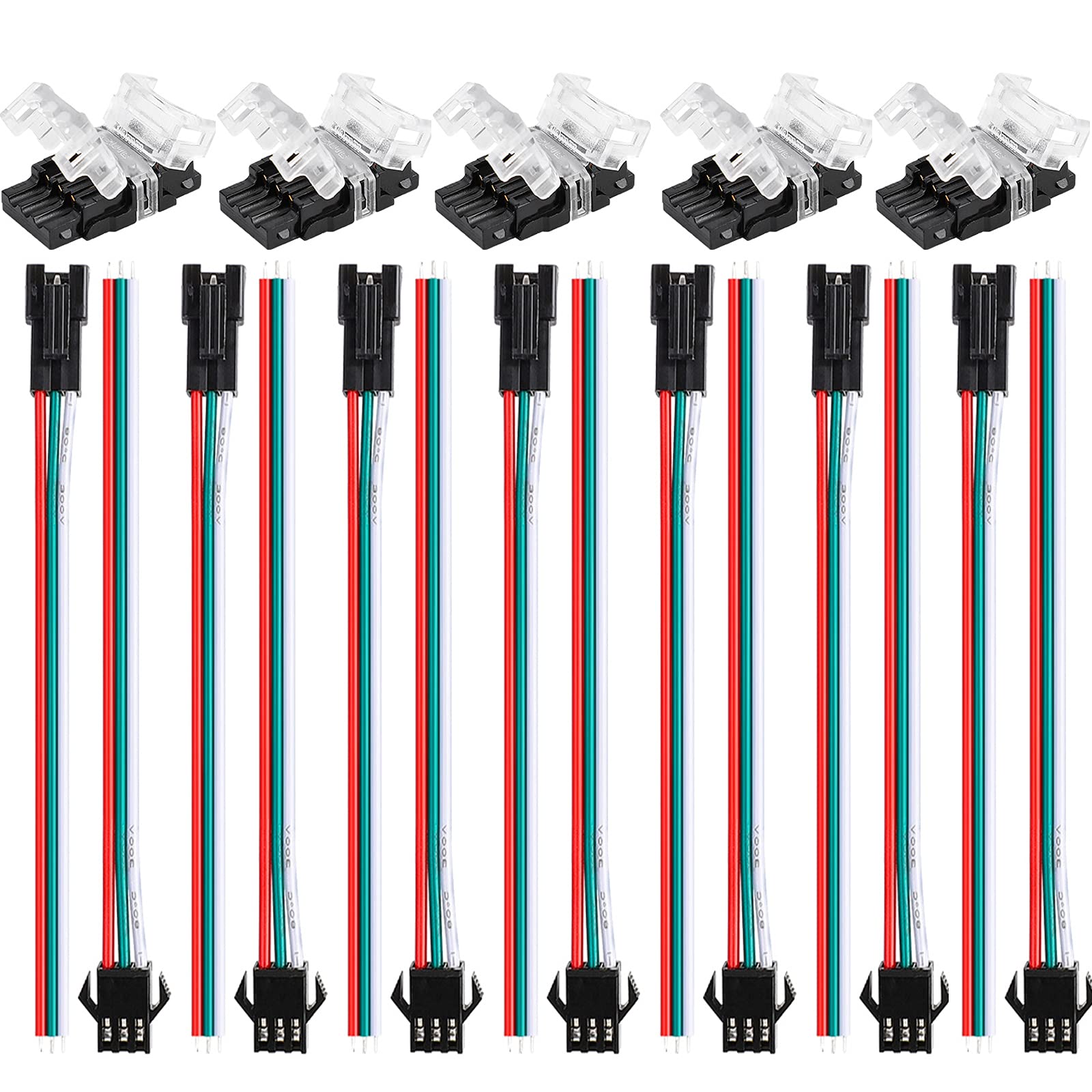

Custom Pin Configurations: Compatible with 22–20 AWG solid/multi-core wires and ribbon strips

Environmental Adaptations: IP66/IP67 waterproof housings for outdoor/facade installations

Full Branding Control: Private labeling, custom packaging, and compliance documentation

Design Support: Engineering collaboration from concept to production, including material selection and thermal management optimization

Applications Across Global Markets

Beauty STC connectors are trusted by architects and contractors for:

DMX512 Systems: Stable signal transmission for stage lighting and architectural control networks

Waterproof Daisy-Chaining: IP67-rated end caps for landscape, signage, and marine environments

High-Bay & Floodlight Integration: Robust connections for industrial lighting systems requiring 16A+ current handling

Solderless Installations: Quick-connect solutions for rapid deployment in commercial retrofits

Partner with a Trusted Manufacturer

For technical specifications, compliance documentation, or custom project support, contact our global engineering team directly.

Beauty STC Lighting

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen, Guangdong, China

Email: [email protected] | Phone: +86 13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).